Resin for pultrusion of carbon fiber composite material as well as preparation and use methods of resin

A technology of composite materials and composite resins, applied in shielding materials, electrical components, magnetic field/electric field shielding, etc., to achieve the effect of low viscosity, simple preparation process and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing resin for pultrusion of carbon fiber composite material includes the following steps:

[0025] S1. The epoxy resin system, unsaturated resin system, and internal mold release agent are added in order according to the mass percentage components, and the composite resin system is prepared by dispersing for 5 min-10 min using a high-speed mixer;

[0026] S2. Add the toughening agent and active diluent to the composite resin system in S1 according to the mass percentage, and use a high-speed mixer to disperse for 5-10 minutes to obtain a low-viscosity composite resin system;

[0027] S3. Add the chopped conductive fibers to the S2 medium and low viscosity composite resin system according to the mass percentage, and use a high-speed mixer to disperse for 30 minutes to prepare a composite resin system to obtain a pultruded electromagnetic shielding carbon fiber composite resin.

[0028] A method for using resin for pultrusion of carbon fiber composite materials....

Embodiment 1

[0030] This embodiment provides a pultruded electromagnetic shielding carbon fiber composite resin, which includes the following components by mass percentage:

[0031] Weigh 30 parts of epoxy resin E51, 20 parts of methyltetrahydrophthalic anhydride, 30 parts of unsaturated resin, 2 parts of benzoyl peroxide, 5 parts of 1,4-butyrolactone, 3 parts of carboxyl-terminated liquid nitrile rubber , 3 parts of internal release agent, 5 parts of 1mm length chopped nickel-plated carbon fiber, 2 parts of 1mm stainless steel fiber, add to the mixing tank and stir evenly for use;

[0032] The measured viscosity of the above resin system is: 650mPa·s;

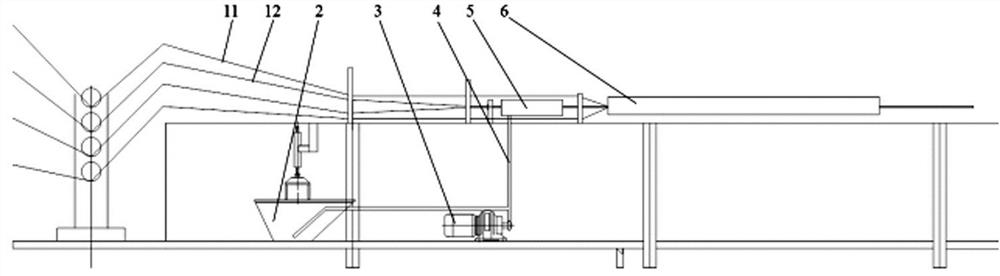

[0033] Pultruded electromagnetic shielding carbon fiber composite material, the design fiber volume content is 65%, such as figure 1 , The tensioning device is arranged in order from top to bottom as carbon fiber cloth 11, carbon fiber yarn 12, carbon fiber yarn 12 and carbon fiber cloth 11. A preforming mold 5 and a curing mold 6 are sequentiall...

Embodiment 2

[0040] This embodiment provides a pultruded electromagnetic shielding carbon fiber composite resin, which includes the following components by mass percentage:

[0041] Weigh 50 parts of epoxy resin TDE-85, 5 parts of dimethylimidazole, 20 parts of unsaturated resin, 2 parts of benzoyl peroxide, 5 parts of butyl glycidyl ether, 5 parts of ethylene glycol diglycidyl ether. , 3 parts carboxyl-terminated liquid nitrile rubber, 5 parts internal release agent, 3 parts 1mm length chopped nickel-plated carbon fiber, 2 parts magnetic nano-modified zinc oxide whiskers. Add to the mixing tank and stir evenly for later use;

[0042] The measured viscosity of the above resin system is: 450mPa·s;

[0043] Pultruded electromagnetic shielding carbon fiber composite material, design fiber content 60% (volume content), such as figure 1 , The tensioning device is arranged in order from top to bottom as carbon fiber cloth 11, carbon fiber yarn 12, carbon fiber yarn 12 and carbon fiber cloth 11. A pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com