Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Good pore connectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

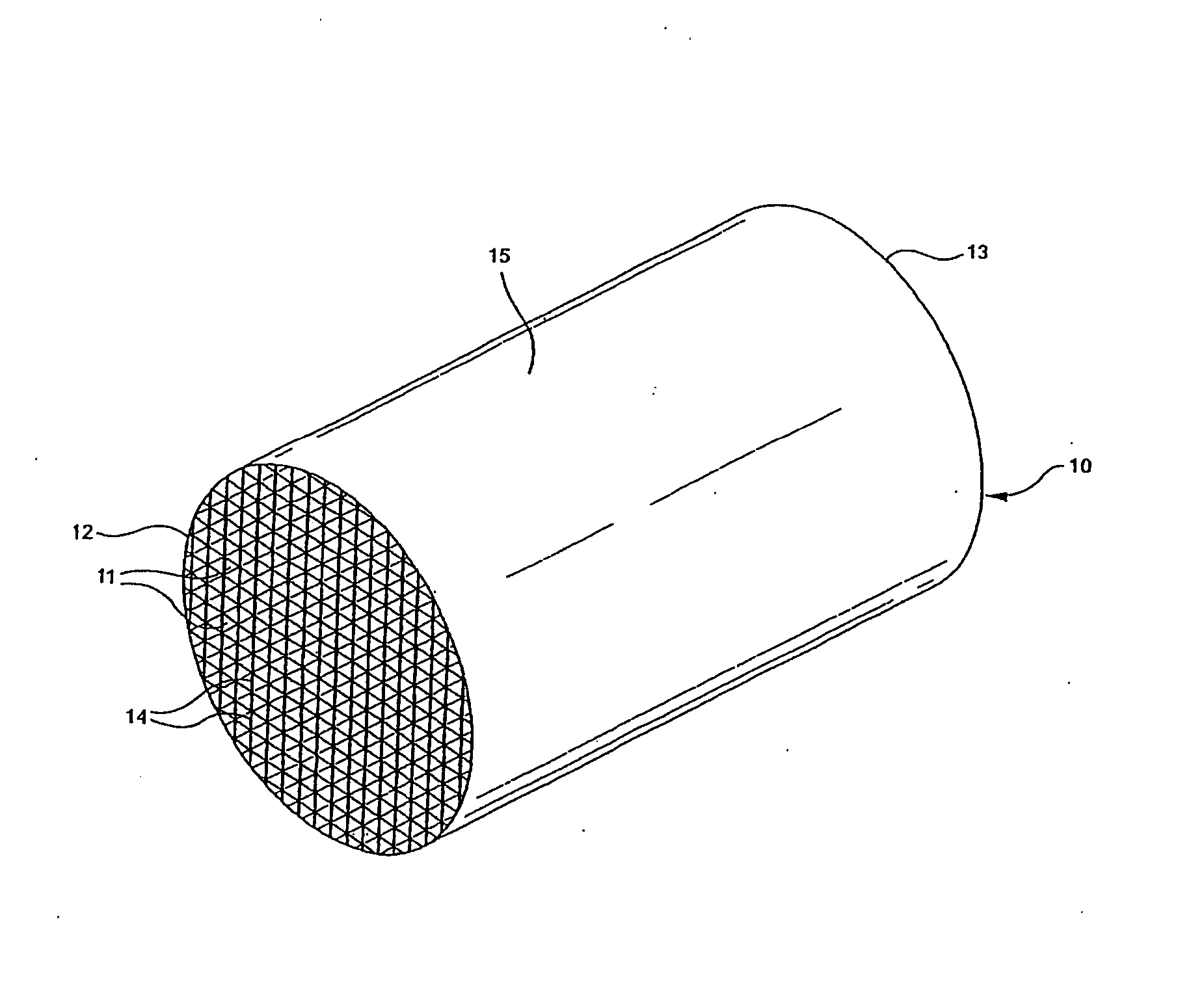

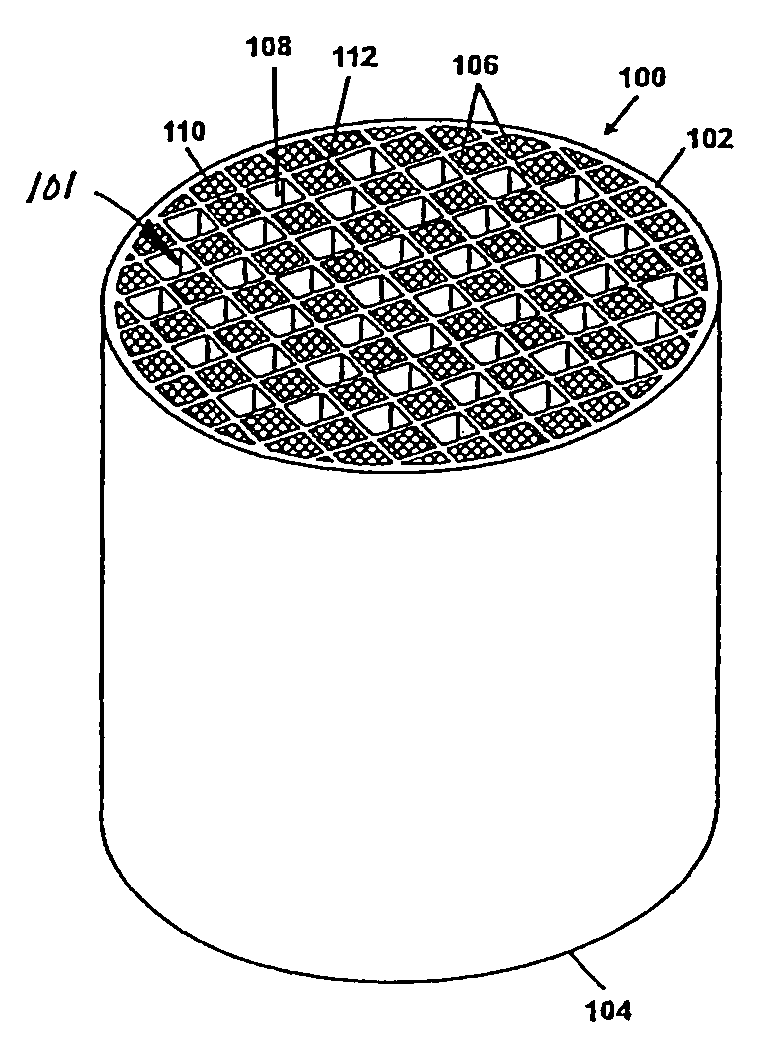

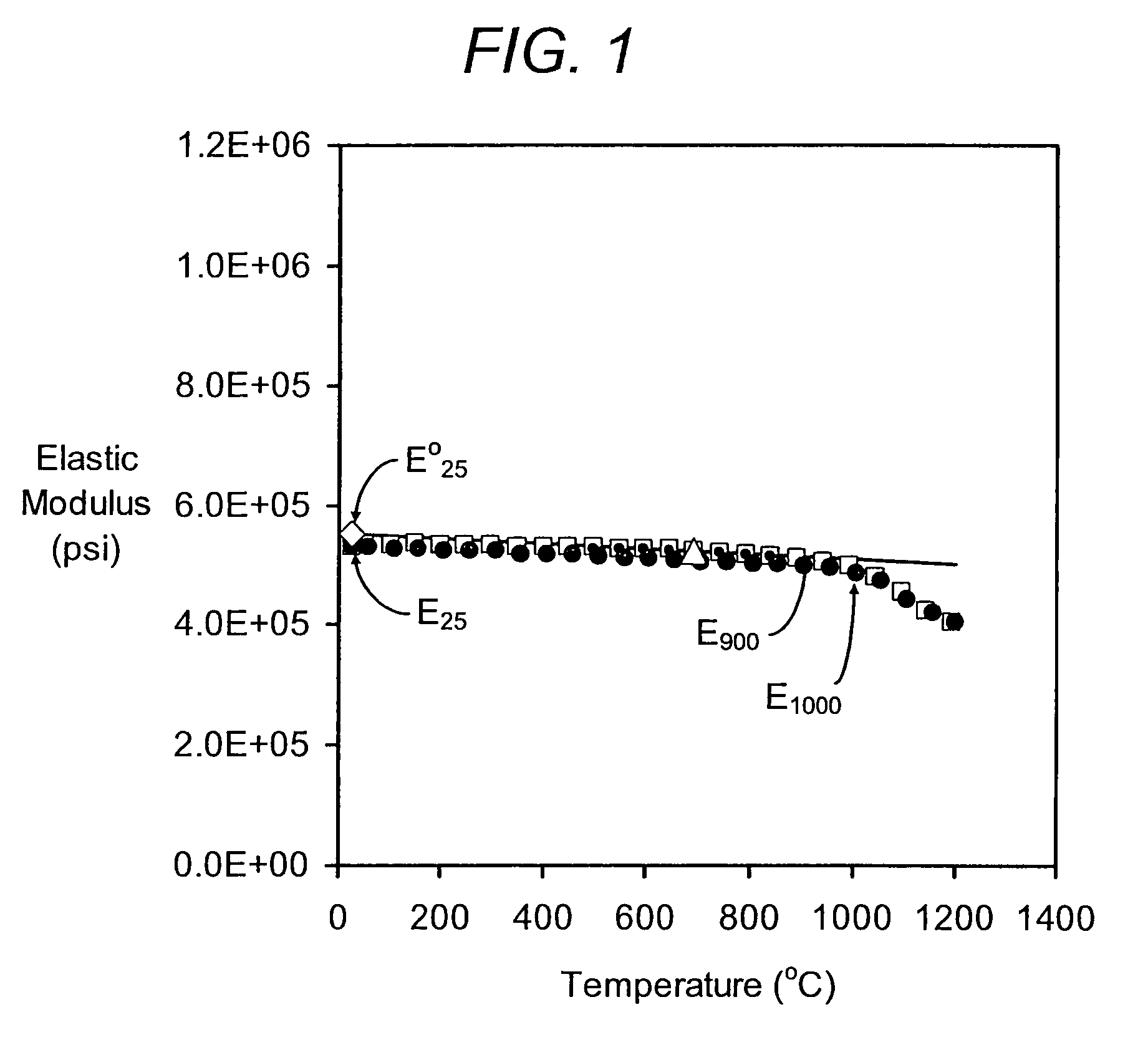

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS20080032091A1Low microcrackingHigh thermal shockLaminationLamination apparatusThermal shockThermal expansion

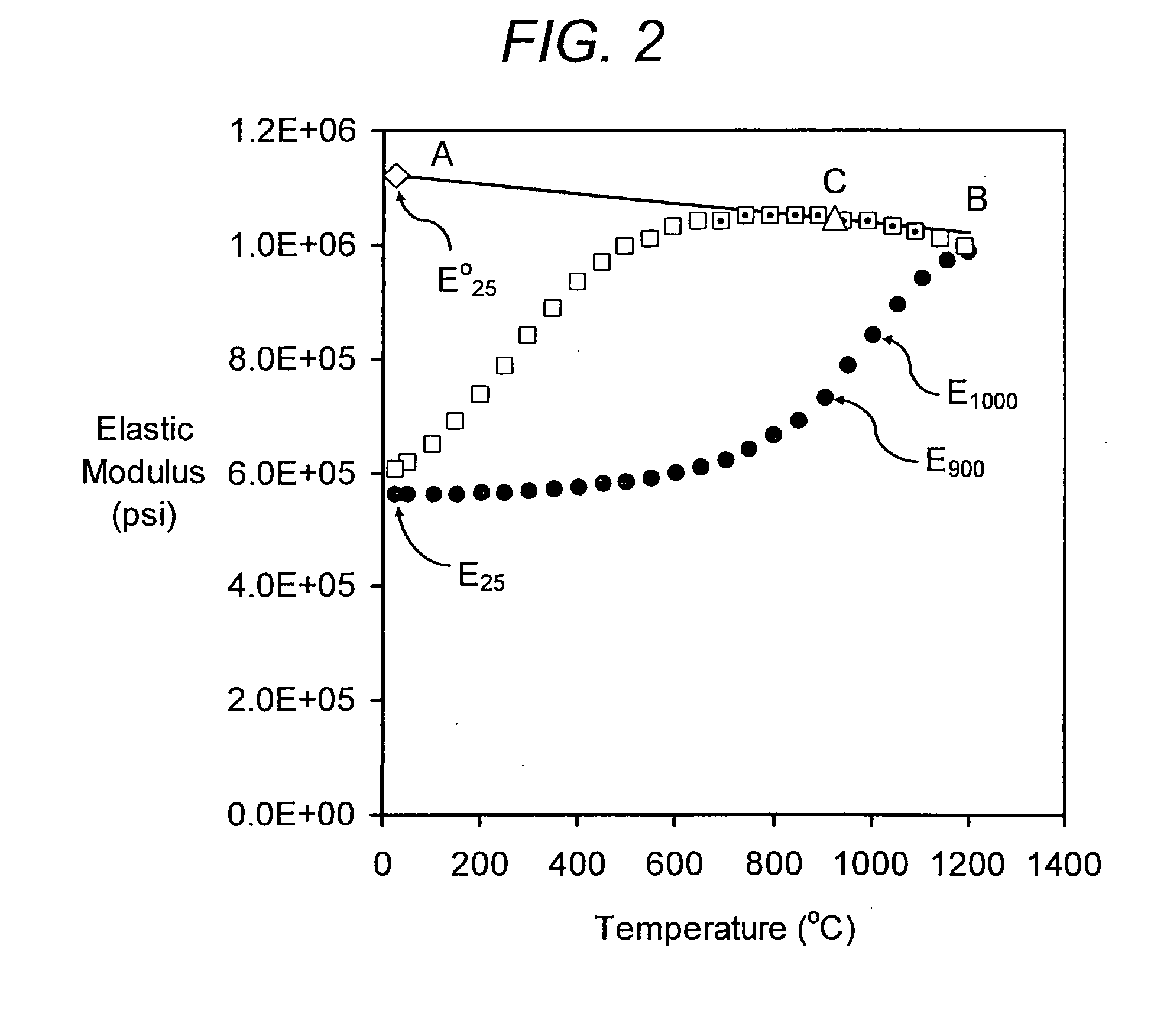

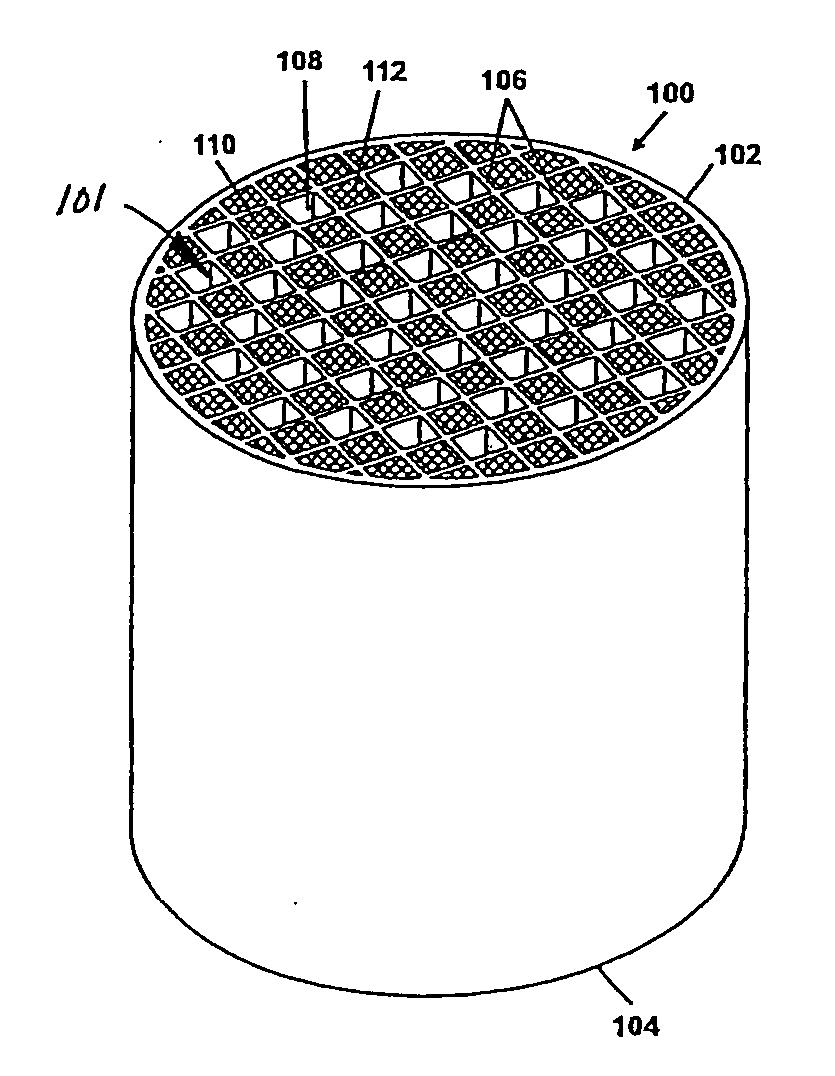

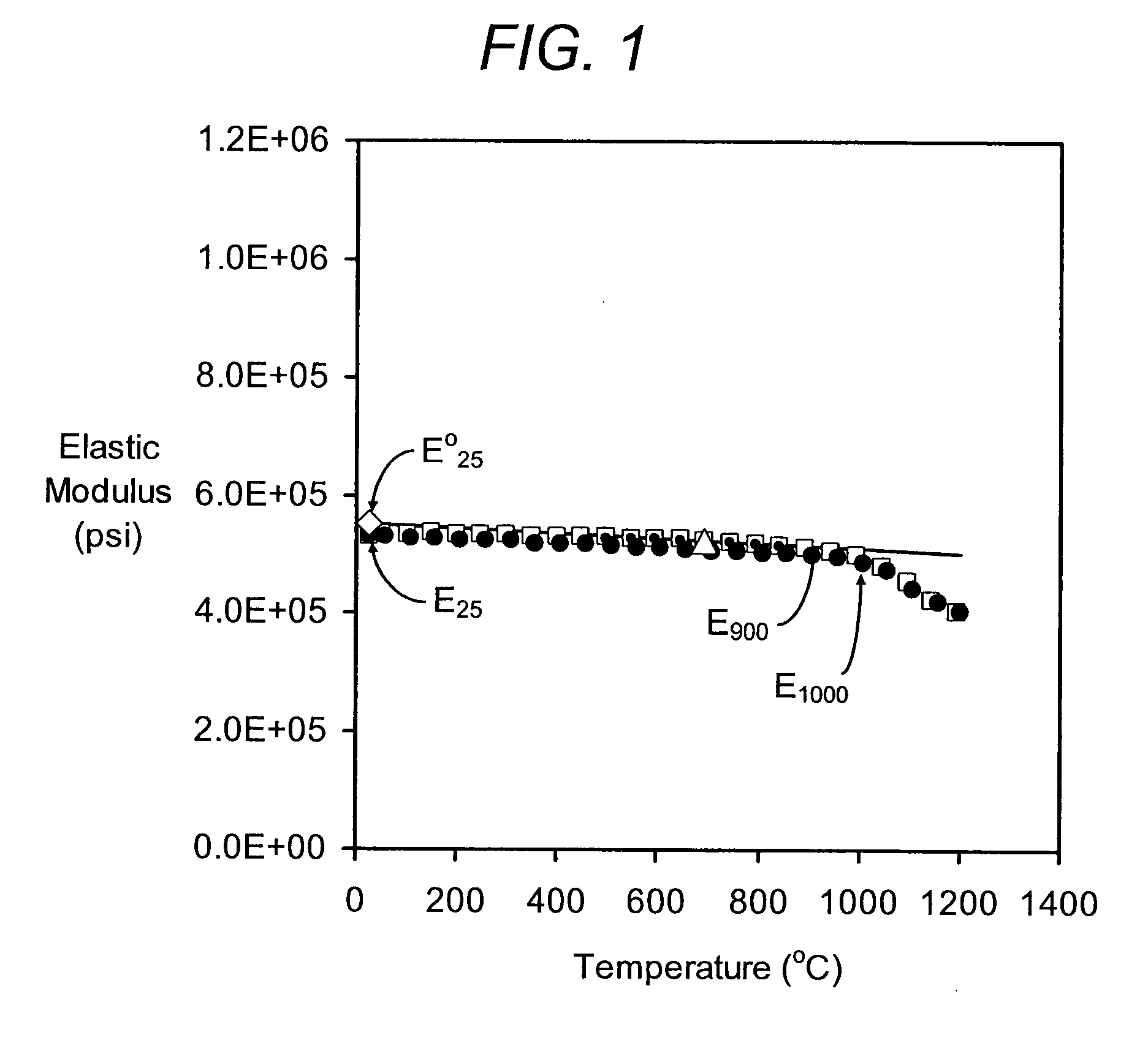

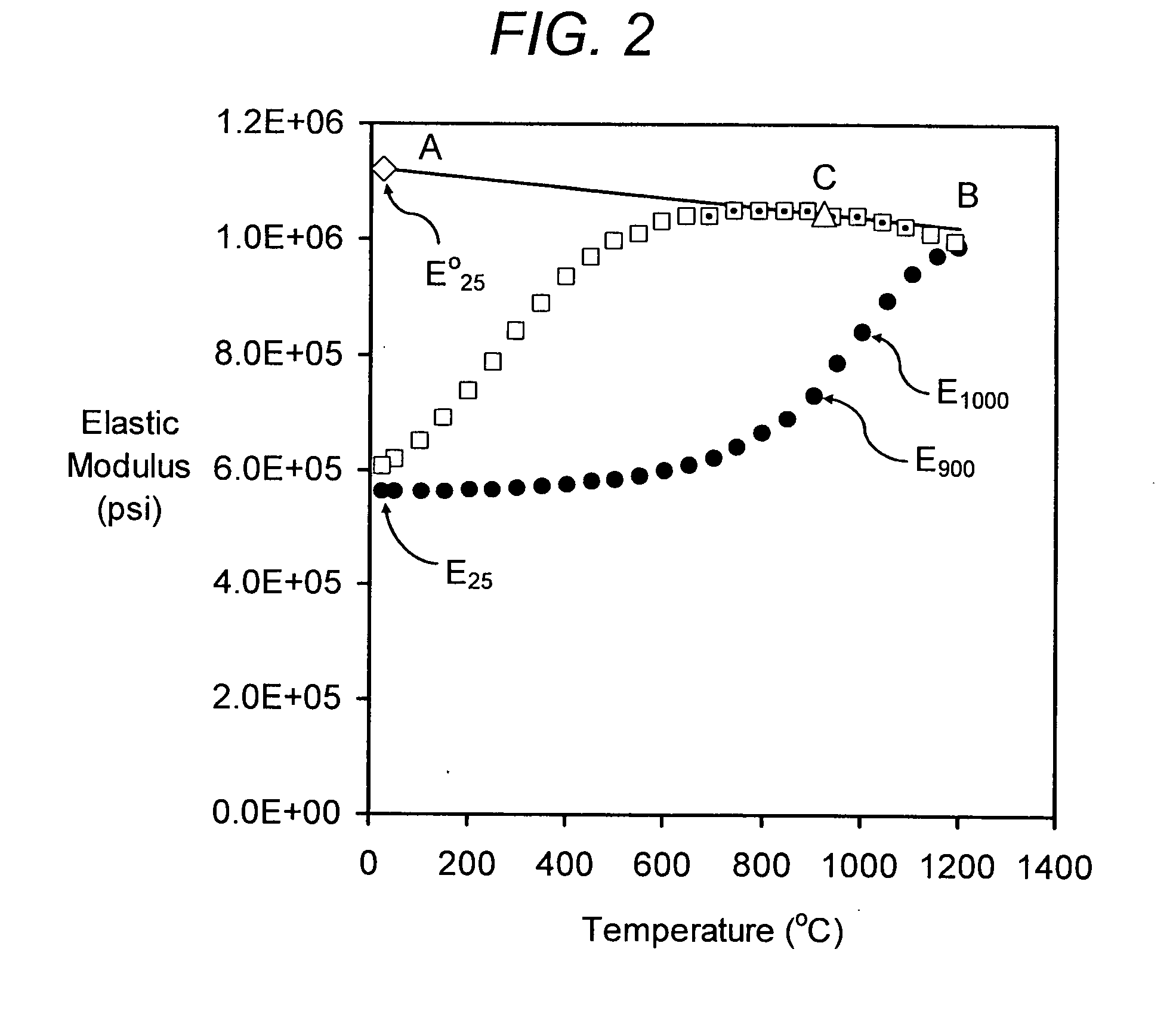

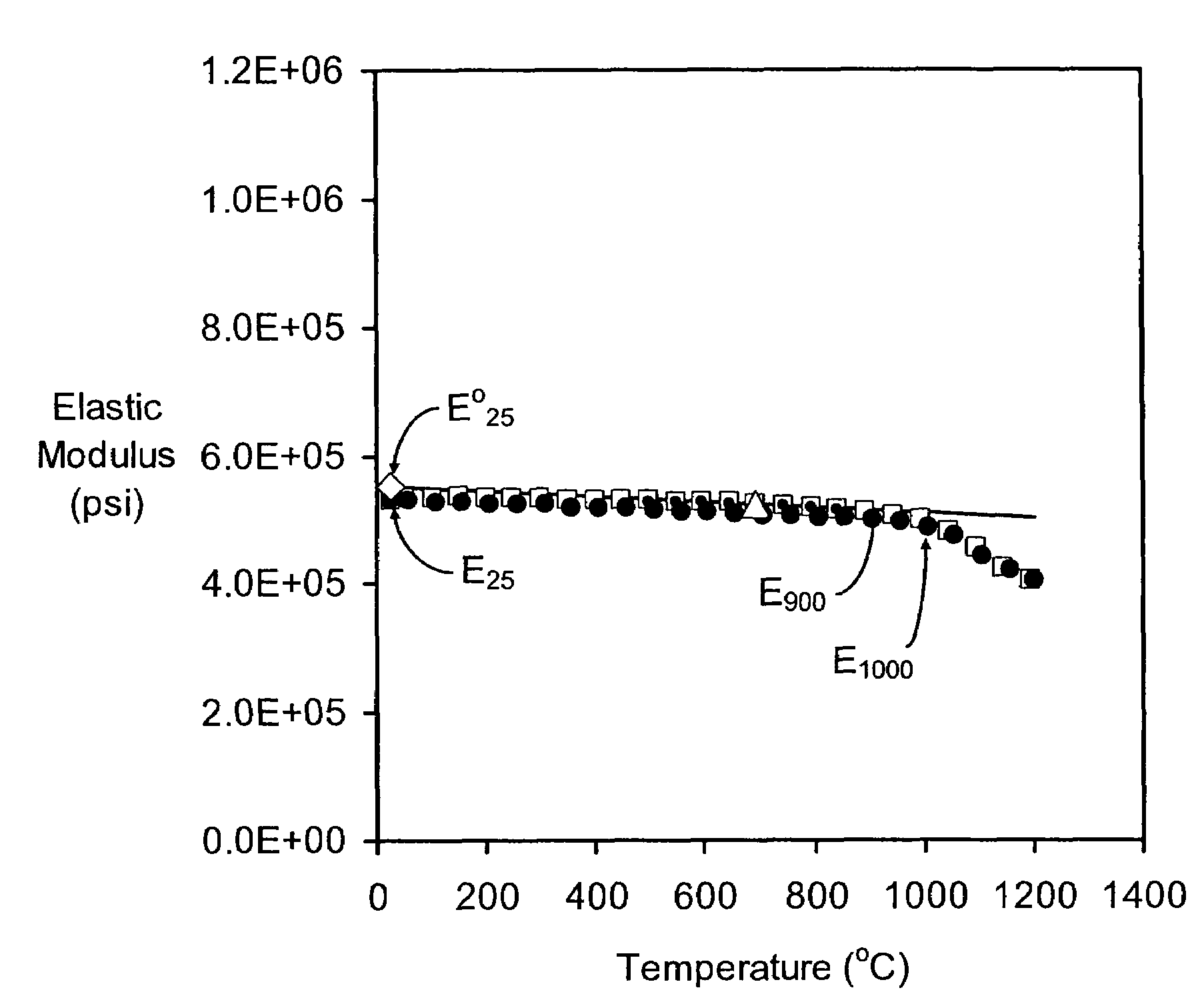

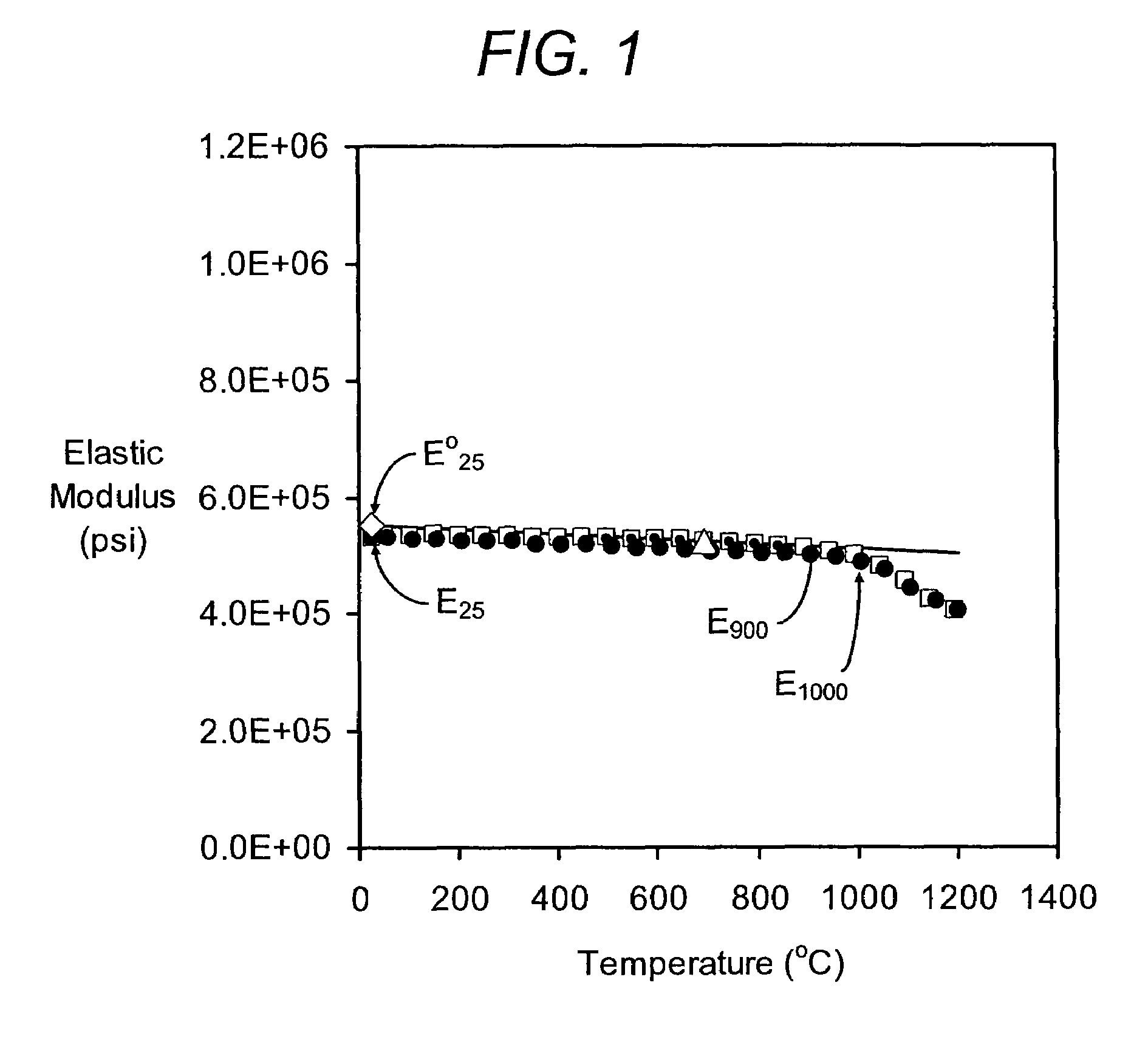

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

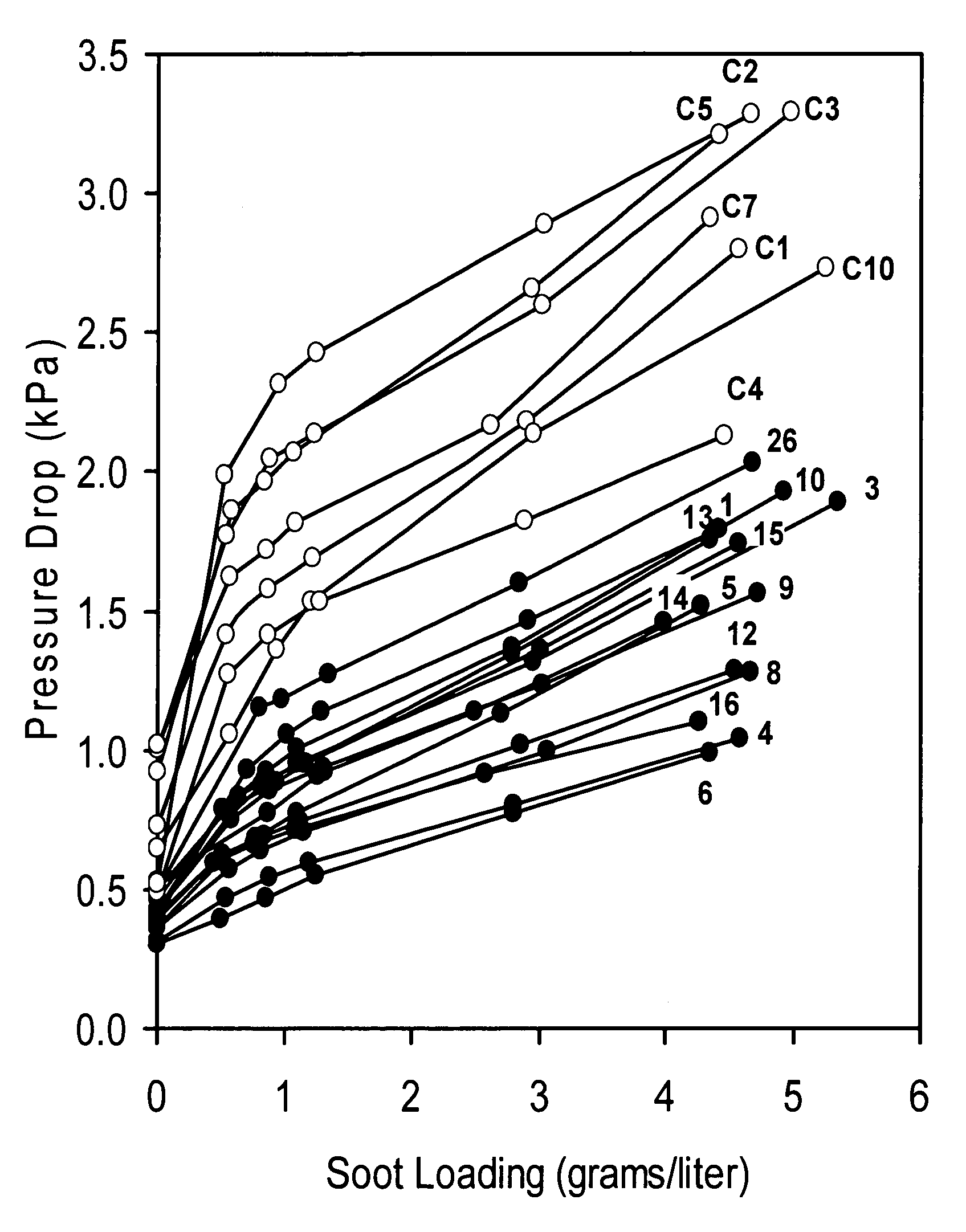

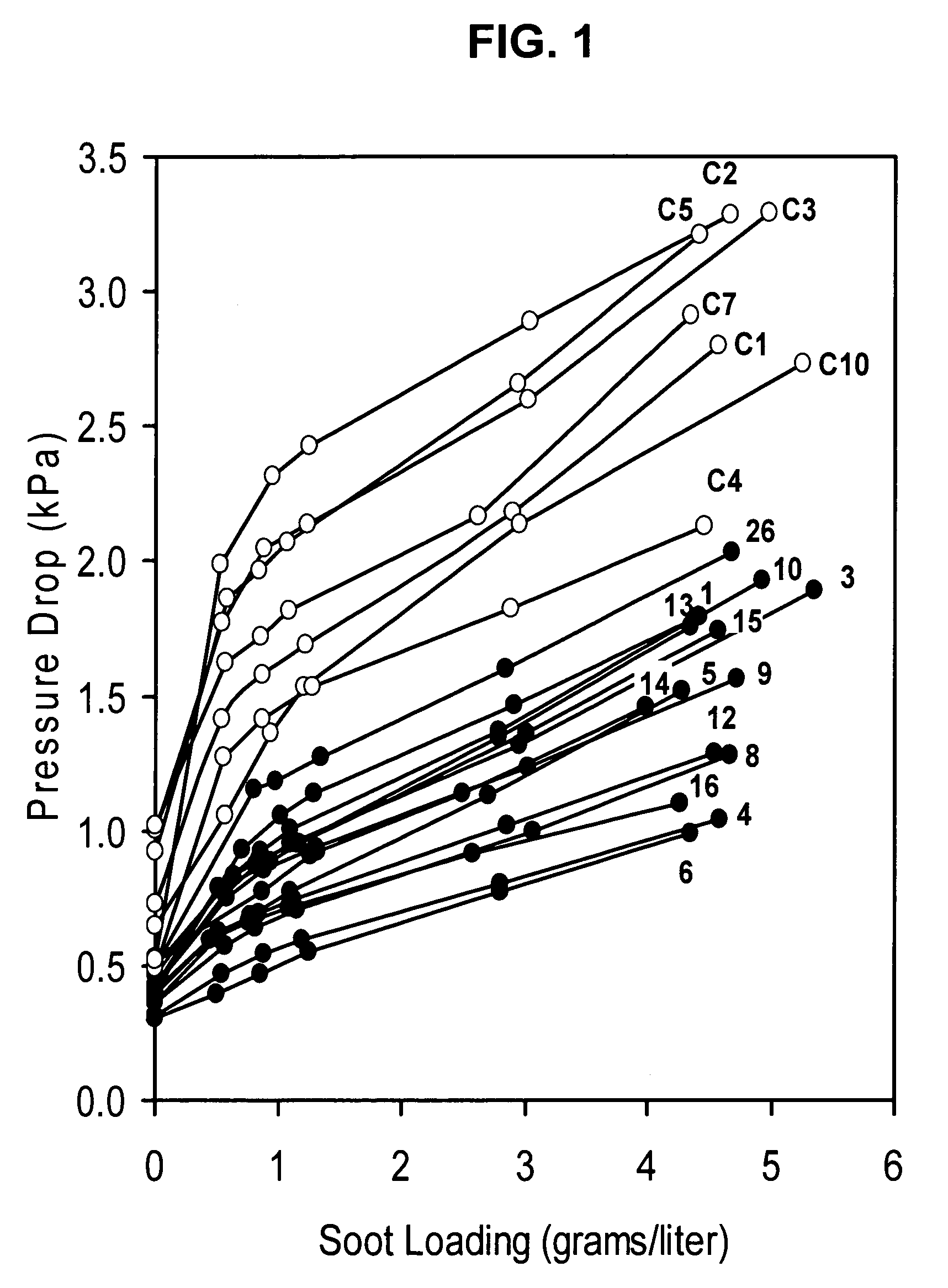

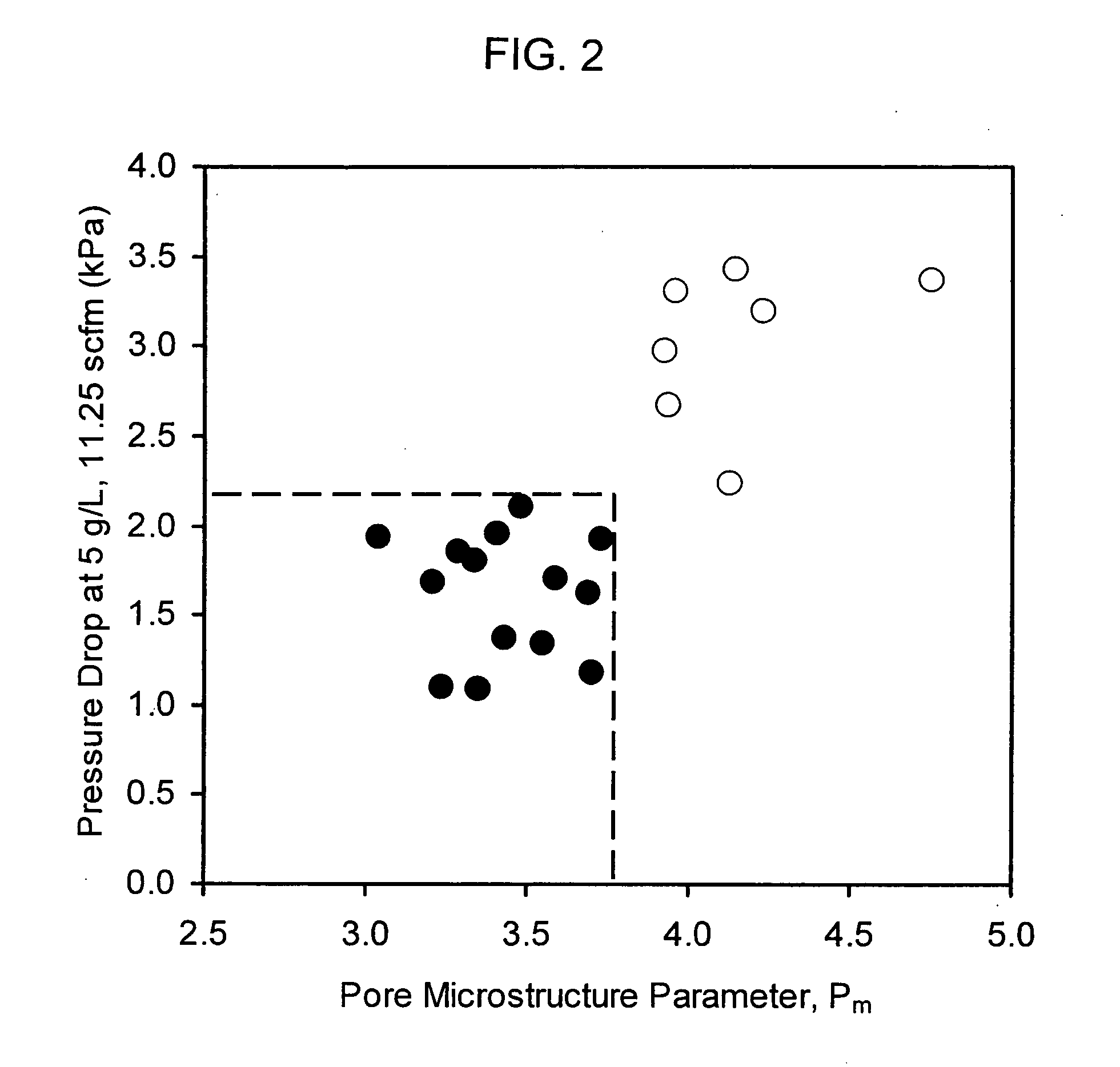

Cordierite filters with reduced pressure drop

ActiveUS7179316B2Lower overall pressure dropEasy to operateCombination devicesAuxillary pretreatmentMicrometerHoneycomb

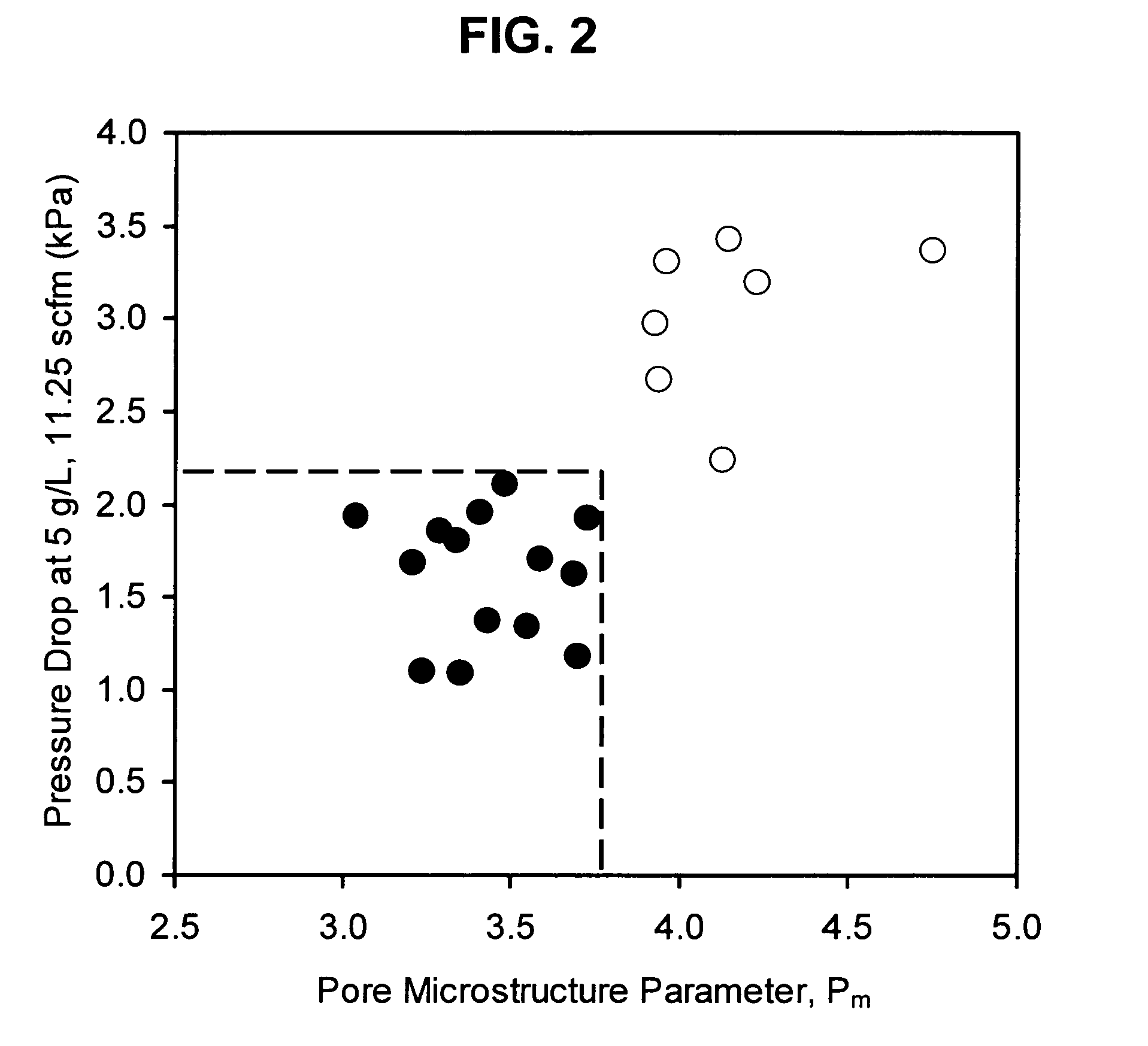

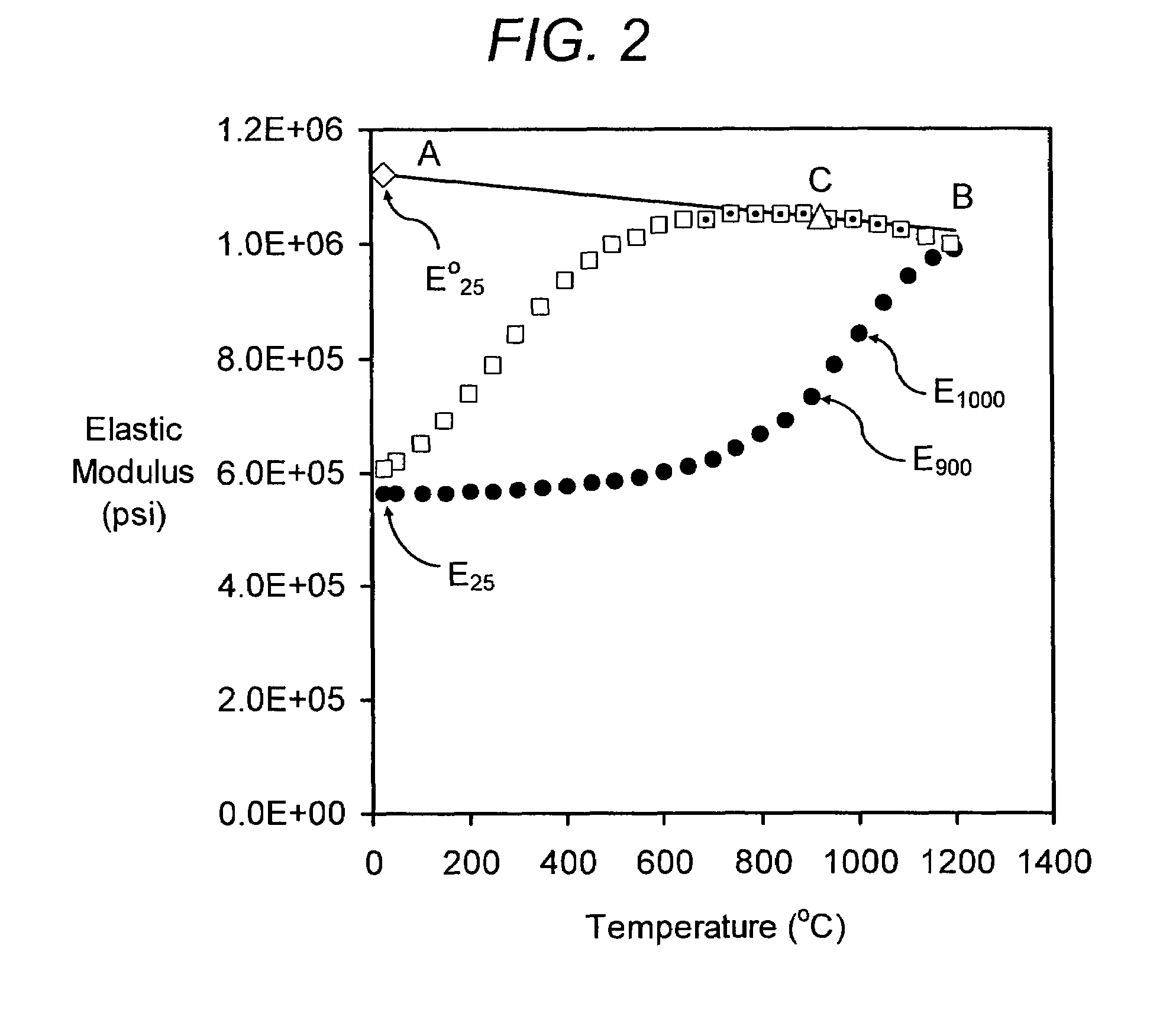

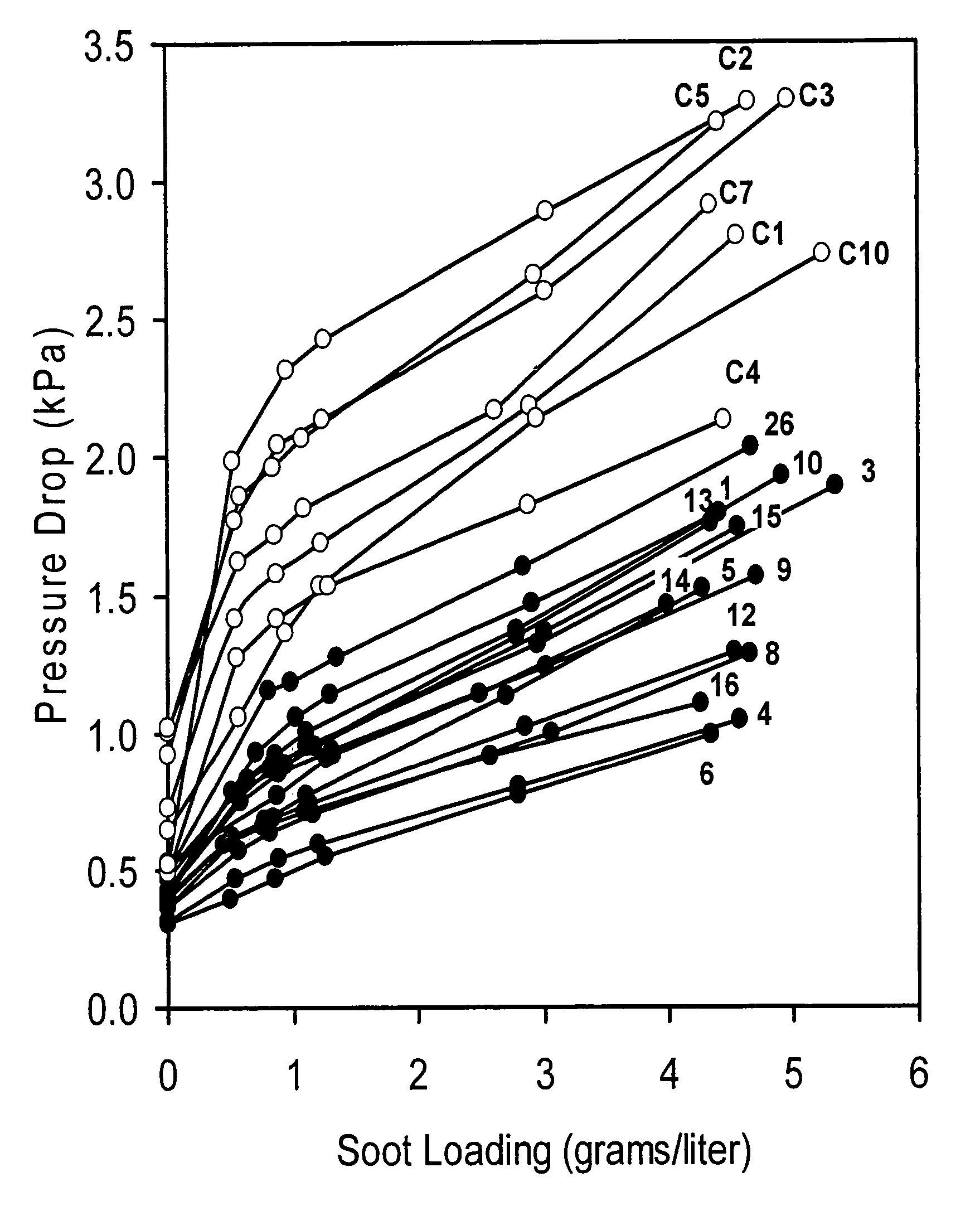

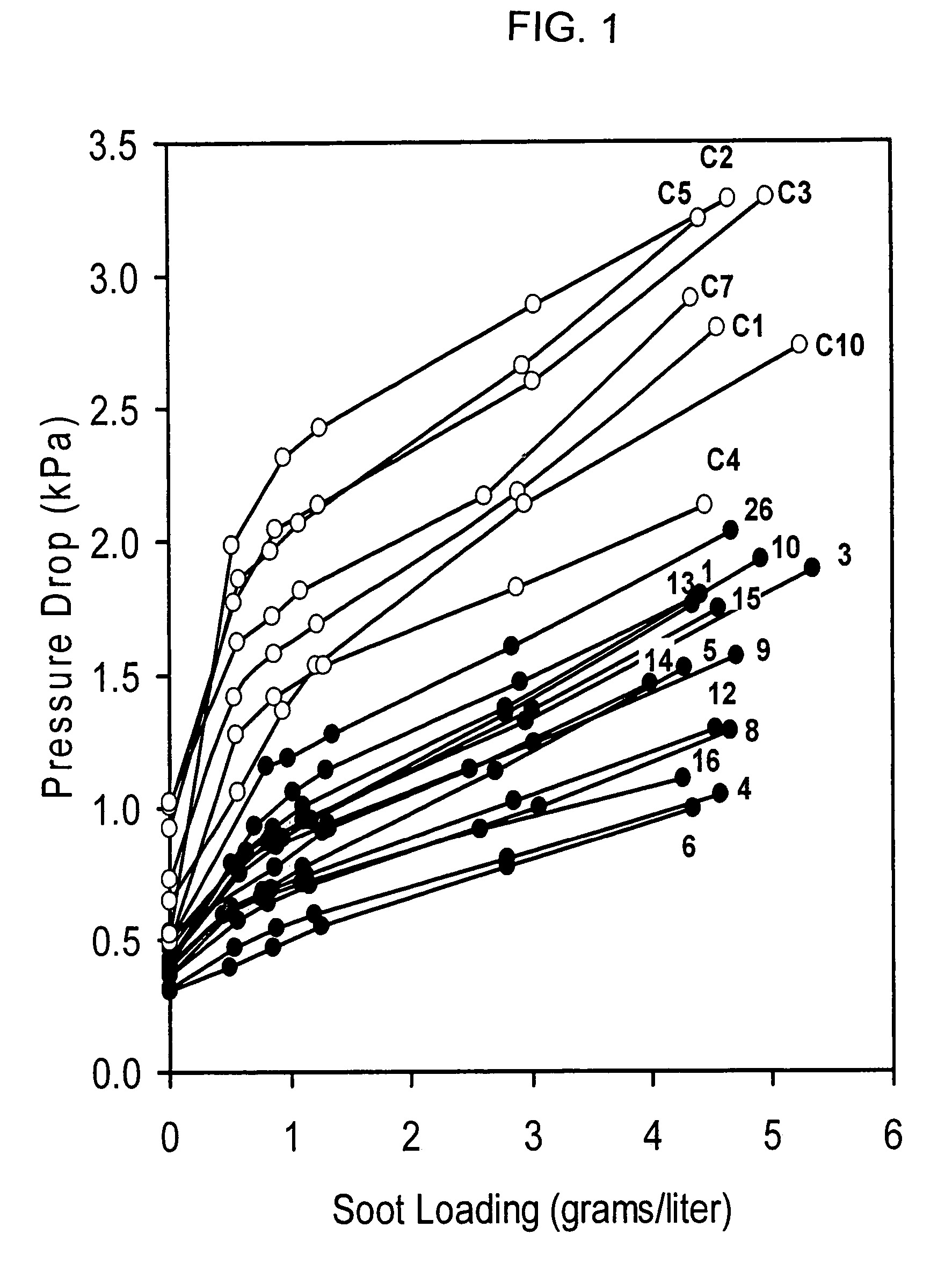

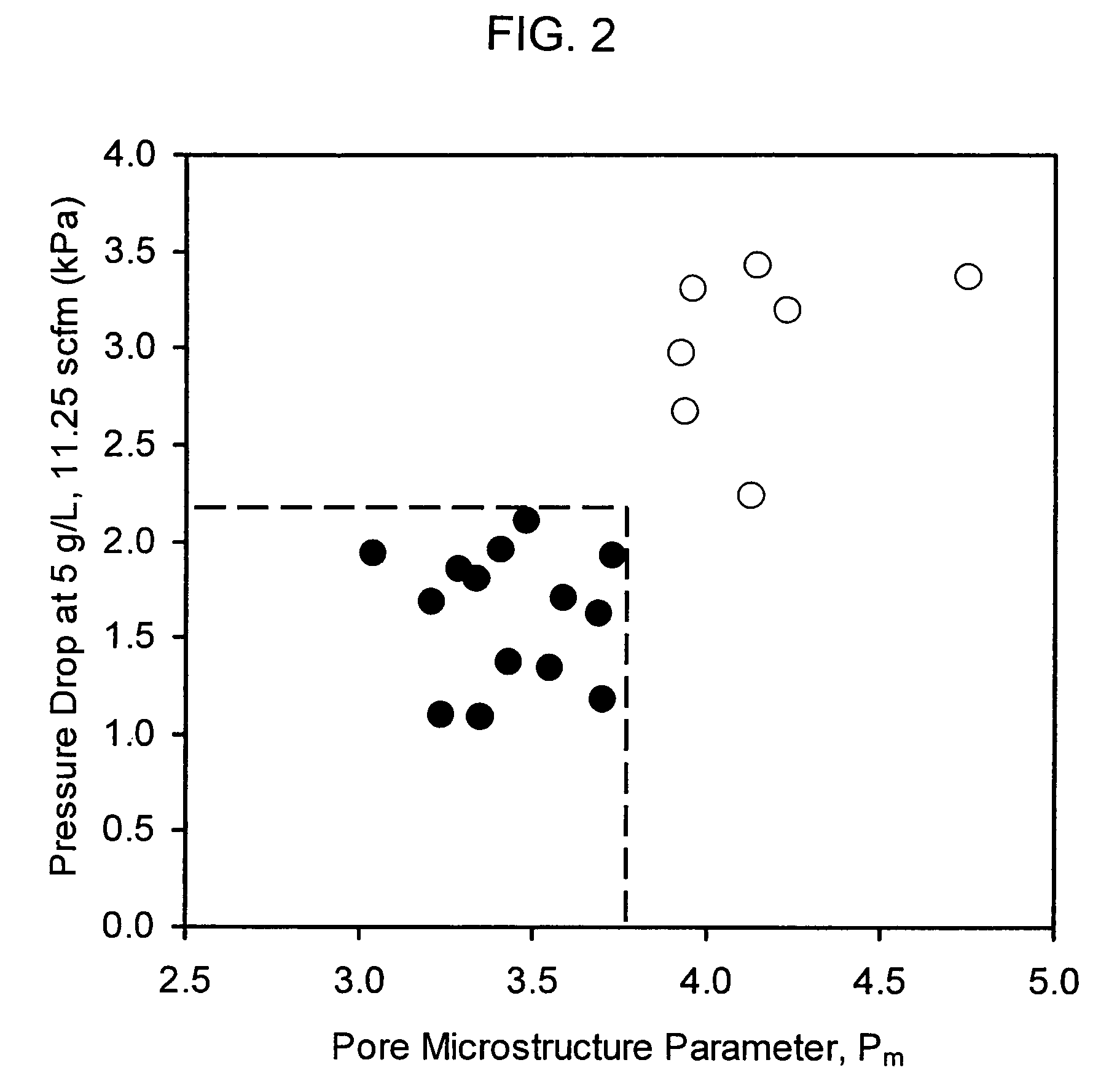

A diesel particulate filter comprising a plugged, wall-flow honeycomb filter body composed of cordierite and having a plurality of parallel end-plugged cell channels traversing the body from a frontal inlet end to an outlet end thereof, wherein the filter exhibits a CTE (25–800° C.) of less than 13×10−7 / ° C., a bulk filter density of less than 0.60 g / cm3, a median pore diameter, d50, of less than 25 micrometers, a porosity and pore size distribution that satisfy the relationship Pm≦3.75, wherein Pm is equal to 10.2474{1 / [(d50)2(% porosity / 100)]}+0.0366183(d90)−0.00040119(d90)2+0.468815(100 / % porosity)2+0.0297715(d50)+1.61639(d50−d10) / d50, wherein d10, and d90 are pore diameters at 10% and 90% of the pore size distribution on a volumetric basis, and d10<d50<d90. A method of making the same is also provided.

Owner:CORNING INC

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS20080032090A1Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS7618699B2Improve efficiencyHigh strengthLayered productsCeramic shaping apparatusThermal expansionInterconnected porosity

Owner:CORNING INC

Narrow pore size distribution cordierite filters with reduced pressure drop

InactiveUS7309371B2Lower overall pressure dropEasy to operateCombination devicesAuxillary pretreatmentHoneycombPore diameter

A diesel particulate filter having a honeycomb body composed of cordierite and exhibiting a CTE (25-800° C.) of less than 13×10−7 / ° C.; a median pore diameter, d50, of less than 25 μm; % porosity not less than 53%; and a narrow pore size distribution wherein a value of d50<sup2>−< / sup2>d10) / d50 is not greater than 0.6; and a value of d90 less than 40 μm wherein d10, and d90 are pore diameters at 10% and 90% of the pore size distribution on a volumetric basis, and d10<d50<d90. The particulate filter preferably exhibits a plugged, wall-flow honeycomb filter body composed of cordierite and having a plurality of parallel end-plugged cell channels traversing the body from a frontal inlet end to an outlet end thereof.

Owner:CORNING INC

Mesoporous carbon material, carbon/metal oxide composite materials, and electrochemical capacitors using them

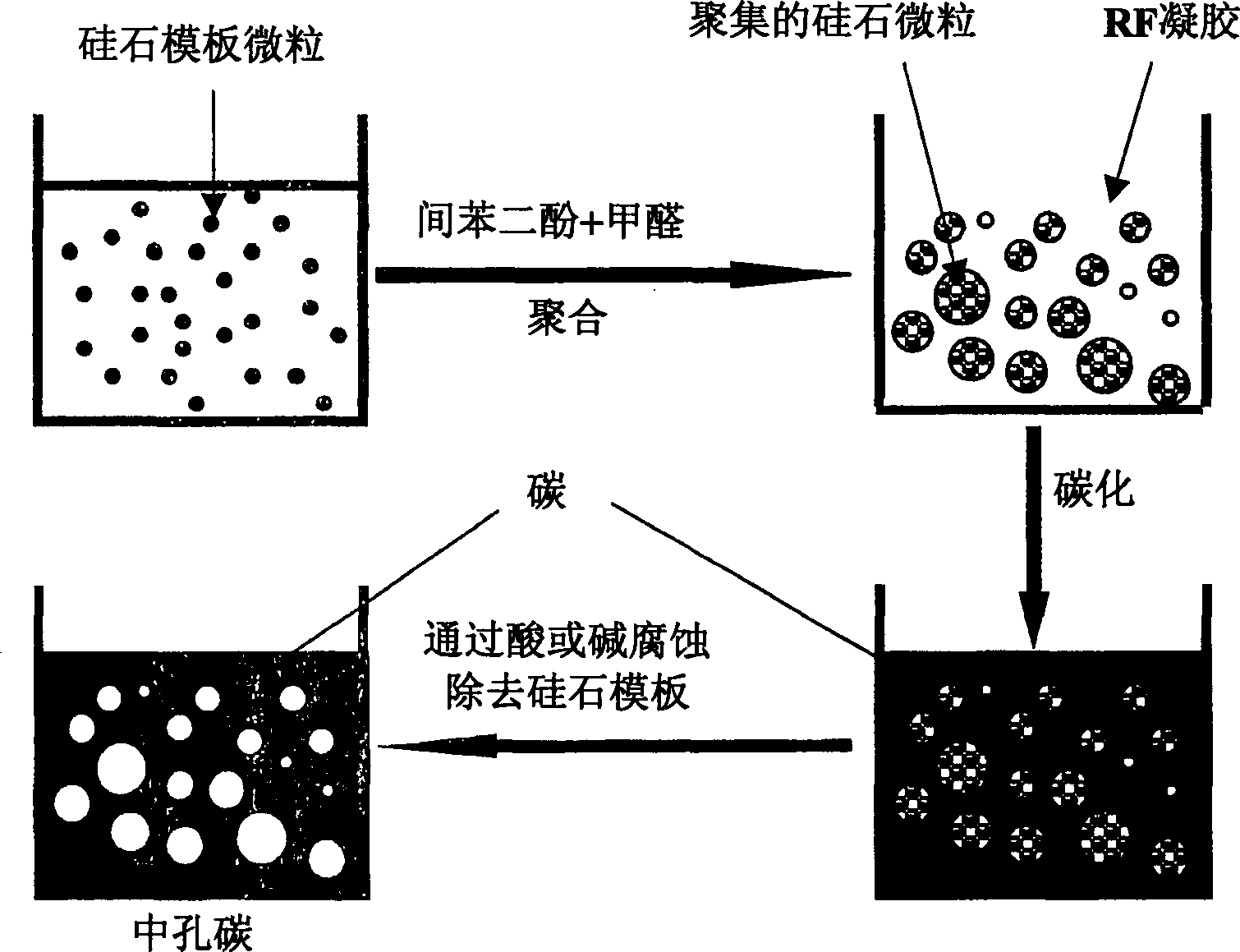

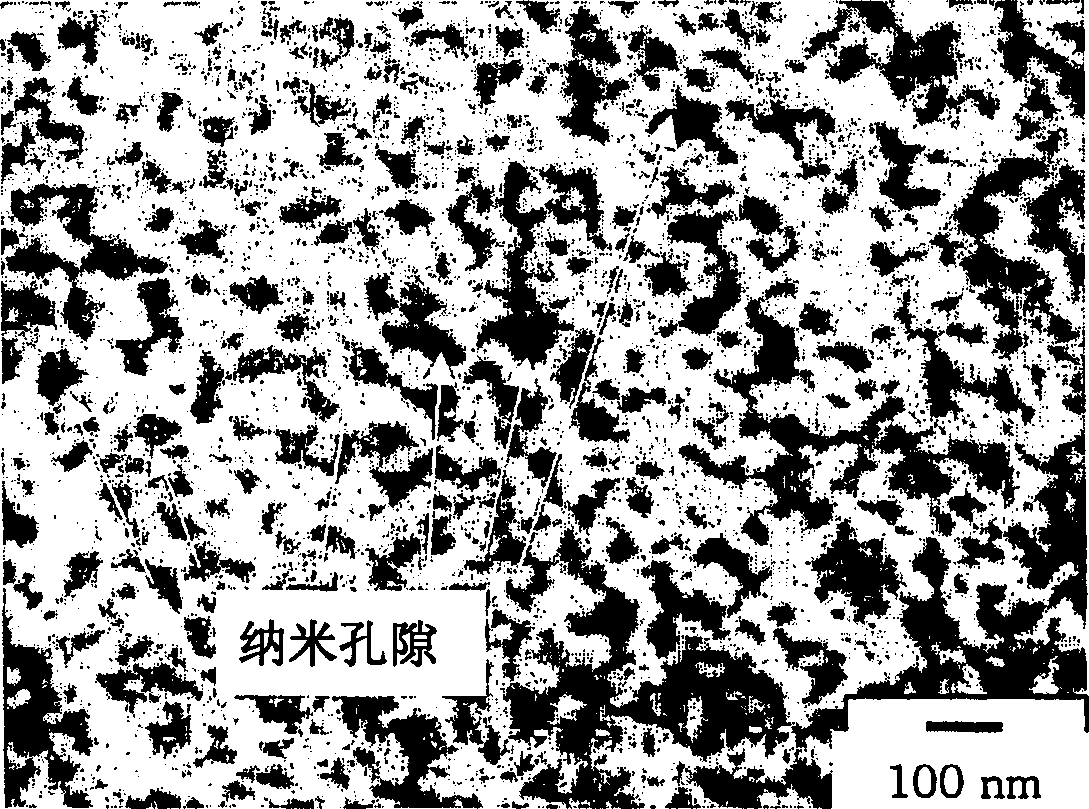

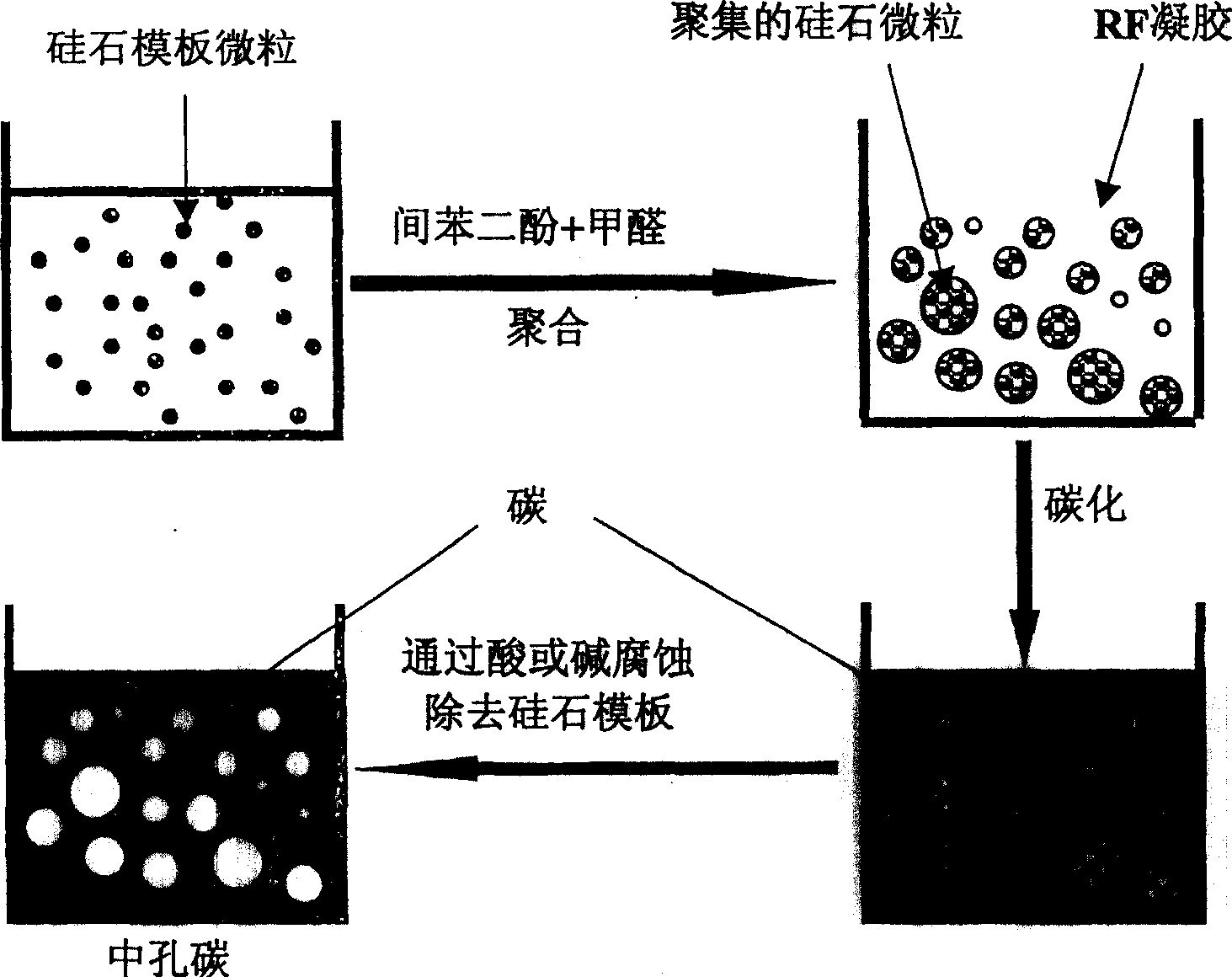

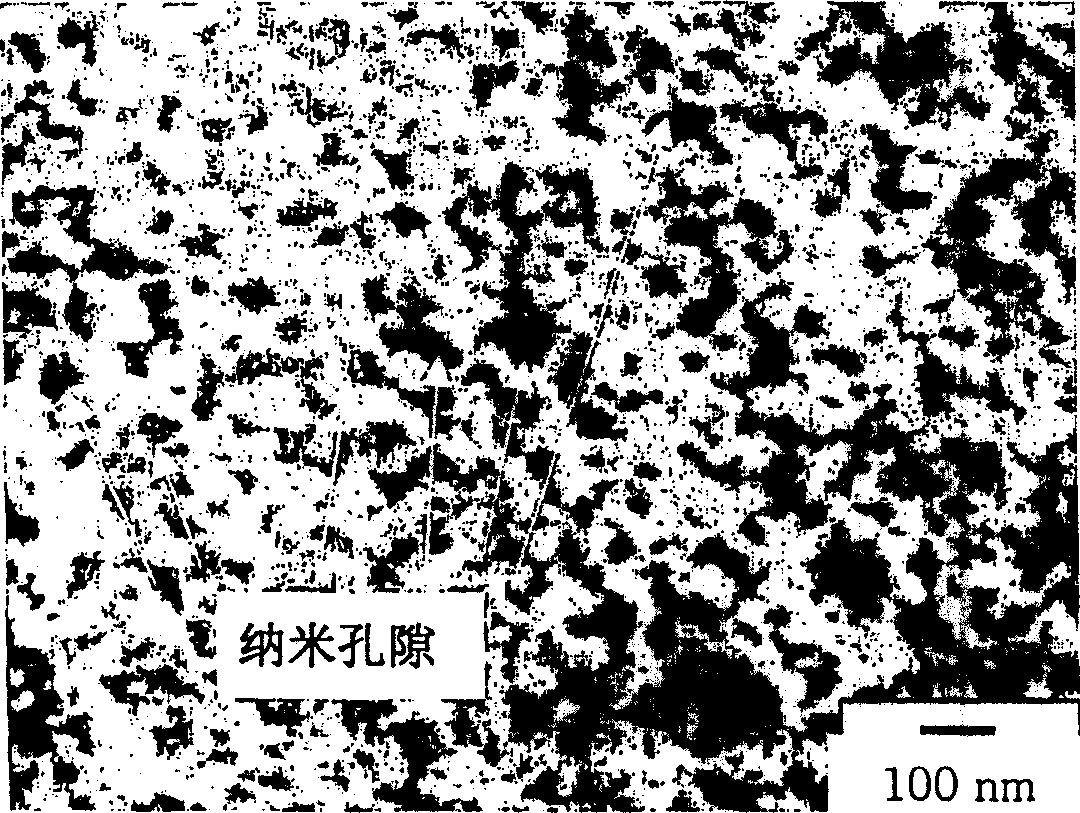

InactiveCN1452592AGood pore connectivityIncreased charge storage capacityHybrid capacitor separatorsHybrid capacitor electrolytesCapacitanceOxide composite

The invention relates to a carbon material with mesopores of 2 to 20 nm and high porosity, a carbon / metal oxide composite material in which metal oxides are deposited in carbon pores by using the carbon material, and an electric double made of the carbon material. A layer capacitor and an electrochemical capacitor made using the carbon / metal oxide composite material. When mesoporous carbon is used as an electrode material for an electric double-layer capacitor, the electric double-layer capacitor is superior to existing electric double-layer capacitors due to its low equivalent series resistance, although its capacitance value per unit weight is low due to its low surface area. Has a higher charge storage capacity. Moreover, when the carbon / metal oxide composite material is used as an electrode material of an electric double-layer capacitor, the capacitor has a higher capacitance value per unit weight through the combination of the electric double-layer capacitor and the metal oxide pseudocapacitor, that is, 254F / g.

Owner:活力韩国株式会社 +1

Low-microcracked, porous ceramic honeycombs and methods of manufacturing same

ActiveUS7927682B2Improve efficiencyHigh strengthLaminationLamination apparatusThermal expansionInterconnected porosity

Substantially non-microcracked, porous, cordierite ceramic honeycomb bodies are provided. Although exhibiting moderately high thermal expansion (CTE) between 7×10−7 to 16×10−7 / ° C. (25-800° C.), the honeycomb bodies exhibit relatively high thermal shock parameter (TSP), such as TSR≧525° C. by virtue of a high MOR / E ratio, and / or low Eratio=ERT / E1000° C. and well interconnected porosity, as witnessed by a relatively high pore connectivity factor (PCF). A method of manufacturing the honeycomb ceramic structure is also provided.

Owner:CORNING INC

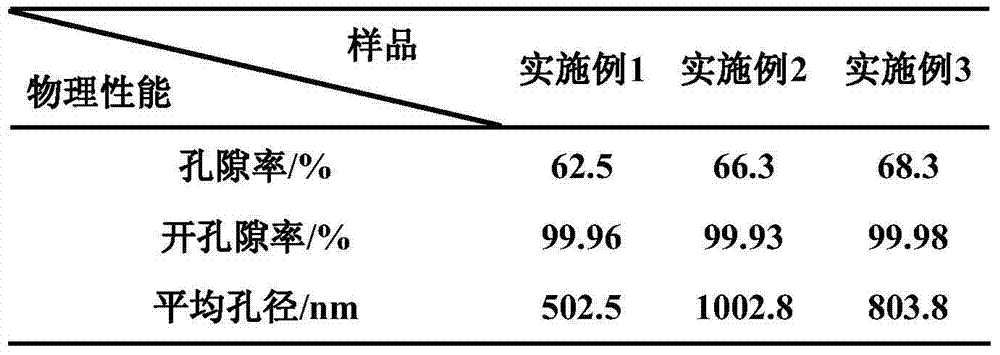

Medical polyvinyl alcohol sponge and preparation method

ActiveCN106916333AEasy to clean and removeGood biocompatibilityAbsorbent padsBandagesPolyvinyl alcohol spongeCross-link

The invention provides a medical polyvinyl alcohol sponge and a preparation method. The preparation method comprises the following steps: adding polyvinyl alcohol and starch into distilled water carrying out dissolving at 50 to 95 DEG C under stirring so as to obtain a mixed solution; adding a cross-linking agent, an emulsifier and a foam stabilizer into the mixed solution and carrying out stirring at 20 to 60 DEG C for 2 to 8 h so as to obtain a second mixed solution; adding an acidic catalyst into the second mixed solution and carrying out an acetalation cross-linking reaction at a constant temperature of 20 to 90 DEG C for 30 to 180 min so as to obtain emulsion-like liquid; and completion of the reaction, pouring the emulsion-like liquid into a mold, carrying out heating at 50 to 95 DEG C for curing, carrying out demoulding and washing after cooling, and then carrying out cutting and sterilization so as to obtain the medical polyvinyl alcohol sponge. The medical polyvinyl alcohol sponge prepared in the invention has a through hole structure, uniform pore diameter, good biocompatibility, excellent affinity, high porosity and fast liquid absorption rate, and is applicable to the field of surgical sciences, especially as a sponge consumable for vacuum sealing drainage.

Owner:WUHAN DRAGONBIO ORTHOPEDIC PROD

Narrow pore size distribution cordierite filters with reduced pressure drop

InactiveUS20070107397A1Lower overall pressure dropEasy to operateCombination devicesAuxillary pretreatmentHoneycombPore diameter

A diesel particulate filter having a honeycomb body composed of cordierite and exhibiting a CTE (25-800° C.) of less than 13x10-7 / ° C.; a median pore diameter, d50, of less than 25 mum; % porosity not less than 53%; and a narrow pore size distribution wherein a value of d50-d10) / d50 is not greater than 0.6; and a value of d90 less than 40 mum wherein d10, and d90 are pore diameters at 10% and 90% of the pore size distribution on a volumetric basis, and d10<D50<D90. The particulate filter preferably exhibits a plugged, wall-flow honeycomb filter body composed of cordierite and having a plurality of parallel end-plugged cell channels traversing the body from a frontal inlet end to an outlet end thereof.

Owner:CORNING INC

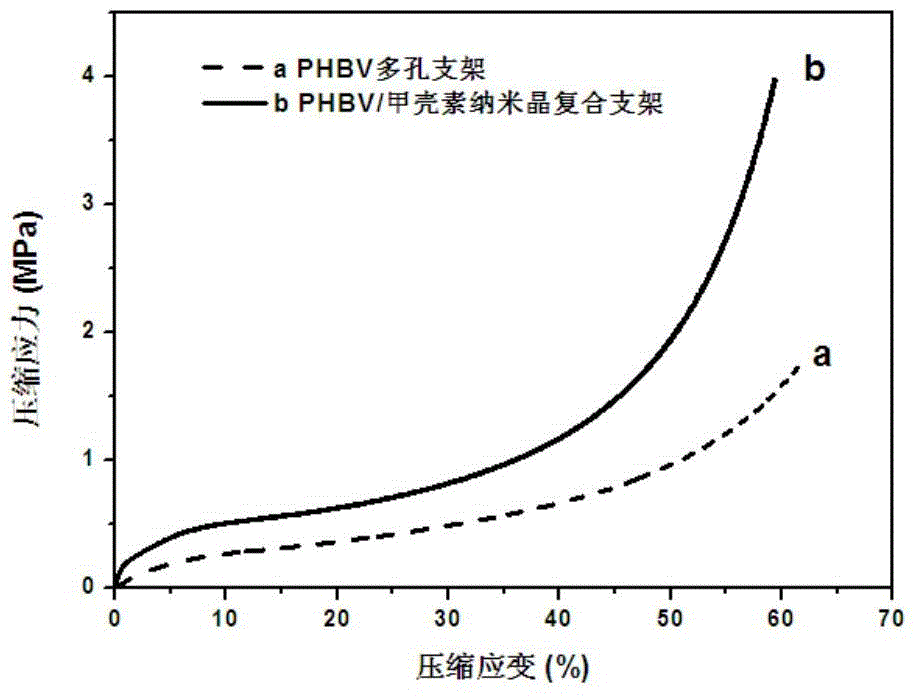

Biomacromolecule/chitin nanocrystalline composite scaffold material and preparation method thereof

ActiveCN104001208AGood pore connectivityHigh mechanical strengthProsthesisFoaming agentBone tissue engineering

The invention discloses a biomacromolecule / chitin nanocrystalline composite scaffold material and a preparation method thereof. Being a blend, the biomacromolecule / chitin nanocrystalline composite scaffold material comprises a biodegradable macromolecule and chitin nanocrystalline in a mass ratio of 1:10-1:100. The biodegradable macromolecule / chitin nanocrystalline composite bone tissue scaffold material is prepared by a freezing / pore-foaming agent leaching method. The composite scaffold has an average porosity of greater than 85%, the pore diameter is regulatable, and the compression modulus is 2MPa-12MPa. By introducing chitin nanocrystalline into a biomacromolecule porous scaffold, the mechanical strength and bioactivity of the scaffold are improved, and the adhesion of cells on the scaffold and the mineralization activity are promoted. The biomacromolecule / chitin nanocrystalline composite scaffold can be applied in the bone repair field as a bone tissue engineering scaffold.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

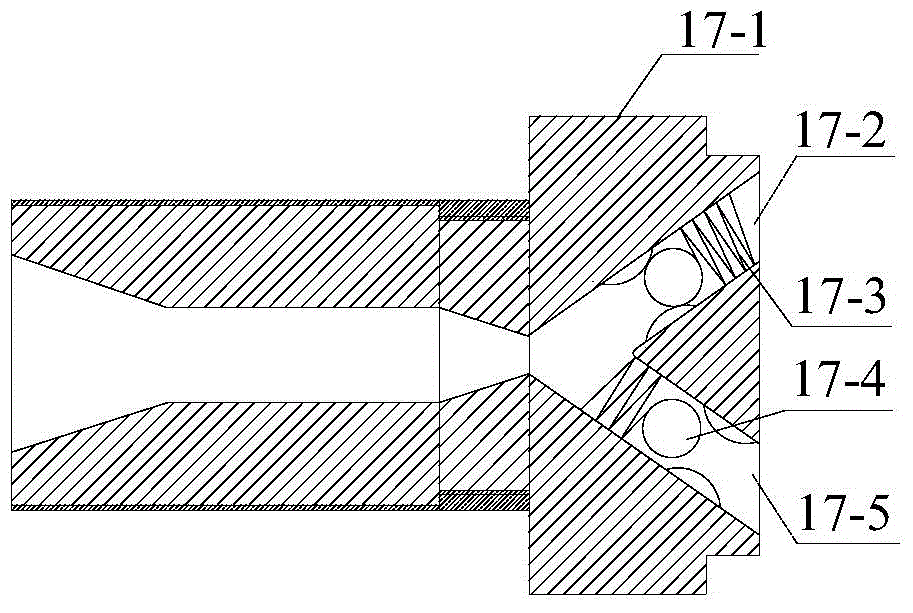

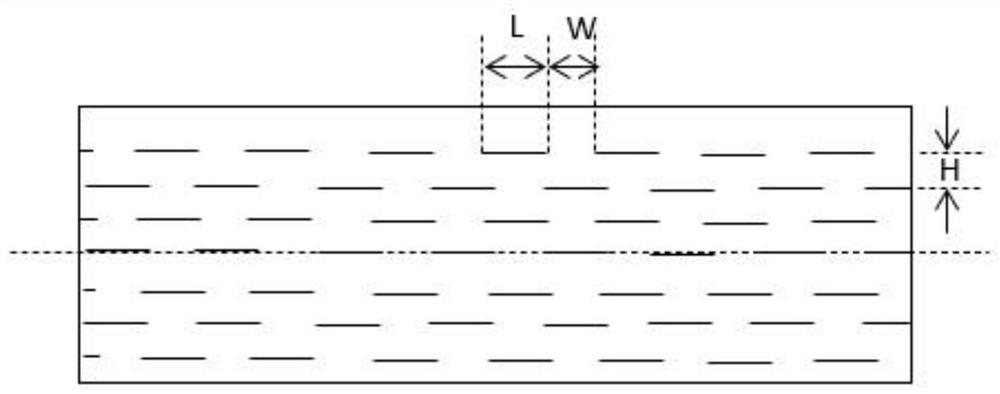

Drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method

The invention discloses a drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method, and belongs to soft coal seam pressure relief permeability increase systems and methods. The system comprises a chemical supply jet flow generation device, a drilling, cutting and discharging integrated device and a water, coal and gas separation device. In the chemical supply jet flow generation device, high-pressure water and chemical reagents are fed into a jet flow mixer to be fully mixed through a high-pressure water pump and a chemical adding pump, so that chemical supply jet flow is formed. The drilling, cutting and discharging integrated device can achieve the integration of drilling, slitting and in-hole slag discharging, and the frequency of the phenomenon that holes are blocked in the slitting process is reduced. The water, coal and gas separation device can completely separate the water, coal slag and gas mixture ejected out in the slitting process, separated gas enters an extraction pipeline, and water enters a water tank after being filtered to be recycled. According to the system, ground stress and gas pressure are relieved through slitting, and physical permeability increase is achieved; under the combined action of physical and chemical permeability increase, the air permeability of a coal seam and the gas extraction effect are remarkably improved.

Owner:CHINA UNIV OF MINING & TECH

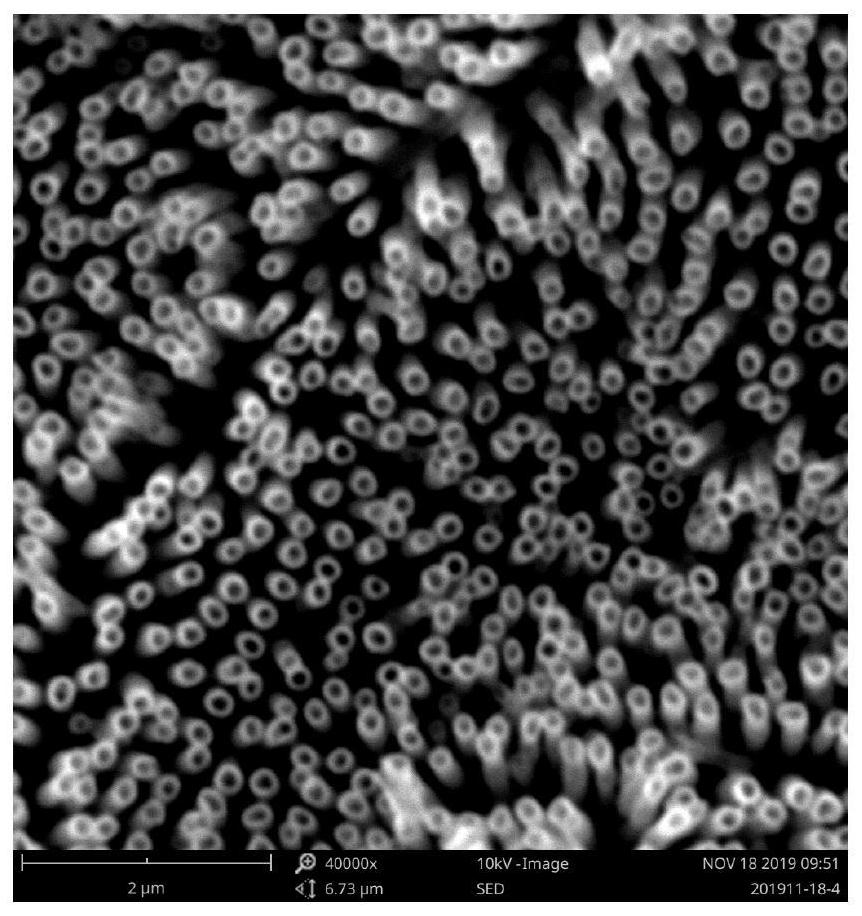

Nanofiber-foam-based continuous recovery device for floating oil on water surface and manufacturing method thereof

ActiveCN104846796ALarge specific surface areaHigh porosityWater cleaningGeneral water supply conservationManufacturing technologyNanofiber

The invention provides a nanofiber-foam-based continuous recovery device for floating oil on the water surface and a manufacturing method thereof. The nanofiber-foam-based continuous recovery device for the floating oil on the water surface is characterized by comprising protective net covers, super-oleophylic hydrophobic nanofiber open-cell foam is arranged inside the protective net cover, oil collecting capillary nets are distributed inside the super-oleophylic hydrophobic nanofiber open-cell foam and connected with a main oil conveying pipe, the main oil conveying pipe is connected with a pump, and the pump is connected with an oil storage tank. The manufacturing technology is simple, the production cost is low, operation is convenient, expandability is high, recovery devices of different specifications and numbers can be selected according to requirements to be connected with the oil pump and the oil storage tank, and therefore a recovery system for the floating oil on the water surface is formed. Adsorption separation can be performed on the floating oil on the water surface efficiently and continuously, oil products obtained through separation are high in purity, and the nanofiber-foam-based continuous recovery device has broad application prospects in the fields of environment pollution treatment and oil product purification.

Owner:DONGHUA UNIV

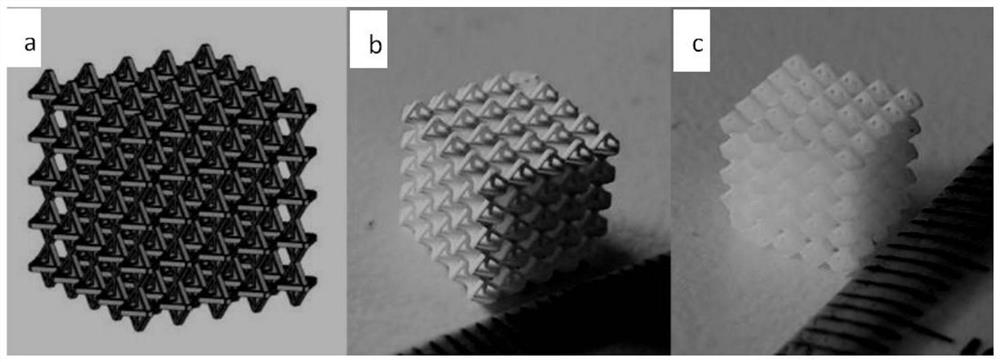

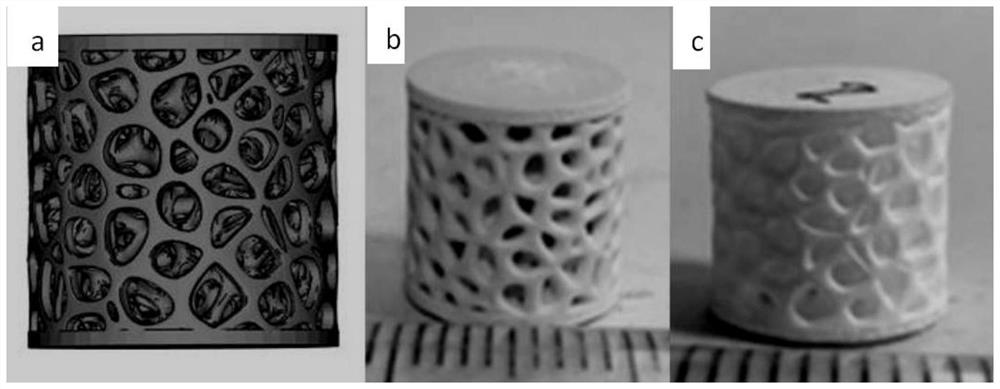

3D printing porous zirconium oxide ceramic and preparation method thereof

PendingCN112250465AImprove mechanical propertiesGood for dense packingAdditive manufacturing apparatusCeramic shaping apparatusPtru catalystZirconia ceramic

The invention provides 3D printing porous zirconia ceramic and a preparation method thereof, and belongs to the technical field of advanced ceramic materials and additive manufacturing. Zirconia powder serves as a main raw material, the 3D printing zirconia porous ceramic is prepared through photocuring 3D printing and high-temperature glue discharging sintering, rapid and accurate forming of theporous zirconia ceramic can be achieved by accurately controlling the content of the zirconia powder, parameters of photocuring printing and the specific process of high-temperature glue discharging sintering, the pore channel structure is controllable, and ceramic products with complex structures and shapes can be prepared; the method does not need a mold, a pore-forming agent or a pore-forming template, and is low in preparation cost and high in production efficiency. The 3D printing porous zirconium oxide ceramic product prepared by the method is good in mechanical property, high in porosity, thin in pore wall, large in surface area and high in pore passage connectivity, and can be widely applied to the industrial field as a filter, a catalyst carrier, a heat exchanger, a heat accumulator, a bone tissue engineering bracket and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

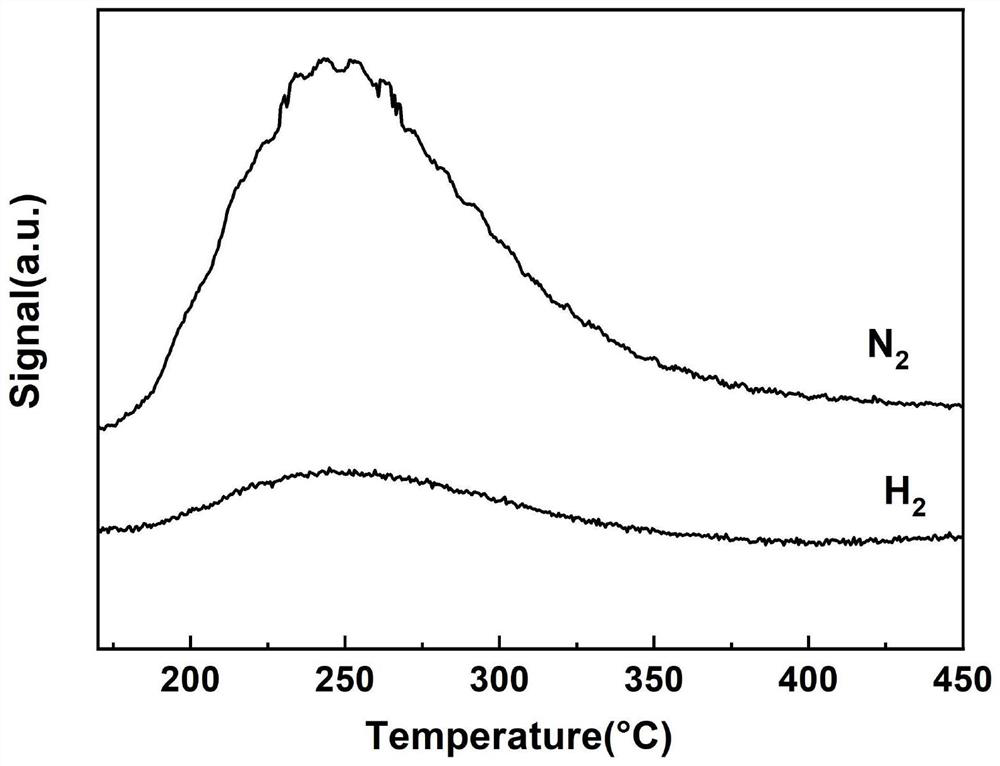

Low-temperature activation efficient ammonia decomposition catalyst

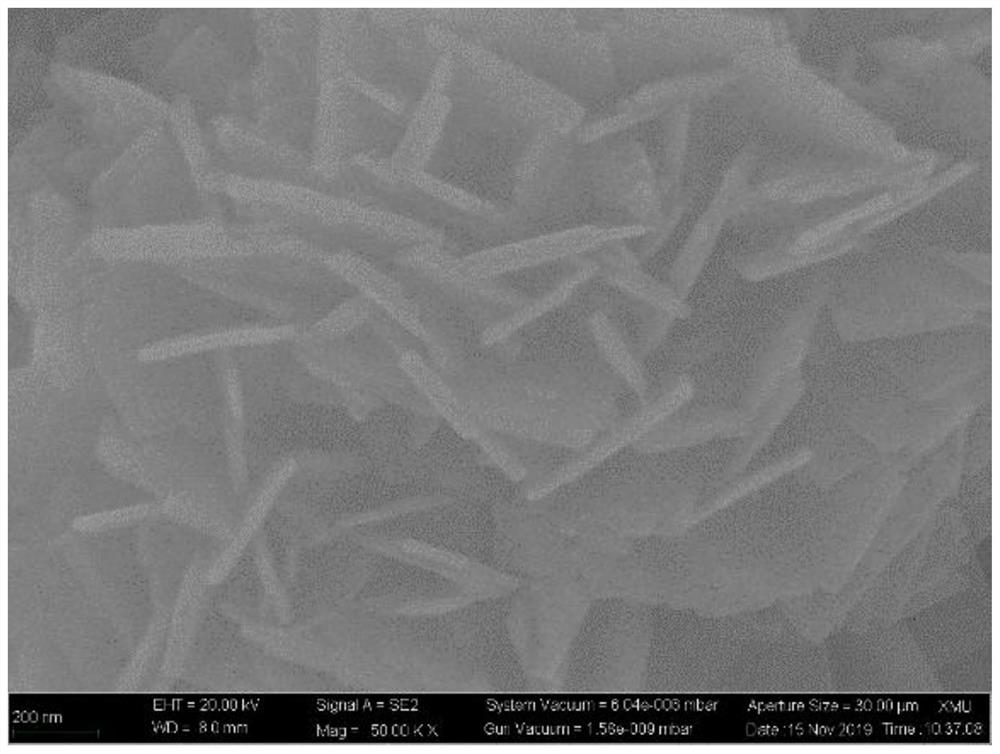

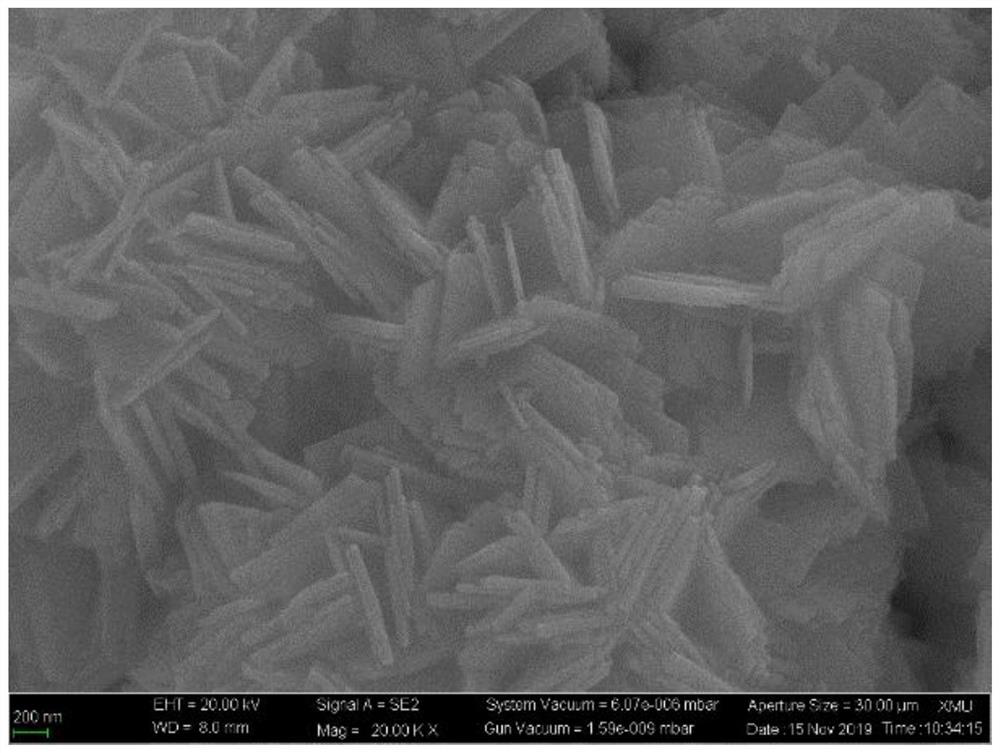

PendingCN113181957AShorten crystallization timeReduce stackingFerrierite aluminosilicate zeoliteMolecular sieve catalystsMolecular sieveMetallic Nickel

The invention provides a low-temperature activation efficient ammonia decomposition catalyst and a preparation method thereof, and belongs to the field of ammonia decomposition catalysis. The catalyst is a nickel-containing FER molecular sieve; according to the molecular sieve, a nickel-containing carbon material is taken as a nickel source and a hard template agent, and metal nickel is introduced into the FER molecular sieve in situ; and the content of nickel in the nickel-containing molecular sieve is 0.1-5wt.% in terms of nickel element. the invention also provides a preparation method of the catalyst. The method specifically comprises the following steps of: adding a nickel-containing carbon material, a silicon source, an aluminum source, an organic template agent, inorganic base and a solvent into a reactor according to proportions; continuously stirring the materials to obtain uniform sol, aging the uniform sol; transferring the sol to a hydrothermal reaction kettle for crystallization; performing filtering, washing, drying and roasting on a product which is obtained after the reaction is finished; carrying out hydrogen transformation on an obtained molecular sieve; and finally roasting to obtain the nickel-containing FER molecular sieve. The catalyst disclosed by the invention has the advantages of rich microporous structure, short crystallization time and high catalyst activity and stability; the temperature required by ammonia decomposition is greatly reduced; and the catalyst has huge industrial application potential.

Owner:XIAMEN UNIV

Preparation method of nano-fiber-foam-based acoustic material

ActiveCN104464712ALarge specific surface areaHigh porositySound producing devicesFiberAcoustic absorption

The invention provides a preparation method of a nano-fiber-foam-based acoustic material. The preparation method is characterized by concretely including the steps that step1, activating treatment is performed on the surfaces of nano-fiber foams; step2, at the temperature of 32 DEG C-35 DEG C, under the pressure intensity of 7.39*106 Pa-8.0*106 Pa, a mixture of supercritical carbon dioxide fluid, adhesive and surface roughness modified particles treats the nano-fiber foams obtained in the previous step, then the pressure intensity is lowered, in this way, the nano-fiber foams are desorbed from the supercritical carbon dioxide fluid, and the adhesive and the surface roughness modified particles are evenly dispersed on the surfaces of fibers; step3, a thermo-crosslink method is adopted for solidifying and crosslinking the adhesive and combining the surface roughness modified particles on the surfaces of the fibers, so that the nano-fiber-foam-based acoustic material is obtained. The nano-fiber-foam-based acoustic material is better in acoustic absorption performance.

Owner:DONGHUA UNIV

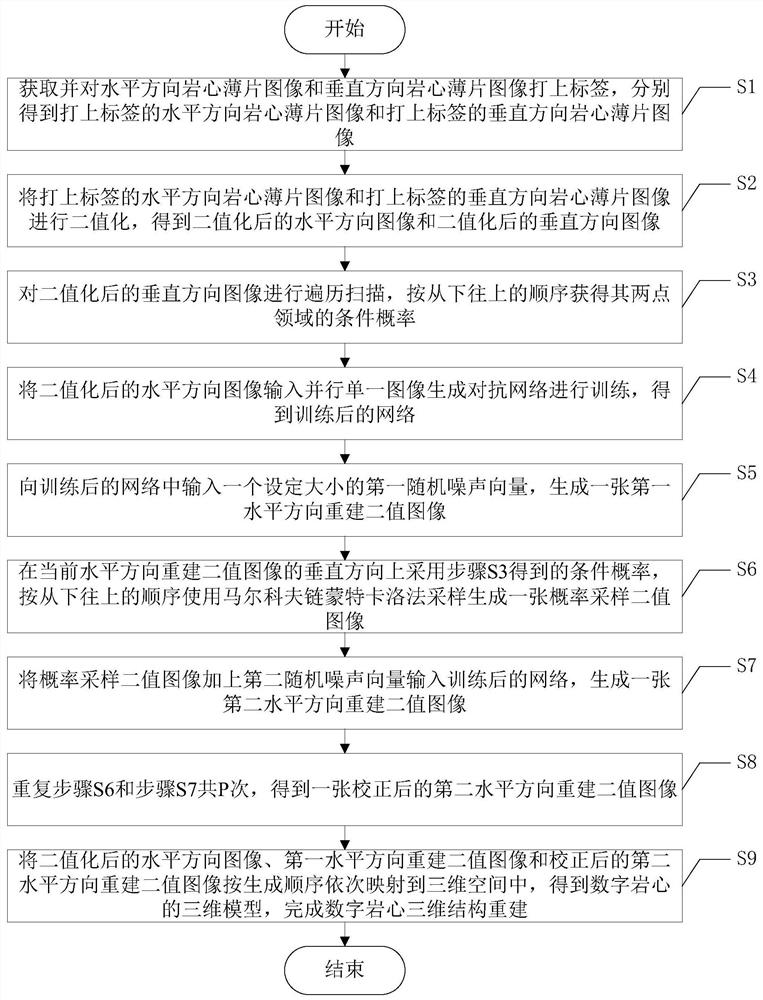

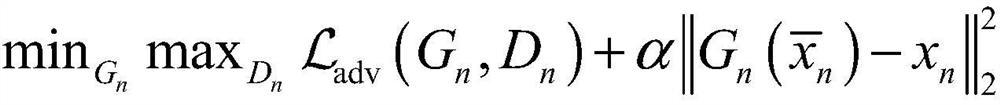

Digital rock core three-dimensional structure reconstruction method using two-dimensional slice image

ActiveCN112381916AReflect anisotropyReliable and efficient restorationImage analysisGeometric image transformationRock coreComputer graphics (images)

The invention discloses a digital rock core three-dimensional structure reconstruction method using a two-dimensional slice image, and the method comprises the steps: training a parallel single imagegenerative adversarial network model, learning the distribution of two-dimensional images, and reconstructing a rock core structure in a three-dimensional space through combining with a Markov chain Monte Carlo method. The method can reflect anisotropism of the rock, can reliably and effectively restore a real rock core structure for the rock with high heterogeneity, and is good in pore connectivity, higher in calculation speed and wider in application range.

Owner:SOUTHWEST PETROLEUM UNIV

Calcium phosphate bone cement with hollow through structure, preparation method and application thereof

ActiveCN110540404AGood biocompatibility and biodegradabilityPromote growthMonocomponent protein artificial filamentCeramicwareSolid phasesPhosphoric acid

The invention discloses a calcium phosphate bone cement with a hollow through structure, a preparation method and an application thereof, belongs to the technical field of calcium phosphate bone cement, wherein the calcium phosphate bone cement with a hollow through structure comprises a solid phase and a solidifying liquid, the solid phase comprises calcium phosphate powder and a fiber mixture, the fiber mixture is an absorbable fiber and a fibrin fiber, and the diameter of the absorbable fiber is 100-500mum, the length is 0.5 mm-1.5 mm, preferably, that diameter of the absorbable fiber is 200-400mum. The prepared calcium phosphate bone cement can form three-dimensional connected macropores, promote cell adhesion and proliferation, and improve the mechanical strength of the bone cement.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Method of manufacturing a cordierite structure

InactiveUS20070107398A1Lower overall pressure dropEasy to operateDispersed particle filtrationExhaust apparatusHoneycombVolumetric Mass Density

Owner:CORNING INC

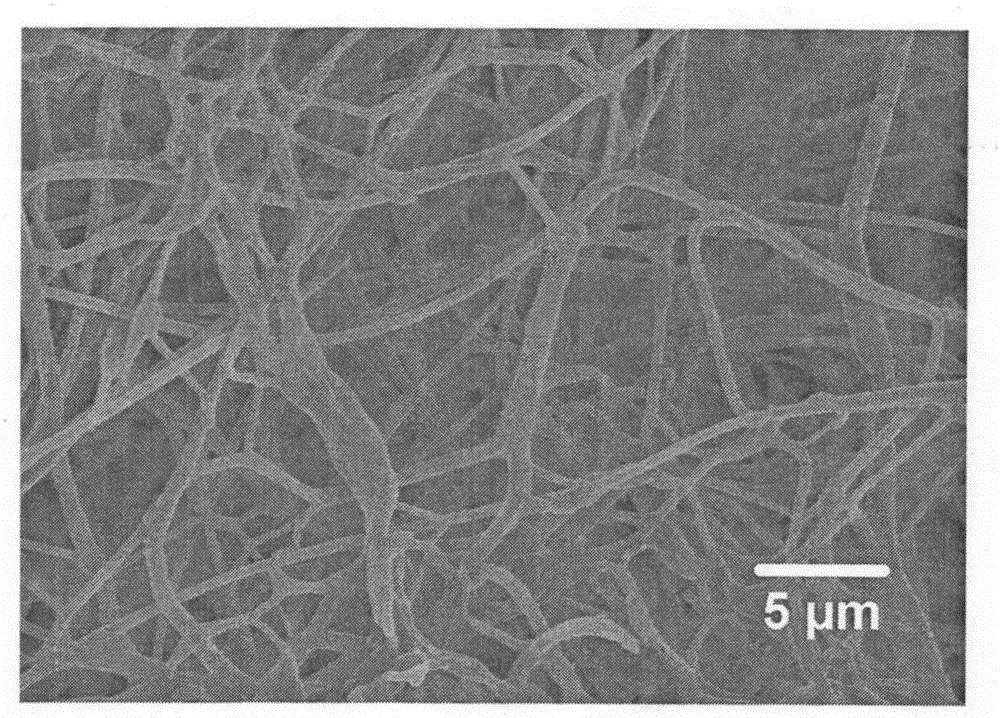

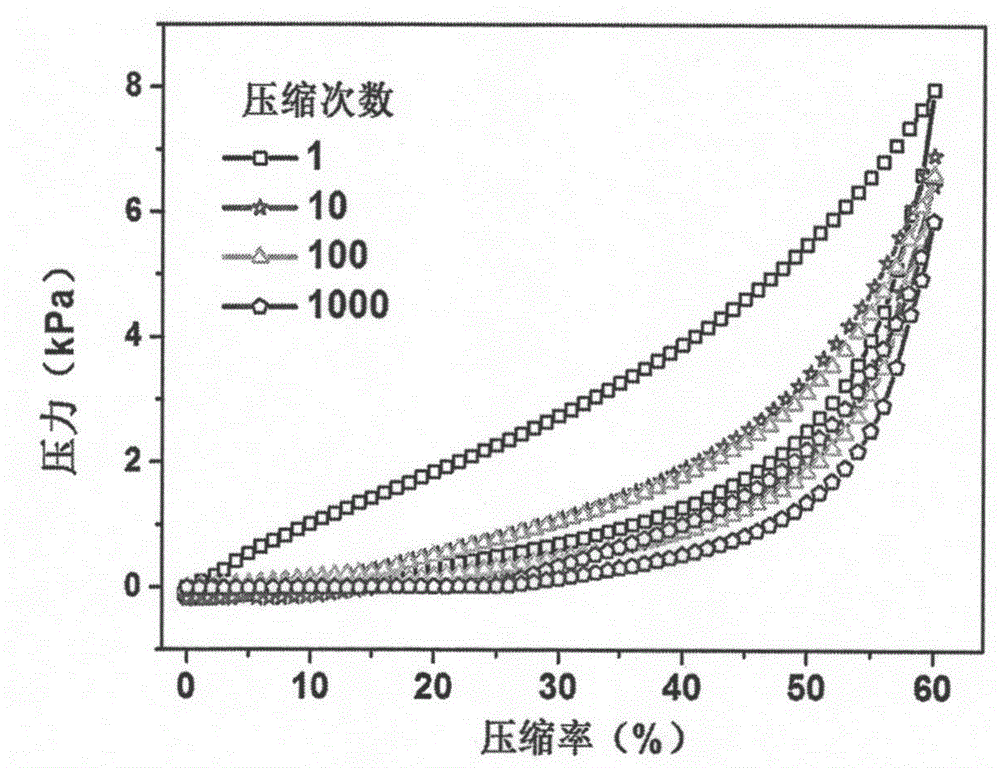

Biomass fiber-based three-dimensional porous material and preparation method thereof

The invention provides a biomass fiber-based three-dimensional porous material and a preparation method thereof. The biomass fiber-based three-dimensional porous material comprises biomass fibers, wherein the biomass fibers are mutually cross-linked and supported to form a three-dimensional network structure. The preparation method of the biomass fiber-based three-dimensional porous material is characterized by comprising the following steps: purifying the biomass raw materials; activating the purified biomass materials; preparing a biological cross-linking agent solution, and dispersing the biomass materials in the solution through an orientation high-speed pulping method to form uniform dispersion liquid of biomass fibers with draw ratio of 10-30000; and molding the dispersion liquid to obtain the biomass fiber-based three-dimensional porous material. The biomass fiber-based three-dimensional porous material has the advantages of being wide in raw material selectivity, free of pollution, simple in preparation process, low in cost and controllable in structure, and having huge application value in the fields of biomedical application, tissue engineering, energy sources, environment protection and aerospace.

Owner:DONGHUA UNIV

Preparation method for porous beta-TCP ceramic/gelatin composite material

A preparation method for a porous beta-TCP ceramic / gelatin composite material belongs to the field of preparation of artificial bone scaffold materials. Concretely, the preparation method is used to prepare the porous beta-TCP ceramic / gelatin composite material of which the structure and the composition are similar to those of natural bone. According to the preparation method, a foaming process is employed for preparing porous beta-TCP, a high-temperature adhesive K2HPO4 is added for improving the scaffold strength, and a porous beta-TCP support is combined with gelatin for improving the strength and the toughness of the porous support, and thus the porous beta-TCP ceramic / gelatin composite material of which the structure and the composition are similar to those of natural bone is prepared. The porous beta-TCP ceramic / gelatin composite material prepared by the preparation method has the advantages of good pore connectivity, high porosity, high water absorption rate, high compressive strength and the like, the composition and the structure of the composite scaffold are similar to those of natural bone, and the composite scaffold has wide application prospect.

Owner:邹仕放

Silicon carbide block with macroporous and mesoporous composite structure, and preparation method thereof

ActiveCN103739288AAperture adjustableReduce mass transfer resistanceCeramicwareDiffusion resistanceSilicon oxide

The invention provides a preparation method of a silicon carbide block with a macroporous and mesoporous composite structure. The preparation method comprises the following steps: preparing the mixed solution of ethylene oxide, tetraethoxysilane and nitric acid in the mol ratio of x: 1: 0.25, wherein x is greater than or equal to 0.45 and less than or equal to 0.55; pouring the mixed solution into a die and sealing, demolding after standing, carrying out hydro-thermal treatment by using ammonium hydroxide to obtain a silicon oxide template, soaking the silicon oxide template into the methylbenzene solution of polycarbosilane, heating until the methylbenzene completely volatilizes, carrying out pyrolysis treatment under the protection of an insert gas to obtain a silicon carbide and silicon oxide composite block, and then carrying out soaking treatment by using hydrofluoric acid to obtain the silicon carbide block. The method provided by the invention is capable of directly obtaining the silicon carbide block with the macroporous and mesoporous composite structure, and avoids the problems of specific surface area reduction, diffusion resistance increase and pore blockage due to subsequent processing; besides, the silicon carbide block is adjustable in macroporous pore diameter and good in pore connectivity; as a result, the mass transfer resistance is greatly reduced and the catalytic efficiency is improved; and moreover, the preparation method is simple in preparation and convenient to operate.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for regulating pore structure of water-soluble polymer tissue engineering scaffold by use of polyester template

InactiveCN102690435AAperture controllableGood pore connectivityMonocomponent polyesters artificial filamentProsthesisPolyesterStem like cell

The invention discloses a method for regulating the pore structure of a water-soluble polymer tissue engineering scaffold by use of a polyester template. The method comprises the following steps of: adding polylactic acid microspheres or fiber into a water-soluble polymer solution; performing freeze drying; and then removing the template to obtain a porous tissue engineering scaffold. The experimental result shows that: the method can obtain a tissue engineering scaffold with aperture of 100-500 microns, over 90% of porosity and over 700% of swelling degree; the scaffold has the characteristics of controllable aperture, sequential arrangement of holes, good pore connectivity and coexistent big and small pores; the structure with coexistent big and small pores is favorable for inoculating and adhering cells, transporting nutrient substances and discharging metabolic products; and moreover, the research indicates that: the differentiation behavior of the stem cell in the scaffold can be intervened in by adjusting the pore structure of the scaffold.

Owner:SHANGHAI UNIV

Mesoporous carbon material, carbon/metal oxide composite materials, and electrochemical capacitors using them

InactiveCN1231414CGood pore connectivityIncreased charge storage capacityHybrid capacitor separatorsHybrid capacitor electrolytesCapacitancePorosity

The invention relates to a carbon material with mesopores of 2 to 20 nm and high porosity, a carbon / metal oxide composite material in which metal oxides are deposited in carbon pores by using the carbon material, and an electric double made of the carbon material. A layer capacitor and an electrochemical capacitor made using the carbon / metal oxide composite material. When mesoporous carbon is used as an electrode material for an electric double-layer capacitor, the electric double-layer capacitor is superior to existing electric double-layer capacitors due to its low equivalent series resistance, although its capacitance value per unit weight is low due to its low surface area. Has a higher charge storage capacity. Moreover, when the carbon / metal oxide composite material is used as an electrode material of an electric double-layer capacitor, the capacitor has a higher capacitance value per unit weight through the combination of the electric double-layer capacitor and the metal oxide pseudocapacitor, that is, 254F / g.

Owner:VIBRANT KOREA CO LTD +1

Composite foundation composed of rubble/ sand inverted filter layer and porous concrete piles and treatment method

InactiveCN103938609AContinuous and effective drainageReduce congestionSoil preservationPorosityCrushed stone

The invention discloses a composite foundation composed of a rubble / sand inverted filter layer and porous concrete piles and a treatment method. The exterior structure of the foundation is the rubber / sand inverted filter layer, and the interior of the foundation is porous concrete. The pile diameter is 0.3 m-0.8 m, and the thickness of the rubble / sand inverted filter layer outside the piles is 0.2 m-0.4 m. After underwater maintenance for 28 days, the compressive strength of the porous concrete is not lower than 5 MPa, the permeability coefficient is not lower than 5 mm / s, the pile spacing is 3-5 times of the pile diameter, and the porosity rate of the porous concrete is greater than 20 percent. The treatment method of the foundation comprises the steps that according to the requirements for foundation settlement and bearing capacity, the pile diameter, the pile spacing, the foundation reinforcement range, the reinforcement depth, the pile arrangement mode, the amount of packing in pile holes and the thickness of pile top granular materials or wet clay are determined, and piles are constructed. According to the composite foundation, the problem that the porous concretes are blocked by slurry is effectively weakened; the rubble / sand inverted filter layer plays a role in water permeability and inverted filtering, and therefore the piles can be drained continuously and effectively in the composite foundation.

Owner:SHANDONG UNIV

Sound-absorbing material and preparation method thereof

InactiveCN106782476ASimple structureLarge specific surface areaUltrasonic/sonic fibre treatmentSound producing devicesFiberAdhesive

The invention provides a preparation method of a sound-absorbing material. The characteristics lie in that the preparation method specifically comprises the steps of firstly, performing activation treatment on the surface of nano-fiber foam; secondly, dissolving a phenolic adhesive, graphene oxide and ZnO quantum dots into acetone, and performing ultrasonic treatment for 24-48h to acquire a mixed slurry; thirdly, processing the nano-fire foam acquired in the first step by adopting a supercritical carbon dioxide fluid and the mixed slurry acquired in the second step, then reducing the intensity of pressure, enabling the nano-fiber foam to desorb the supercritical carbon dioxide fluid, and enabling the phenolic adhesive, the graphene oxide and the ZnO quantum dots to be uniformly scattered at the fiber surface; and fourthly, enabling the adhesive to be cured and crosslinked by adopting a thermal crosslinking method so as to acquire a sound-absorbing material. The sound-absorbing material has more excellent sound-absorbing performance. A sound-absorbing material with the thickness being 5mm is tested by using an ISO10534-2 method, the low-frequency sound absorption coefficient is above 0.70, and the maximum sound absorption coefficient is above 0.99.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

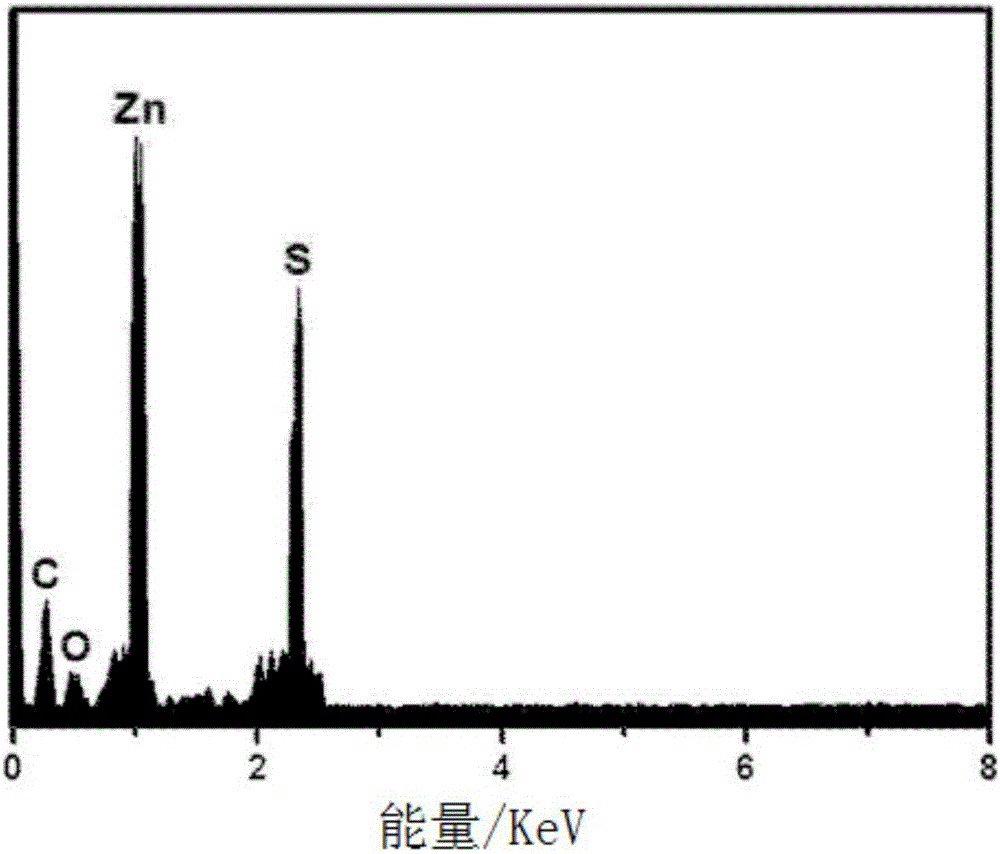

Method for preparing buffer layer material of thin-film solar cell

ActiveCN106684176AImprove performanceSolve pollutionFinal product manufactureSemiconductor devicesThio-High pressure

The invention relates to a method for preparing a buffer layer material of a thin-film solar cell. The method comprises the following steps: mixing organic zinc salts with thio-organic matters, after that, generating an ammonium complex of zinc sulfide by an ammonia aeration reaction; transforming the ammonium complex of the zinc sulfide into a crystal structure by adopting a sedimentation method, and crushing the crystal by an ultrasonic treatment; and finally, in a high pressure sealed reaction, using graphene and an auxiliary agent to modify, and then the buffer layer material of the thin-film solar cell is prepared. Compared with the prior art, the method for preparing the buffer layer material of the thin-film solar cell provided by the invention takes the organic zinc salts and the thio-organic matters as raw materials, which thoroughly solves the problem of cadmium metal pollution; the preparation method is simple, and the process condition is moderate; and besides, the prepared buffer layer material has excellent performance, and the efficiency of the solar thin-film batteries is greatly improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

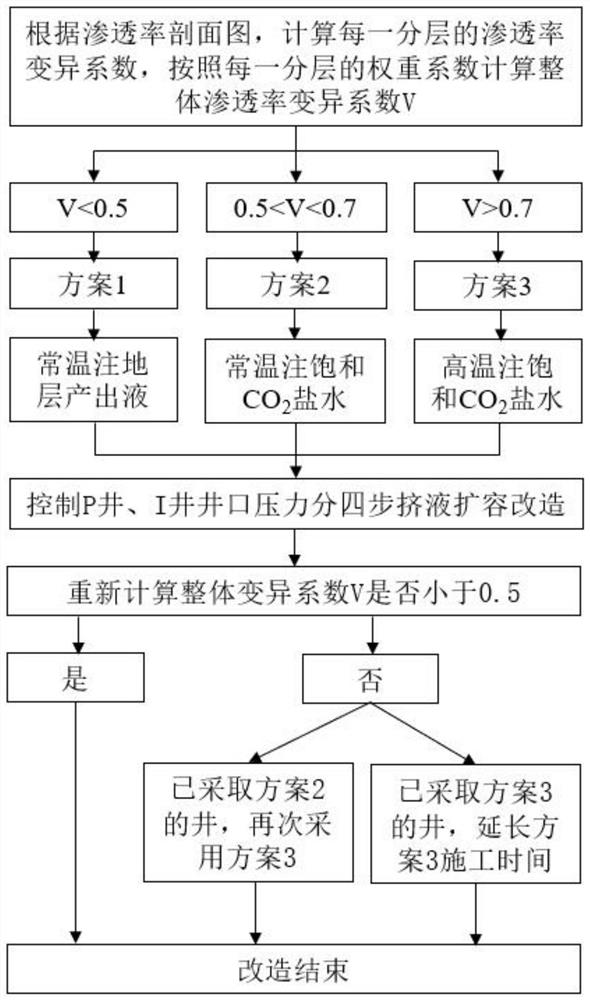

Method for improving permeability of oil sand reservoir by squeezing saturated CO2 brine

ActiveCN113266333AHigh porosityImprove permeabilityFluid removalOther gas emission reduction technologiesPhysicsSaline water

The invention relates to a method for improving the permeability of an oil sand reservoir by squeezing saturated CO2 brine. The method comprises the following steps of calculating the overall permeability variable coefficient of a permeability profile, and reasonably selecting conventional water injection, injecting saturated CO2 brine at normal temperature and injecting CO2 saturated brine at high temperature; calculating a permeability improvement coefficient, and drawing a relationship between the initial permeability and the permeability improvement coefficient; reasonably controlling the pressure of the wellhead to gradually and slowly squeeze the saturated CO2 brine into the reservoir; recalculating the overall permeability variation coefficient, and when the overall variation coefficient of the stratum is reduced to be less than 0.5, determining that the transformation succeeds; and if the variable coefficient of the overall permeability of the stratum is still larger than 0.5, injecting CO2 saline water again at high temperature for 24 hours or prolonging the injection time by 2 days. On the premise of not influencing the traditional liquid extrusion expansion effect, the CO2 solution selectively corrodes argillaceous components, the permeability heterogeneity in the borehole direction is weakened while the overall permeability of a reservoir is increased, and therefore it is guaranteed that a steam cavity is evenly expanded in the borehole direction, the crude oil yield is increased, and the crude oil recovery rate is increased.

Owner:NORTHWEST UNIV

Preparation method of gentamicin sulphate-loading porous hydroxyapatite/PLGA (poly(DL-lactide-co-glycolide) microspheres

ActiveCN103751116AGood pore connectivityPore connectivity is goodAntibacterial agentsOrganic active ingredientsBiocompatibility TestingFreeze dry

The invention discloses a preparation method of gentamicin sulphate-loading porous hydroxyapatite / PLGA (poly(DL-lactide-co-glycolide) microspheres. The preparation method comprises the following steps: adding PLGA microspheres in an acetone / alcohol solution, adding a diammonium hydrogen phosphate solution, pouring in a calcium nitrate solution, adjusting pH, ageing, washing, drying, calcining, and grinding to obtain porous hydroxyapatite; placing the porous hydroxyapatite powder in a water solution containing gentamicin sulphate / PEG (polyethylene glycol), and carrying out freeze drying to obtain gentamicin sulphate-loading porous hydroxyapatite; and uniformly mixing the PLGA solution and the gentamicin sulphate-loading porous hydroxyapatite, pouring in a polyvinyl alcohol solution, stirring, washing, and carrying out freeze drying to obtain the gentamicin sulphate-loading porous hydroxyapatite / PLGA (poly(DL-lactide-co-glycolide) microspheres. The gentamicin sulphate-loading porous hydroxyapatite / PLGA (poly(DL-lactide-co-glycolide) microspheres prepared by adopting the preparation method are high in medicine loading rate, small in burst release, good in biocompatibility, simple in preparation process, easily available in raw materials, and low in cost; and industrialization is easily realized.

Owner:SOUTH CHINA UNIV OF TECH

High-strength self-lubricating metal ceramic bearing and preparation method thereof

The invention discloses a high-strength self-lubricating metal ceramic bearing. The high-strength self-lubricating metal ceramic bearing is prepared from, by weight, 2.3-2.4 parts of ferric citrate, 3.1-3.5 parts of basic nickel carbonate, 25-30 parts of water, an appropriate amount of ammonium hydroxide, 2.9-3 parts of TiH2, 1.1-1.3 parts of nanocarbon, 15-15.4 parts TiC, 0.7-0.9 part of lubricant, 1-1.1 parts of C, 3.9-4.1 parts of Cr, 5.8-6 parts of W, 5.1-5.3 parts of Mo, 3.1-3.3 parts of V and 65-66 parts of Fe. Ferric citrate and basic nickel carbonate are used for carrying out coating modification on TiC, the bonding strength of a ceramic phase and a metal phase is improved, and the strength and the toughness of the bearing are greatly improved. Nanocarbon, ferrocene acetyenic ketone and ferric alginate are adopted, so that the lubricating performance and compactness in the pressing process are improved, the pore connectivity of sintered materials is good, the show porosity is improved, and the wear resistance of the bearing is extremely good.

Owner:ANHUI SILVER BALL BEARING

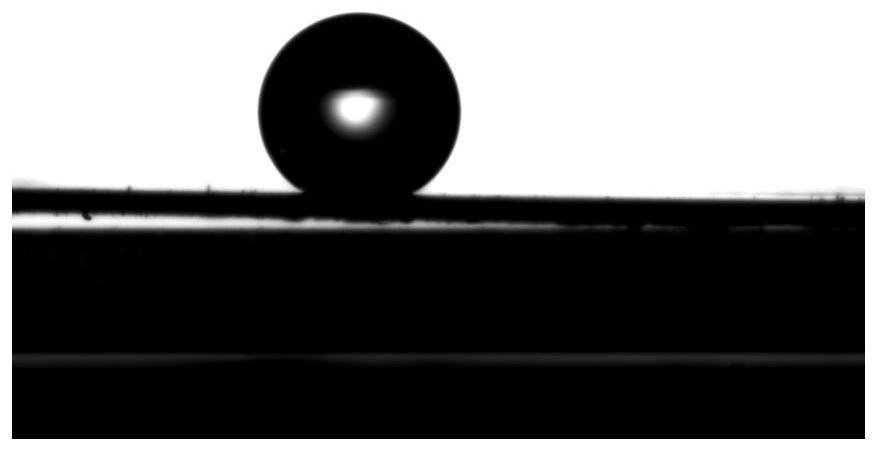

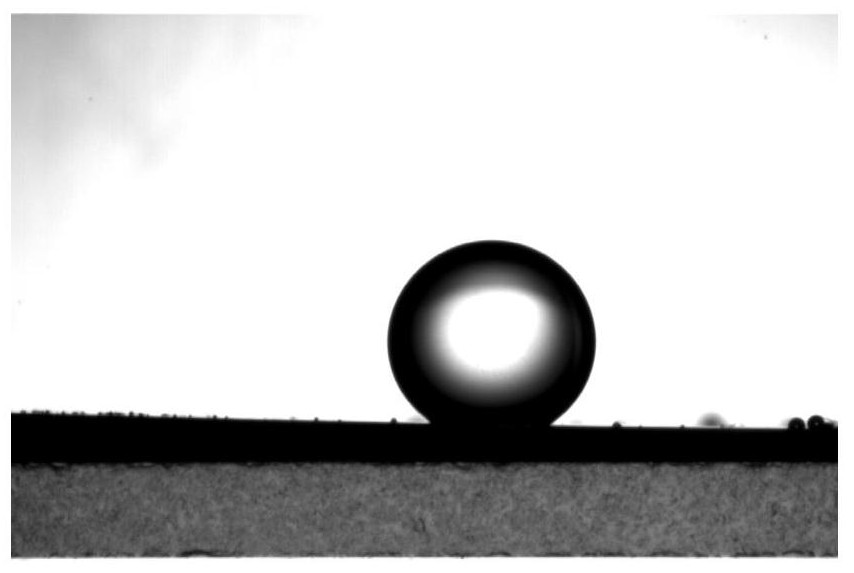

Gradient porous titanium mesh and preparation method of super-hydrophobic gradient porous titanium mesh

ActiveCN113020597AFast molding speedHigh precisionAdditive manufacturing apparatusSurface reaction electrolytic coatingPorous titaniumChemical stability

The invention relates to the technical field of surface processing, in particular to a gradient porous titanium mesh and a preparation method of a super-hydrophobic gradient porous titanium mesh for efficient oil-water separation. The porous titanium with the internal pore size changing in a gradient mode in the thickness direction is prepared through the metal 3D printing technology, the gradient porous titanium serves as a base body to conduct super-hydrophobic modification treatment on all the three-dimensional surfaces of the gradient porous titanium, and finally the gradient porous titanium material with high liquid permeation rate, high separation efficiency, good repeatability, good chemical stability and high mechanical strength and for oil-water separation is obtained.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com