Silibinin slow release micropill with double layers of coatings and preparation method of silibinin slow release micropill

A technology of silybin and sustained-release pellets, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, and pharmaceutical formulations, which can solve the problems of no sustained-release effect, increase in vivo bioavailability, Poor patient compliance and other issues, to achieve the effect of improving relative bioavailability, easy operation, and reducing the number of medications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

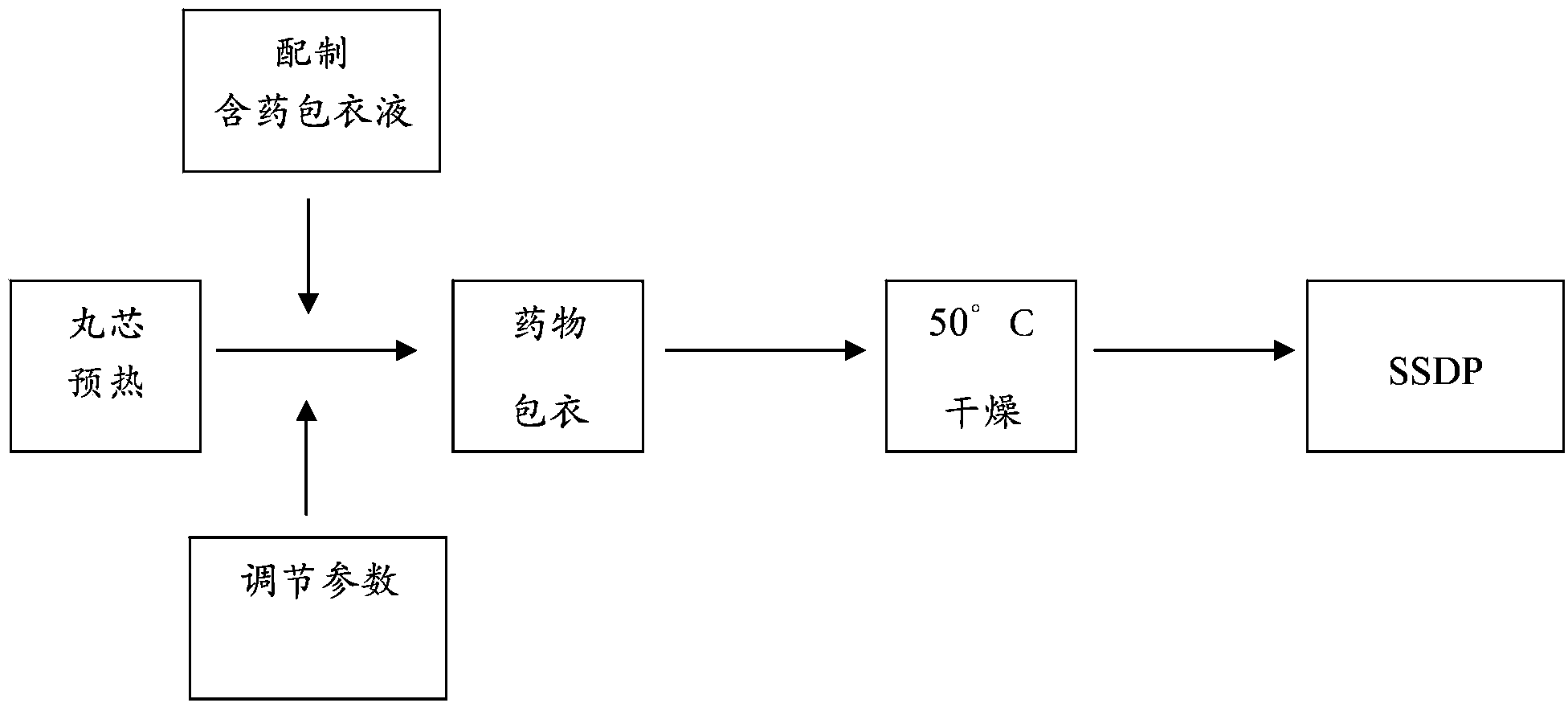

Method used

Image

Examples

Embodiment 1

[0042] Weigh 100g of blank ball cores, place them in a Mini-250 extrusion spheronizing fluidized coating machine, and preheat for 30 minutes.

[0043] Weigh 4g silibinin and 8g PVP K respectively 30 , 12g PEG400, 16g Tween 80, added to 200mL 50% ethanol water and magnetically stirred until clarified and uniform, added 1.2g talcum powder, magnetically stirred, and set the coating parameters of the solid dispersion layer: the coating speed was 800rpm, the air inlet speed was 25Hz, The wind speed is 18Hz, and the spray speed of the coating spray gun is 1mL min -1 , the air inlet temperature is 45°C, the material temperature is 40°C, coating is carried out, after the coating is completed, take it out, and dry it in a vacuum oven at 50°C for 2 hours to obtain silibinin solid dispersion pellets. The obtained silibinin solid dispersion pellet is carried out electron microscope observation, and the results are shown in Figure 5 ; Measure the dissolution curve of silybin solid dispe...

Embodiment 2

[0046] Weigh 100g of blank ball cores, place them in a Mini-250 extrusion spheronizing fluidized coating machine, and preheat for 30 minutes.

[0047] Weigh 6g silibinin and 3g PVP K respectively 30 , 6g F68, 6g Tween 80, added to 150mL of 60% ethanol water and magnetically stirred until clarified and homogeneous, added 2g of magnesium stearate, magnetically stirred, and set the coating parameters of the solid dispersion layer: the coating speed is 800rpm, the air inlet speed is 25Hz , the wind speed is 18Hz, and the spray speed of the coating spray gun is 1mL min -1 , the inlet air temperature is 45°C, and the material temperature is 40°C. Carry out coating, take out after coating, and dry in a vacuum oven at 50° C. for 12 hours to obtain silybin solid dispersion pellets. The test results are as in Example 1.

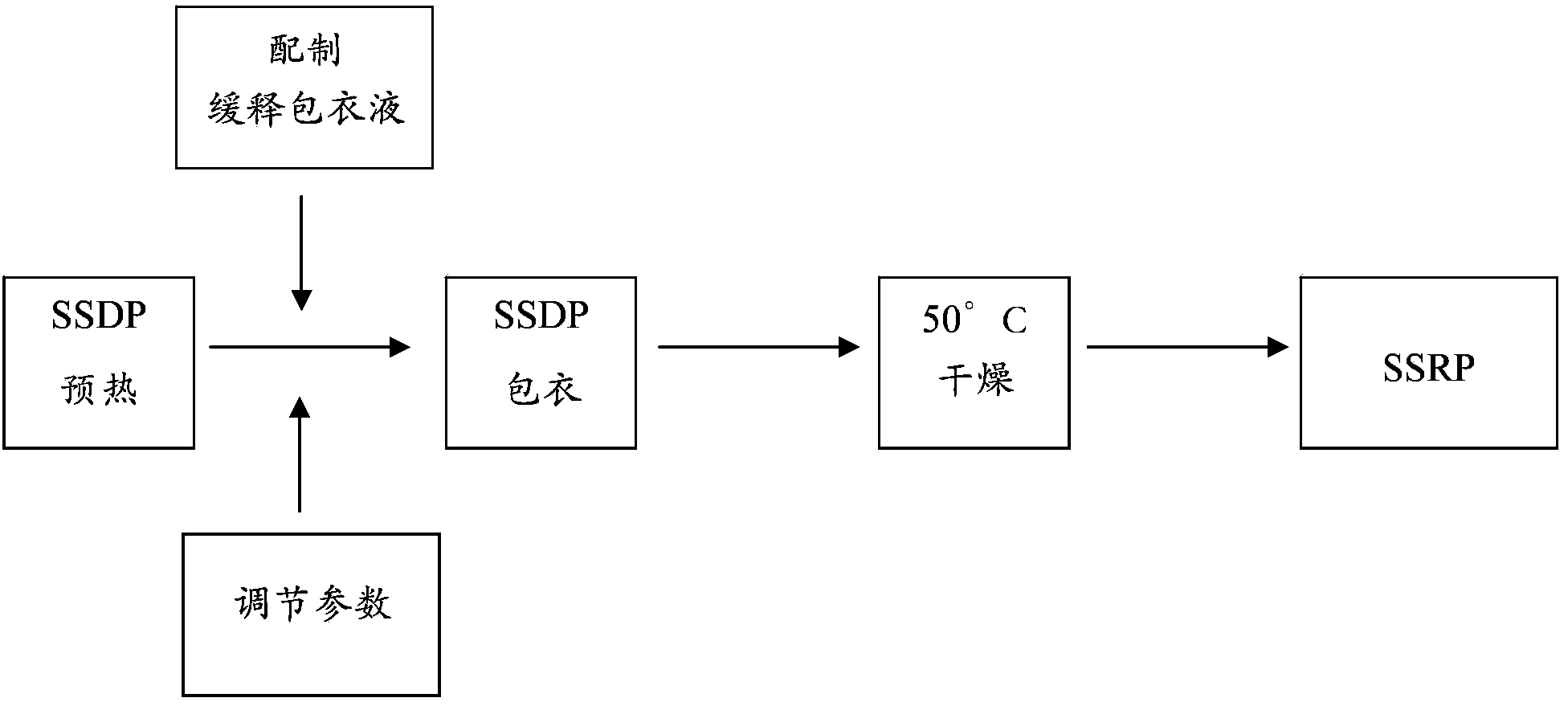

[0048] Take 100g of the silibinin solid dispersion pellets prepared above, weigh 5g EC, 4g dibutyl phthalate, and 3g PEG6000 respectively, add them to 150mL pure et...

Embodiment 3

[0050] Weigh 100g of blank ball cores, place them in a Mini-250 extrusion spheronizing fluidized coating machine, and preheat for 30 minutes.

[0051] Weigh respectively 8g silybin, 40g PVP K 25 , 15g F68, 30g PEG400, 15g Tween 80, 2g soybean lecithin, add to 200mL75% ethanol water and magnetically stir until clarified, add 6.4g talcum powder, magnetically stir, set the coating parameters of the solid dispersion layer: the coating speed is 800rpm , the air inlet speed is 25Hz, the air outlet speed is 18Hz, and the spray speed of the coating spray gun is 1mL min -1 , the inlet air temperature is 45°C, and the material temperature is 40°C. Carry out coating, take out after coating, and dry in a vacuum oven at 50° C. for 12 hours to obtain silybin solid dispersion pellets. The test results are as in Example 1.

[0052] Take 100g of silibinin solid dispersion pellets prepared above, weigh 10g EC, 2g micropowder silica gel, and 3g PEG6000 respectively, add them to 150mL pure eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com