Method for monitoring a filled container, and monitoring system for filled containers

A technology for monitoring systems and containers, which is applied in the field of monitoring systems and can solve problems such as expensive settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

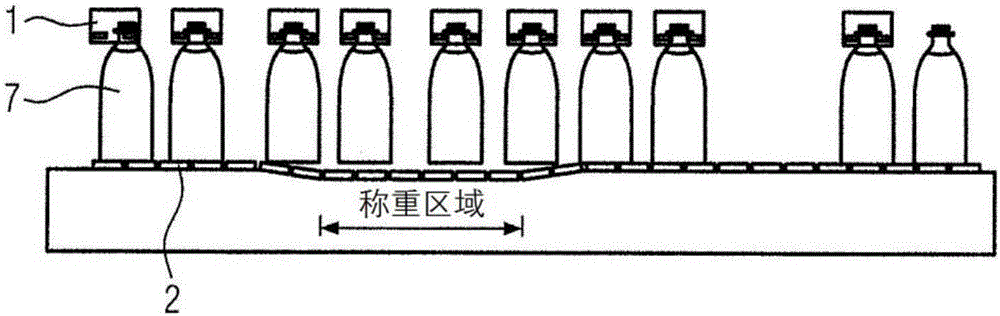

[0069] Figure 1a A schematic side view of a part of a monitoring system according to the invention is shown. Here, each filled container 7 is held by a carriage 1 on a conveyor, shown in this case as a conveyor chain 2 , and weighed by the carriage in the illustrated weighing area. In the example shown, the containers are conveyed on a linear conveyor.

[0070] In the example shown, the conveyor is (slightly) lowered in the weighing area. The lowering of the weighing area can be achieved, for example, by using thinner anti-wear belts or the like. This has the effect that in this region the entire weight of the filled container is carried by the carriage and the filled container can be weighed.

[0071] After weighing, the filled containers can be returned to and travel with a conveyor described in this example as a conveyor chain 2 . Typically, by way of example, if the weight falls within desired tolerance limits, the filled container is returned to and travels with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com