Modular building, prefabricated volume-module and method for production of a modular building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The above and other advantages, features and preferred embodiments of the invention will now be described in more detail with reference to the accompanying drawings.

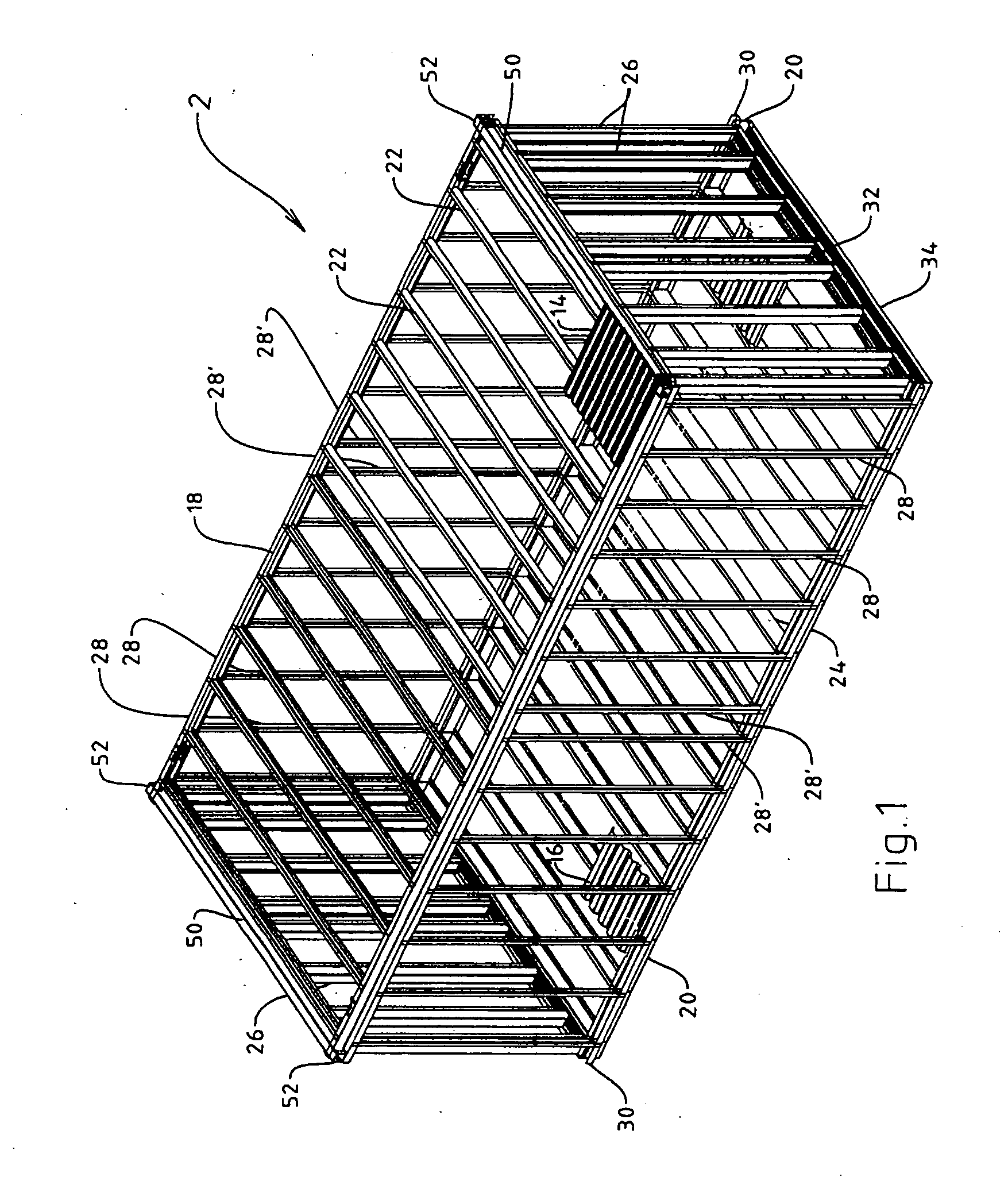

[0027]FIG. 1 is a perspective view of an embodiment of an inventive volume module formed as a lightweight module.

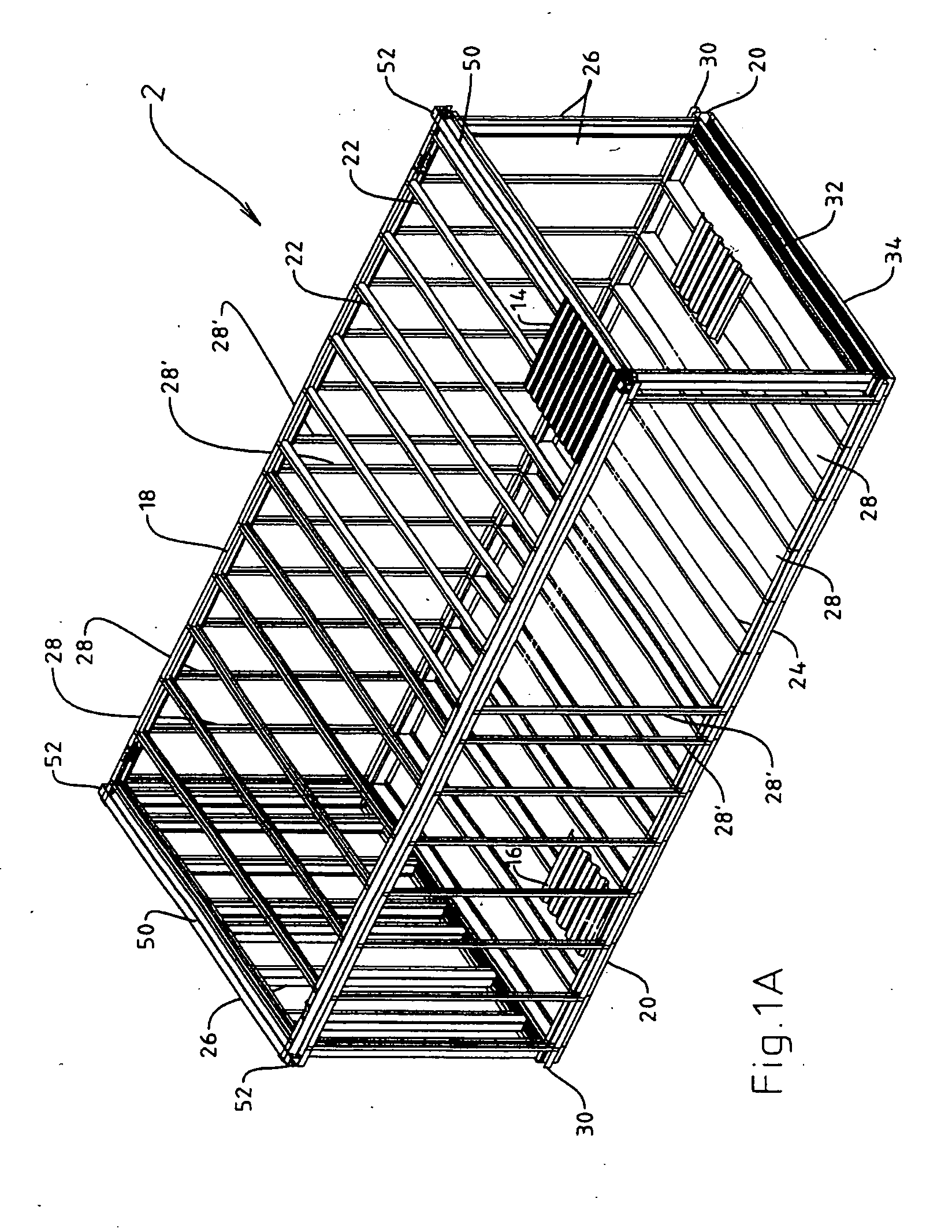

[0028]FIG. 1A corresponds to FIG. 1 but shows a lightweight module which is partly open.

[0029]FIG. 2 shows an enlarged detail of an upper corner of the lightweight module in FIG. 1.

[0030]FIG. 3 shows schematically the roof plane of the lightweight module in FIG. 1 and parts of an adjoining module.

[0031]FIG. 4 shows an enlarged detail of the area marked C1 in FIG. 3.

[0032]FIG. 5 shows schematically the bottom plane of the lightweight module in FIG. 1 and parts of an adjoining module.

[0033]FIG. 6 is a schematic side view of a long side of the lightweight module in FIG. 1 and also shows two frame columns.

[0034]FIG. 7 is a schematic side view of an end wall of the lightweight module in FIG. 1.

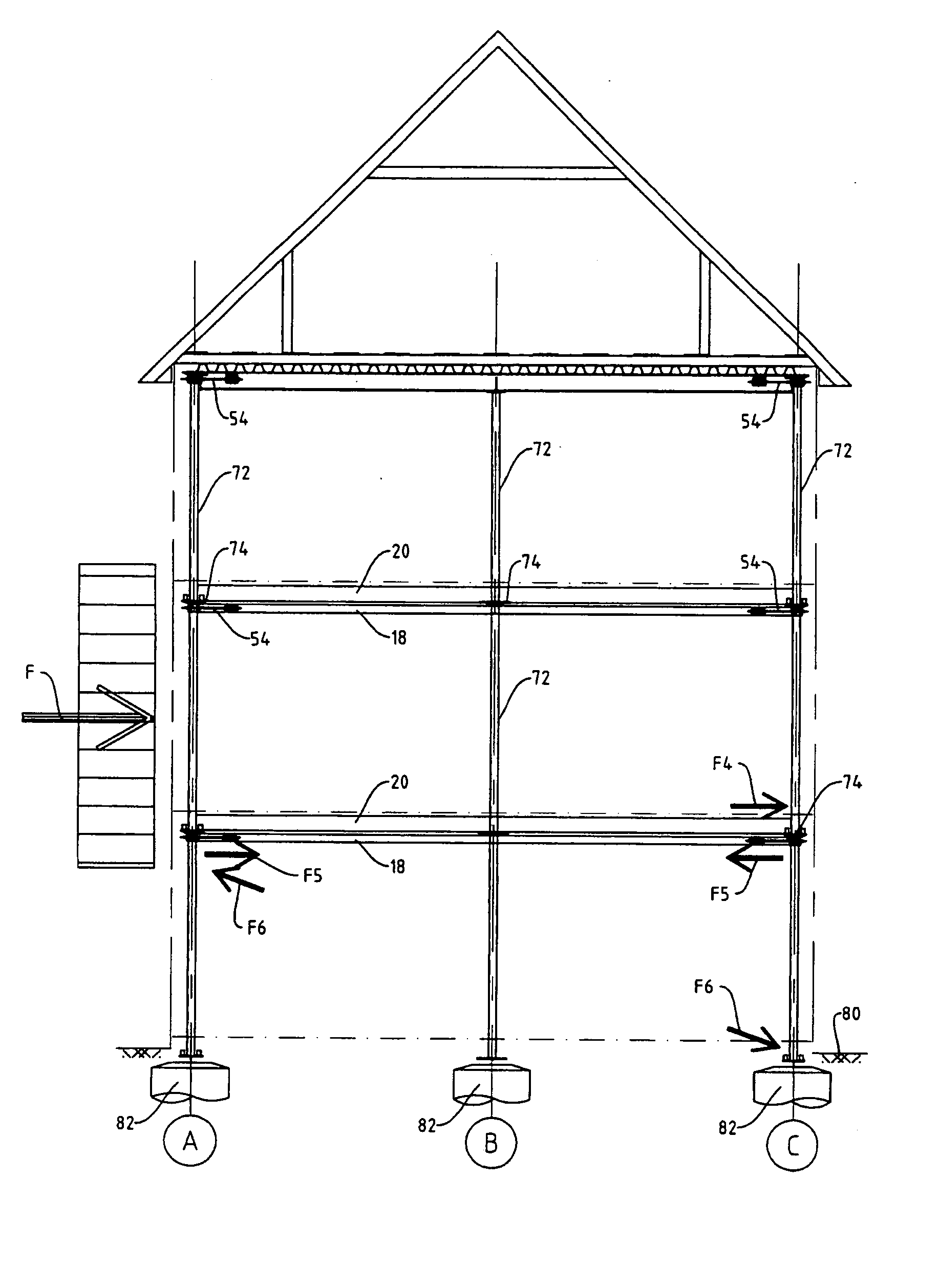

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com