Method for preparing gypsum-based self-leveling material by using desulfurization gypsum

A desulfurized gypsum, gypsum-based technology, applied in the field of gypsum-based self-leveling materials and their preparation, can solve the problems of high cost, poor strength, etc., and achieve the effects of low cost, excellent performance, and cheap and easily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

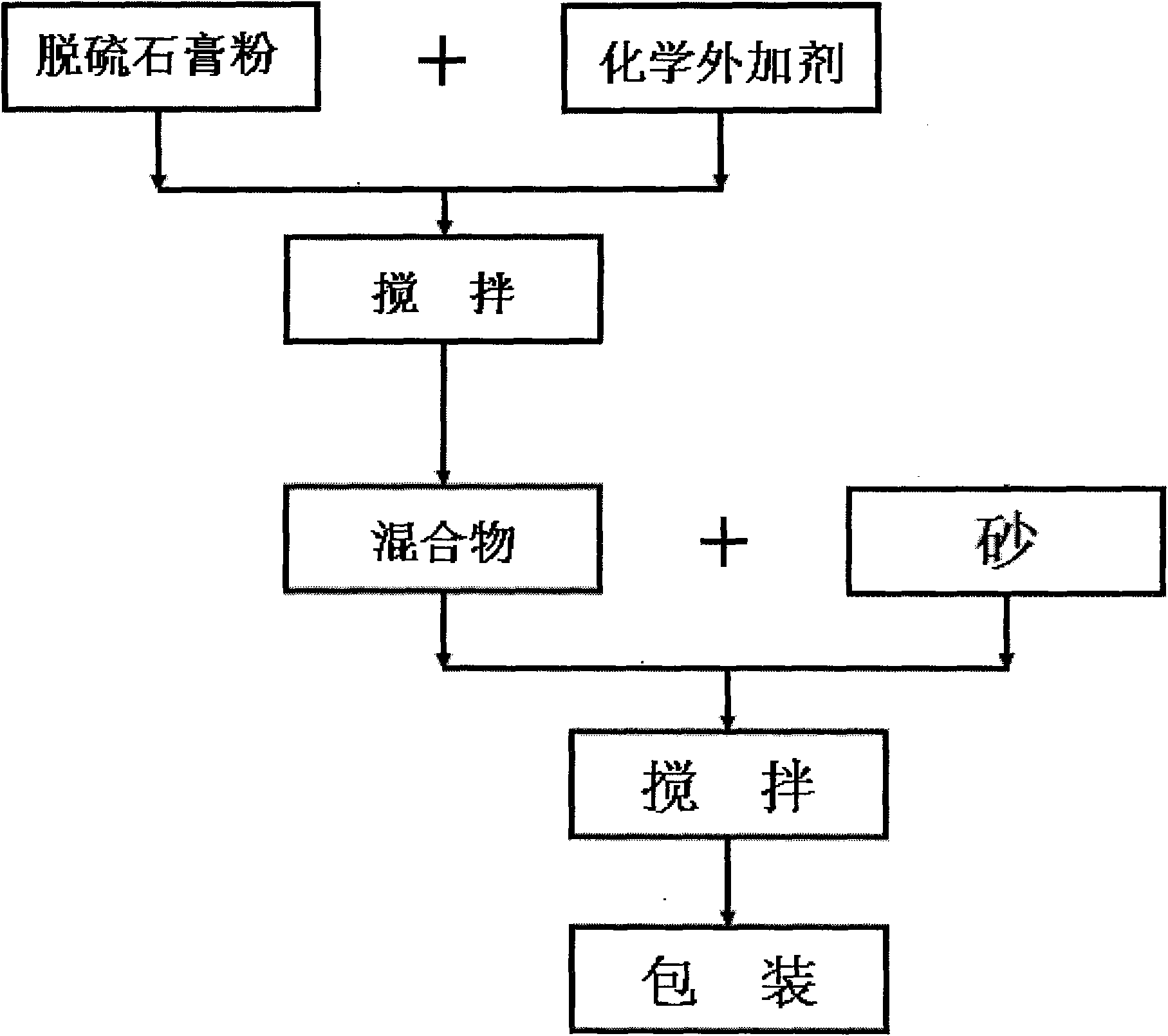

Method used

Image

Examples

Embodiment 1

[0026] By weight, 60 parts of gypsum powder prepared from desulfurized gypsum, 0.1 part of citric acid, 0.5 part of methyl cellulose ether, 3 parts of Portland cement, 0.3 part of polycarboxy water reducer, 0.1 part of defoamer, Put 1 part of redispersible latex powder into the mixer, mix for 20 minutes, the mixer speed is 60 rpm, and then mix with 35 parts of sand, the mixing time is 10 minutes, the stirring speed is 60 rpm, and the finished gypsum-based self-leveling is obtained 100 copies of materials.

Embodiment 2

[0028] By weight, 60 parts of gypsum powder prepared from desulfurized gypsum, 0.1 part of sodium citrate, 0.5 part of hydroxypropyl methylcellulose ether, 3 parts of Portland cement, 0.3 part of sulfonated melamine water reducer, 0.1 part of foaming agent and 1 part of redispersible latex powder are put into a mixer, mixed for 20 minutes, and the mixer speed is 60 rpm, and then mixed with 35 parts of sand, the mixing time is 10 minutes, and the stirring speed is 60 rpm, to obtain 100 parts of finished gypsum-based self-leveling material.

Embodiment 3

[0030] By weight, take 62.9 parts of gypsum powder prepared from desulfurized gypsum, 0.3 part of sodium polyphosphate, 0.5 part of hydroxypropyl methylcellulose ether, 0.2 part of sulfonated melamine water reducer, 0.1 part of defoamer, and Put 1 part of dispersed latex powder and 5 parts of talcum powder into the mixer, mix for 20 minutes, the mixer speed is 60 rpm, and then mix with 30 parts of sand, the mixing time is 10 minutes, the stirring speed is 60 rpm, and the finished gypsum is obtained Based on 100 parts of self-leveling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com