Preparation method of low-sulfur nano-iron powder

A technology of nano-iron powder and iron sheet, which is applied in the direction of nano-technology, process efficiency improvement, etc., and can solve the problems that only airflow classification equipment can be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of low-sulfur nano iron powder includes the following steps:

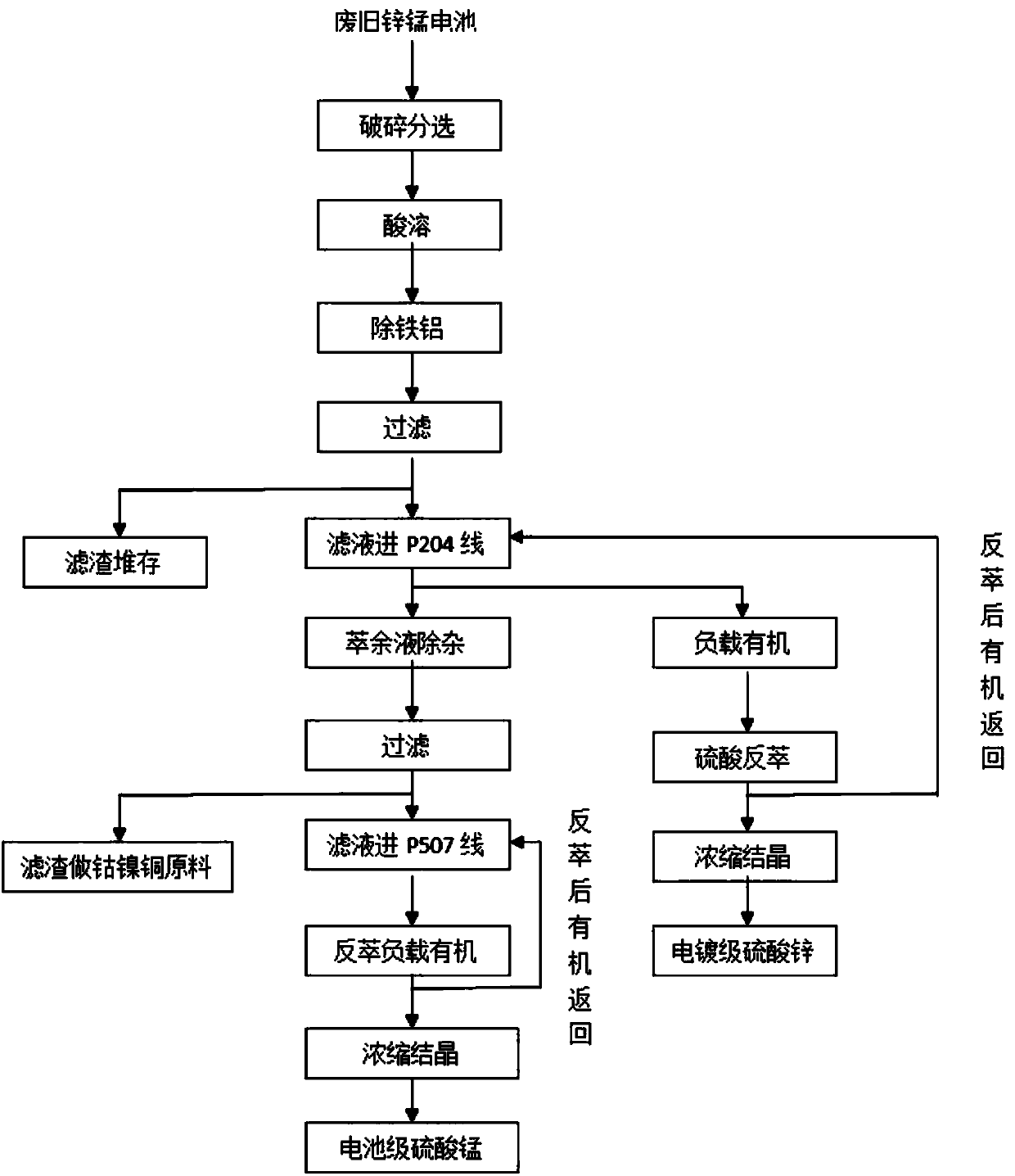

[0057] (1) Crushing of waste zinc-manganese batteries, put the zinc-manganese batteries into a crusher and crush them into powder with a particle size of less than 200um;

[0058] (2) To dissolve the zinc-manganese battery powder material, add the zinc-manganese battery to the bottom water according to the solid-liquid ratio of 4:1, while adding acid to maintain the pH 1.1 of the reaction process, maintain the reaction temperature at 85°C, and stir at 400r / min. After 3.5 hours, take a sample of the filter residue to detect its manganese content. Add a reducing agent based on twice the mass of manganese in the filter residue, and react for 2 hours at pH 1.5, temperature 60°C, and stirring speed 400r / min to extract zinc in the residue. The manganese content is reduced to less than 0.5%;

[0059] (3) In addition to iron and aluminum, add step (1) crushed powder according to 2.2 times the mass of ...

Embodiment 2

[0075] A preparation method of low-sulfur nano iron powder includes the following steps:

[0076] (1) Crushing of waste zinc-manganese batteries, put the zinc-manganese batteries into a crusher and crush them into powder with a particle size of less than 200um;

[0077] (2) To dissolve the zinc-manganese battery powder material, add the zinc-manganese battery to the bottom water according to the solid-liquid ratio of 4:1, while adding acid to maintain the pH 1.1 of the reaction process, maintain the reaction temperature at 85°C, and stir at 400r / min. After 3.5 hours, take a sample of the filter residue to detect its manganese content. Add a reducing agent based on twice the mass of manganese in the filter residue, and react for 2 hours at pH 1.5, temperature 60°C, and stirring speed 400r / min to extract zinc in the residue. The manganese content is reduced to less than 0.5%;

[0078] (3) In addition to iron and aluminum, add step (1) crushed powder according to 2.2 times the mass of ...

Embodiment 3

[0093] A preparation method of low-sulfur nano iron powder includes the following steps:

[0094] (1) Crushing of waste zinc-manganese batteries, put the zinc-manganese batteries into a crusher and crush them into powder with a particle size of less than 200um;

[0095] (2) To dissolve the zinc-manganese battery powder material, add the zinc-manganese battery to the bottom water according to the solid-liquid ratio of 4:1, while adding acid to maintain the pH 1.1 of the reaction process, maintain the reaction temperature at 85°C, and stir at 400r / min. After 3.5 hours, take a sample of the filter residue to detect its manganese content. Add a reducing agent based on twice the mass of manganese in the filter residue, and react for 2 hours at pH 1.5, temperature 60°C, and stirring speed 400r / min to extract zinc in the residue. The manganese content is reduced to less than 0.5%;

[0096] (3) In addition to iron and aluminum, add step (1) crushed powder according to 2.2 times the mass of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com