Mud-resistant and salt-resistant polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of concrete polycarboxylate water reducer, can solve the problems of non-conforming to green energy saving, low conversion rate, complicated process, etc., to increase water reducing effect, reduce production cost, The effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

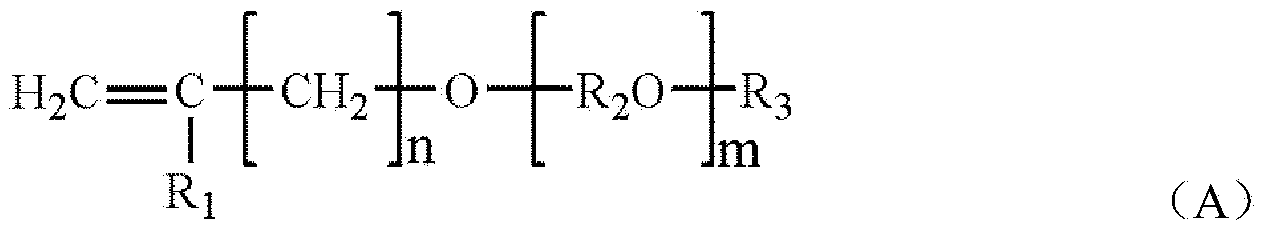

Method used

Image

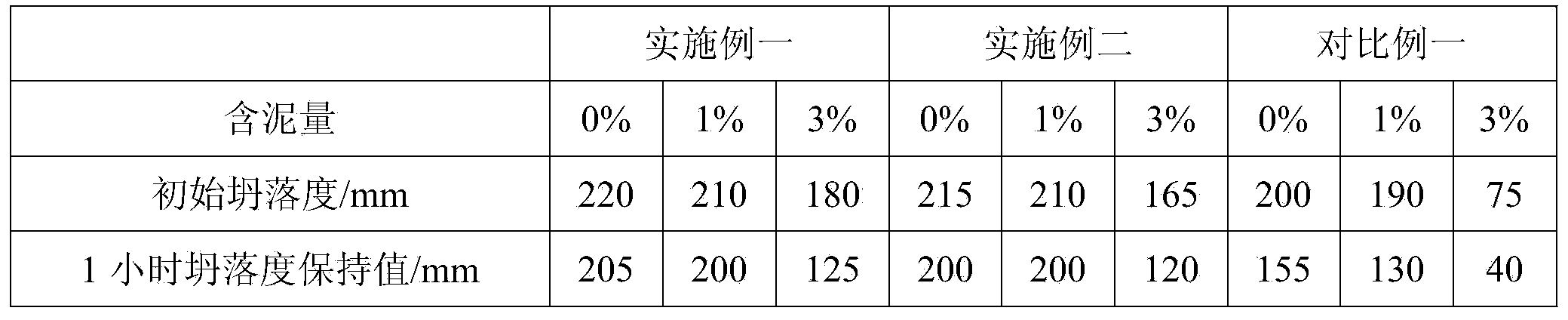

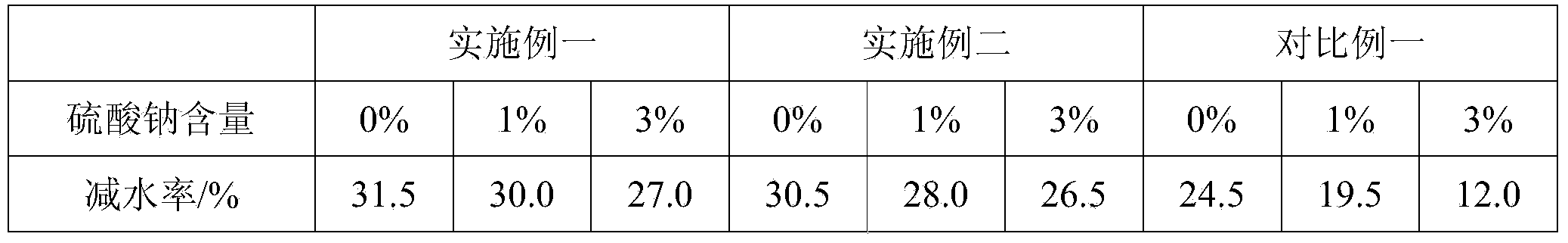

Examples

Embodiment 1

[0031] By mass, 60 parts of allyl polyoxyethylene ether with a molecular weight of 1000, 2 parts of hydrogen peroxide and 40 parts of water were added to the reaction device; 20 parts of acrylic acid, 10 parts of vinyltrimethoxysilane, 10 parts of methallyl Sodium sulfonate, 2 parts of thioglycolic acid, 1 part of vitamin C, and 50 parts of water are evenly mixed and added dropwise to the reaction device, and the addition is completed within 4 hours; the reaction temperature is 50°C, and the total reaction time is 12 hours. After the reaction, cool to 30-40°C, add aqueous sodium hydroxide solution to adjust the pH value and solid content, and obtain a certain concentration of silane-modified polycarboxylate water reducer.

Embodiment 2

[0033] By mass, 90 parts of methallyl polyoxyethylene ether with a molecular weight of 2400 and 70 parts of water were added to the reaction device; 9 parts of methacrylic acid and 1 part of vinyl tris(β-methoxyethoxy) Silane, 0.5 parts of mercaptopropionic acid, and 30 parts of water are mixed evenly and added dropwise to the reaction device, and the dropwise addition is completed within 3 hours; at the same time, 5 parts of ammonium persulfate, 3 parts of potassium bisulfite, and 20 parts of water are mixed evenly and then dropped Added to the reaction device, the dropwise addition was completed within 4 hours; the reaction temperature was 60°C, and the total reaction time was 6 hours. After the reaction, cool to 30-40°C, add aqueous sodium hydroxide solution to adjust the pH value and solid content, and obtain a certain concentration of silane-modified polycarboxylate water reducer.

Embodiment 3

[0035] By mass, 80 parts of methallyl polyoxypropylene ether with a molecular weight of 5000 and 50 parts of water were added to the reaction device; 6 parts of maleic anhydride, 10 parts of γ-methacryloxypropyl trimethoxy Silane, 4 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5 parts of thioglycolic acid and 50 parts of water are mixed evenly and then added dropwise to the reaction device, and the dropwise addition is completed within 2 hours; at the same time, 10 parts of potassium persulfate, 30 parts of water were mixed evenly and then added dropwise to the reaction device, and the dropwise addition was completed within 3 hours; the reaction temperature was 85°C, and the total reaction time was 4 hours. After the reaction is finished, cool to 30-40°C, add potassium hydroxide aqueous solution to adjust the pH value and solid content, and obtain a certain concentration of silane-modified polycarboxylate water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com