Light weight metal framing member

a metal framing member and light weight technology, applied in the direction of girders, building repairs, walls, etc., can solve the problems of wood warping and going out of shape, scarce lumber supply, and increased costs, so as to reduce shrinkage and twisting of the framing member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

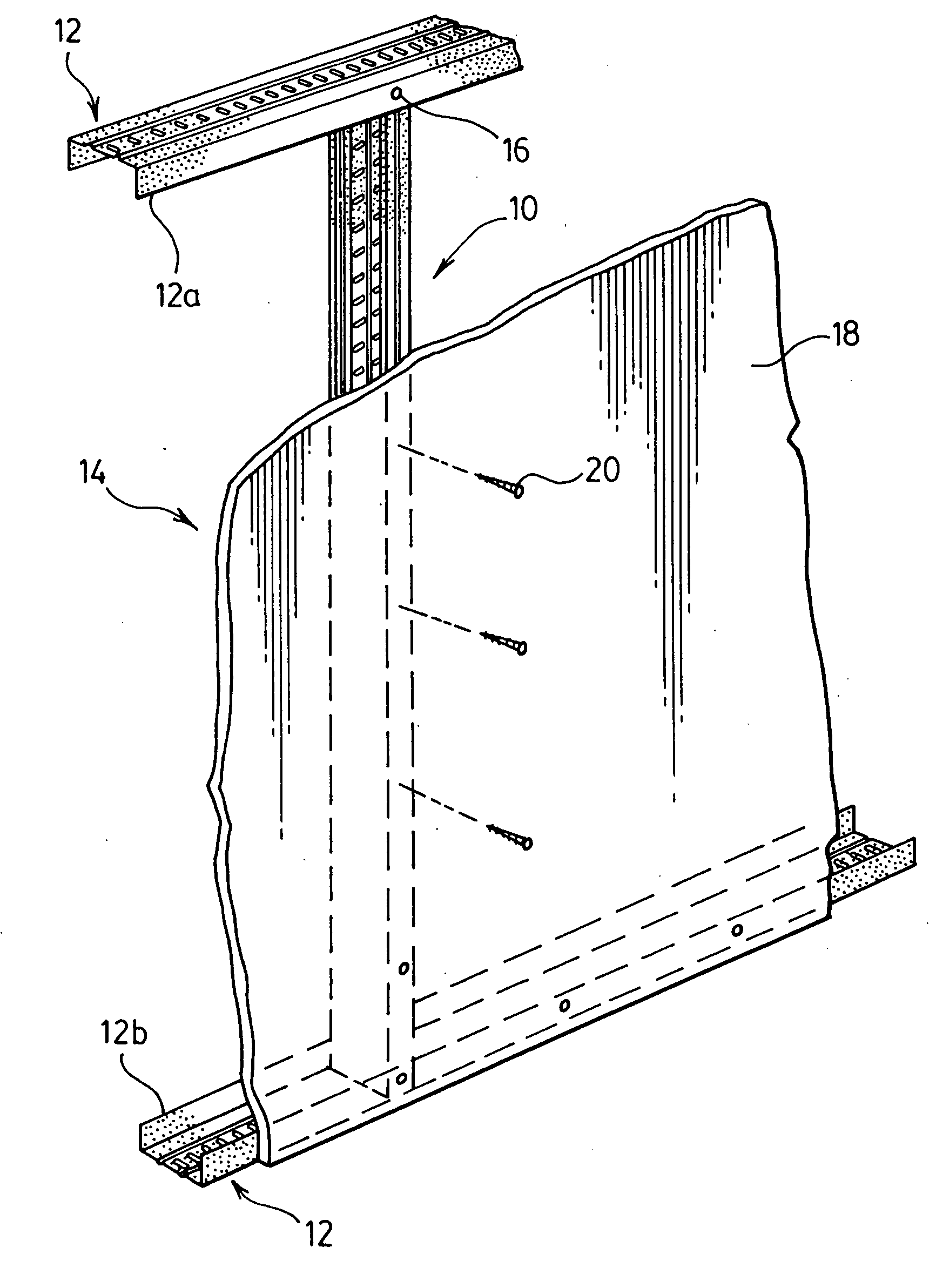

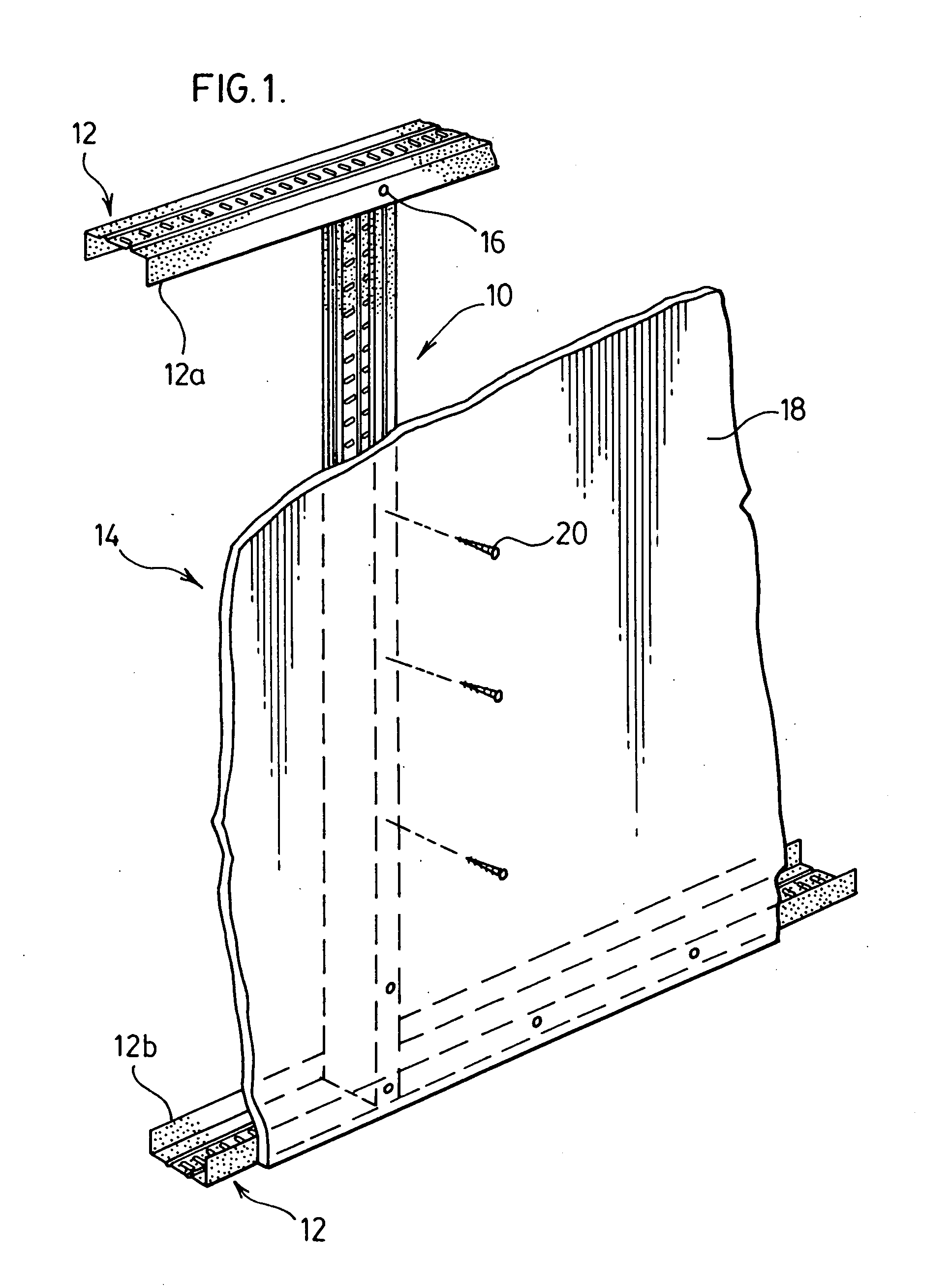

[0028]The present invention is directed to metal framing members such as metal studs 10 and tracks 12 utilized in framing partition walls 14 as illustrated in FIG. 1. The partition walls 14 are framed from a metal track 12 forming the top plates 12a and bottom plates 12b that are bridged by the parallel spaced apart metal studs 10. The spacing between the metal studs 10 is that typically utilized in construction of walls generally at 16 inches on center although other spacing such as 24 inches on center may be utilized. The studs 10 are attached to the top plate 12a and bottom plate 12b through the use of suitable screws 16. Once the partition wall 14 is framed utilizing the studs 10, top plate 12a and bottom plate 12b, a suitable wall covering material such as wall board 18 is attached to the partition wall utilizing suitable screws 20.

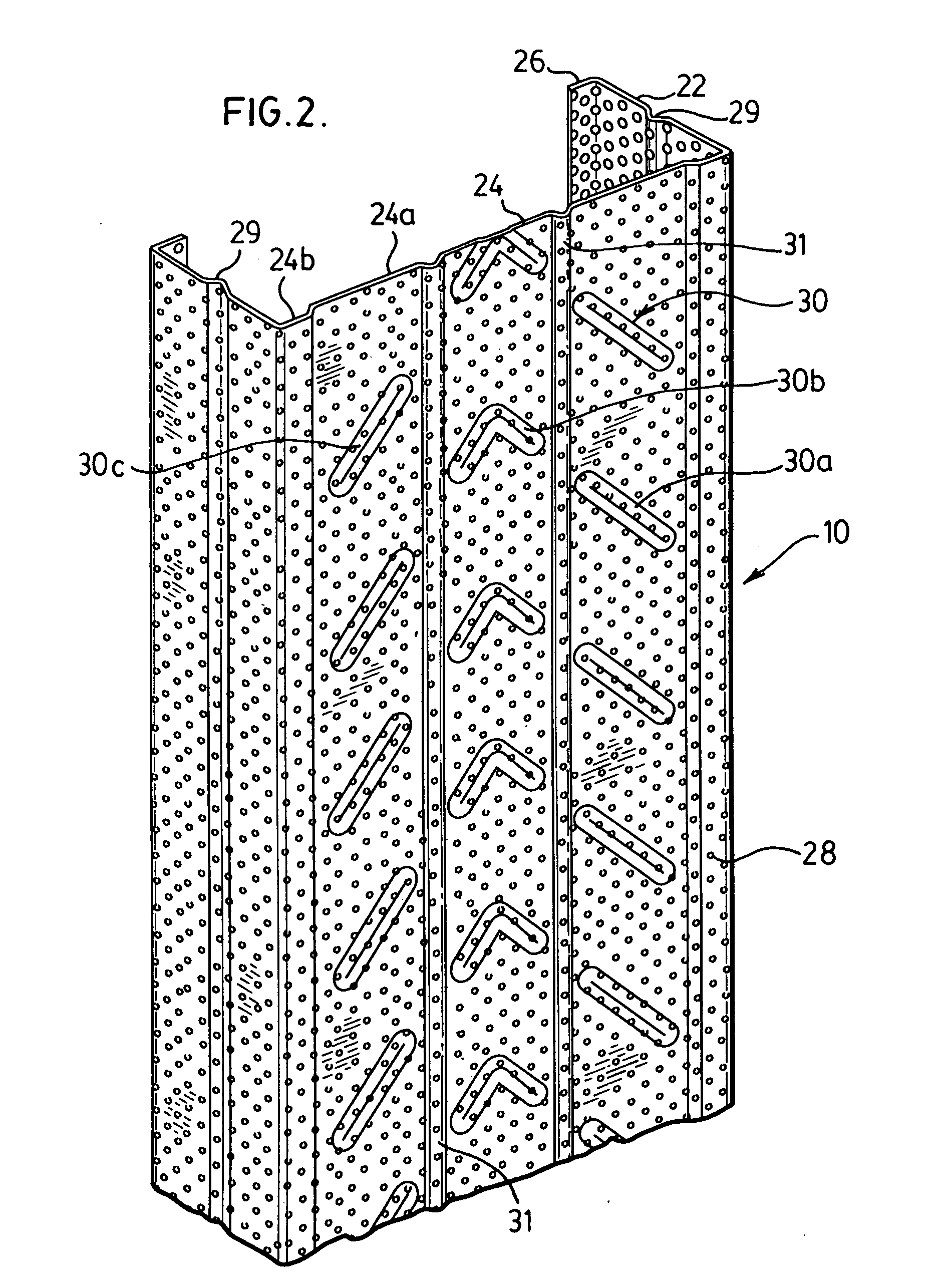

[0029]As illustrated in FIGS. 2, the metal stud 10 has a generally C-shaped rectangular cross-section with two parallel spaced apart side walls 22 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com