Method for preparing nanometer aluminum composite powder coated with nitro-cotton

A technology of composite powder and nitrocellulose bag, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of incomplete coating of nano-aluminum powder surface, poor oxidation resistance, large Agglomeration and other problems, to achieve the effect of improving antioxidant performance, preventing agglomeration, and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

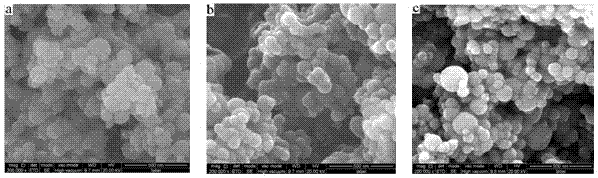

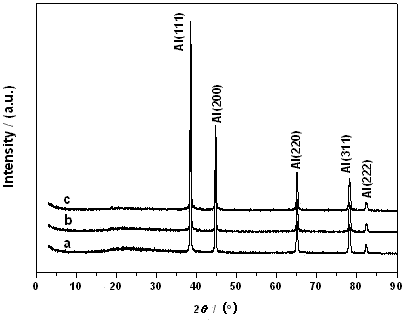

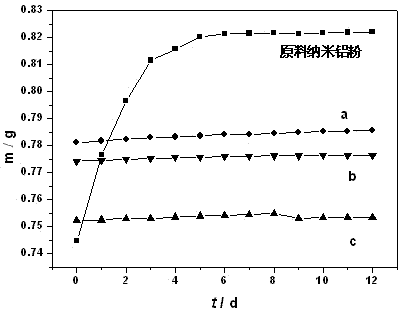

[0024] Weigh 4.0 g of nano-aluminum powder with an average particle size of 50 nm, add it to 100 mL of absolute ethanol, and ultrasonically disperse it for 30 min to make the nano-aluminum powder evenly dispersed in absolute ethanol; weigh 0.2 g of silane coupling agent KH- 550, join in the dehydrated ethanol suspension of the nano-aluminum powder after ultrasonic dispersion, continue ultrasonic dispersion 10 min, stir 2 h in the constant temperature water bath of 60 ℃, leave standstill and remove supernatant liquid with glue tip dropper, Dry in a vacuum drying oven at 60 °C for 8 h to obtain nano-aluminum powder treated with a coupling agent; weigh 5.0 g of nitrocellulose and 0.5 g of diethyl phthalate (DEP) and dissolve in 1000 mL of acetic acid Ethyl ester, and supplemented by ultrasonic dissolution, the configuration was 5.0 g·L -1 nitrocellulose solution; weigh 2.0 g of nano-aluminum powder treated with coupling agent, add it into 100 mL cyclohexane, and ultrasonically di...

Embodiment 2

[0026] Weigh 4.0 g of nano-aluminum powder with an average particle size of 50 nm, add it to 100 mL of absolute ethanol, and ultrasonically disperse it for 30 min to make the nano-aluminum powder uniformly dispersed in absolute ethanol; weigh 0.32 g of silane coupling agent KH- 560, join in the dehydrated ethanol suspension of the nano-aluminum powder after ultrasonic dispersion, continue ultrasonic dispersion 10 min, stir 2 h in the constant temperature water bath of 60 ℃, leave standstill and remove supernatant liquid with glue head dropper, Dry in a vacuum drying oven at 60 °C for 8 h to obtain nano-aluminum powder treated with a coupling agent; weigh 5.0 g of nitrocellulose and 0.4 g of dibutyl phthalate (DEP) and dissolve in 1000 mL of acetic acid Ethyl ester, and supplemented by ultrasonic dissolution, the configuration was 5.0 g·L -1 nitrocellulose solution; weigh 2.0 g of nano-aluminum powder treated with coupling agent, add it into 100 mL cyclohexane, and ultrasonical...

Embodiment 3

[0028] Weigh 4.0 g of nano-aluminum powder with an average particle size of 50 nm, add it into 100 mL of absolute ethanol, and ultrasonically disperse it for 30 min to make the nano-aluminum powder evenly dispersed in absolute ethanol; weigh 0.24 g of silane coupling agent CG- 103, added to the dehydrated ethanol suspension of nano-aluminum powder after ultrasonic dispersion, continued ultrasonic dispersion for 10 min, stirred in a constant temperature water bath at 60 °C for 2 h, and left to remove the supernatant with a rubber dropper. Dry in a vacuum drying oven at 60 °C for 8 h to obtain nano-aluminum powder treated with a coupling agent; weigh 5.0 g of nitrocellulose and 0.3 g of dibutyl phthalate (DBP) and dissolve in 1000 mL of acetone , and supplemented by ultrasonic dissolution, the configuration was 5.0 g·L -1 nitrocellulose solution; weigh 2.0 g of nano-aluminum powder treated with coupling agent, add it into 100 mL cyclohexane, and ultrasonically disperse for 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com