Method for coating energetic crystal surfaces

A technology of surface coating and crystal, which is applied in the direction of non-explosive/non-thermal agent components, explosives processing equipment, nitrated acyclic/alicyclic/heterocyclic amine explosive composition, etc., can solve the problem of limited coating strength and achieve The effect of high-efficiency coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A coating method for HMX energetic crystals, comprising the following steps:

[0040] At room temperature, Tris was dissolved in a mixed solution of water and ethanol with a volume ratio of 9:1 to prepare a solution with a Tris concentration of 10 mM; then hydrochloric acid was added dropwise to prepare a buffer solution with a pH of 8.0 for use.

[0041] Then, dopamine hydrochloride is dissolved in the buffer solution, makes the dopamine hydrochloride solution that concentration is 1g / L;

[0042] Next, 10g HMX (average particle diameter is 60 μm) is added in the dopamine hydrochloride solution prepared in 200mL, and is stirred into uniform suspension under the stirring rate of 500rpm;

[0043] After continuing to stir for 6h, filter with suction and dry in vacuo.

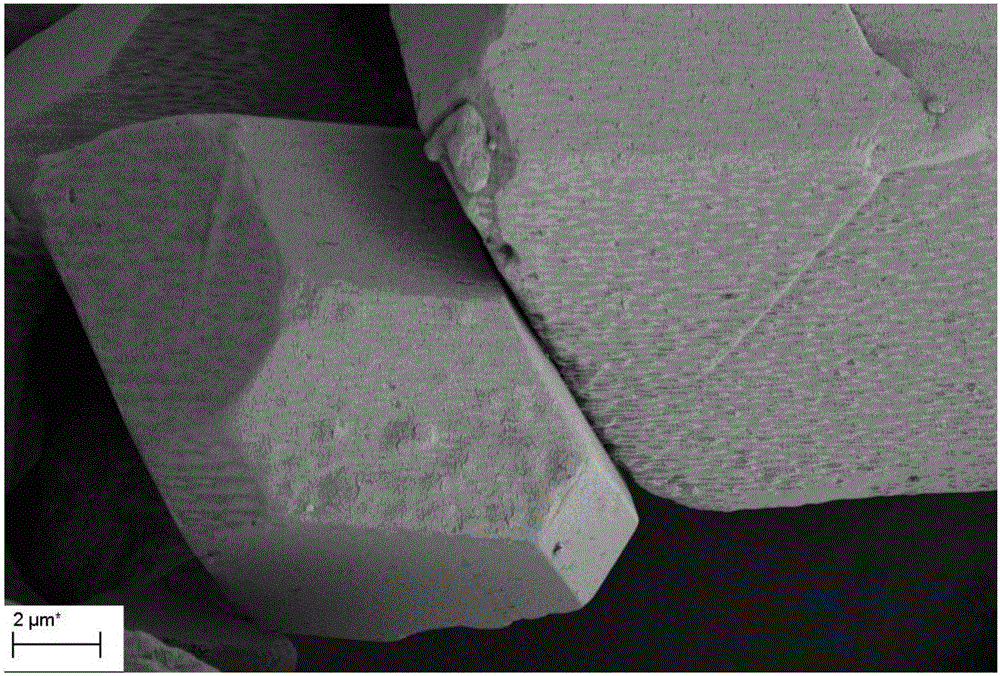

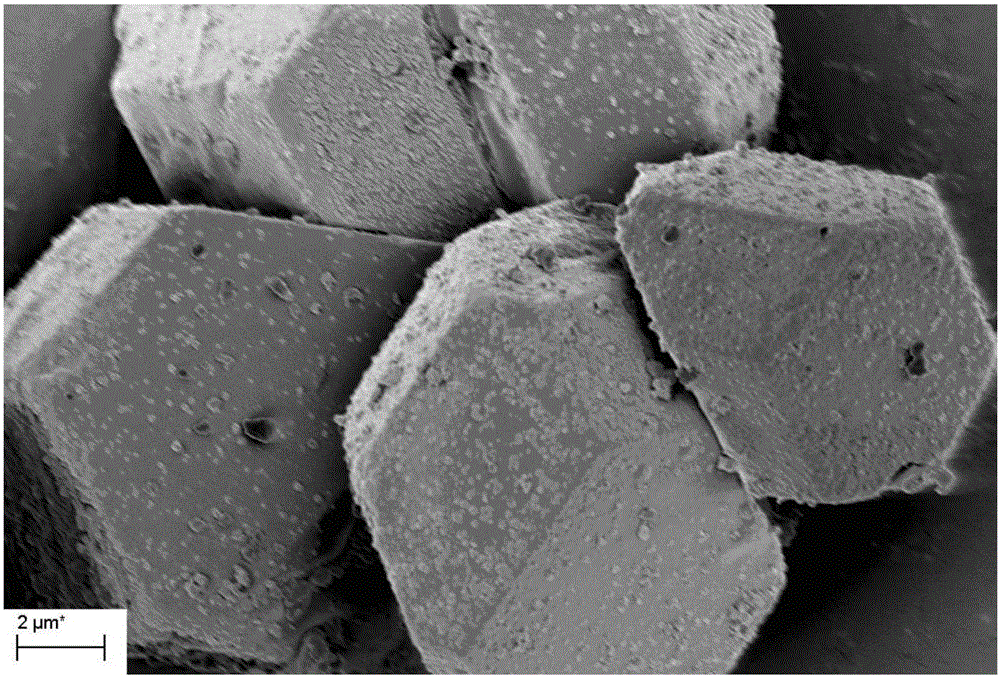

[0044] The surface of the HMX crystal prepared in this example is completely covered. After high-performance liquid chromatography analysis, the coating amount of dopamine on the surface of the HMX crystal i...

Embodiment 2

[0047] A coating method for Octojin energetic crystals, comprising the following steps:

[0048] At room temperature, Tris was dissolved in a mixed solution of water and ethanol with a volume ratio of 9:1 to prepare a solution with a Tris concentration of 10 mM; then hydrochloric acid was added dropwise to prepare a buffer solution with a pH of 8.5 for use.

[0049] Then, dopamine hydrochloride is dissolved in the buffer solution, makes the dopamine hydrochloride solution that concentration is 2g / L;

[0050] Next, 10g HMX (average particle diameter is 10 μm) is added in the dopamine hydrochloride solution prepared in 200mL, and is stirred into uniform suspension under the stirring rate of 600rpm;

[0051] After continuing to stir for 6h, filter with suction and dry in vacuo.

[0052] The surface of the HMX crystal prepared in this example is completely covered. After high-performance liquid chromatography analysis, the coating amount of dopamine on the surface of the HMX cry...

Embodiment 3

[0054] A coating method for TATB energetic crystals, comprising the following steps:

[0055] At room temperature, Tris was dissolved in a mixed solution of water and ethanol with a volume ratio of 9:1 to prepare a solution with a Tris concentration of 10 mM; then hydrochloric acid was added dropwise to prepare a buffer solution with a pH of 9.5 for use.

[0056] Then, dopamine hydrochloride is dissolved in the buffer solution, makes the dopamine hydrochloride solution that concentration is 2.5g / L;

[0057] Next, 10gTATB (average particle diameter is 5 μm) is added in the dopamine hydrochloride solution prepared in 200mL, and is stirred into a uniform suspension under the stirring rate of 800rpm;

[0058] After continuing to stir for 3h, filter with suction and dry in vacuum.

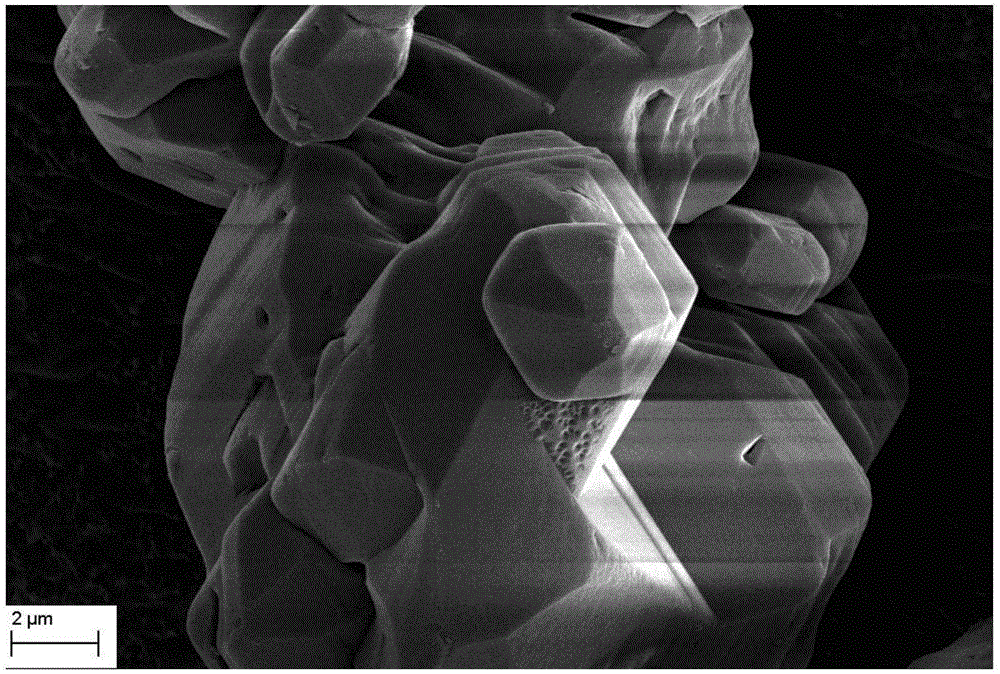

[0059] As a comparison, image 3 is the SEM image of untreated TATB crystals. Figure 4 It is the coated TATB crystal. like Figure 4 As shown, the surface of the prepared TATB crystal is completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com