Alkaline powder for treating leaked sulfuric acid and preparation method of alkaline powder

An alkaline and powder technology, applied in the field of alkaline powder disposal of leaked sulfuric acid and its preparation, can solve the problems of adverse effects on the environment and human health, water environment and soil environment, easy to produce irritating odor, etc., and reach the end of disposal. Easy to judge, easy to judge the end point, less hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

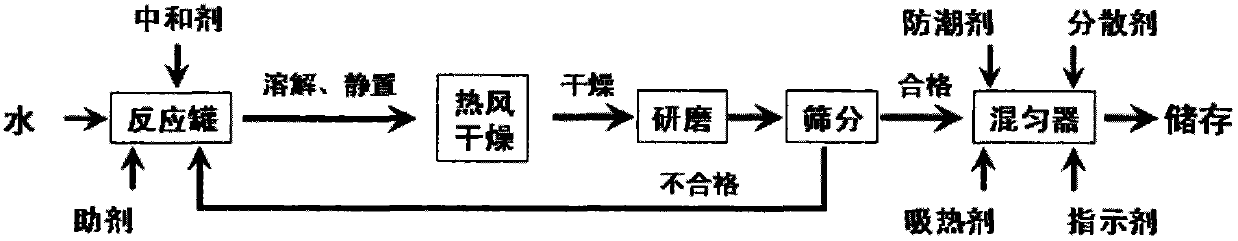

Method used

Image

Examples

Embodiment 15

[0042] Embodiment 15L concentrated sulfuric acid (98%, about 10kg) leakage treatment

[0043] Prepare 30kg of alkaline powder for handling sulfuric acid leakage, and its composition ratio is: 17.0kg of neutralizer (15.5kg of sodium bicarbonate, 1.2kg of calcium carbide slag modified product), 5.1kg of auxiliary agent (diatomaceous earth), absorbent Heat agent 6.8kg (potassium nitrate); moistureproof agent 0.654kg (polyacrylamide); dispersant 0.44kg (sodium stearate); indicator 0.006kg (bromothymol blue). The specific preparation method is to add clear water (about 18 L) that can just dissolve the neutralizing agent and auxiliary agent in the reaction tank, start stirring, and add a certain amount of neutralizing agent and auxiliary agent (each excess 10%) in sequence in proportion, and wait for After stirring evenly, stop stirring, let stand for 12 hours (overnight), then send to dry under reduced pressure, then through grinding and sieving, weigh 22.1kg of the part that passe...

Embodiment 211

[0045] Embodiment 211L concentrated sulfuric acid (98%, about 20kg) leakage treatment

[0046] Prepare 50kg of alkaline powder for handling sulfuric acid leakage, and its composition ratio is: neutralizer 26.9kg (sodium bicarbonate 20.6kg, calcium hydroxide 6.3kg), auxiliary agent 8.6kg (diatomaceous earth); endothermic agent 12.8kg (potassium chloride 10.8kg, potassium nitrate 2kg), moisture-proof agent 0.974kg (polyacrylamide), dispersant 0.72kg (sodium stearate), indicator 0.006kg (methyl red). The specific preparation method is to add clear water (about 75 L) that can just dissolve the neutralizing agent and auxiliary agent in the reaction tank, start stirring, and add a certain amount of neutralizing agent and auxiliary agent (each excess 10%) in sequence in proportion. After stirring evenly, stop stirring, let stand for 12 hours (overnight), then send to dry under reduced pressure, then through grinding and sieving, take 35.5kg of the parts that pass the inspection (40 m...

Embodiment 35

[0048] Embodiment 35L concentrated sulfuric acid (50%, about 7kg) leakage treatment

[0049] Prepare 21.0kg of alkaline powder used to handle sulfuric acid leakage, and its composition ratio is: 6.4kg of neutralizer (3.0kg of sodium carbonate, 2.8kg of modified carbide slag), 10.0kg of auxiliary agent (diatomaceous earth); Heat agent 3.2kg (potassium chloride 2.7kg, potassium nitrate 0.5kg), moisture-proof agent 1.276kg (polyacrylamide), dispersant 0.12kg (sodium stearate), indicator 0.004kg (bromothymol blue). The specific preparation method is: add clear water (about 18 L) that can just dissolve the neutralizing agent and auxiliary agent in the reaction tank, start stirring, and add a certain amount of neutralizing agent and auxiliary agent (each excess 10%) in proportion, Stop stirring after being stirred evenly, leave standstill for 12 hours (overnight), then send to vacuum drying, then by grinding and sieving, take by weighing 13.2kg of the part that passes the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com