Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Carbon plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

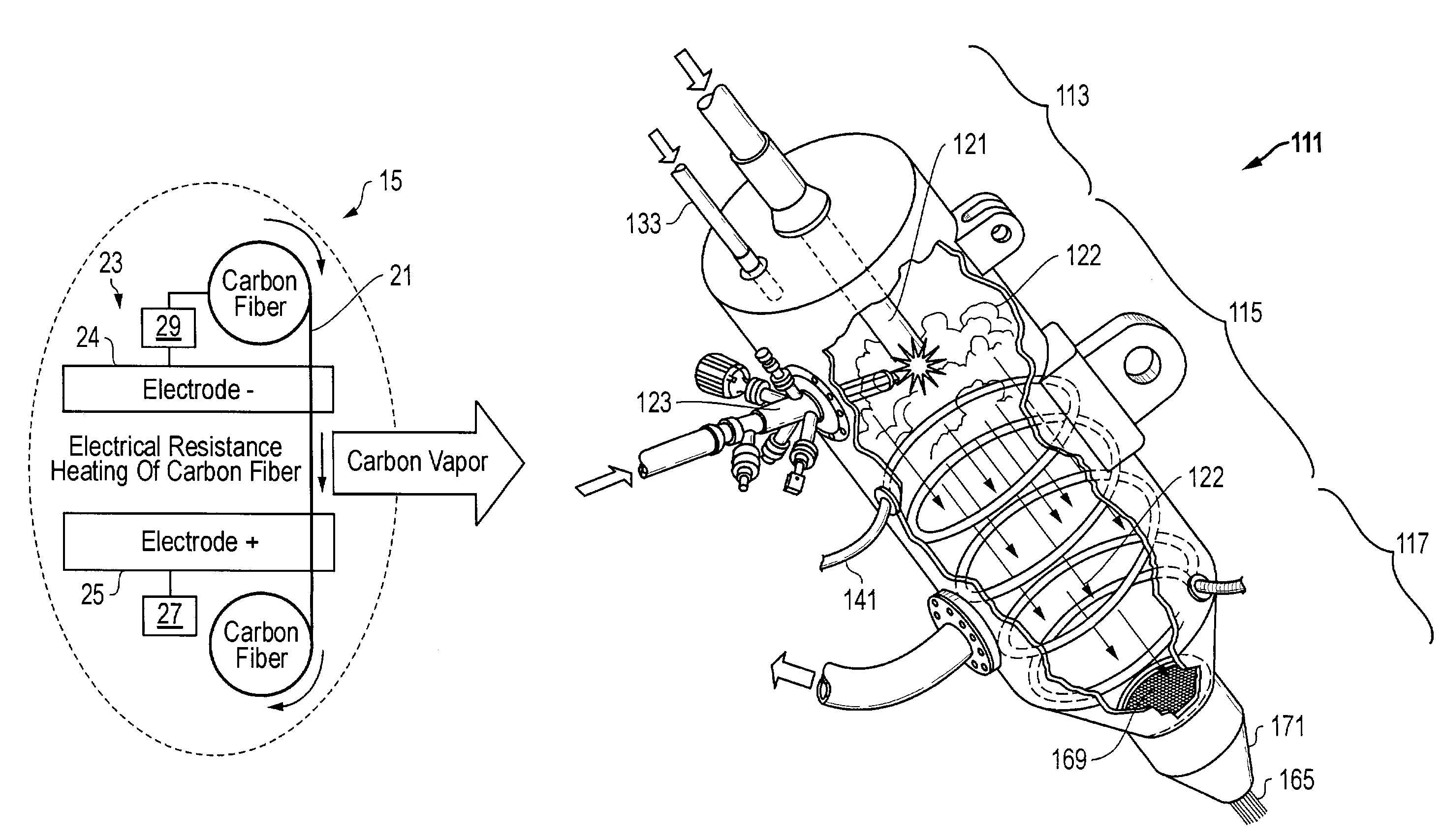

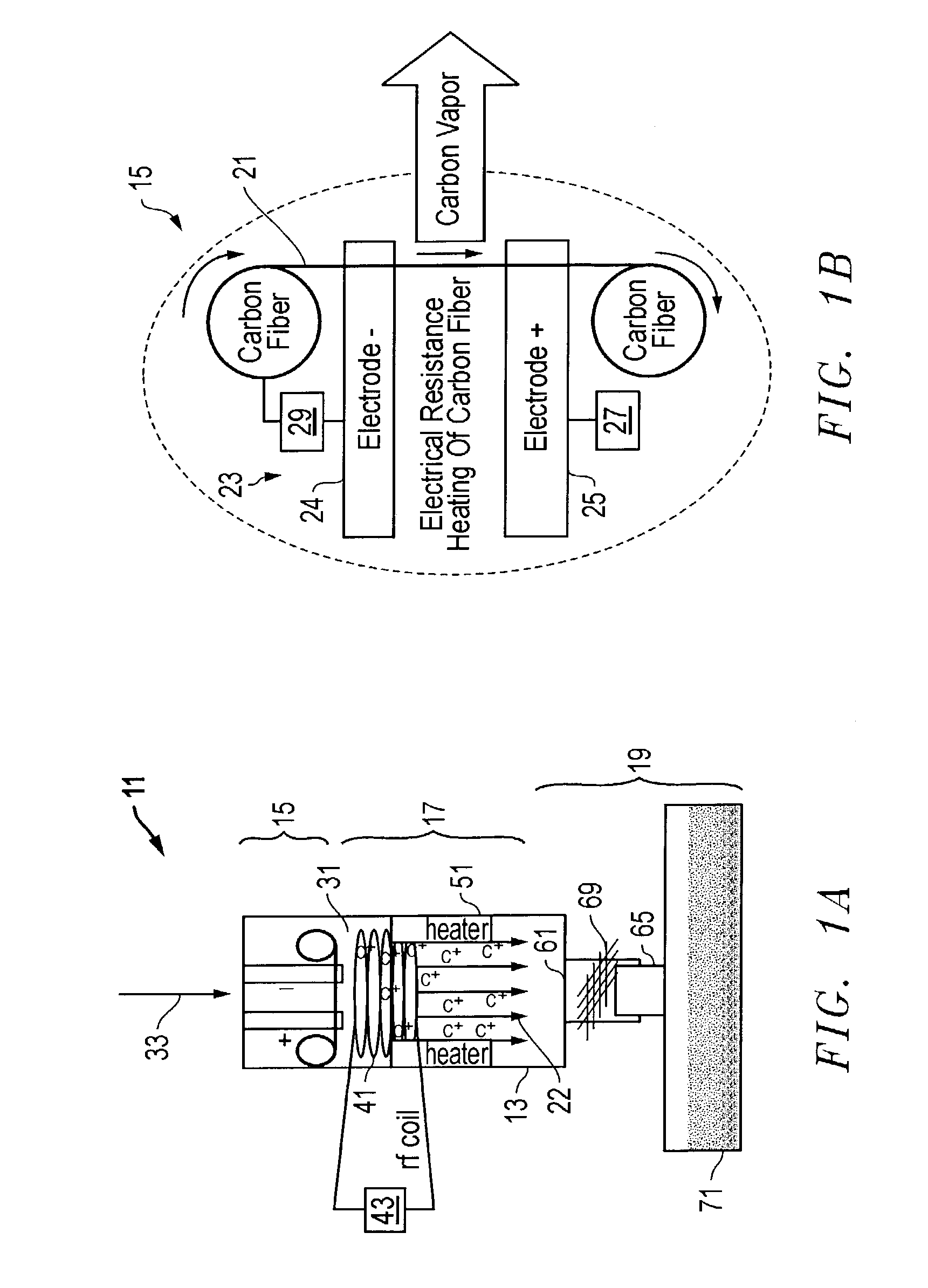

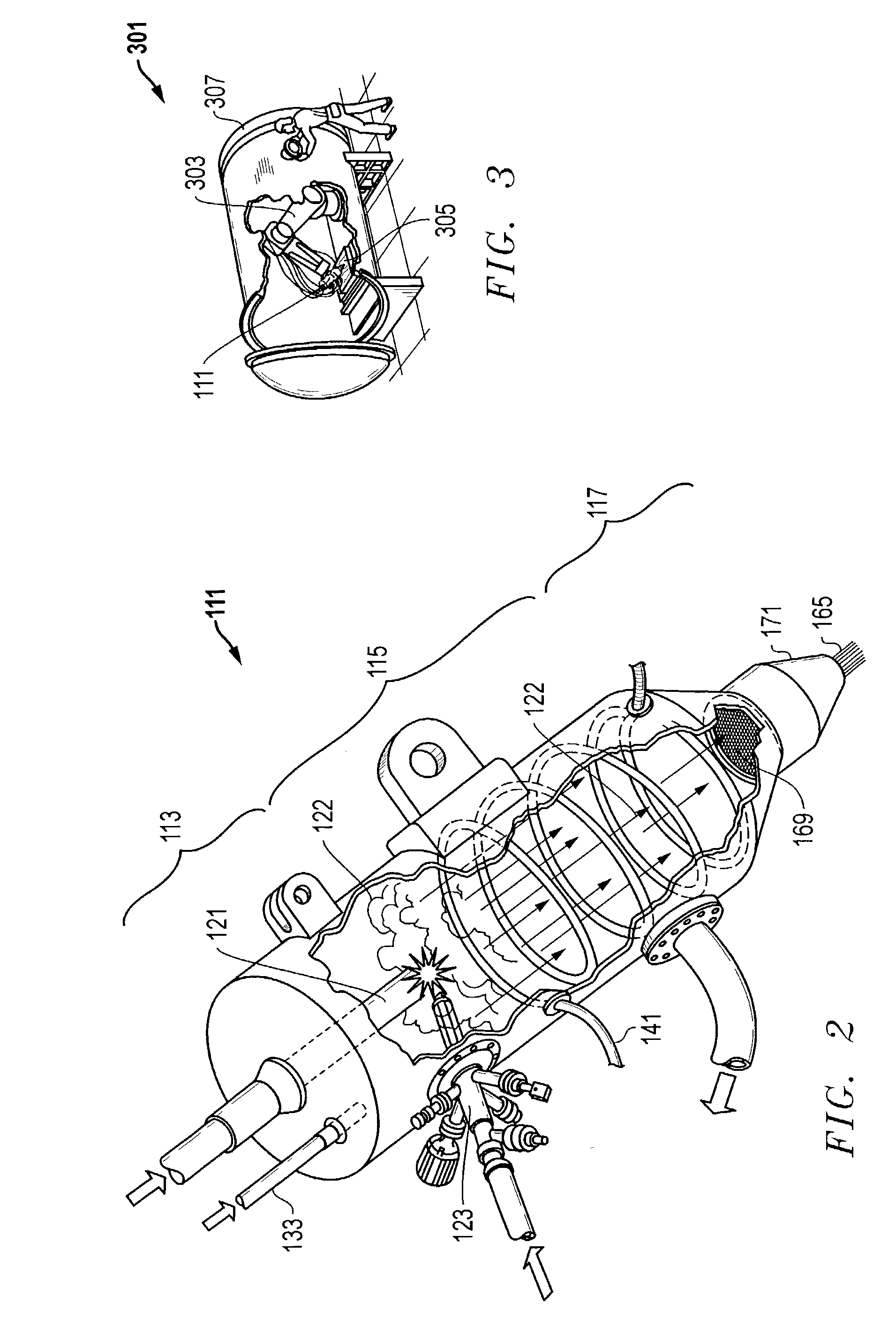

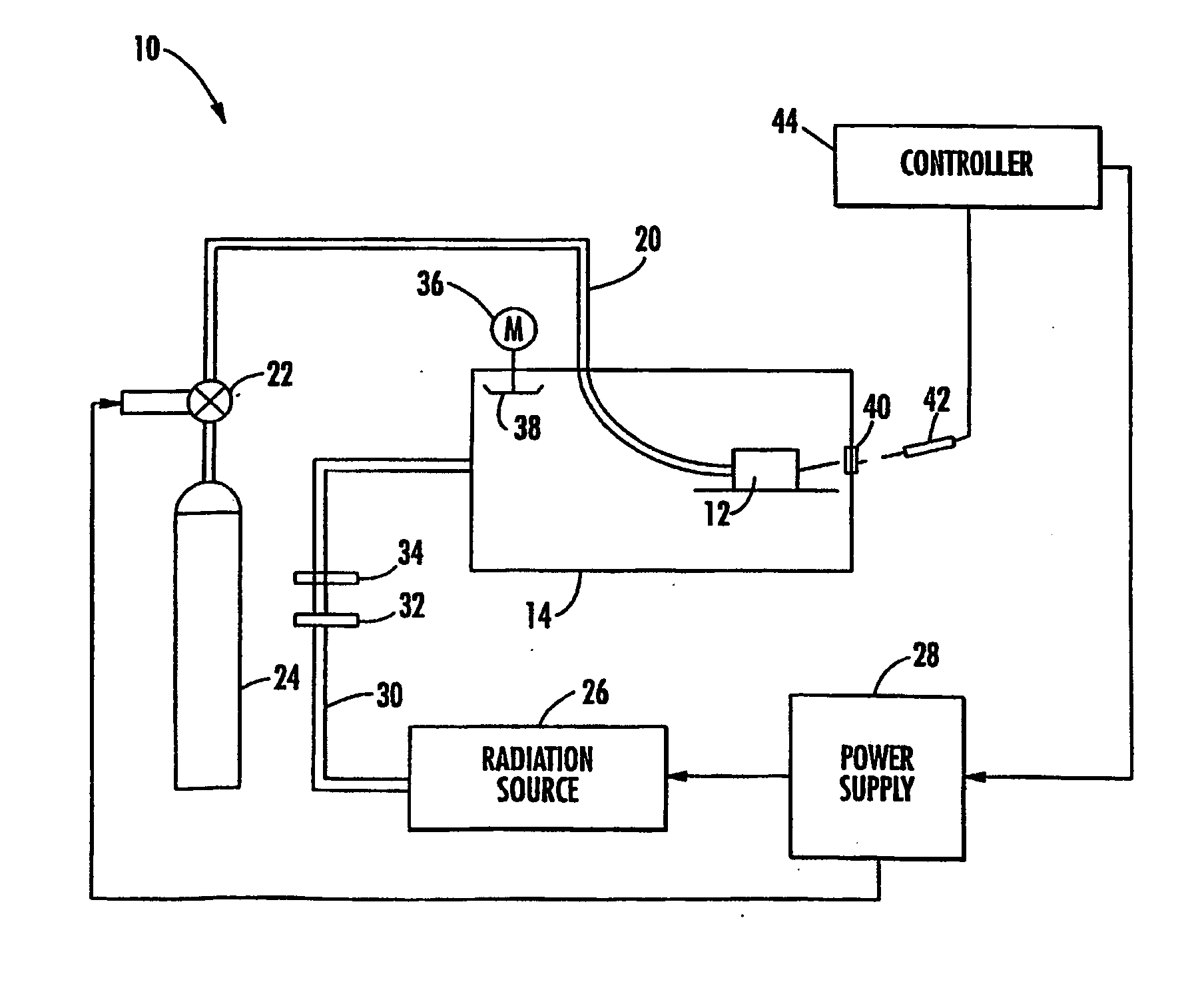

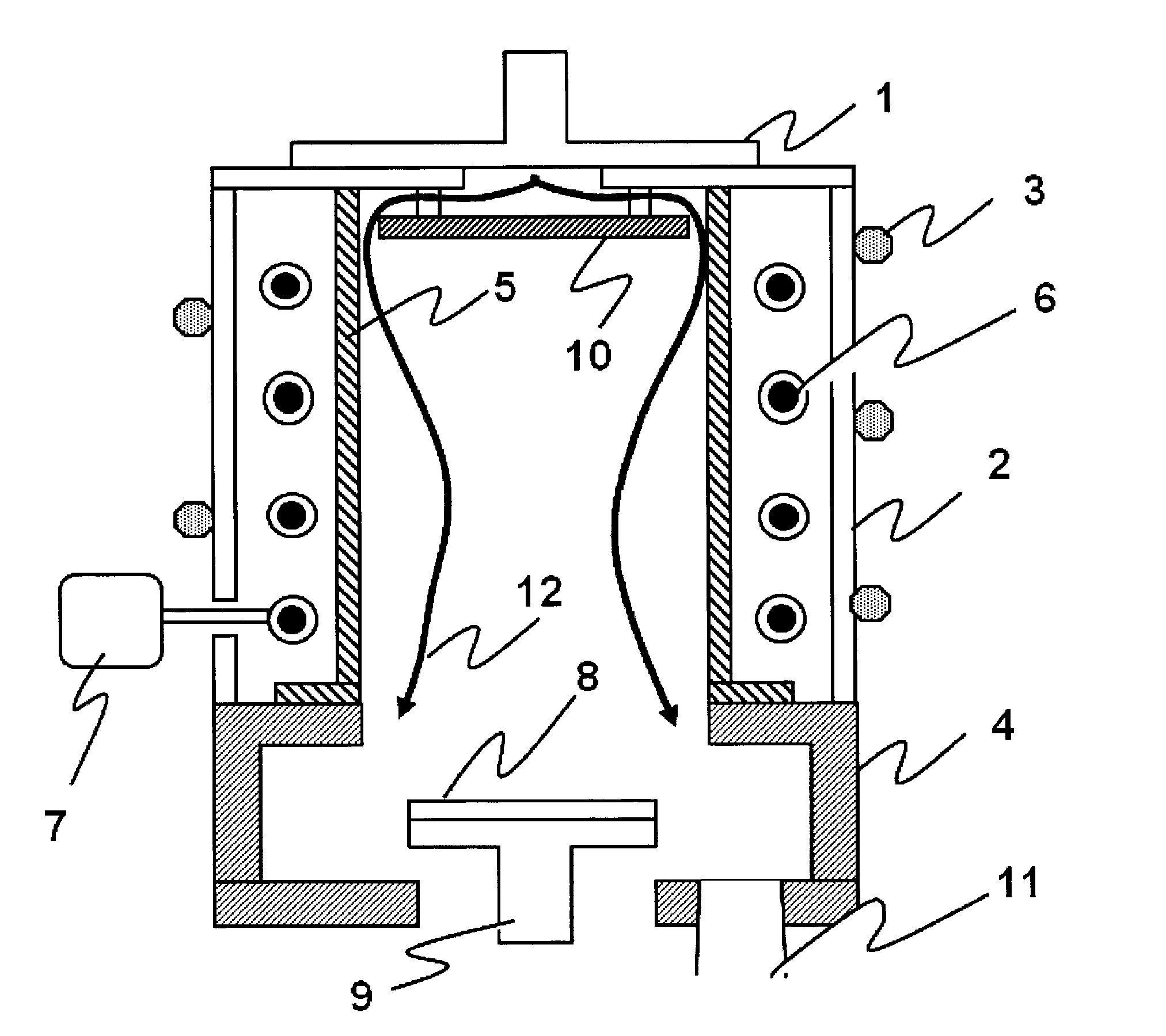

System, method, and apparatus for continuous synthesis of single-walled carbon nanotubes

InactiveUS7261779B2Simple structureIncrease concentrationMaterial nanotechnologyFibre chemical featuresRadio frequency energyRobotic arm

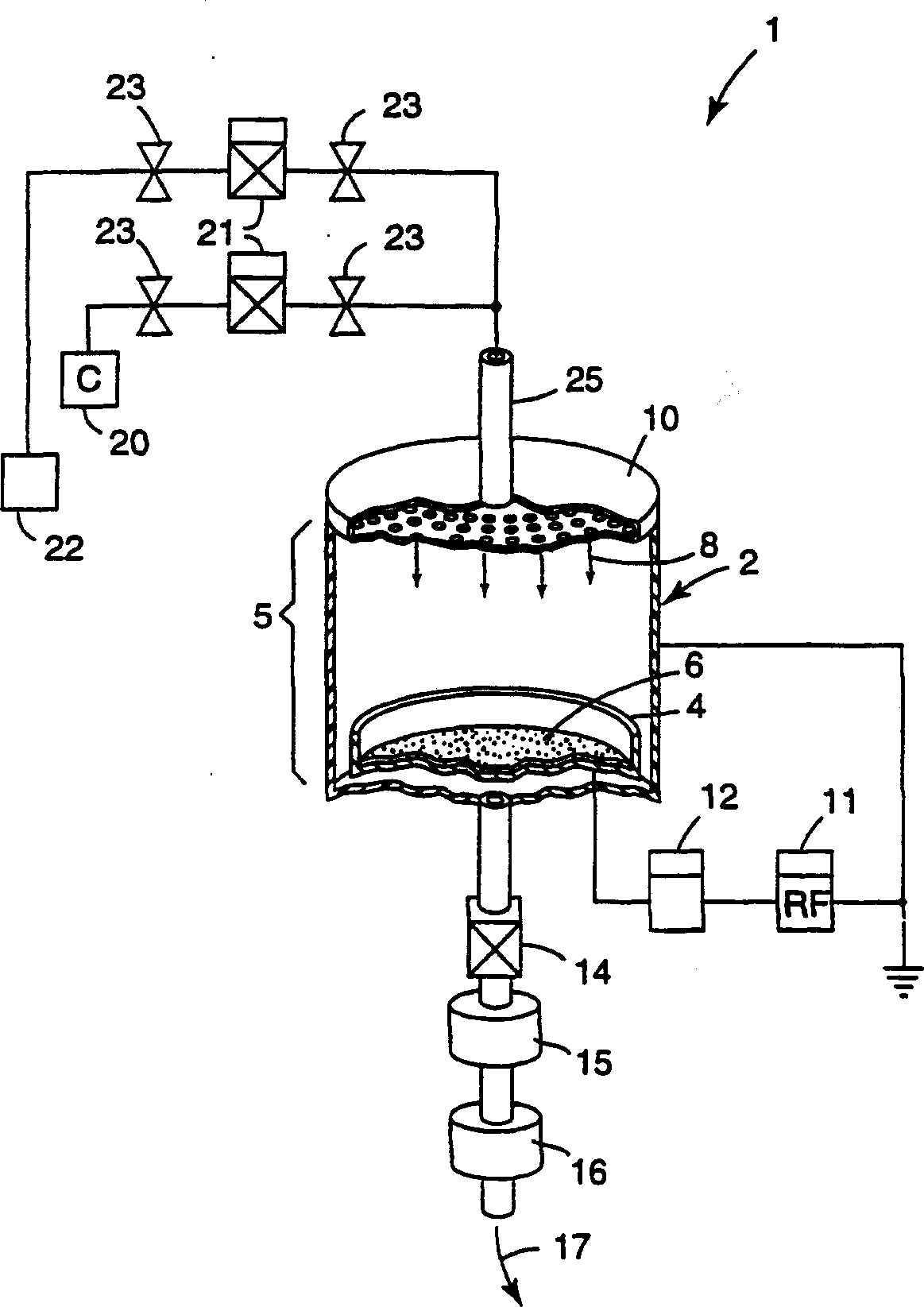

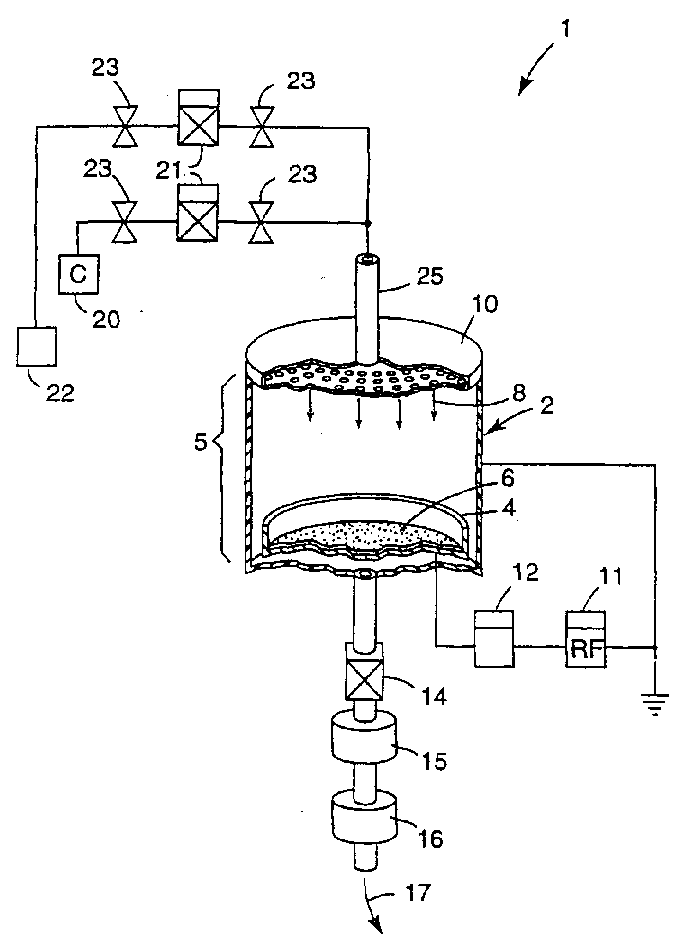

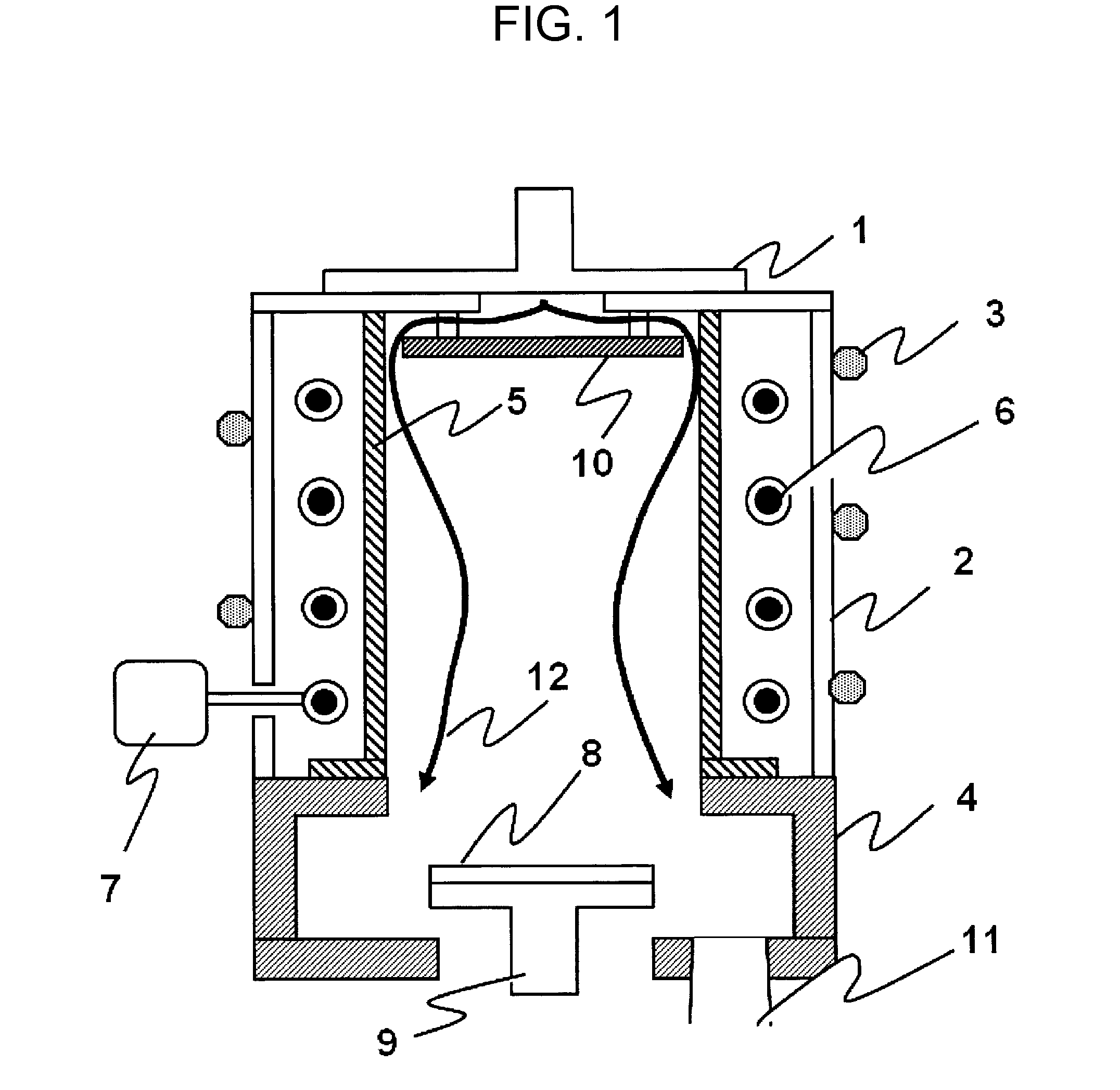

A process for producing single-walled carbon nanotubes in a continuous manner includes carbon plasma generation, plasma stabilization, and product deposition. The plasma is generated by electrical resistance heating or electron beam vaporization of feedstock. The plasma is stabilized with radio frequency energy from inductance coils and with electrical resistance heaters in the reactor. Stabilization homogenizes the plasma energy density and concentration, leading to a more efficient reactor. Finally, a transition metal catalyst and associated catalyst support are used to form the end product. The formation region may have variations of geometry and supporting equipment that will affect the rate and purity of the swcnt production. The formation region is immediately downstream from the plasma stabilization region. In addition, the entire apparatus is designed so that it can be mounted vertically such that continuous deposition of product can be applied with precision using an overhead robotic arm.

Owner:LOCKHEED MARTIN CORP

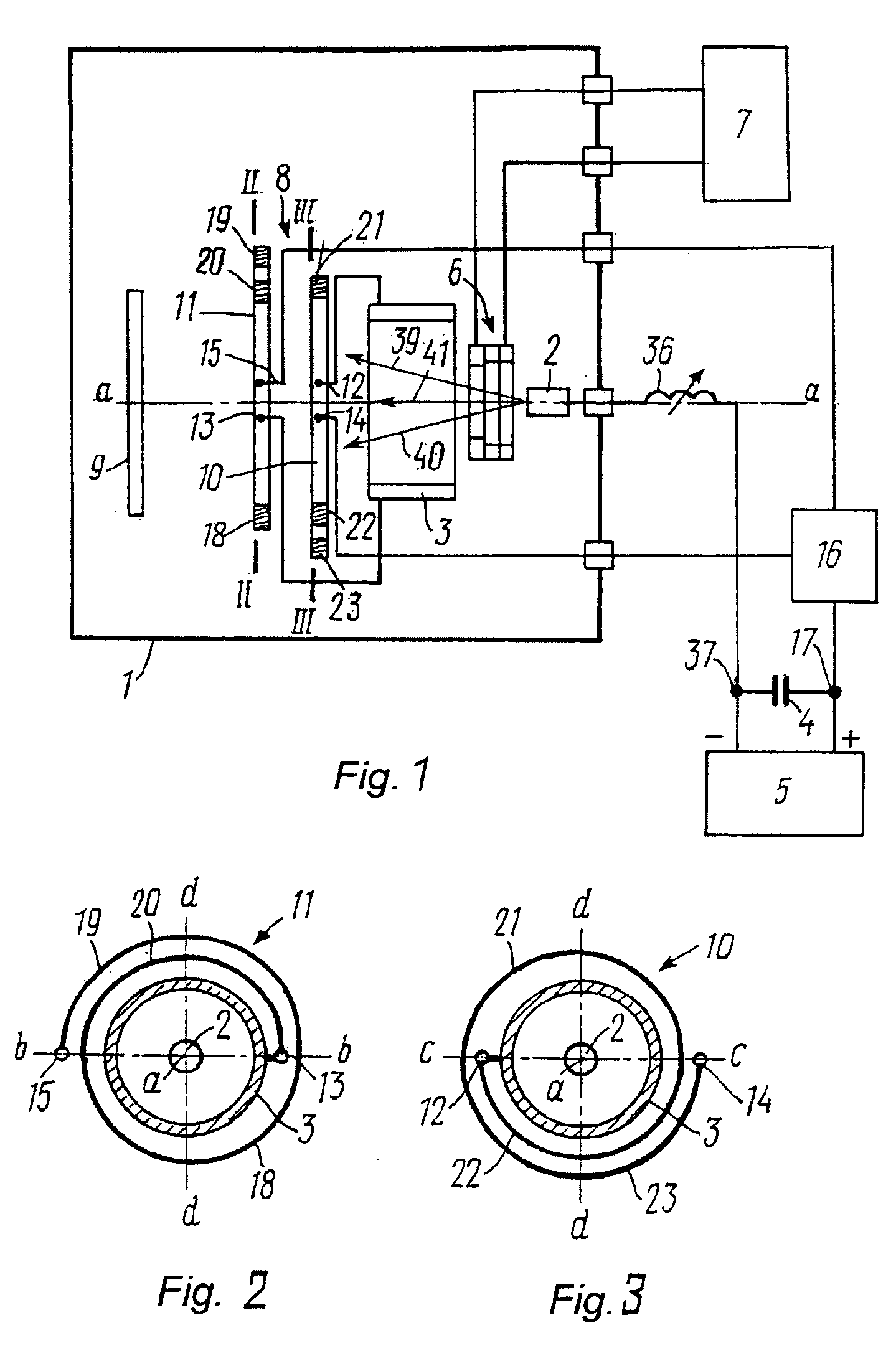

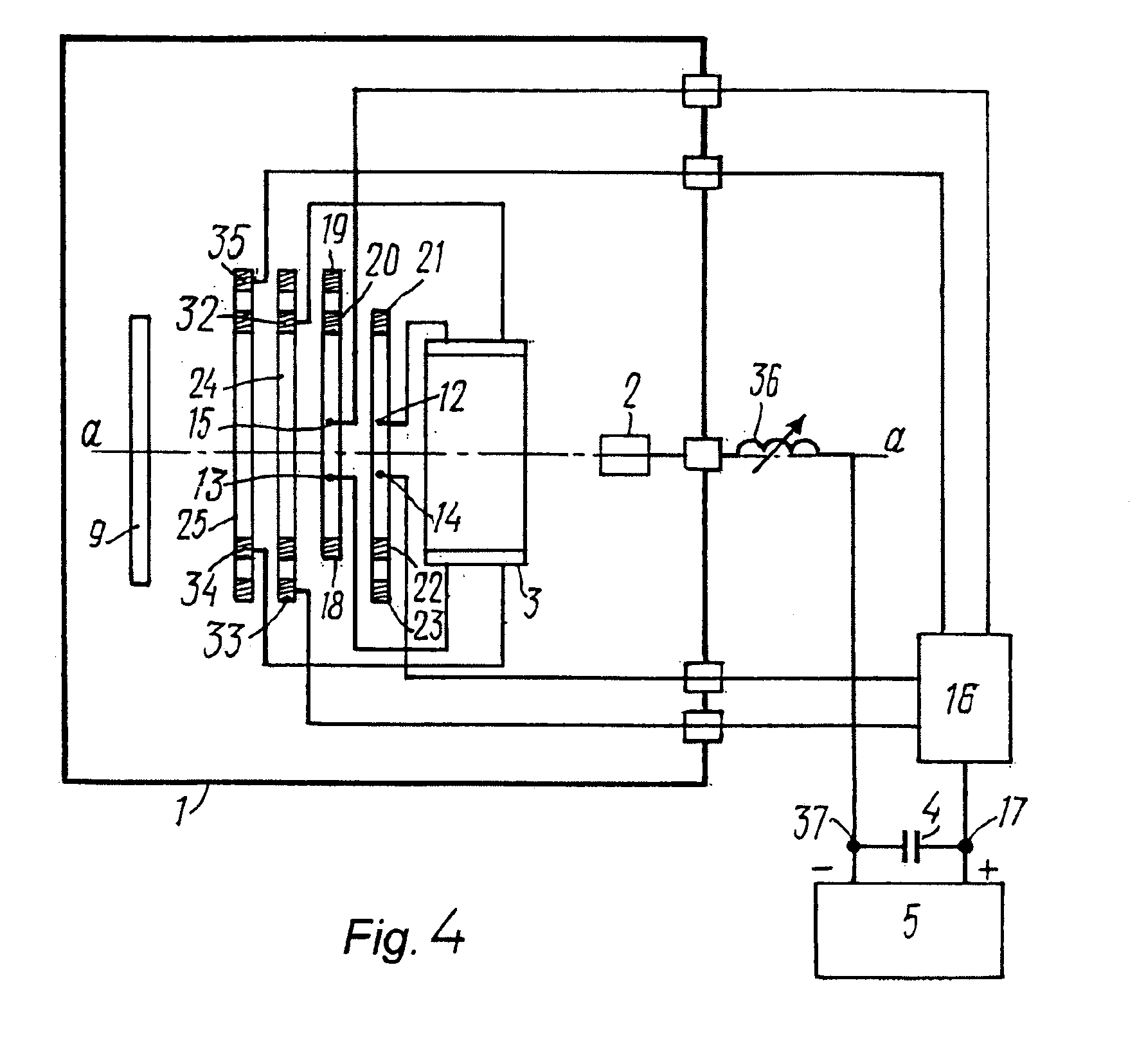

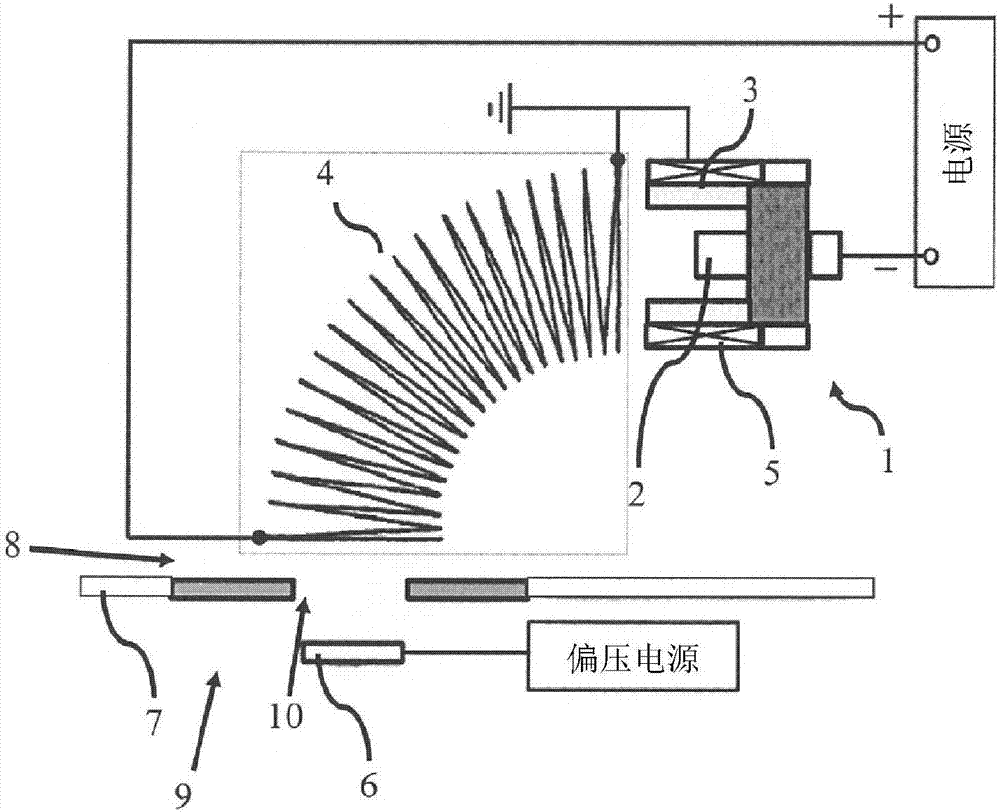

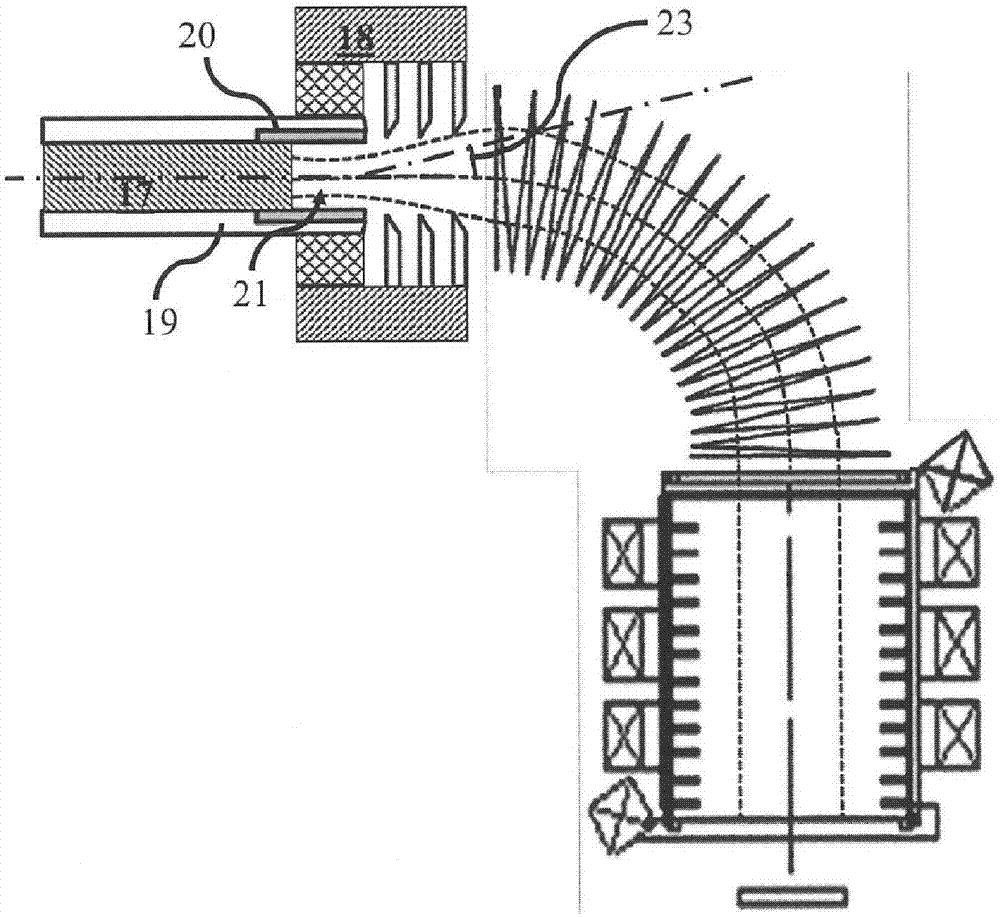

Pulsed carbon plasma apparatus

InactiveUS6855237B2High degreeImprove life performanceCellsElectric discharge tubesDiamond-like carbonMachine parts

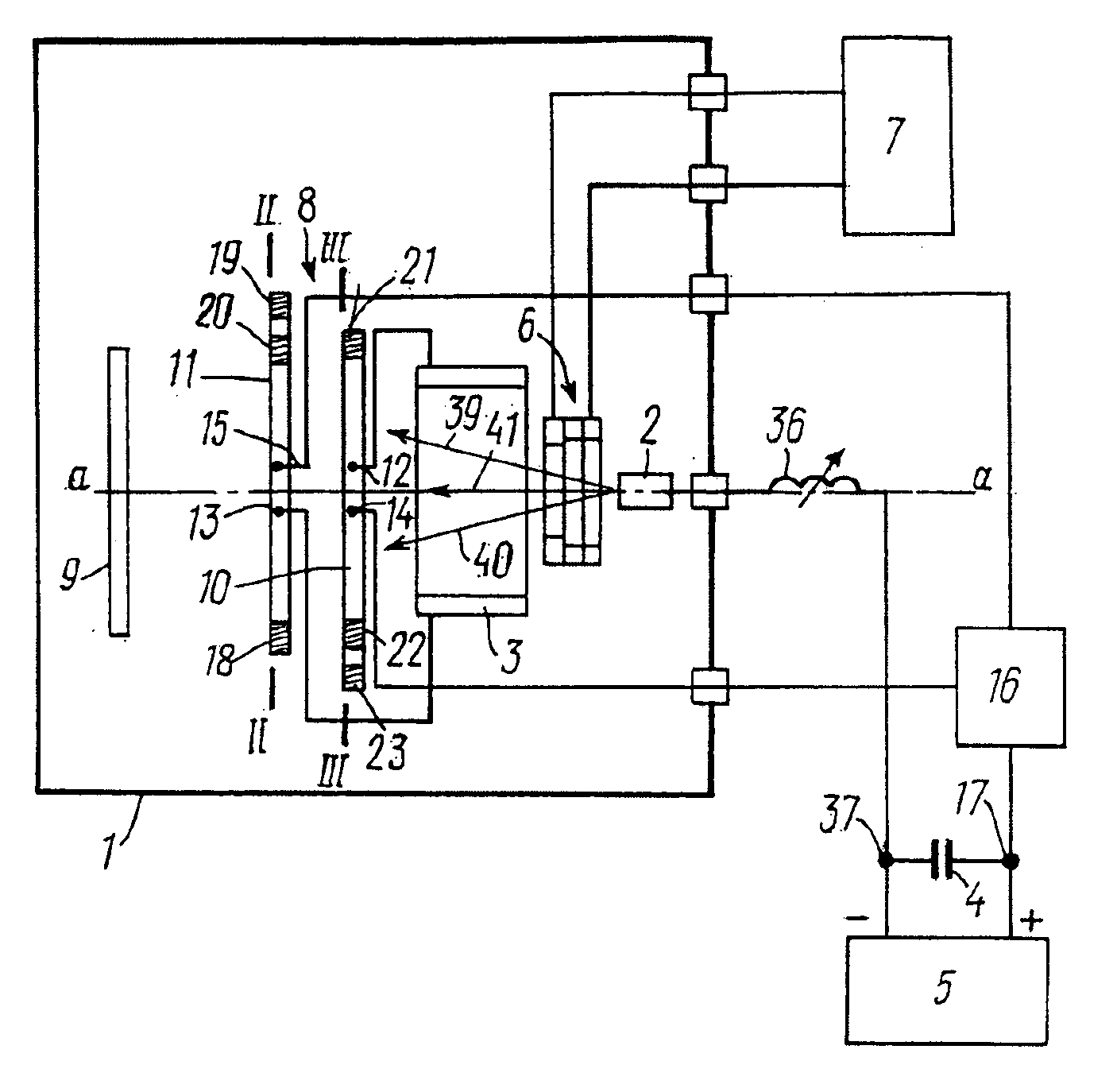

The present invention provides a pulsed carbon plasma apparatus to produce a diamond-like carbon coating over an extended object, the coating having a high degree of thickness uniformity achieved by scanning the plasma flow over the surface of the object. The pulsed carbon plasma apparatus of the invention comprises a carbon plasma flow scanning device having at least one pair of deflecting coils, where the deflecting coils have, in the scanning plane, a different number of turns on opposite sides. The object may be made of metal, ceramic, glass or plastic. The coatings may be used to improve life and operating performance of tools and machine parts, and as decorative coatings.

Owner:INT TECH EXCHANGE

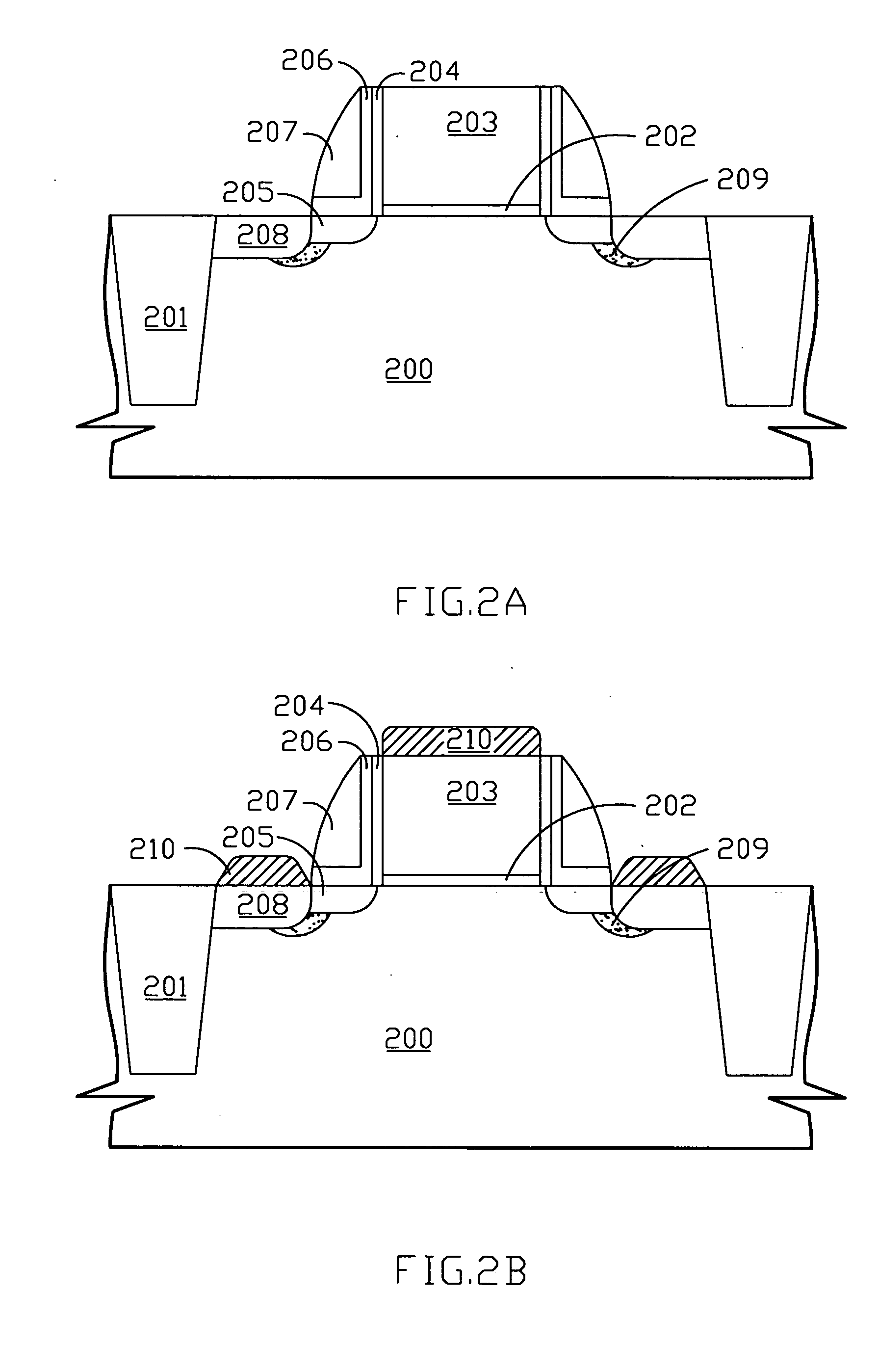

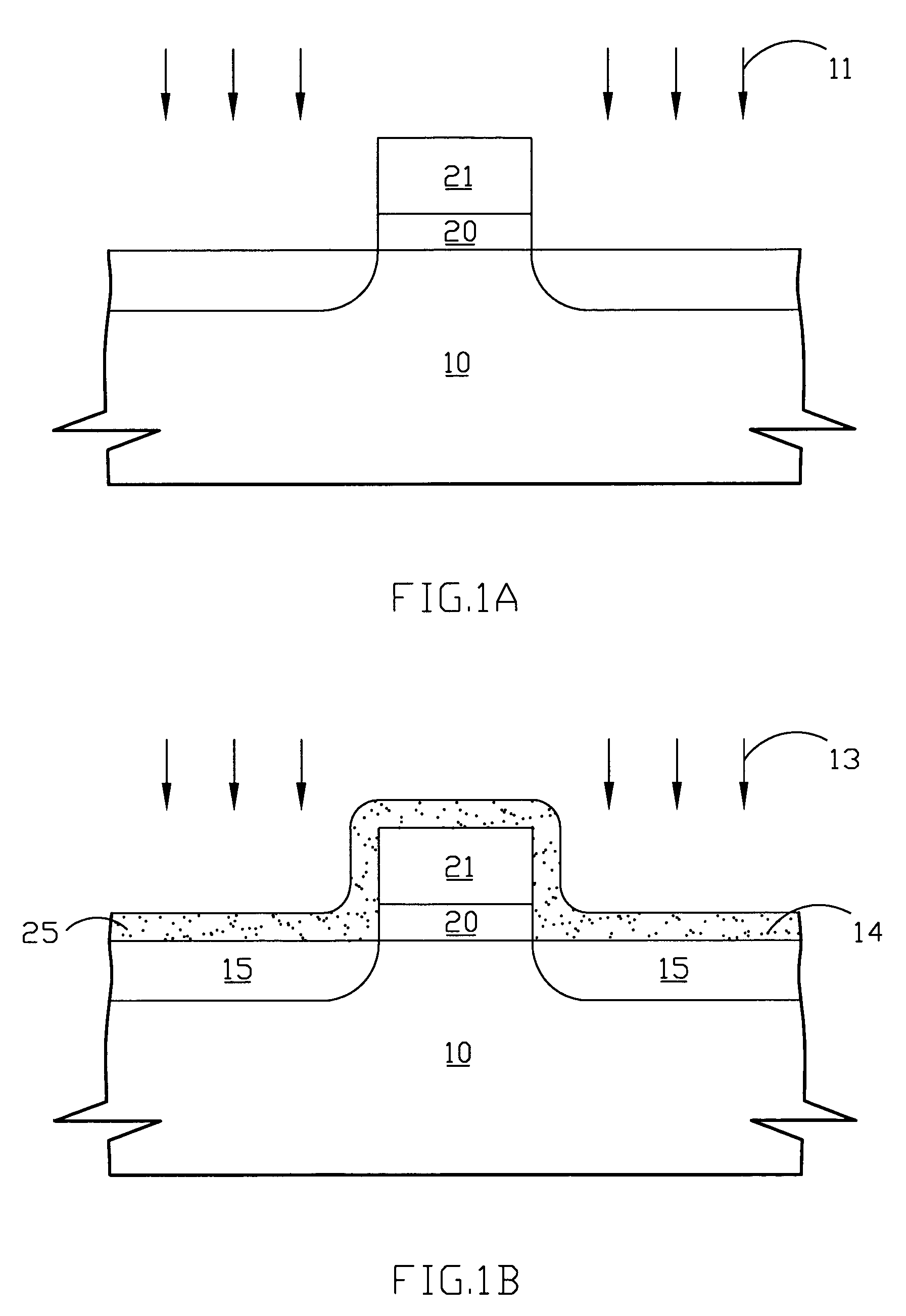

Method of surface pretreatment before selective epitaxial growth

InactiveUS20050130434A1Efficient removalQuality improvementTransistorFrom solid stateDevice formSurface roughness

A method of surface pretreatment before selective epitaxial growth is provided. A semiconductor substrate having metal-oxide-semiconductor devices formed thereon is provided, and a lightly dry etching process with a carbon-free plasma source is performed to remove a portion of the semiconductor substrate. Then, a selective epitaxial growth process is performed to form a semiconductor layer on the semiconductor substrate. A clean surface for selective epitaxial growth is provided by the lightly dry etching process, which can resolve the undercut issue and surface roughness.

Owner:UNITED MICROELECTRONICS CORP

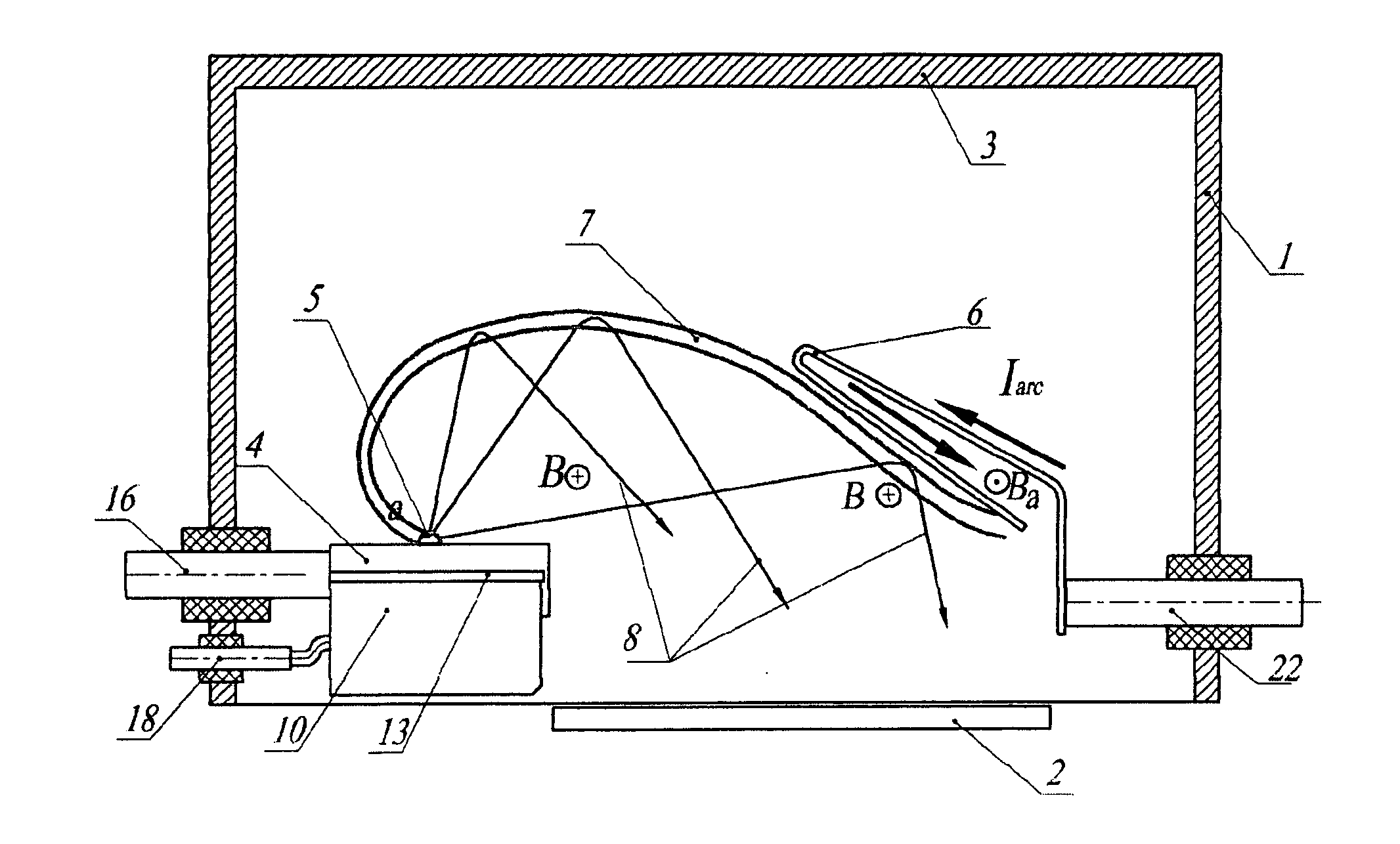

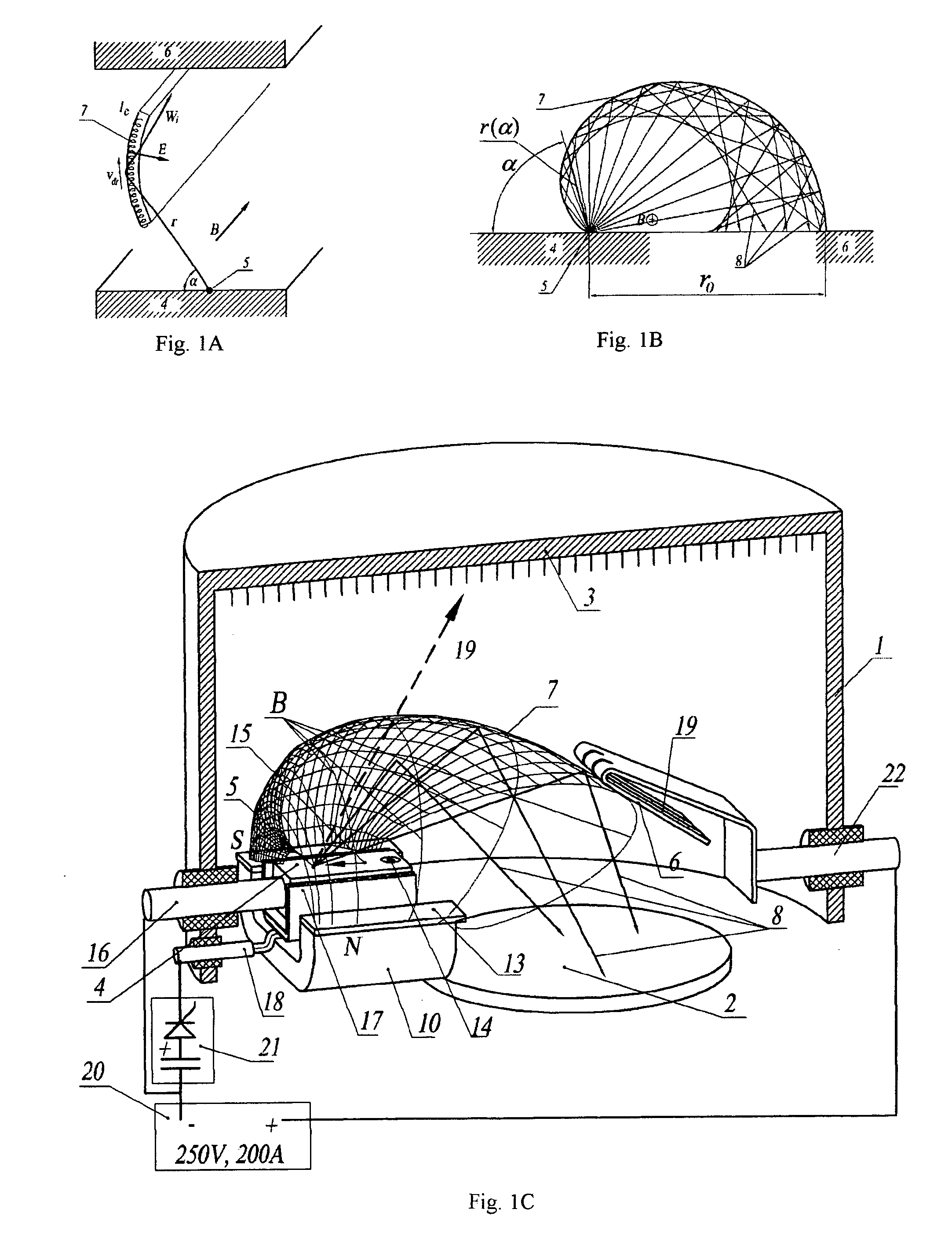

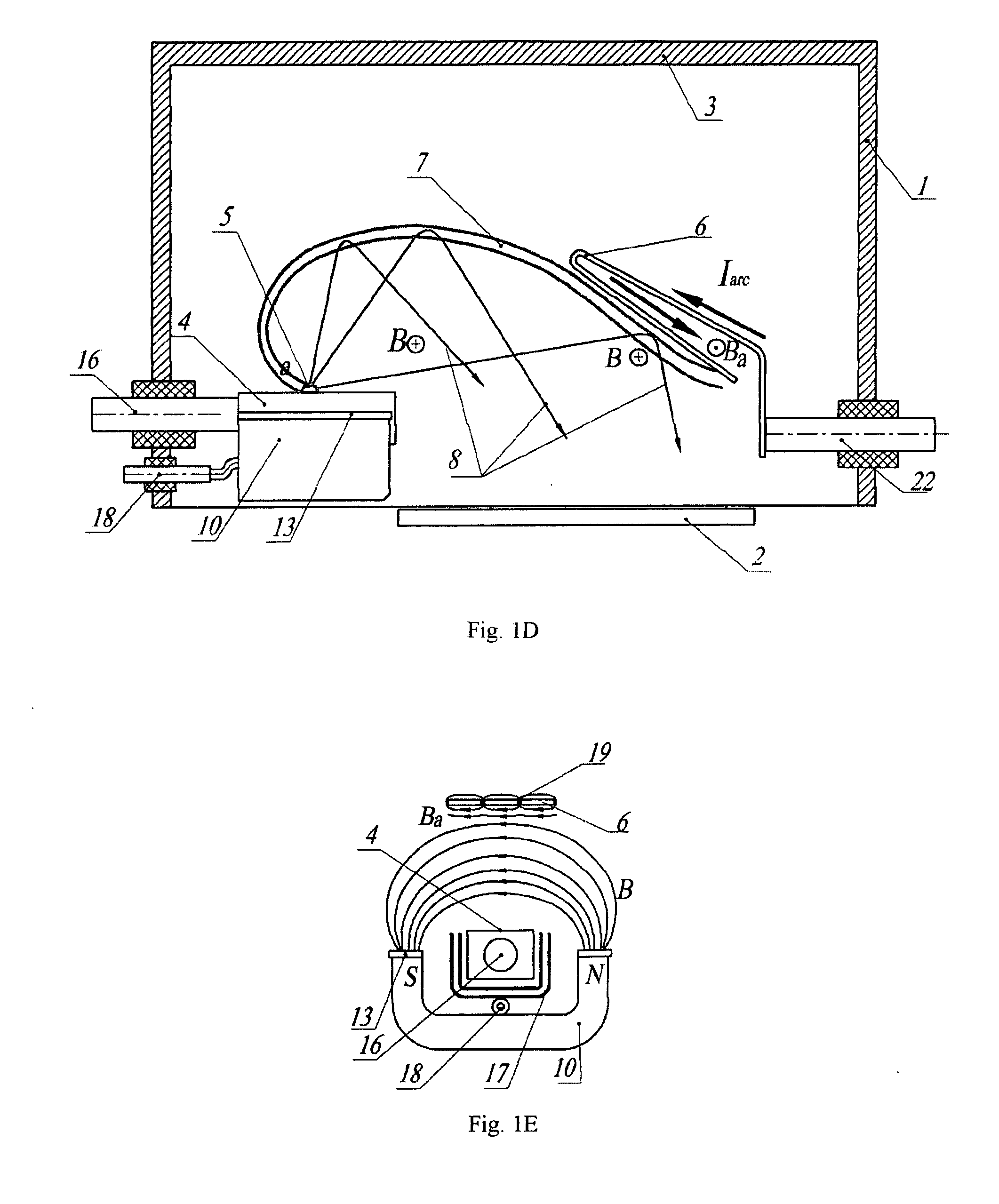

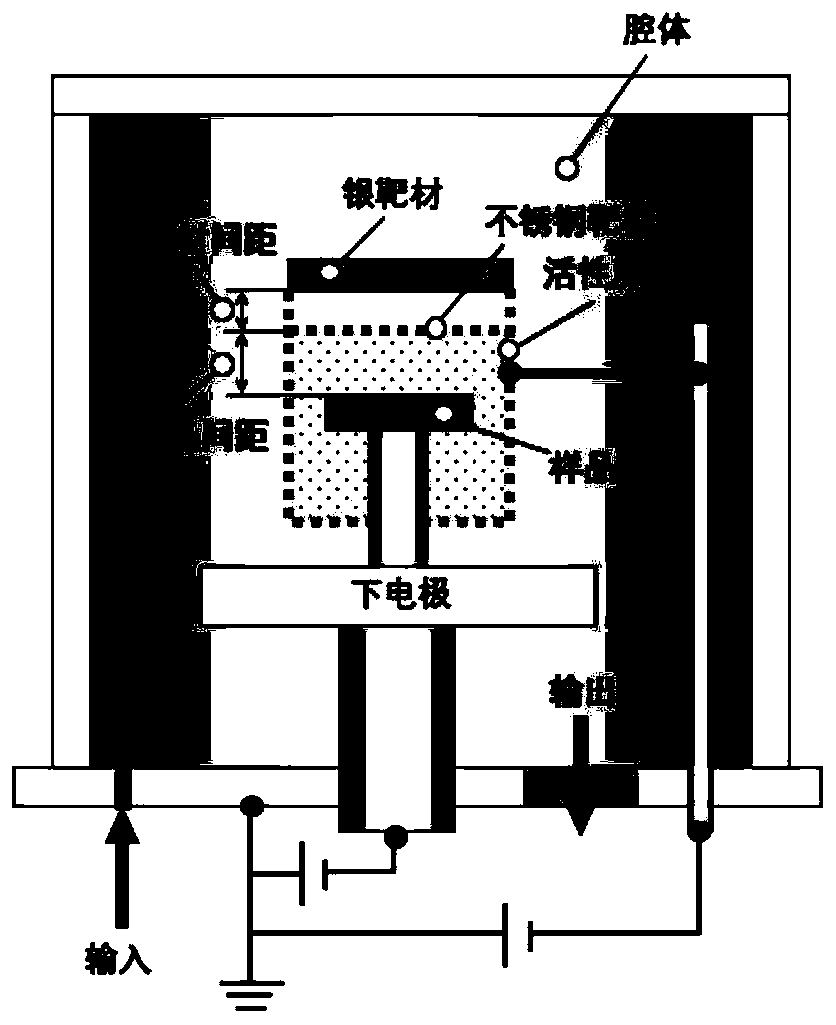

Cathode-arc source of metal/carbon plasma with filtration

InactiveUS20070034501A1Improve transportation efficiencyIncrease the number ofCellsElectric discharge tubesStationary conditionsCurrent sheet

The a cathode-arc source of metal plasma with filtration, used, in particular, for deposition of DLC, utilizes the effect of fast ions reflection from the Hall stratum in a transversal arched magnetic field to filtrate vacuum arc plasma arc from contaminating macroparticles and vapor. Various embodiments for producing maximal plasma flux at the source outlet, in particular, a pulse source with more the one cathode units for deposition of coating inside pipes / cavities, for deposition of coating in a stationary / quasi-stationary condition are offered. The cathode is made of a consumable material and is exposed to poles of magnets on both ends of cathode for creating a transversal magnetic field of an arched configuration in a discharge gap between the cathode and the anode. The anode geometry adequate to the mechanism of the arc current passage through a transversal magnetic field is offered. To avoid longitudinal and transverse short circuits of the current layer, an installation of non-conducting surfaces at ends or sectioned shields under a floating potential at the cathode sides is provided. The method of creating the Hall stratum in said transversal magnetic field of arched configuration is offered.

Owner:BENDER EFIM

Diamond-like film preparation method

ActiveCN101319324AHigh densityIncrease the number ofVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention discloses a method for preparing diamond-like carbon film (DLC), belonging to the metal or non-metal surface modification treatment technical field. The method adopts pulsed arc discharge by using graphite as a cathode electrode and a physically and chemically combined vapor deposition method for the decomposition and ionization of hydrocarbons gas to produce DLC deposition on a surface of a workpiece. The invention comprises the main operation steps of ultrasonic cleaning, vacuumizing, ion cleaning and DLC deposition, wherein argon gas is passed through in the ion cleaning step; a pulse frequency of the arc discharge in the DLC deposition step is 5 and 35Hz with voltage of between 200 and 400V; methane, ethane or propane are preferred as the hydrocarbons gas. A high-speed and high-energy carbon plasma ion beam is formed to generate collide decomposition and ionization to the passed through hydrocarbons gas through specific pulsed arc discharge to increase increasing density of the carbon ion and diffraction performance, thereby improving deposition speed and adhesive force of DLC, reducing internal stress, and improving precision and performance of DLC.

Owner:庄严

Method and apparatus for coating diamond-like carbon onto particles

InactiveCN1279729AEfficient depositionChange surface propertiesGranule coatingTransportation and packagingCapacitanceDiamond-like carbon

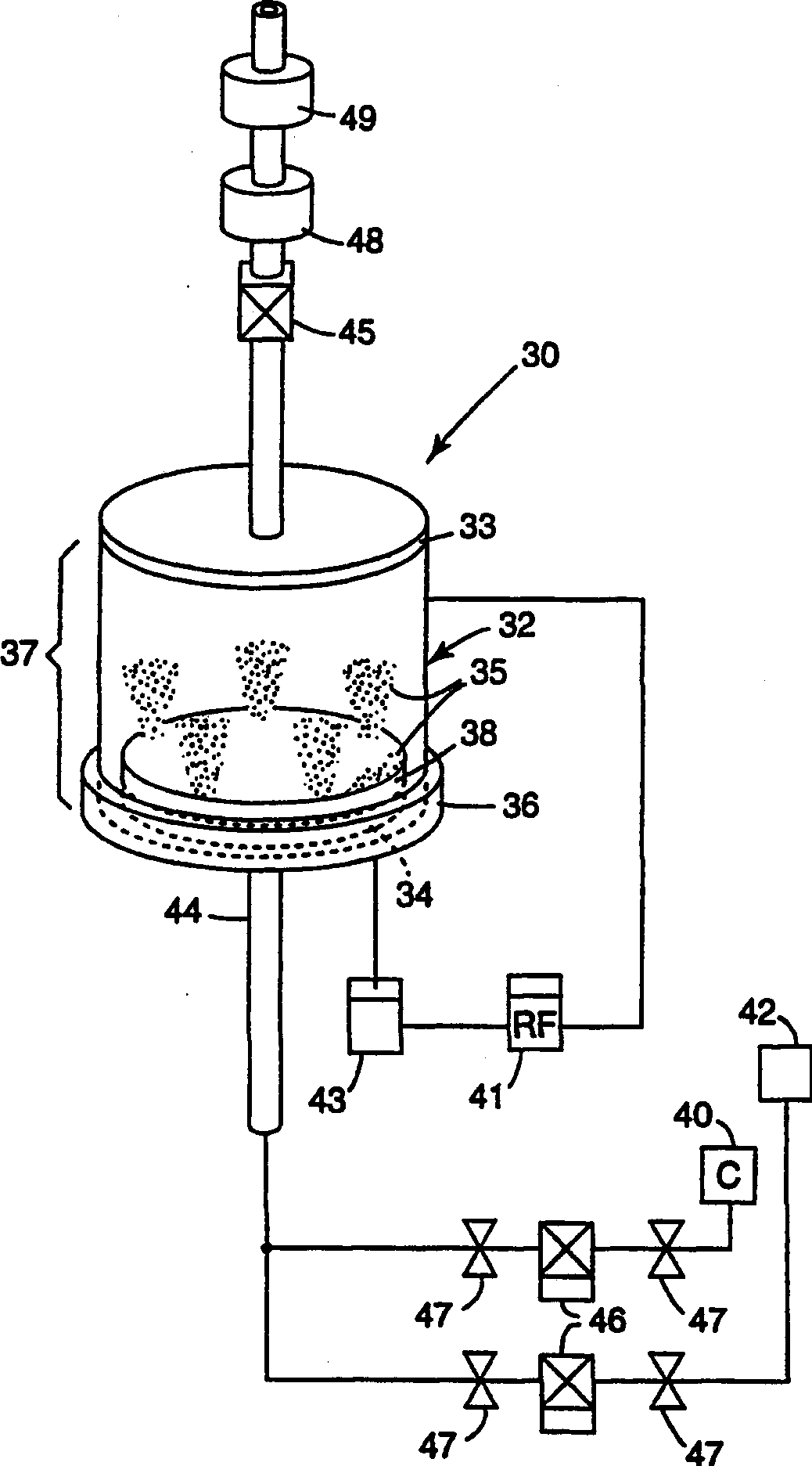

A method for making particles coated with a diamond-like network, which can include additive components. The method comprises subjecting a multiplicity of particles to a carbon-based plasma in an evacuated radio frequency powered capacitively coupled reactor system in which ion sheaths are formed around the electrodes and wherein the particles are agitated in such a manner as to expose their surfaces to the reactive species in the plasma while keeping the particles substantially within an ion sheath.The advantages of the present invention include (i) the efficient deposition of DLN onto particles at high deposition rates, (ii) the deposition of densely-packed DLN coatings, (iii) the ability to perform in situ surface cleaning of particles by ion bombardment with oxygen- and argon-containing plasmas prior to deposition of DLN, and (iv) the ability to tailor the bulk and surface properties of the coatings by manipulating the composition of the coating and the intensity of ion bombardment during the coating process.

Owner:3M CO

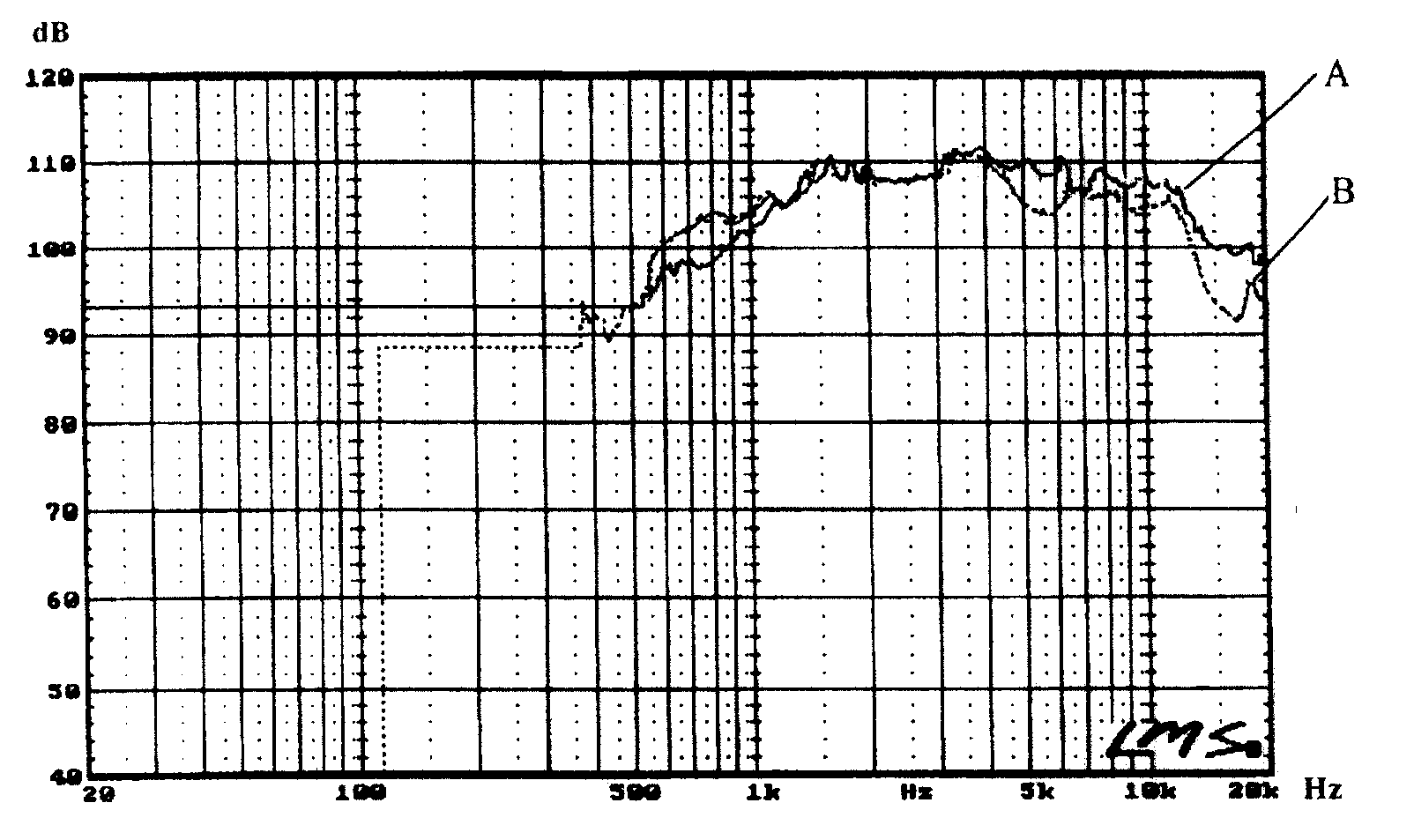

Method for mfg. diamondoid composite diaphragm of loudspeaker

InactiveCN1402589AQuality improvementImprove bindingVacuum evaporation coatingSputtering coatingCarbon plasmaSound quality

The vacuum-cathode arc source is adopted in the invention and the graphite is as the target cathode. Using the carbon plasma generated by the vacuum-cathode graphite arc deposits the diamond-like film on the diaphragm to be coated. The ivnention can produce in batch size of the compound speaker diaphragm coated with diamond like film in various shape specifications with good performances. The invention raises the frequency response characteristics of the speakers and improves the sound quality.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

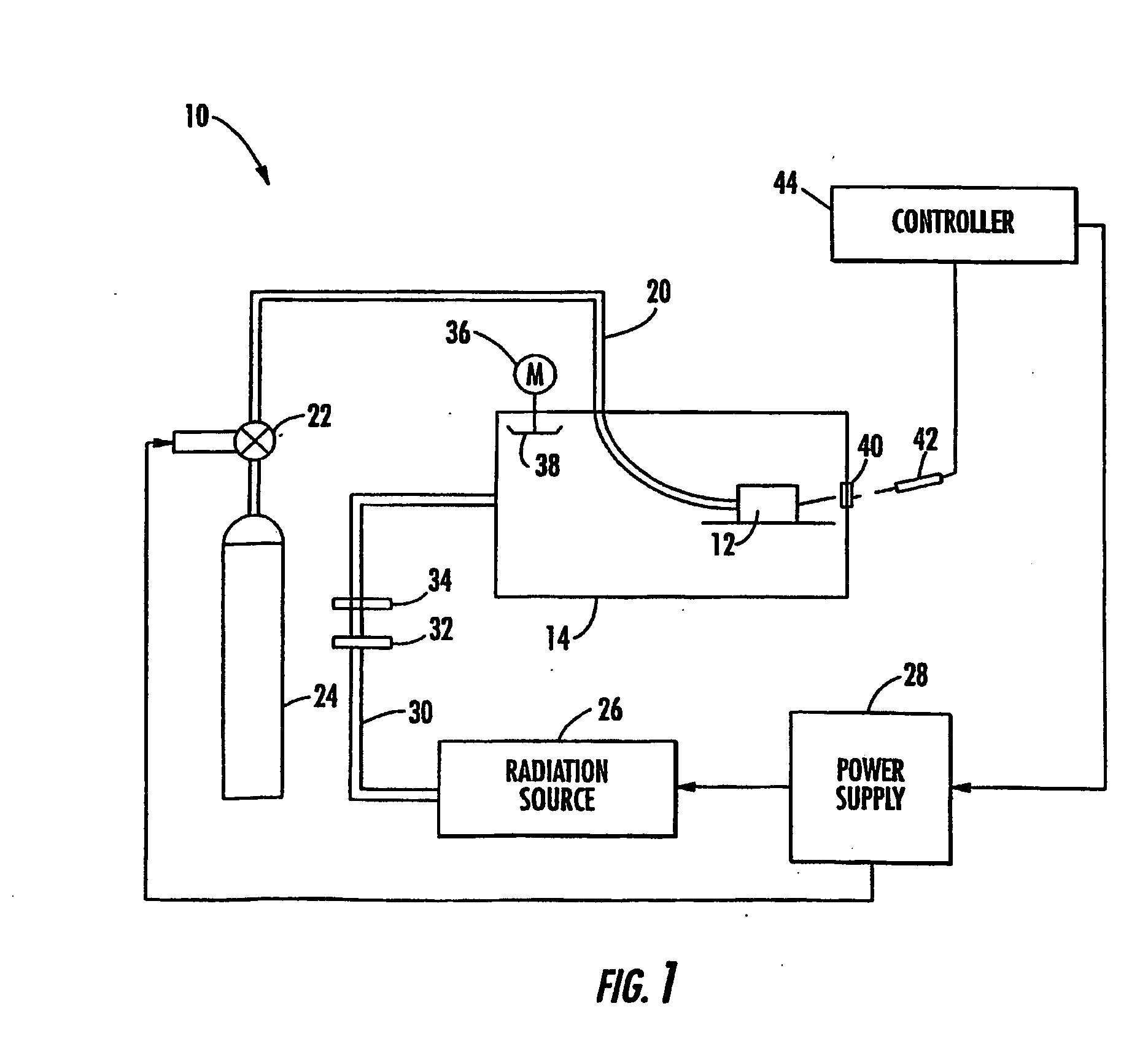

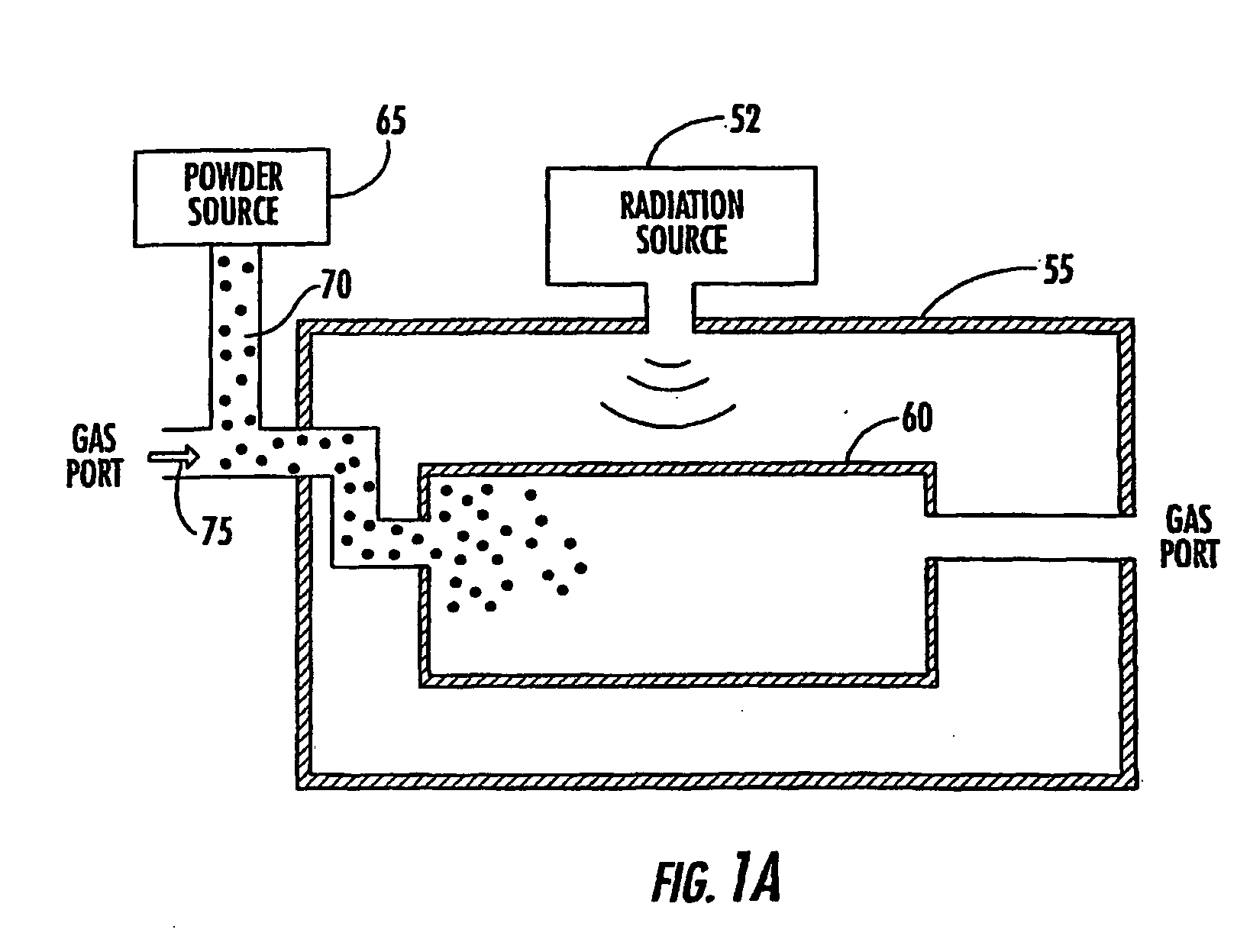

Plasma-assisted carburizing

InactiveUS20060062930A1Solid state diffusion coatingChemical vapor deposition coatingCarbon plasmaElectromagnetic radiation

A system and method of carburizing a surface region of an object includes subjecting a gas to electromagnetic radiation, generated from a radiation source (52), in the presence of a plasma catalyst (70) to initiate a plasma containing carbon. The method also includes exposing the surface region of the object to the plasma for a period of time sufficient to transfer at least some of the carbon from the plasma to the object through the first surface region.

Owner:BTU INTERNATIONAL

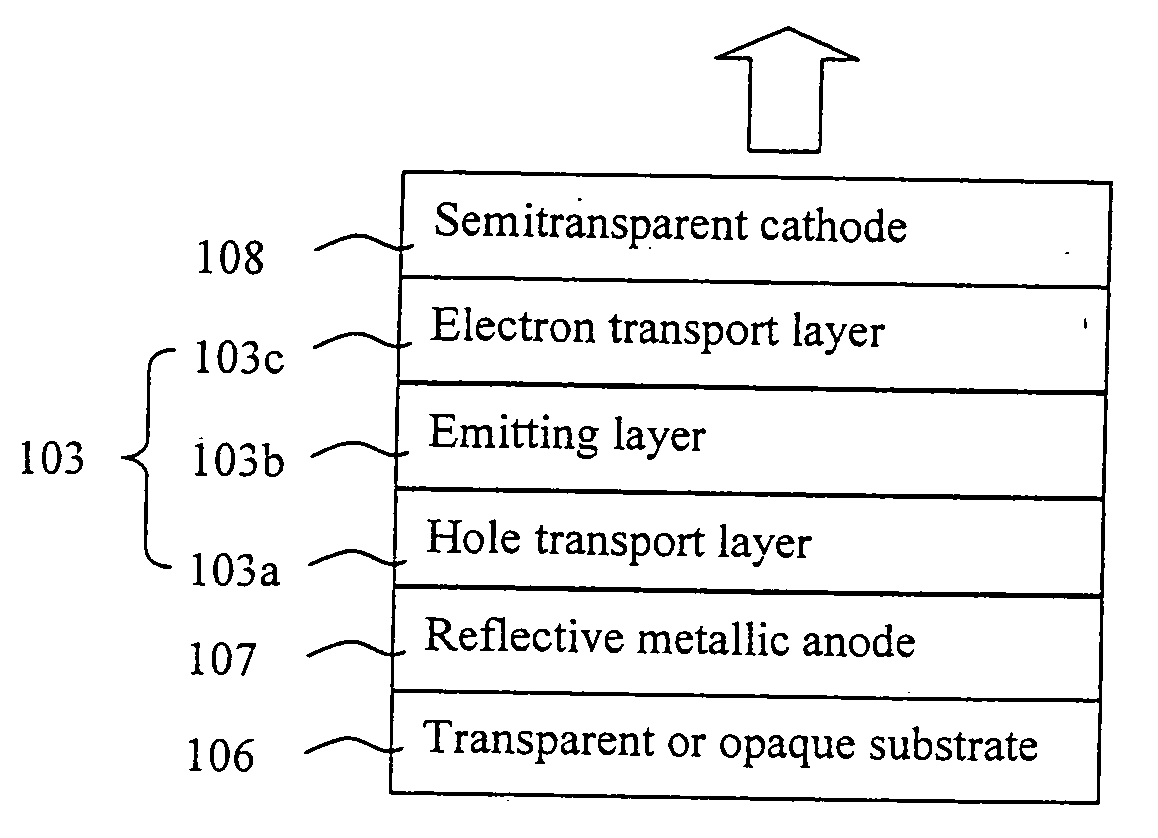

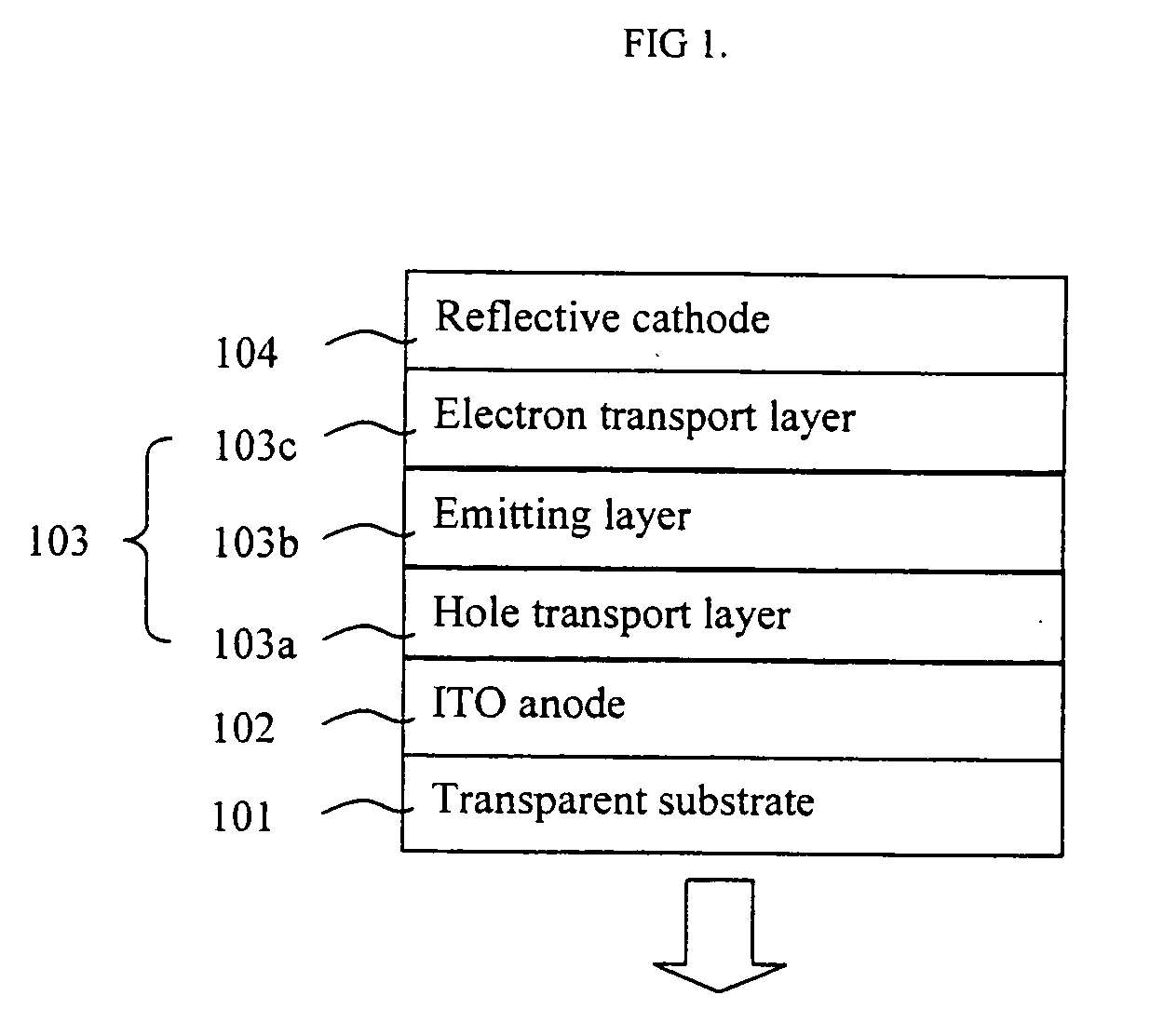

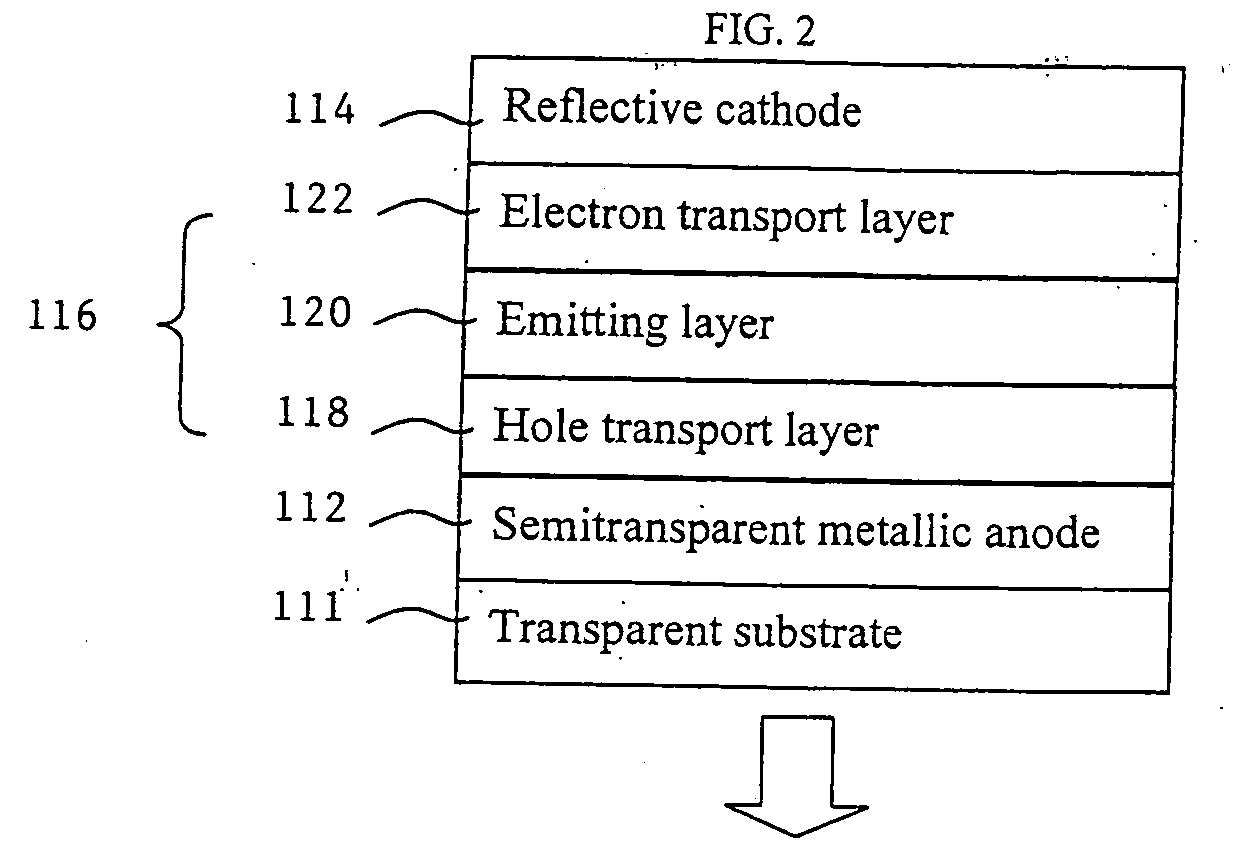

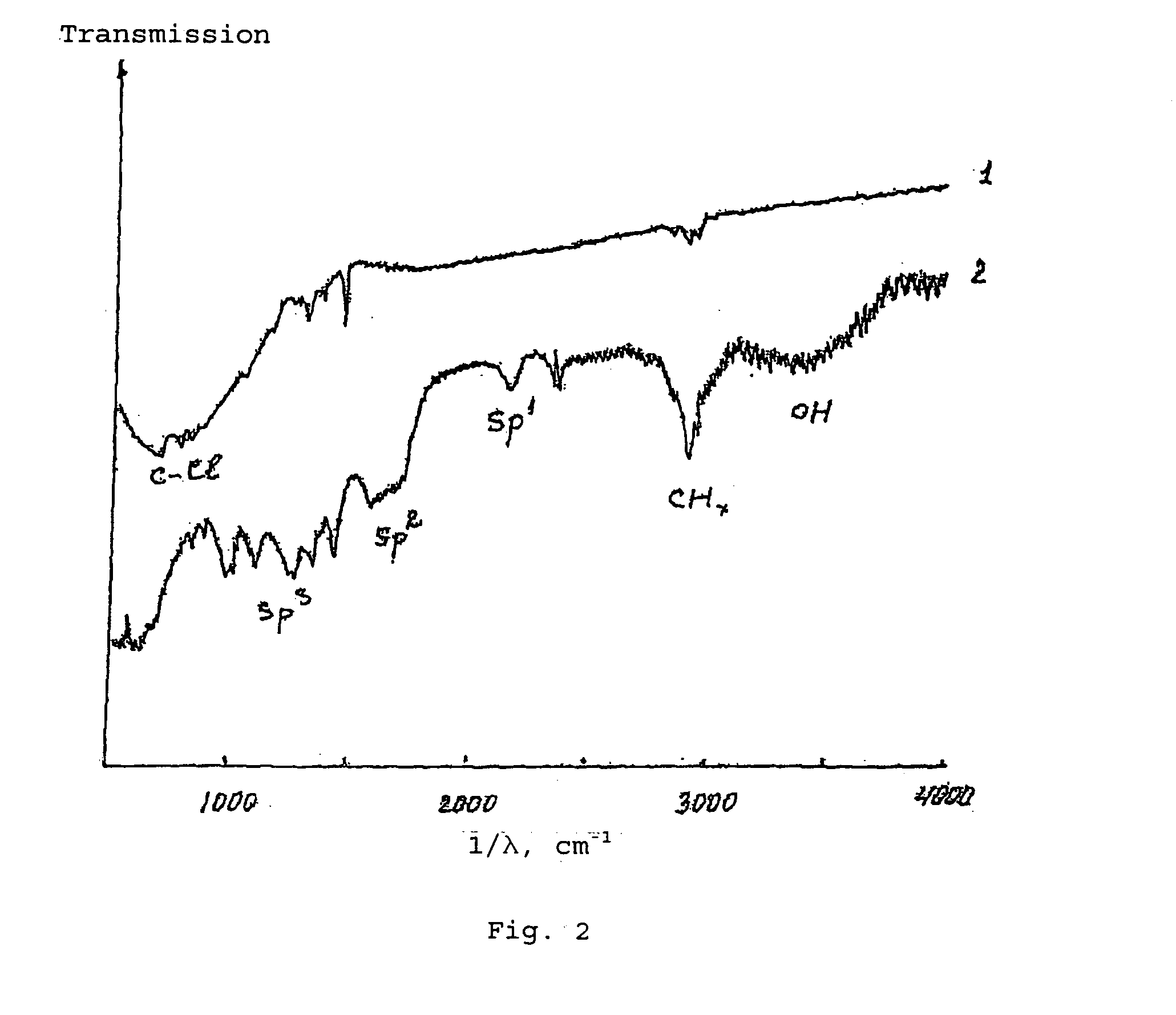

Metallic anode treated by carbon tetrafluoride plasma for organic light emitting device

InactiveUS20070046183A1Improve abilitiesEasy to makeDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceCarbon plasma

Owner:THE HONG KONG UNIV OF SCI & TECH

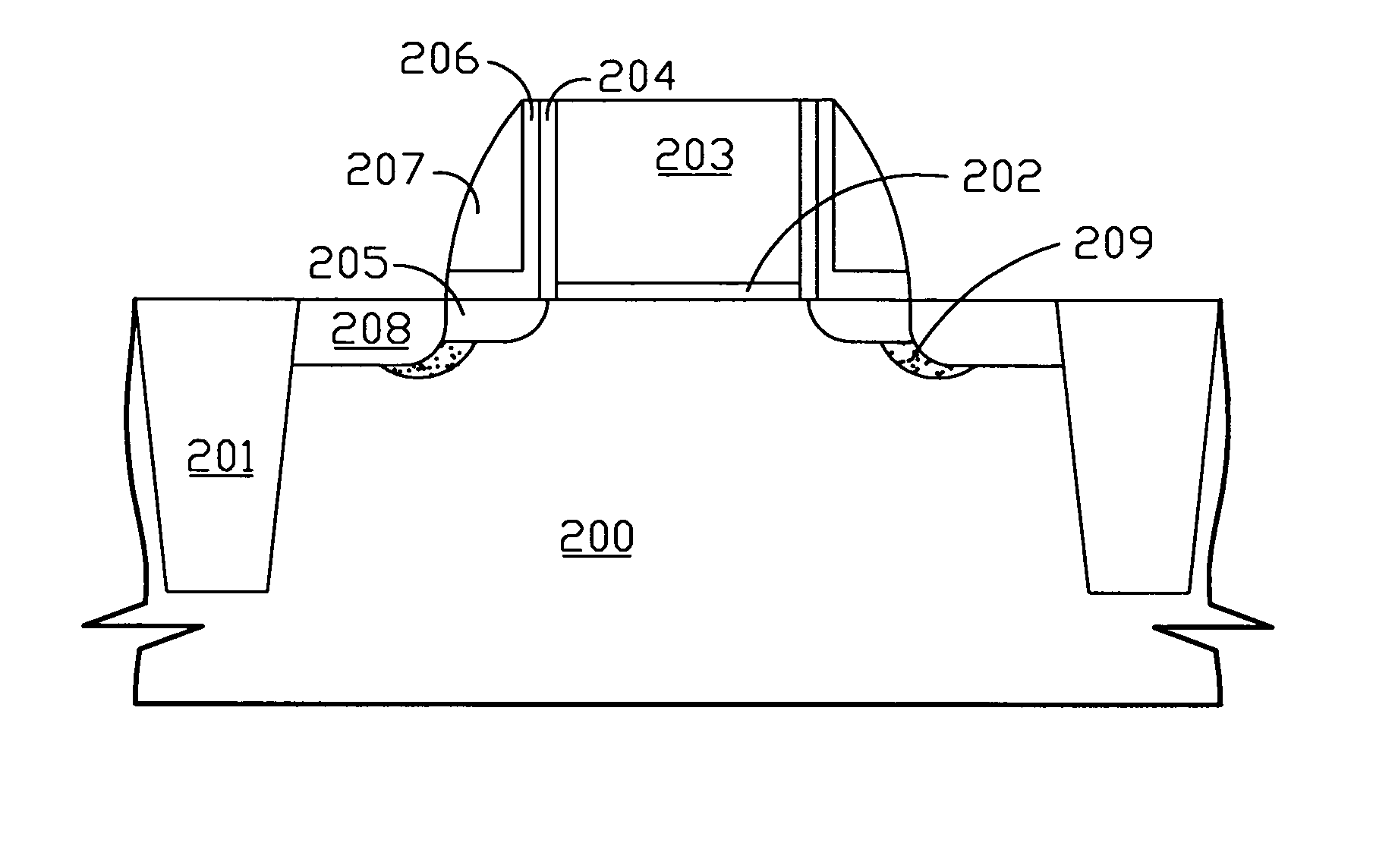

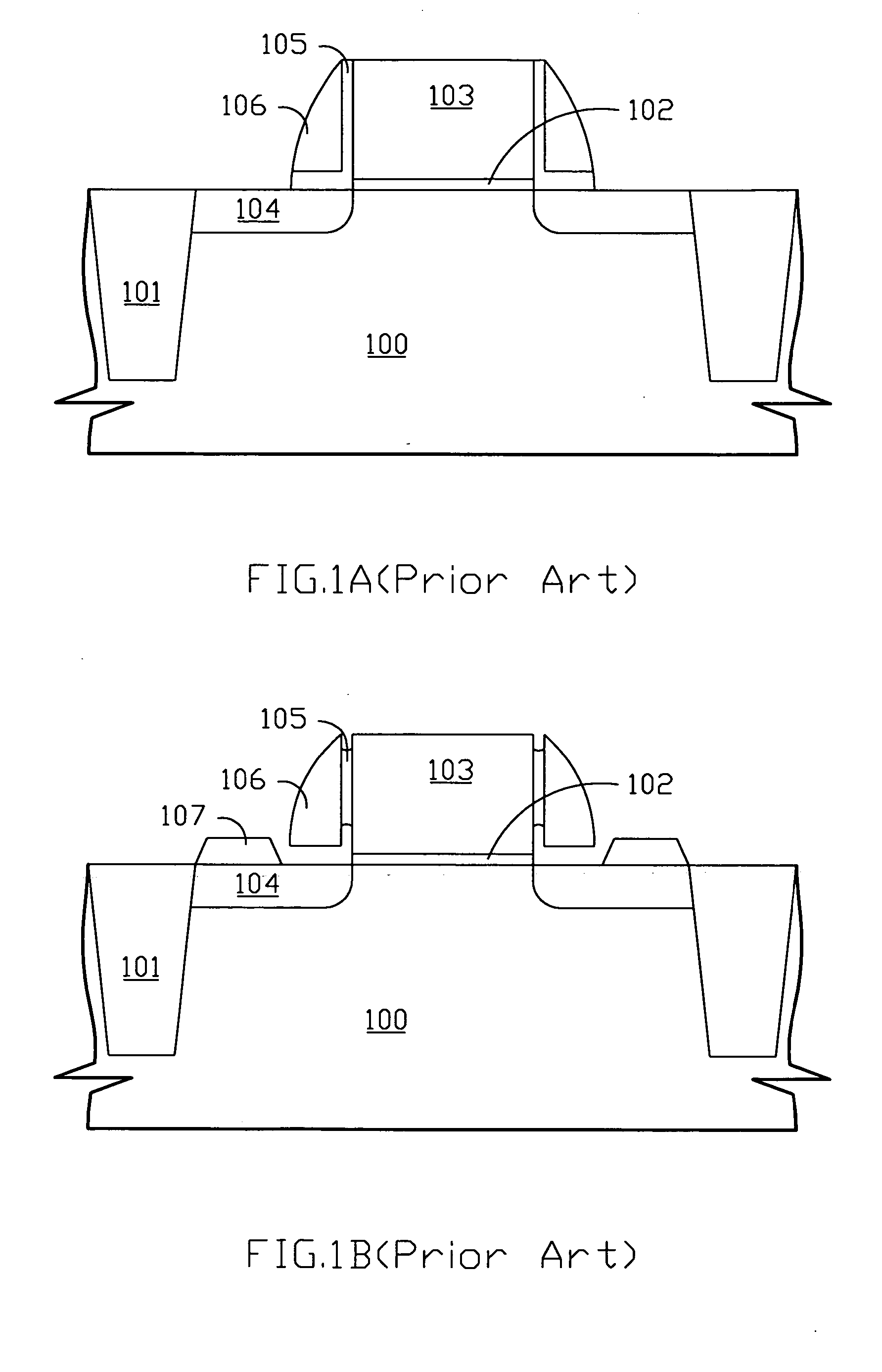

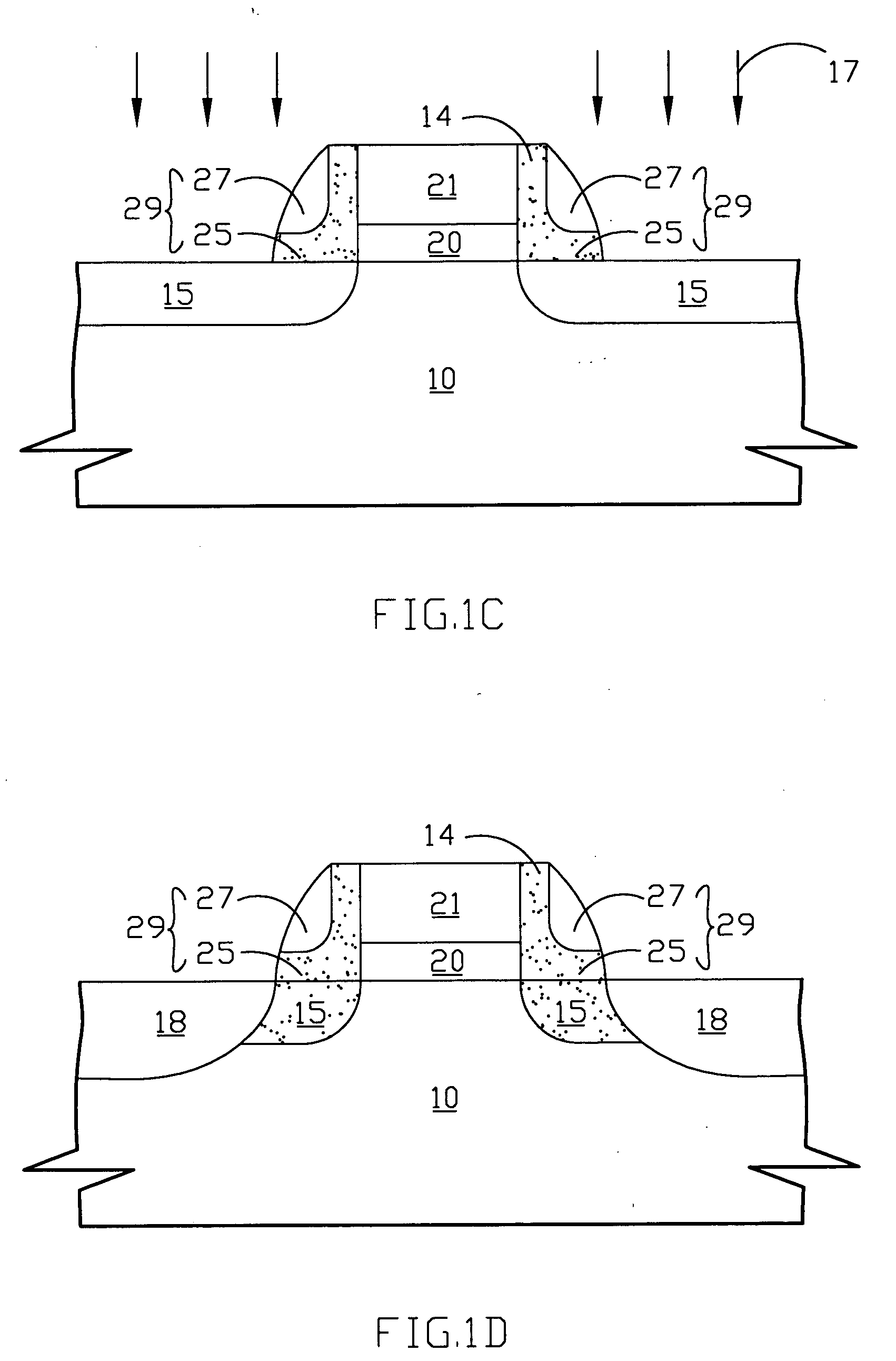

Method for forming a junction region of a semiconductor device

ActiveUS20050164461A1Improve leakage currentReduce harmSemiconductor/solid-state device manufacturingSemiconductor devicesDopantCarbon plasma

A method for forming a junction region of a semiconductor device is disclosed. The steps of the method include providing a semiconductor substrate. A gate structure is formed on the semiconductor substrate. A dopant is implanted into the semiconductor substrate to form the junction region. An insulator layer is formed on the gate structure and the semiconductor substrate. A carbon-containing plasma treatment is performed to the insulator layer. A spacer is formed on a side-wall of the gate structure and the dopant is implanted into the semiconductor substrate to form a source / drain region next to the junction region. A heat treatment is performed to the semiconductor substrate.

Owner:UNITED MICROELECTRONICS CORP

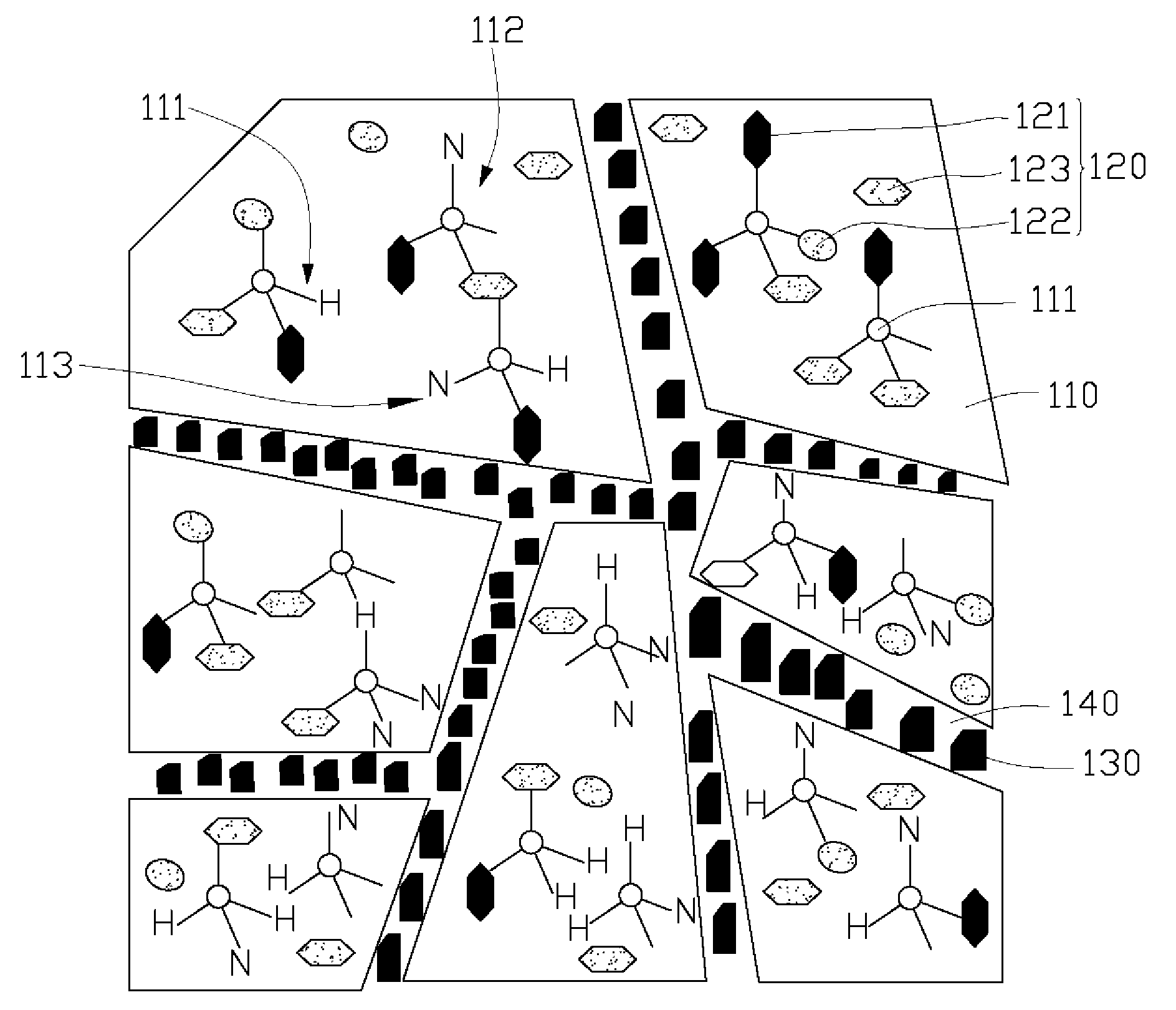

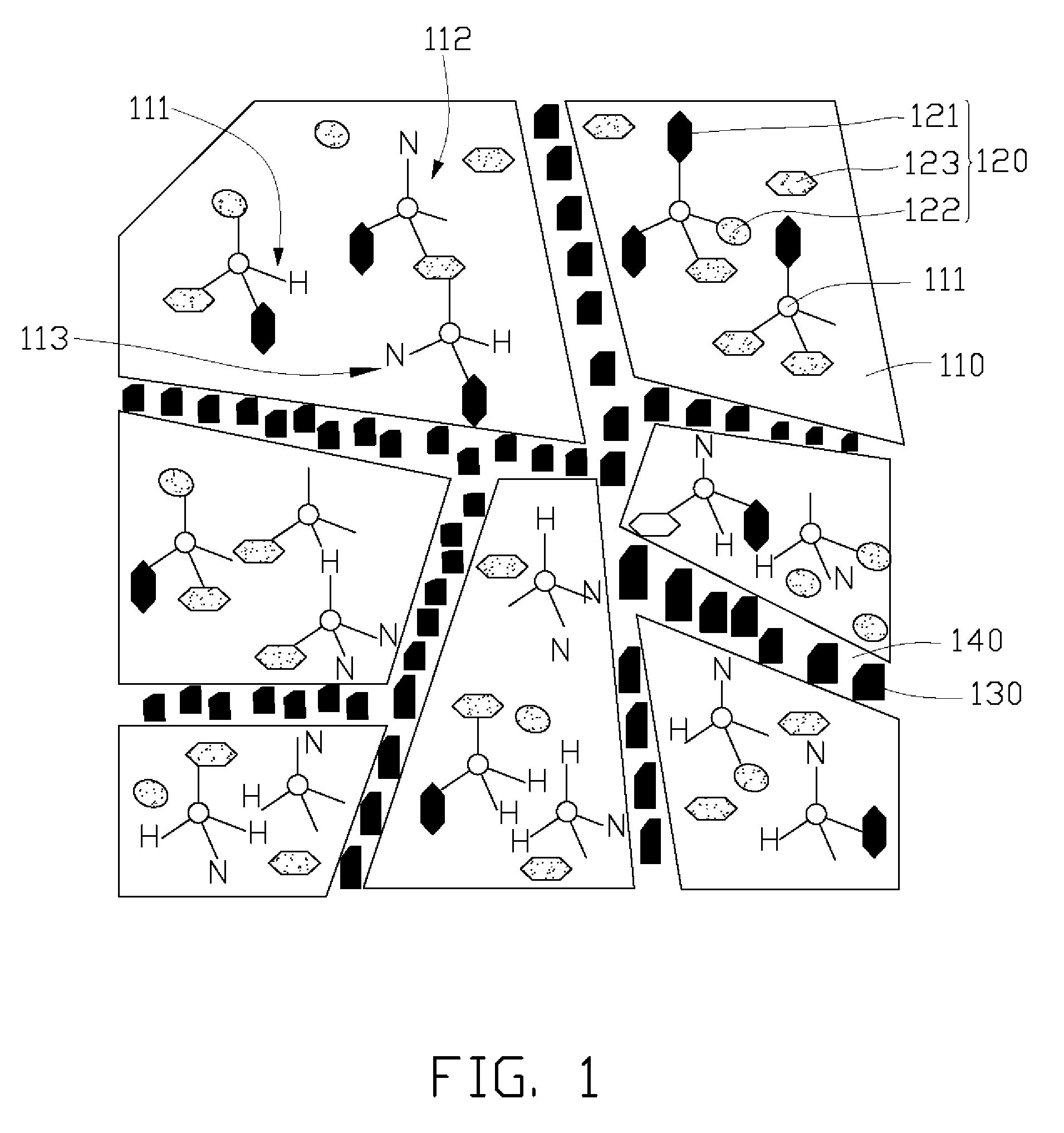

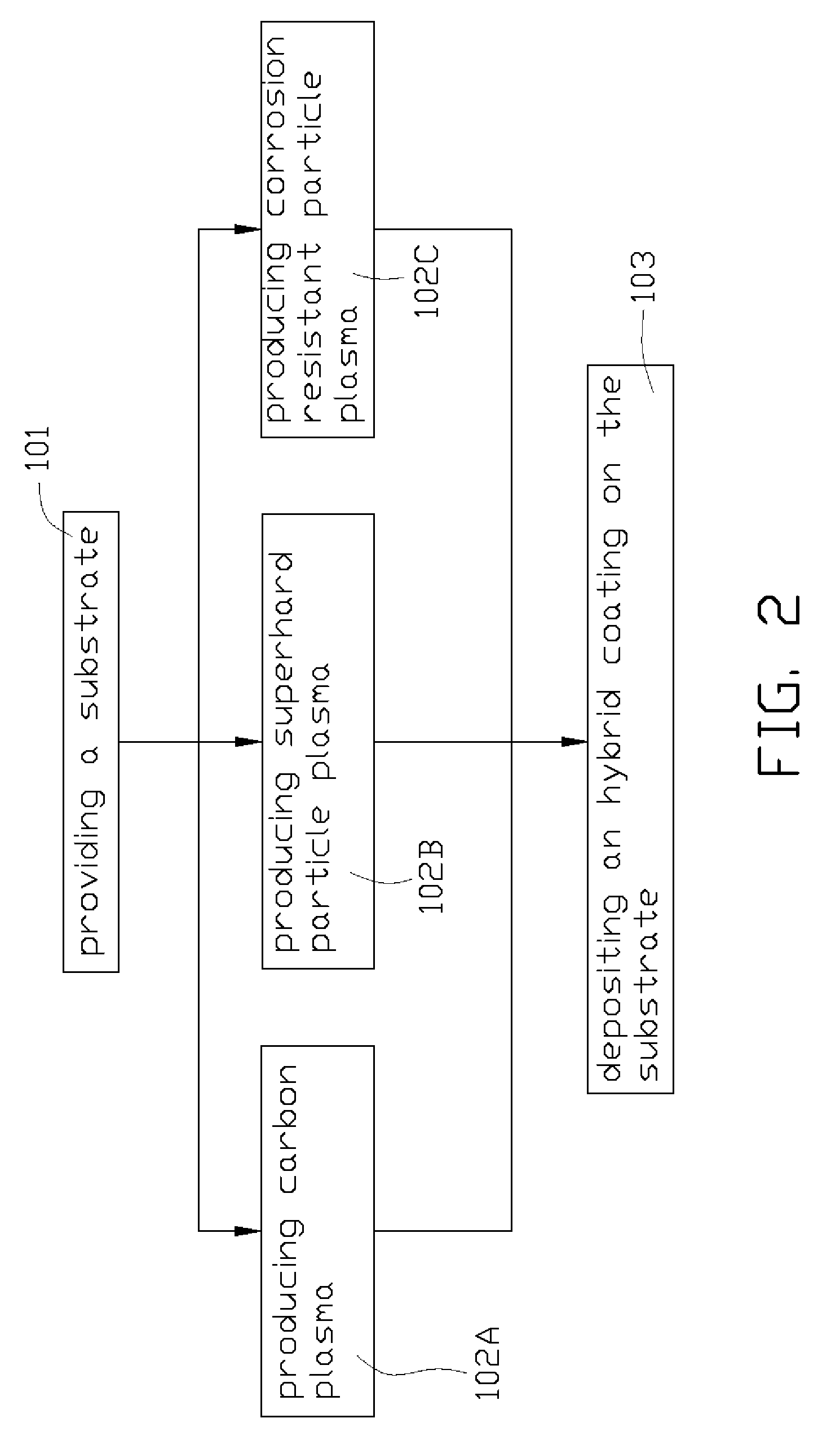

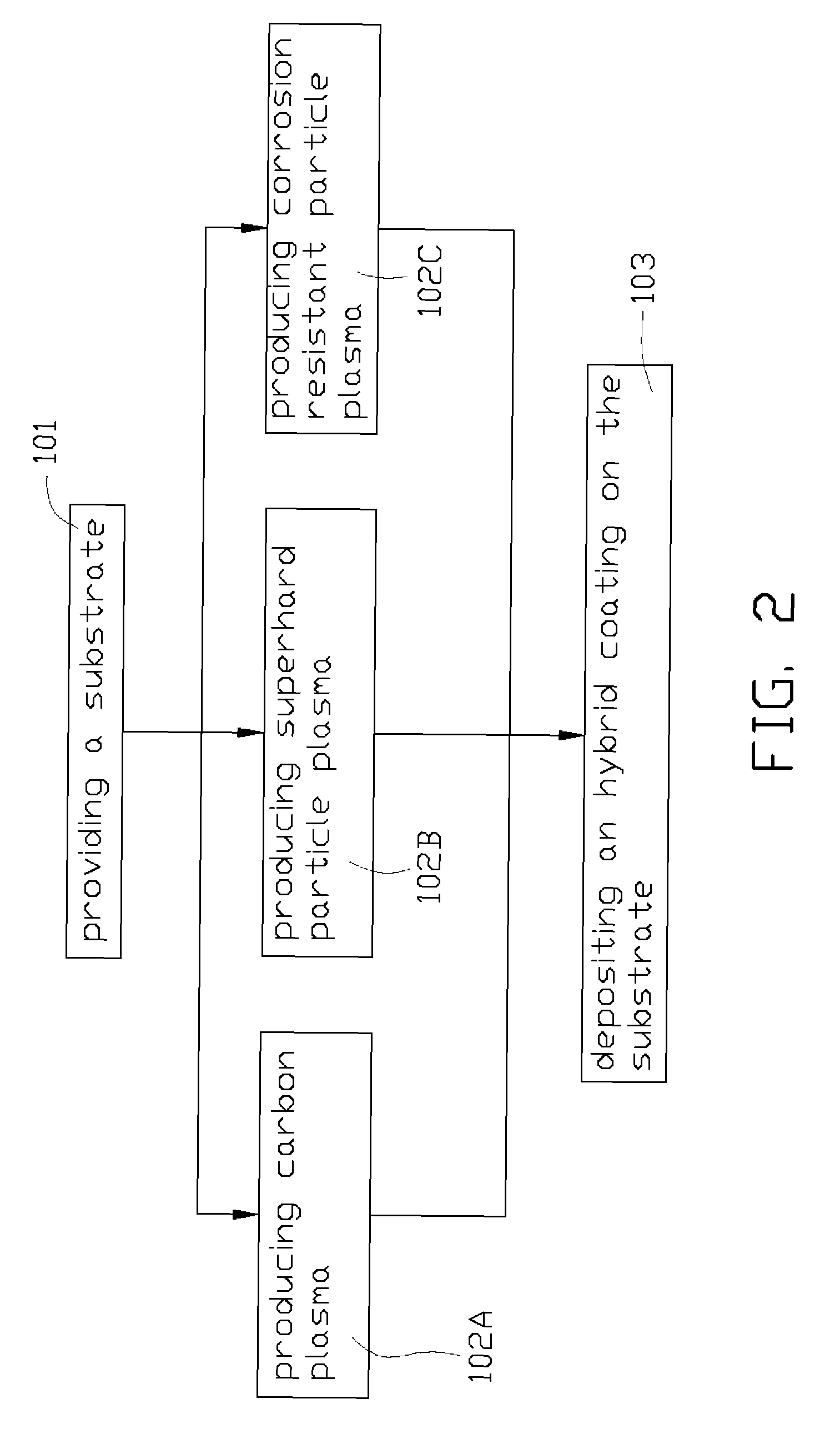

Hybrid coating structure and method for making the same

A hybrid coating structure (500) includes a substrate (510) and a hybrid coating (100). The hybrid coating further includes a number of diamond-like carbon grains (110), each grains containing a number of superhard nano-particles (120) incorporated therein; and a number of corrosion-resistant nano-particles (130). The superhard nano-particles are comprised of a material selected from the group consisting of silicon carbide, titanium carbide, and titanium nitride. The corrosion-resistant nano-particles are comprised of a material selected from the group consisting of chrome and chrome nitride. A method for making a hybrid coating structure includes steps of: providing a substrate; producing carbon plasma, superhard particle plasma and corrosion-resistant particle plasma by a sputtering method; and depositing a hybrid coating.

Owner:HON HAI PRECISION IND CO LTD

Method for forming a superhard amorphous carbon coating in vacuum

InactiveUS20070134436A1Increase compressive stressVacuum evaporation coatingSputtering coatingPulse streamCarbon plasma

A method for forming a superhard amorphous carbon coating in vacuum, comprising the steps of: placing an article in a vacuum chamber, evacuating the chamber, treating a surface for the article with accelerated ions; applying, on the treated surface, a layer of a material that provides adhesion for subsequent layers, initiating pulsed electric-arc discharge on a graphite cathode, and obtaining a pulsed carbon plasma stream from a plurality of cathode spots that move along the cathode surface. After that, the carbon plasma is condensed in a predetermined area on the article surface to produce a superhard amorphous carbon coating, the article temperature being maintained within the range of 200 to 450 K through controlling a repetition frequency of the electric-arc discharge pulses. According to the invention, the carbon plasma pulsed stream has average ion energy of 25-35 eV and ion concentration of 1012, 1013 cm−3; axis of the carbon plasma stream being set at angle of 15-45° to a predetermined surface of an article. During application of the coating, the article temperature change Δt is maintained within the range of 50-100 K.

Owner:ARGOR ALJBA

Method for preparing diamond-like carbon film by pulsed discharge deposition

InactiveCN102732851AExtended service lifeEasy to removeChemical vapor deposition coatingCarbon filmCarbon ion

The invention discloses a method for preparing a diamond-like carbon film by pulsed discharge deposition and belongs to the technical field of metal or nonmetal surface modification treatment. According to the method, DLC deposition is carried out on the surface of a workpiece by the adoption of pulsed arc discharge with graphite as the cathodic electrode and combined PVD and CVD methods for decomposition and ionization of hydrocarbon gas. The method comprises main operational steps of: ultrasonic cleaning, vacuum-pumping, ion cleaning and DLC deposition. During the ion cleaning process, argon is blown in. During the DLC deposition process, arc discharge pulse frequency is 5-35Hz, and voltage is 200-400V. A hydrocarbon gas which is blown in is preferably methane, ethane or propane. Through special pulsed arc discharge, high-speed and high-energy carbon plasma beam and the blown hydrocarbon gas molecules undergo impact ionization to increase carbon ion density and enhance diffraction performance. Therefore, DLC deposition speed is raised, adhesion is increased, internal stress is minimized, and precision and performance are improved.

Owner:陈卫

Enhanced cathodic arc source for arc plasma deposition

The invention provides an enhanced cathodic arc source for arc plasma deposition. An improved cathodic arc source and method of DLC film deposition with a carbon containing directional-jet plasma flowproduced inside of cylindrical graphite cavity with depth of the cavity approximately equal to the cathode diameter. The generated carbon plasma expands through the orifice into ambient vacuum resulting in plasma flow strong self-constriction. The method represents a repetitive process that includes two steps: the described above plasma generation / deposition step that alternates with a recovery step. This step provides periodical removal of excessive amount of carbon accumulated on the cavity wall by motion of the cathode rod inside of the cavity in direction of the orifice. The cathode rod protrudes above the orifice, and moves back to the initial cathode tip position. The said steps periodically can be reproduced until the film with target thickness is deposited. Technical advantages include the film hardness, density, and transparency improvement, high reproducibility, long duration operation, and particulate reduction.

Owner:VEECO INSTR

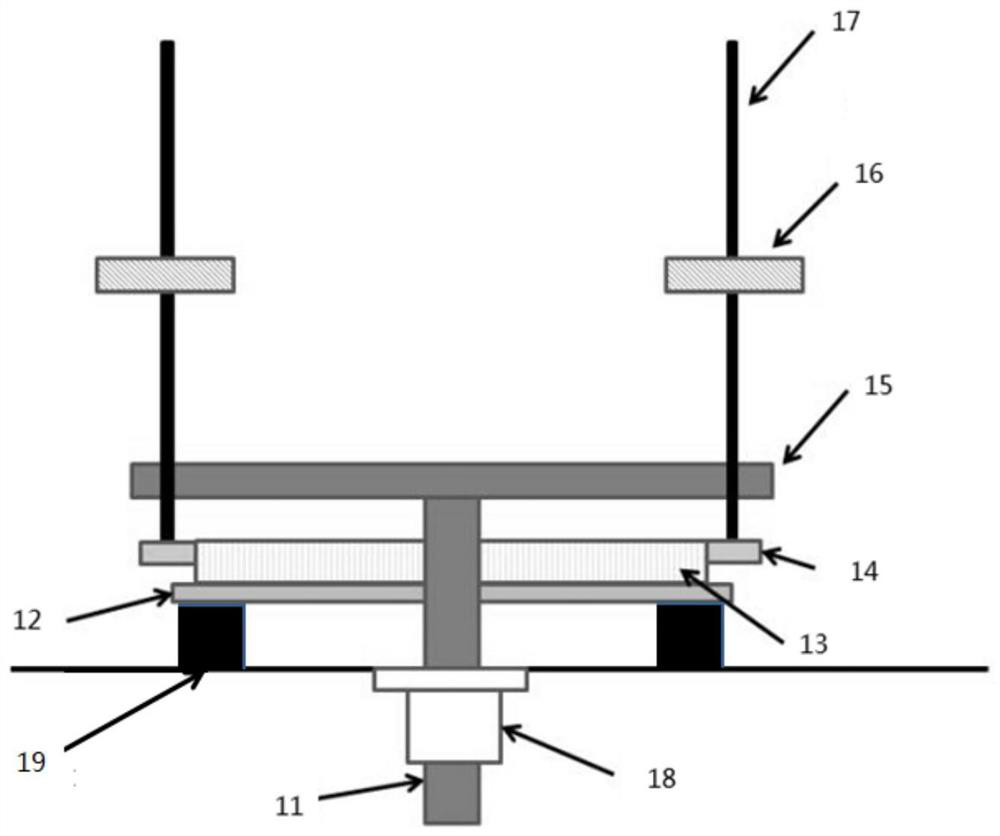

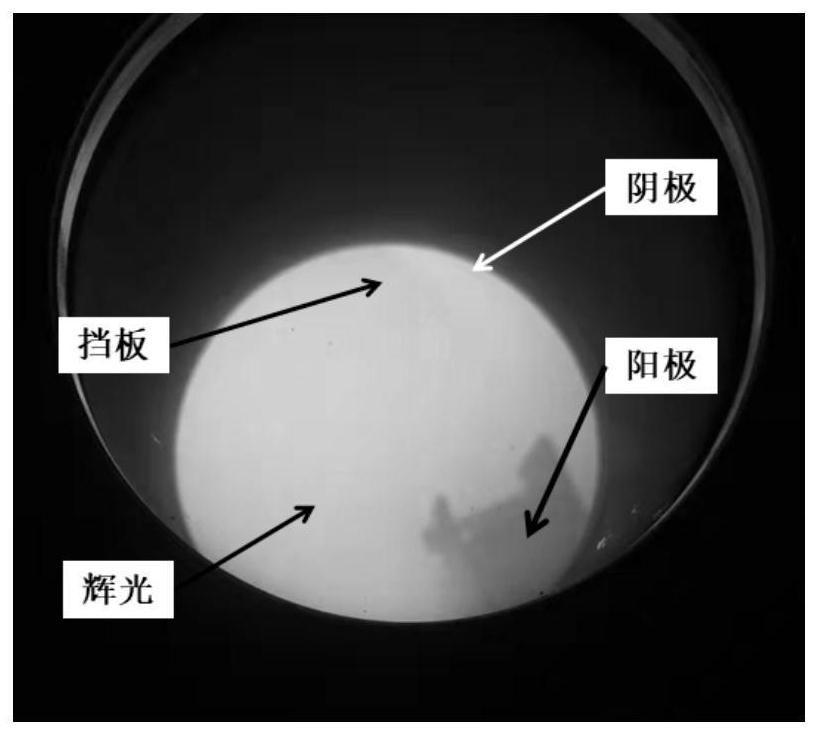

Device and method for depositing pure DLC (diamond-like carbon) by graphite cathode arc enhanced glow discharge

ActiveCN111748789ASolve the problem of "pollution"Achieve decouplingVacuum evaporation coatingSputtering coatingCarbon plasmaGraphite

The invention relates to a device and method for depositing pure DLC (diamond-like carbon) by graphite cathode arc enhanced glow discharge. The invention aims to solve the problem that metal elementspollute DLC when the DLC is prepared by existing metal cathode arc enhanced glow discharge. A discharge path is constructed between a graphite cathode arc and an anode, carbon-containing gas is introduced into the discharge path, and the introduced carbon-containing gas is ionized by high-density electrons emitted by the graphite cathode arc and deposited on the surface of a workpiece to form thepure DLC. The proportion of ions to atoms in carbon-containing plasma can be controlled by changing a discharge mode between the cathode and the anode and adjusting discharge parameters. By the deviceand the method, the adverse effect of metal doping on tribological properties is avoided when the DLC is prepared by metal target enhanced glow discharge. The device and method are applied to the field of preparation of the DLC by plasma enhanced chemical vapor deposition.

Owner:HARBIN INST OF TECH

Method for manufacturing diamondoid composite diaphragm of loudspeaker

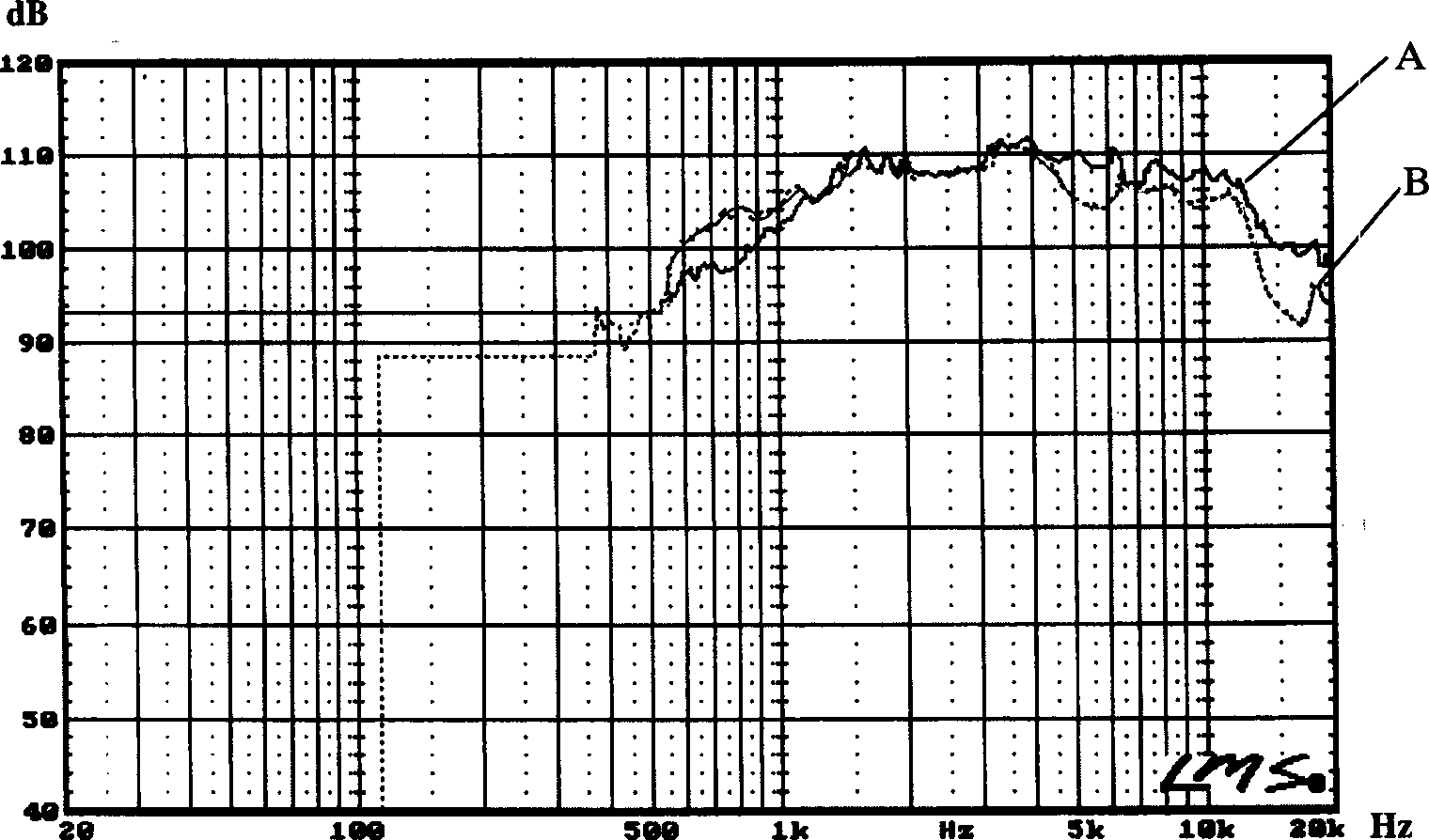

InactiveCN100397953CQuality improvementImprove bindingVacuum evaporation coatingSputtering coatingCarbon plasmaSound quality

The vacuum-cathode arc source is adopted in the invention and the graphite is as the target cathode. Using the carbon plasma generated by the vacuum-cathode graphite arc deposits the diamond-like film on the diaphragm to be coated. The ivnention can produce in batch size of the compound speaker diaphragm coated with diamond like film in various shape specifications with good performances. The invention raises the frequency response characteristics of the speakers and improves the sound quality.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

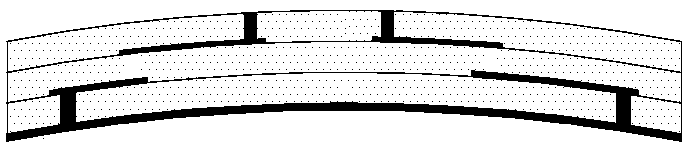

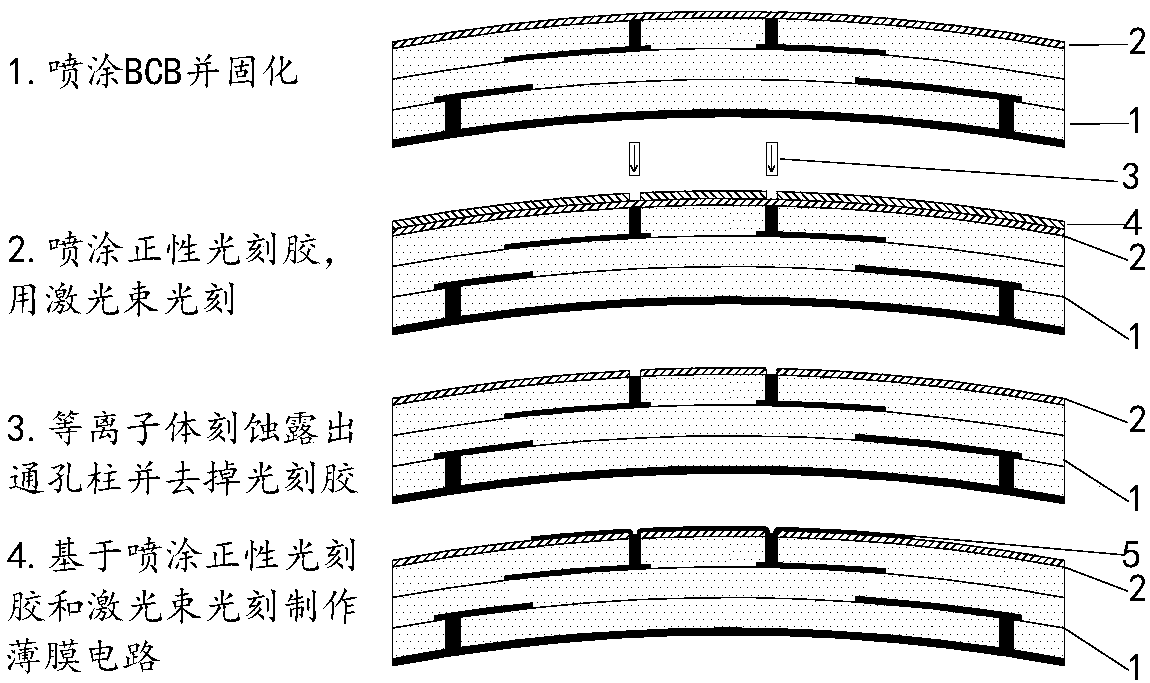

Method for fabricating thin film circuits on warped co-fired ceramic substrate

ActiveCN107871704AEnsure normal preparationReliable Inorganic-Organic Interface AdhesionSemiconductor/solid-state device manufacturingTemperature curveNitrogen atmosphere

The invention discloses a method for fabricating thin film circuits on a warped co-fired ceramic substrate in a polishing-free manner. The method comprises the following steps of 1), spraying the warped co-fired ceramic substrate with a BCB glue solution, and then performing solidification in a nitrogen atmosphere furnace according to a BCB solidification temperature curve; 2), spraying a solidified BCB medium layer with positive photoresist, exposing the positive photoresist over against a through hole column by using laser beams after pre-baking, performing development to remove the exposedpositive photoresist over against the through hole column, and performing post-baking on the photoresist; 3), etching a BCB medium by using oxygen / carbon tetrafluoride plasmas to expose the through hole column, and then removing a residual photoresist mask by using the oxygen plasmas or a photoresist removal solution; 4), based on the positive photoresist spraying and the laser beam photoetching,making a thin film circuit of a bottom layer; and 5), based on the positive photoresist spraying and the laser beam photoetching, making thin film circuits of subsequent layers.

Owner:苏州华博电子科技有限公司

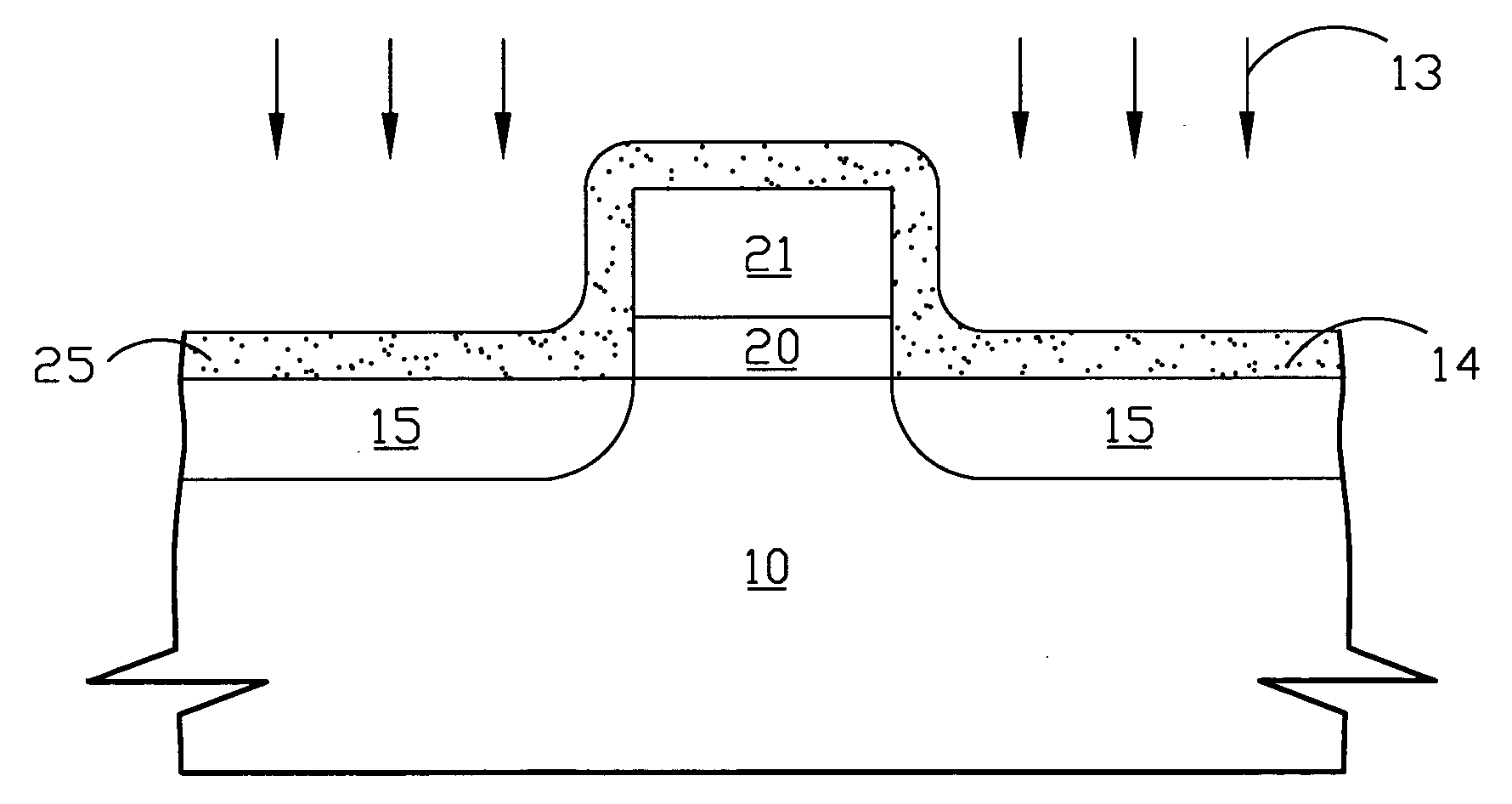

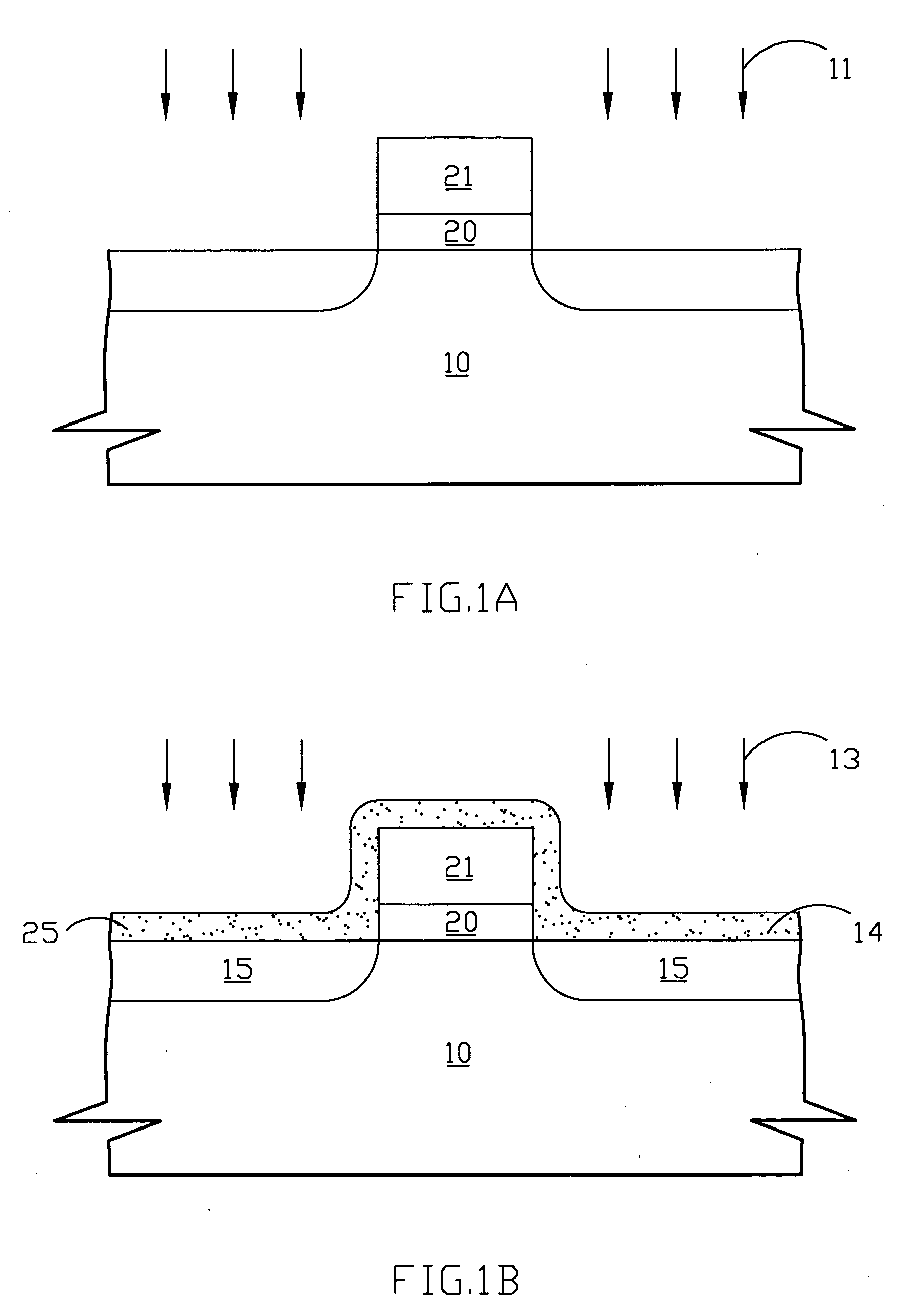

Plasma processing method and plasma ashing apparatus

InactiveUS20130019894A1Prevent and reduce damageProcessing speedElectric discharge tubesElectrostatic cleaningResistNoble gas

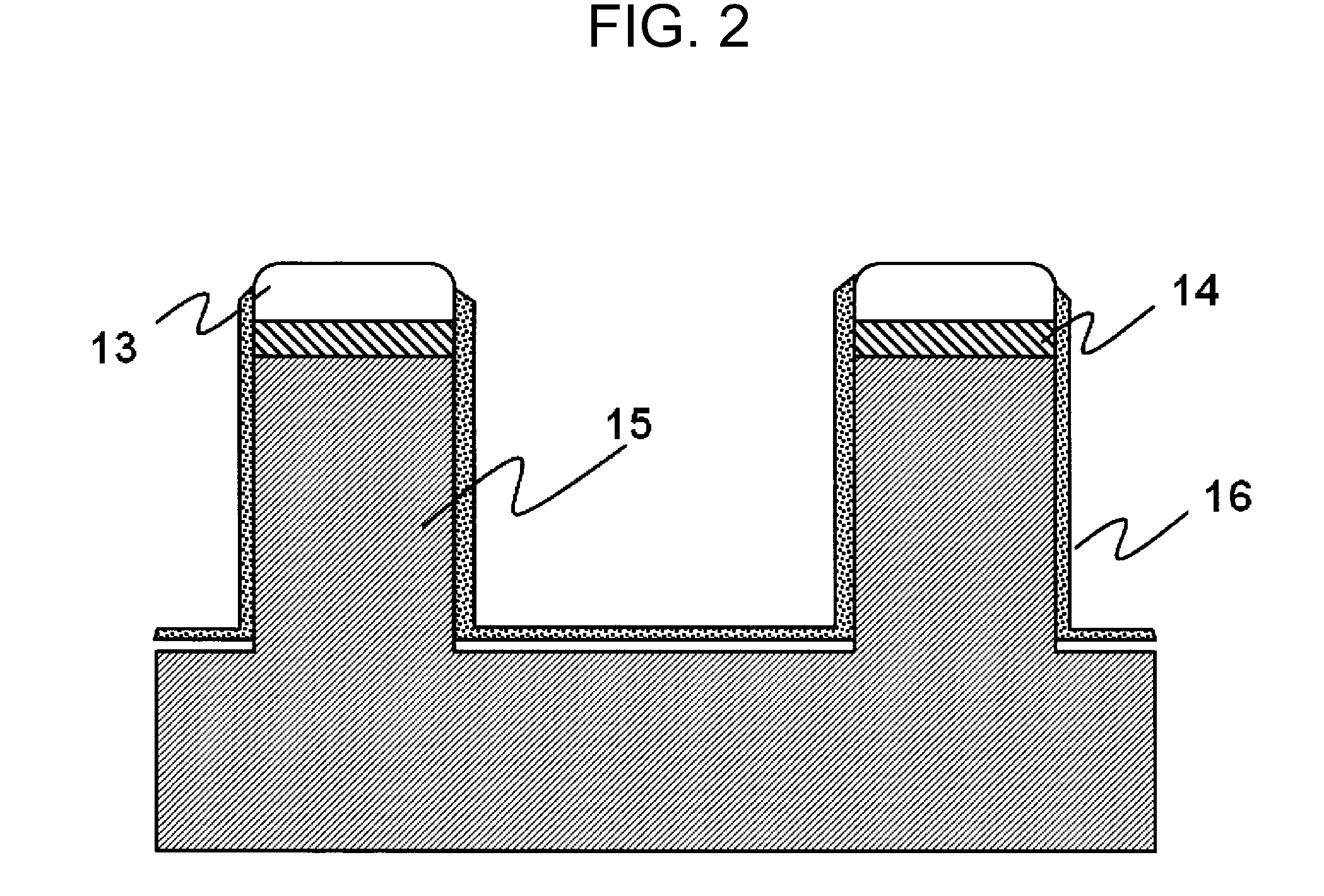

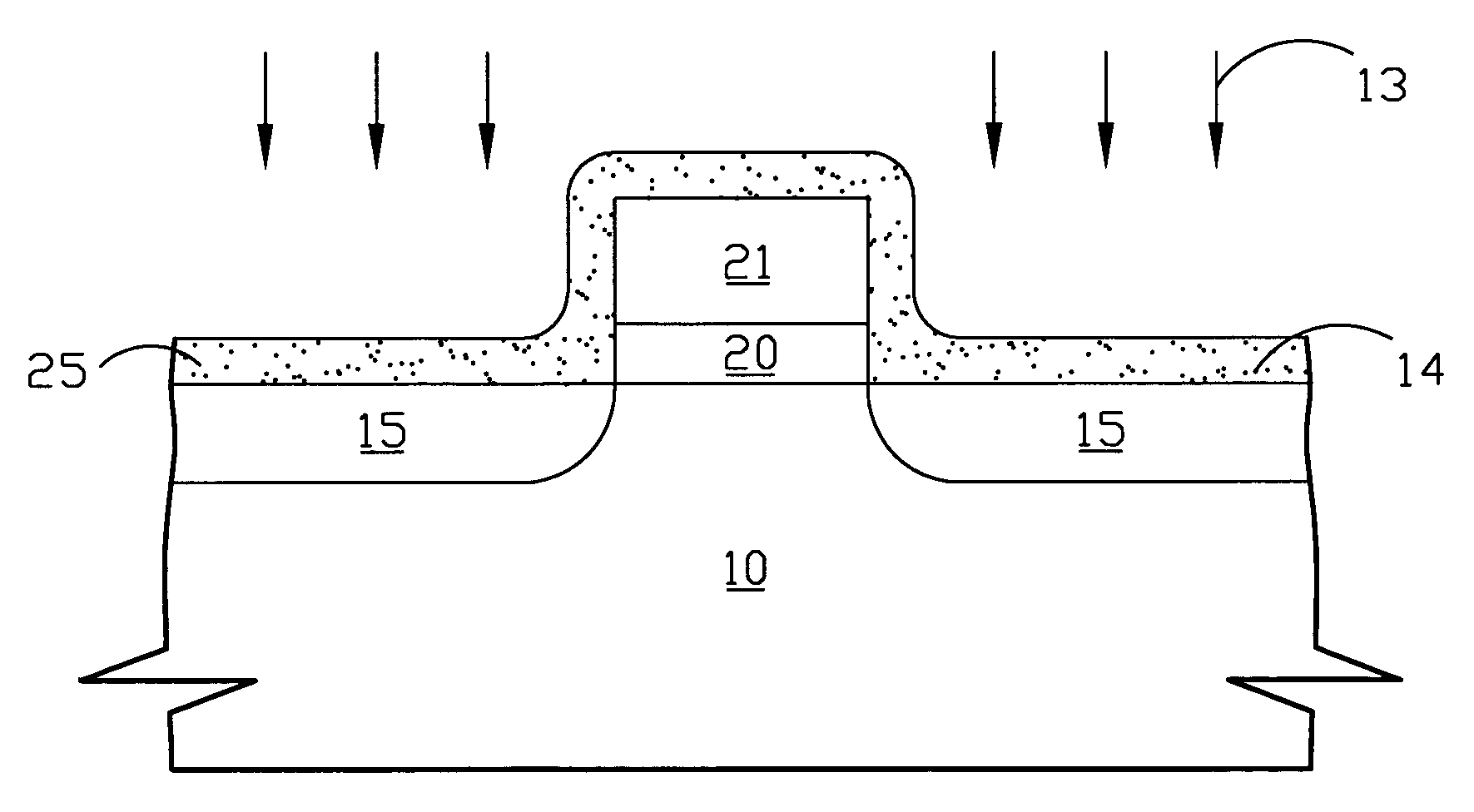

In a plasma ashing processing on a sample including a Low-k film, a processing method that can prevent or reduce a film damage on the Low-k film while performing a high speed ashing processing is provided. A plasma processing method for performing a plasma processing on the sample including a Low-k film 15 includes: a step of performing plasma etching on the sample; and a step of performing plasma ashing on the sample including the Low-k film 15 with a resist mask 13, a carbon hard mask 14, and by-products 16 that have been subjected to plasma etching in the plasma etching process by a carbon (C+) radical 18 and a hydrogen (H+) radical 20 generated from methane (CH4) gas 19, using mixed gas including the methane (CH4) gas 19, which is hydrocarbon gas, and argon (Ar) gas, which is noble gas.

Owner:HITACHI HIGH-TECH CORP +1

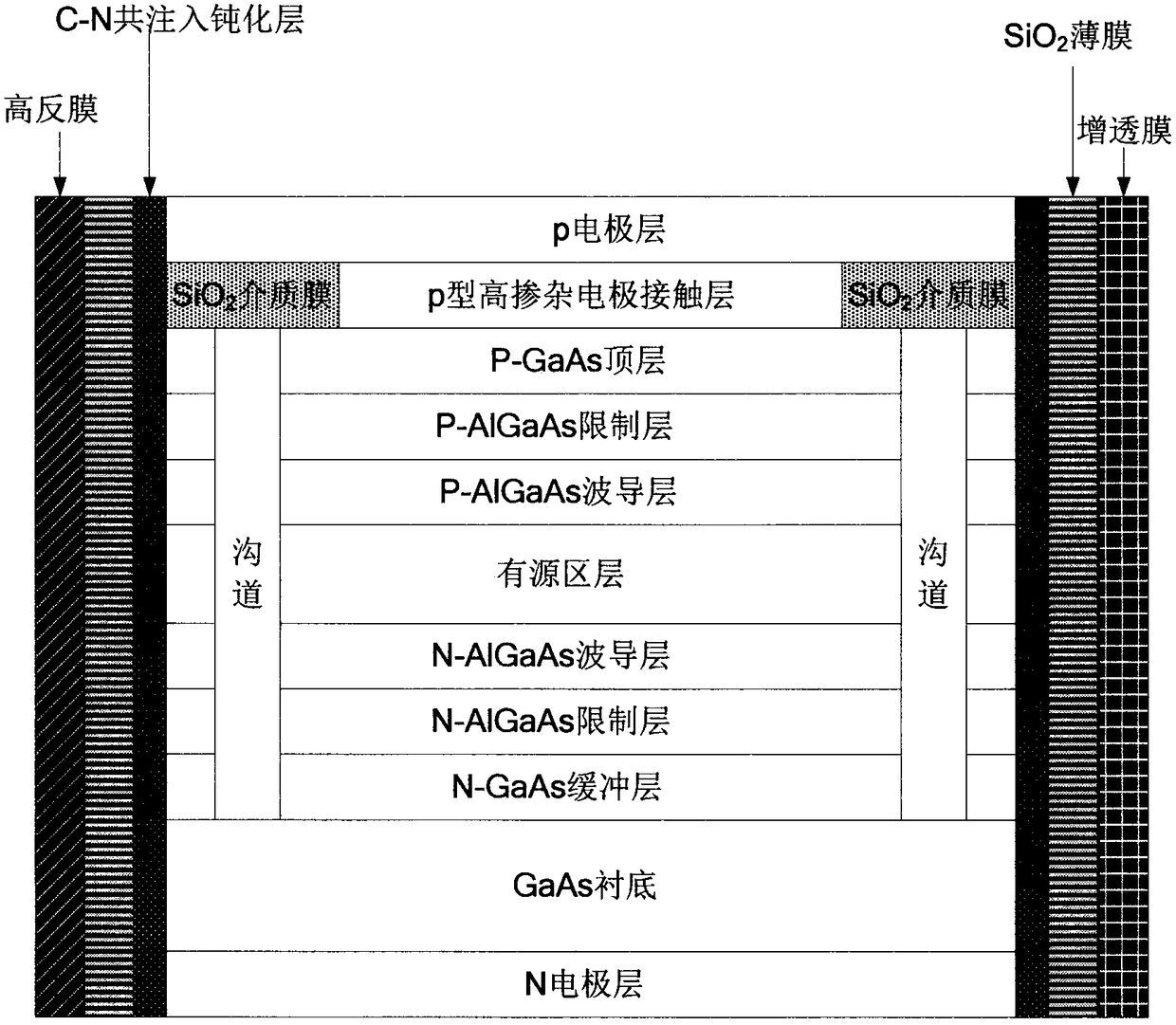

Method for passivating cavity surface of semiconductor laser and semiconductor laser

ActiveCN109066287AImprove reliabilityImprove the level of resistance to optical catastropheLaser detailsLaser optical resonator constructionNitrogen plasmaIon bombardment

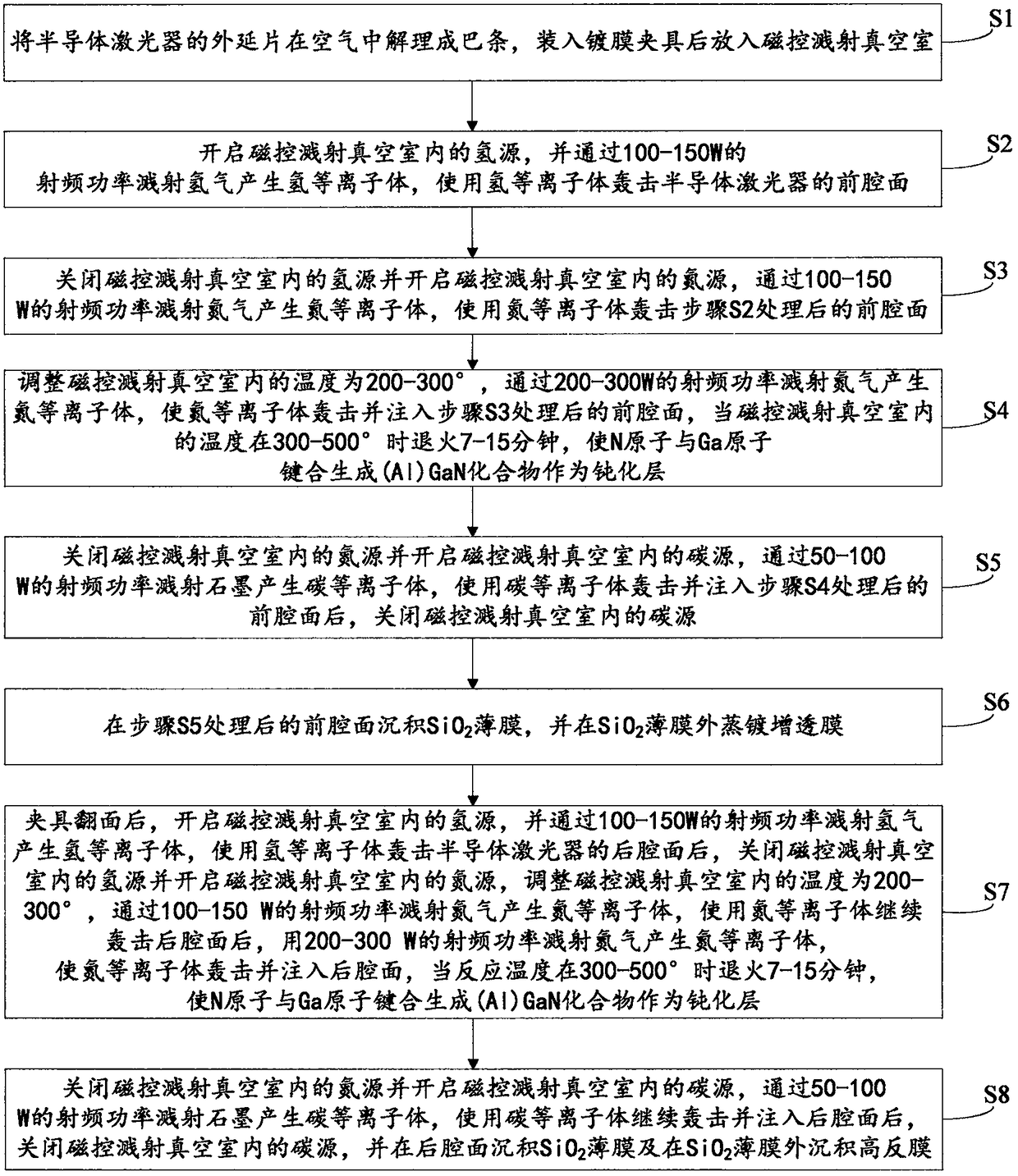

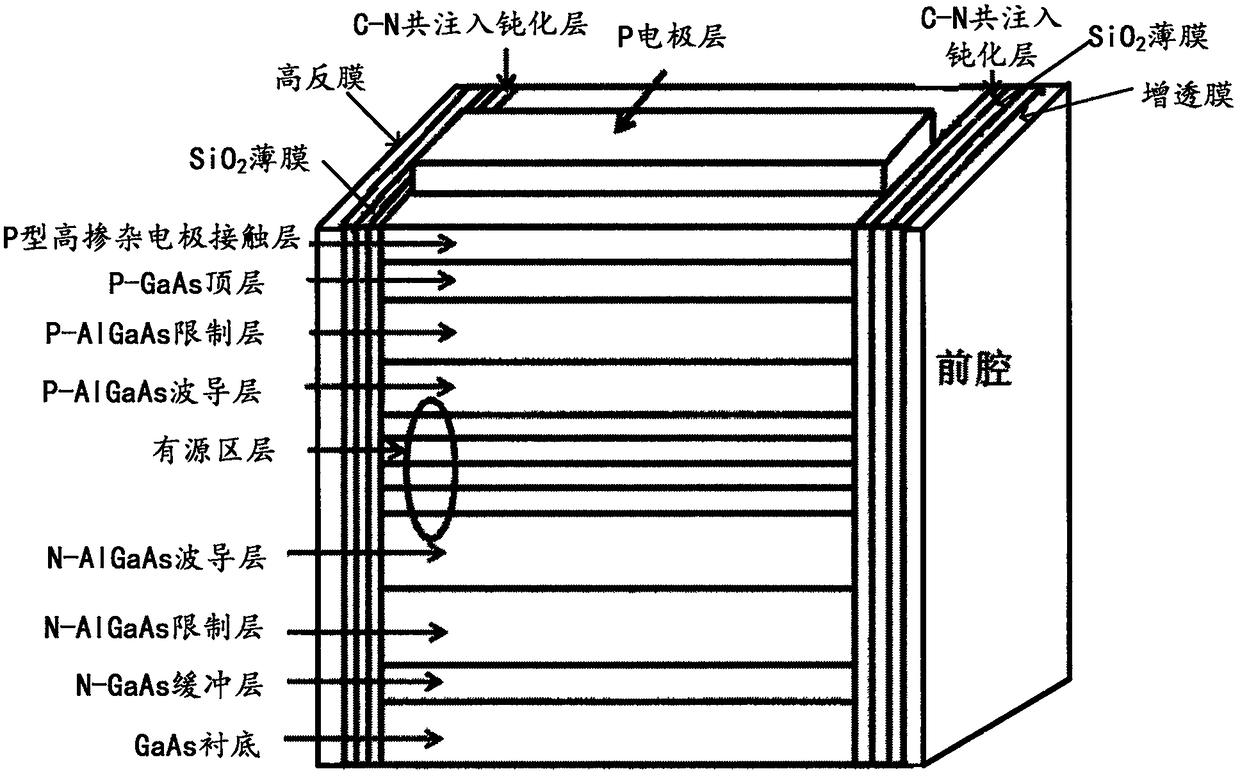

The invention provides a passivation method of a semiconductor laser cavity surface and a semiconductor laser, belonging to the field of semiconductor lasers. By bombarding and injecting nitrogen plasma into the front and back cavity surfaces of semiconductor lasers, the hanging bonds on the cavity surface can be fully bonded to N atoms, which can not only passivate N atoms, but also cause the formation of Ga-N bond is more stable; By bombarding and implanting the front and back cavity surfaces with carbon plasma, C atoms are fully combined with the new broken bonds produced by nitrogen ion bombardment, which compensates the surface damage of the cavity surface and ensures the saturation and stability of the hanging bonds of the cleavage cavity surface. Therefore, the invention not only simplifies the process steps of cavity surface passivation, reduces the process flow time, reduces the production cost, but also improves the anti-optical catastrophe level of the semiconductor laser and the reliability of stable output under the condition of high optical power density, and realizes the purpose of high power and long service life of the semiconductor laser.

Owner:SHANXI FEIHONG LASER TECH +1

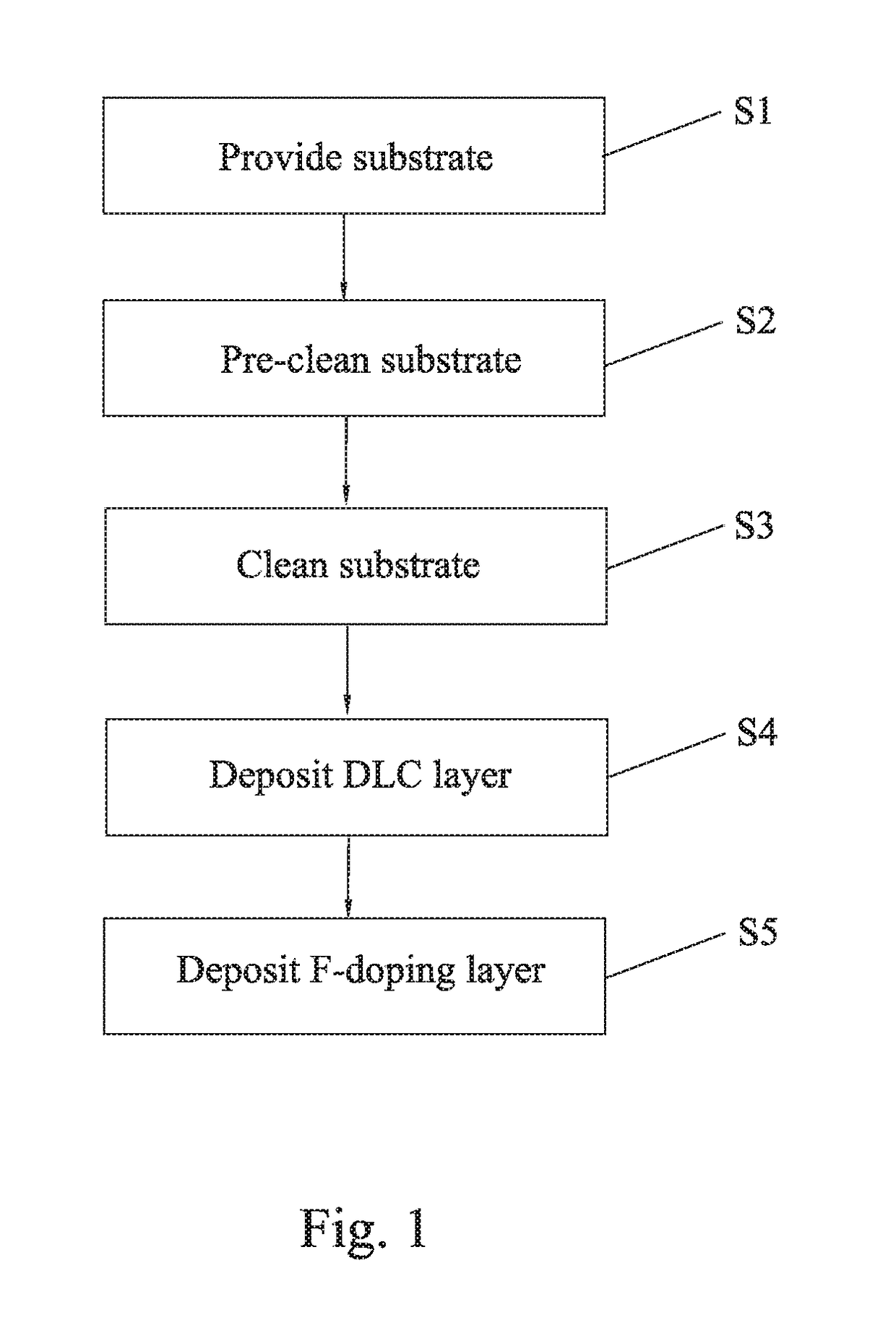

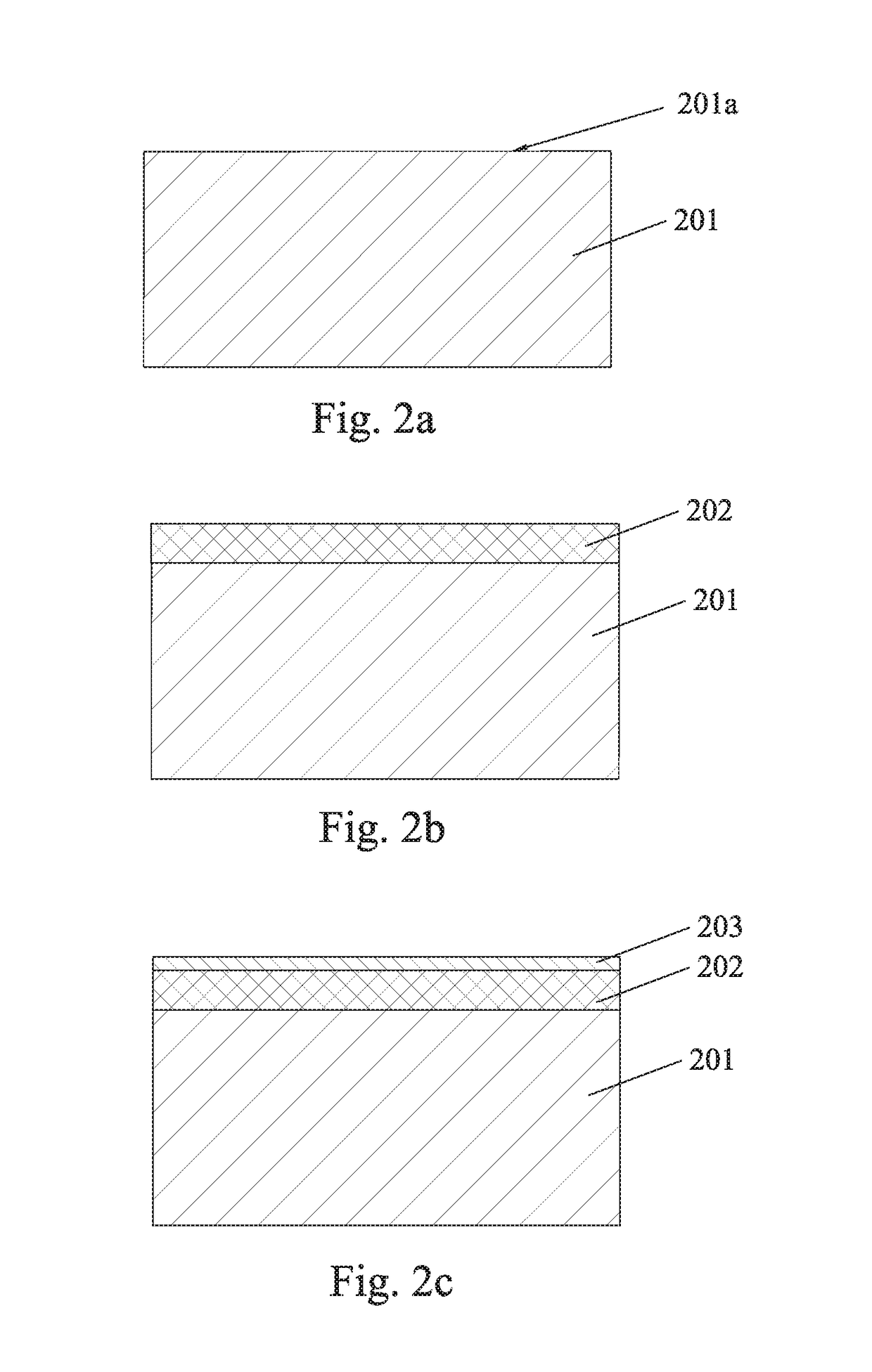

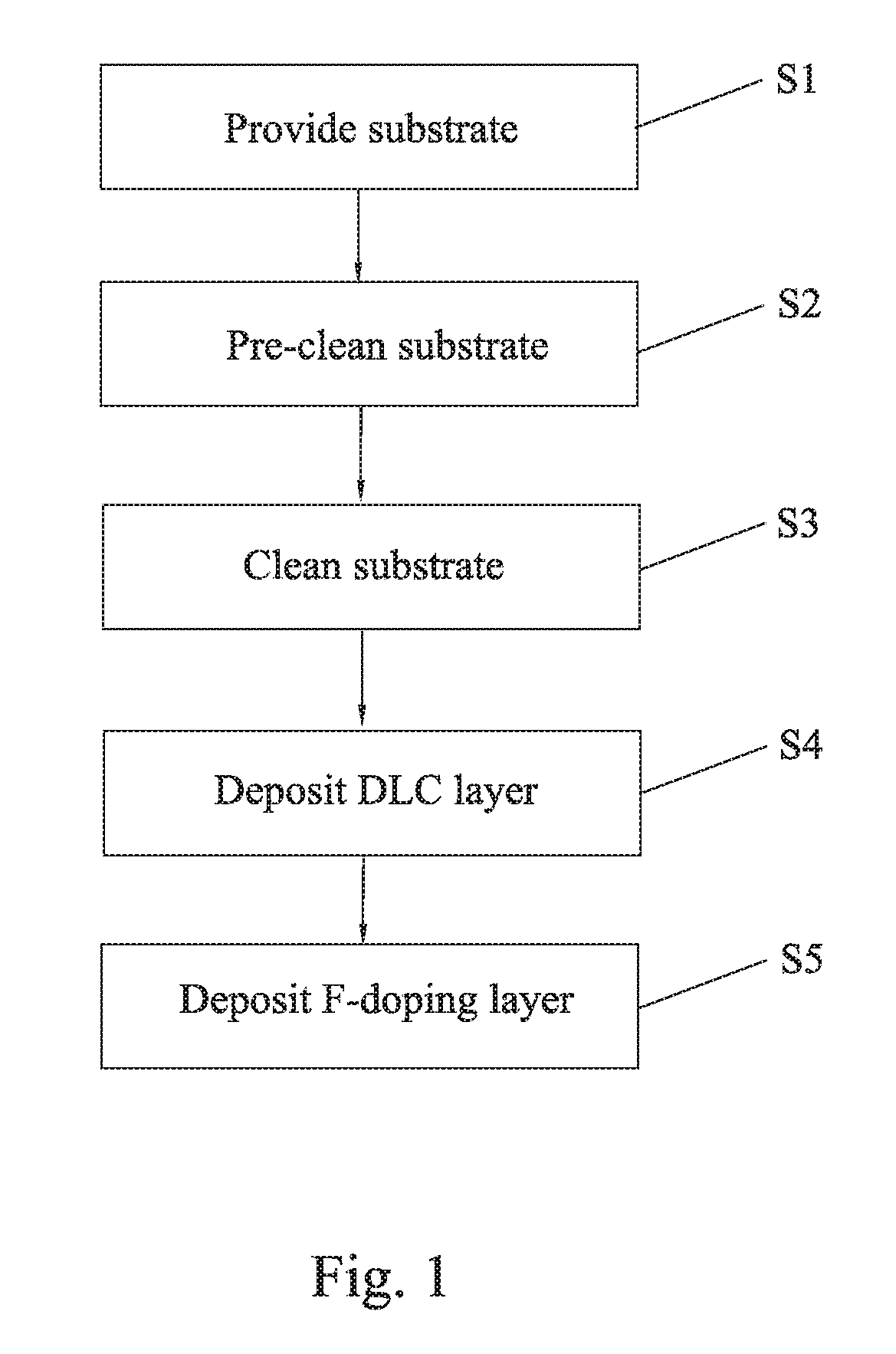

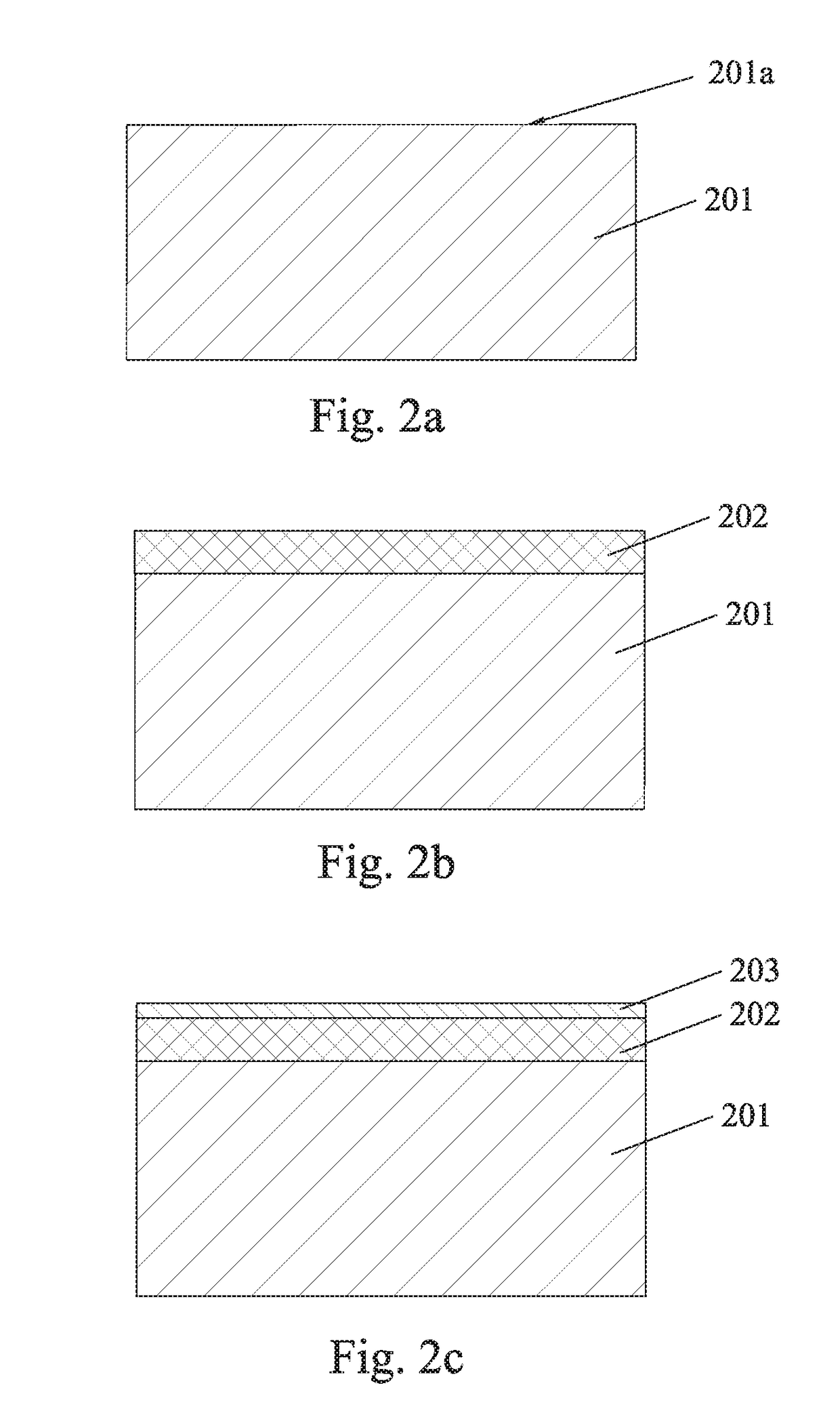

Manufacturing method for a head slider coated with dlc

ActiveUS20170283939A1Improve adhesionHigh hardnessManufacture head surfaceVacuum evaporation coatingDlc coatingSputtering

A manufacturing method for a head slider coated with Diamond-like Carbon (DLC) includes: providing a substrate that is to be finally made into a head slider; depositing a DLC layer on a surface of the substrate, with carbon plasma source being sputtered in a direction that is vertical to the surface of the substrate; and doping a fluorine-doping (F-doping) layer on the DLC layer. Whereby the head slider has good film adhesion performance, higher hardness, better wear resistance, lower surface energy to obtain good hydrophobicity and oleophobicity, and lower fly height in HDD.

Owner:SAE MAGNETICS (HK) LTD

A method for forming a superhard amorphous carbon coating in vacuum

InactiveCN1795285AExtended service lifeGood biocompatibilityVacuum evaporation coatingSputtering coatingCarbon plasmaGraphite

A method for forming a superhard amorphous carbon coating in vacuum, comprising the steps of: placing an article in a vacuum chamber, evacuating the chamber, treating a surface for the article with accelerated ions; applying, on the treated surface, a layer of a material that provides adhesion for subsequent layers, initiating pulsed electric-arc discharge on a graphite cathode, and obtaining a pulsed carbon plasma stream from a plurality of cathode spots that move along the cathode surface. After that, the carbon plasma is condensed in a predetermined area on the article surface to produce a superhard amorphous carbon coating, the article temperature being maintained within the range of 200 to 450 K through controlling a repetition frequency of the electric-arc discharge pulses. According to the invention, the carbon plasma pulsed stream has average ion energy of 25-35 eV and ion concentration of 1012, 1013 cm-3; axis of the carbon plasma stream being set at angle of 15-45° to a predetermined surface of an article. During application of the coating, the article temperature change Deltat is maintained within the range of 50-100 K.

Owner:ARGOR ALJBA

Method for forming amorphous carbon film on surface of plastic substrate

ActiveCN109023232AAchieve surface activationImprove functional protection applicationsVacuum evaporation coatingSputtering coatingOrganic structureCarbon plasma

The invention discloses a method for forming an amorphous carbon film on the surface of a plastic substrate. Firstly, the surface of the plastic substrate is pretreated by an argon plasma under the electric field effect to realize surface activation of the plastic substrate, then the surface of the plastic substrate is subjected to continuous sputtering bombarding through a carbon plasma, and gradual conversion from an organic structure on the surface of the plastic substrate to an inorganic structure is achieved by controlling the carbon plasma bombardment time. The amorphous carbon film having good binding force with the substrate is formed, and the functionalized protective application of the amorphous carbon film to the plastic substrate is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hybrid coating structure

A hybrid coating structure (500) includes a substrate (510) and a hybrid coating (100). The hybrid coating further includes a number of diamond-like carbon grains (110), each grains containing a number of superhard nano-particles (120) incorporated therein; and a number of corrosion-resistant nano-particles (130). The superhard nano-particles are comprised of a material selected from the group consisting of silicon carbide, titanium carbide, and titanium nitride. The corrosion-resistant nano-particles are comprised of a material selected from the group consisting of chrome and chrome nitride. A method for making a hybrid coating structure includes steps of: providing a substrate; producing carbon plasma, superhard particle plasma and corrosion-resistant particle plasma by a sputtering method; and depositing a hybrid coating.

Owner:HON HAI PRECISION IND CO LTD

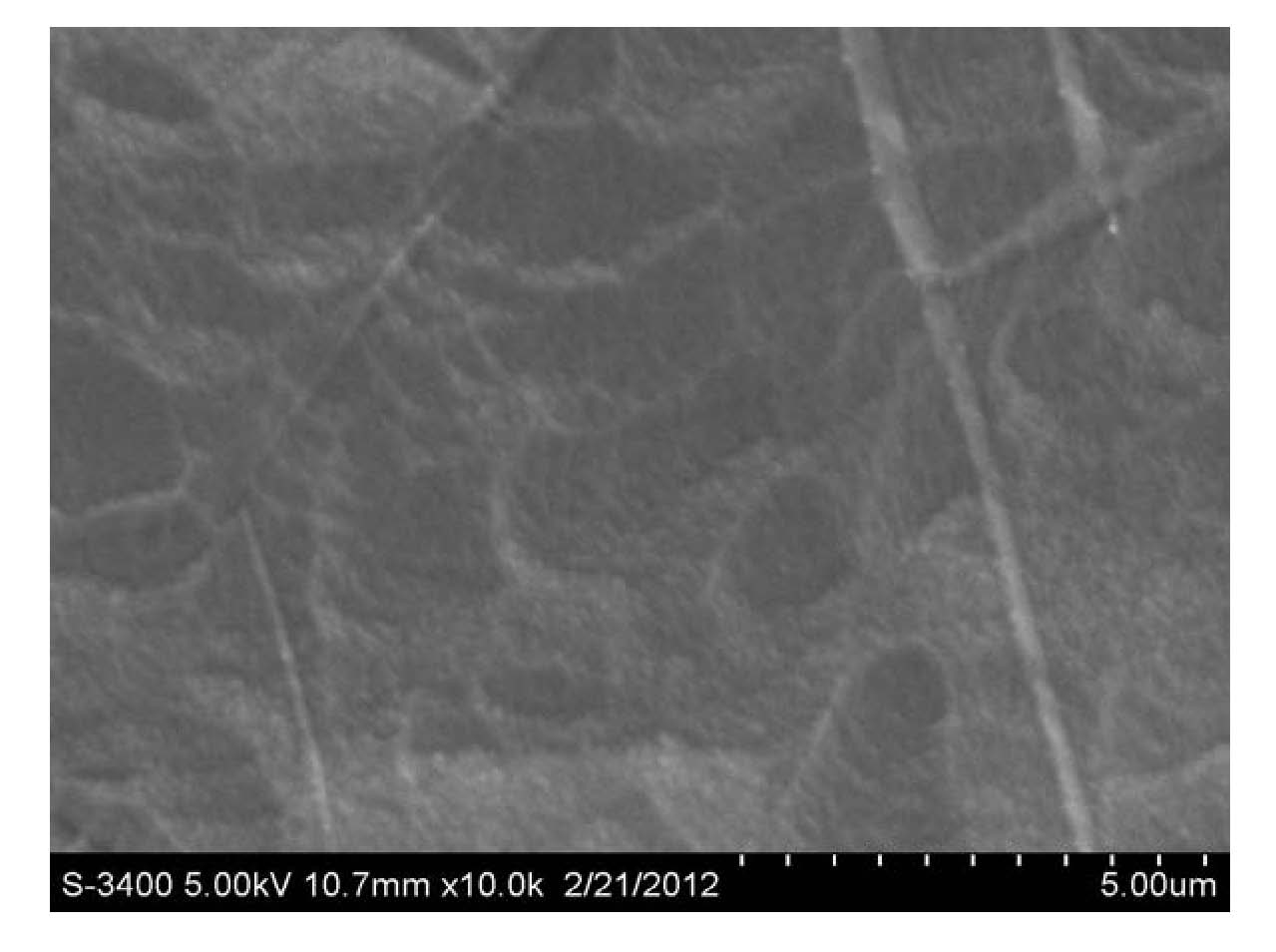

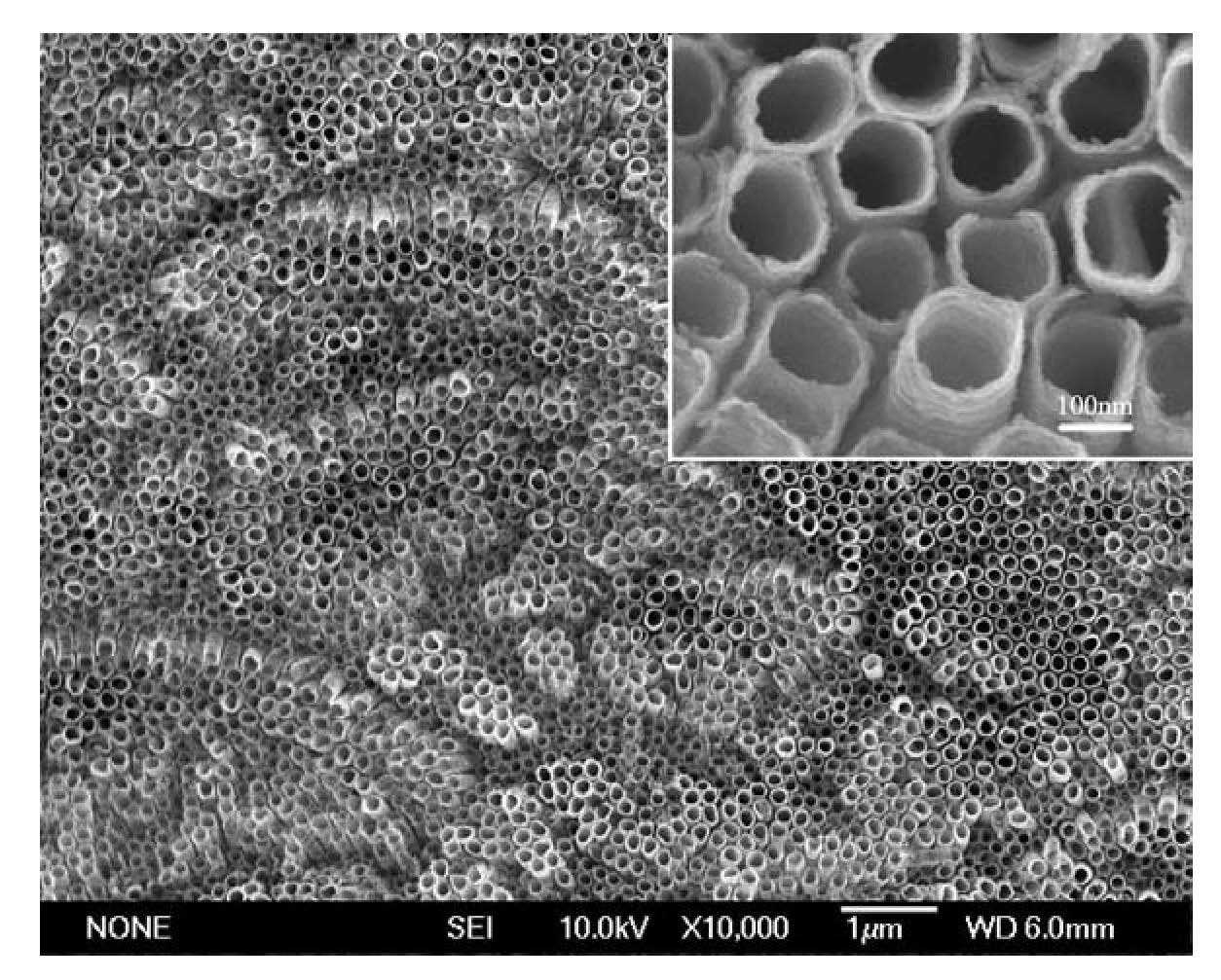

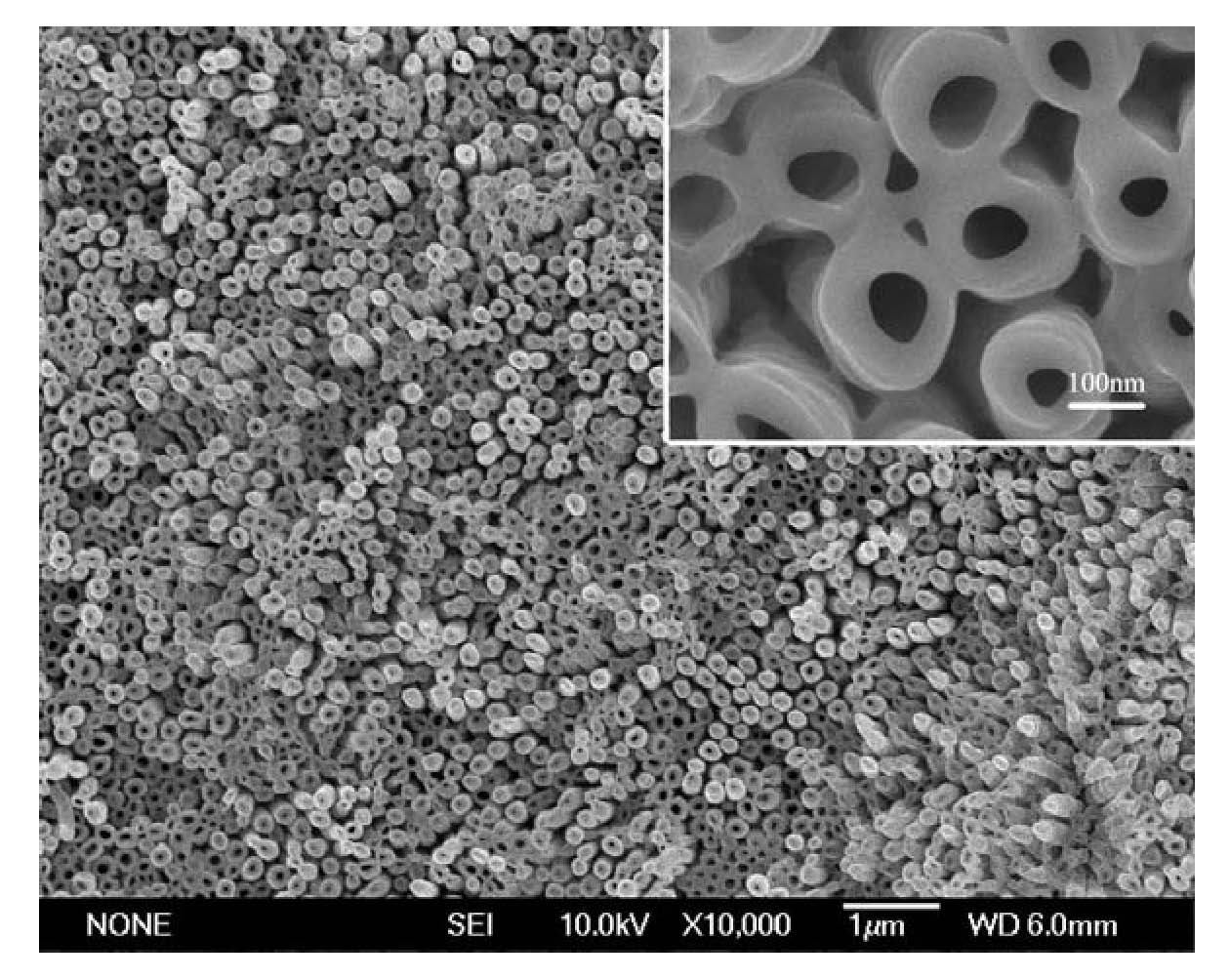

Nano composite material based on titanium metal surface and preparation method thereof

ActiveCN102677055AReduced band gapAchieving photocatalysisSuperimposed coating processTio2 nanotubeComposite film

The invention provides a preparation method of a nano composite material based on a titanium metal surface, which comprises the following steps: carrying out carbon plasma immersion ion implantation and deposition on a regular titanium oxide nanotube array film on a titanium metal surface, thereby forming a graphite / titanium oxide composite film with a nano hollow conical array on the titanium metal surface. The invention implements preparation of the graphite / titanium oxide composite nano material, and solves the problem of single component and structural composition in the nano titanium oxide film material generated by in-situ oxidization on the titanium metal surface in the prior art.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Antibacterial and biocompatible bone implantation material and preparation method and application thereof

ActiveCN109999224ARaise the surface potentialImprove bindingTissue regenerationCoatingsAntibiosisNitrogen plasma

The invention discloses an antibacterial and biocompatible bone implantation material and a preparation method and application thereof. The antibacterial and biocompatible bone implantation material comprises a bone implantation material body and a composite antibacterial layer formed on the surface of the bone implantation material body; the composite antibacterial layer is obtained by injectinga carbon-containing plasma or a silicon-containing plasma into a surface layer of the bone implantation material body to obtain a transition layer and then injecting a nitrogen-containing plasma or aphosphorus-containing plasma into the transition layer; the carbon-containing plasma, the silicon-containing plasma, the nitrogen-containing plasma and the phosphorus-containing plasma all do not contain hydrogen and oxygen; the relative surface potential of the antibacterial and biocompatible bone implantation material is 0.01-0.5 V. The antibacterial and biocompatible bone implantation materialand the preparation method and application thereof have the advantages that a plasma injection technology is adopted to construct the high potential surface, and the antibiosis and biosecurity are given to the surface of the bone implantation material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for growing metal carbide on metal surface

ActiveCN108411266AEnhancement effect is goodImprove bindingVacuum evaporation coatingSputtering coatingChemical vapor depositionZirconium alloy

The invention belongs to the preparation technology for growing metal carbide on metal surfaces and relates to a method for growing metal carbide on a metal surface. The method includes the preparation steps that firstly, tungsten, zirconium or a tungsten-zirconium alloy is sputtered onto the metal base body surface in a magnetron sputtering manner, and a compact thin film layer is formed; secondly, a metal base body is heated to 100-500 DEG C, and cooling is performed till room temperature is achieved after heat preserving is performed for 0.5-1 h; thirdly, carbon plasma is made to react witha thin film layer of the metal base body to generate tungsten carbide and / or zirconium carbide through a plasma chemical vapor deposition system. According to the method, a zirconium carbide or tungsten carbide or zirconium carbide and tungsten carbide composite layer can grow on the surface of a metal bar, plate or foil with the melting point larger than 500 DEG C, and the mechanical propertiesof the surface of the metal bar, plate or foil are improved and include strength, abrasion resistance, toughness and impacting strength.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for forming a junction region of a semiconductor device

ActiveUS7060547B2Improve leakage currentReduce harmSemiconductor/solid-state device manufacturingSemiconductor devicesDopantCarbon plasma

Owner:UNITED MICROELECTRONICS CORP

Cold cathodes made of carbon materials

InactiveUS20070197732A1Improve launch performanceReduce field strengthElectric discharge tubesFibre typesCarbon filmCarbon fibers

Owner:TETRANOVA

Manufacturing method for a head slider coated with DLC

ActiveUS9840767B2Improve adhesionHigh hardnessManufacture head surfaceVacuum evaporation coatingSputteringDiamond-like carbon

A manufacturing method for a head slider coated with Diamond-like Carbon (DLC) includes: providing a substrate that is to be finally made into a head slider; depositing a DLC layer on a surface of the substrate, with carbon plasma source being sputtered in a direction that is vertical to the surface of the substrate; and doping a fluorine-doping (F-doping) layer on the DLC layer. Whereby the head slider has good film adhesion performance, higher hardness, better wear resistance, lower surface energy to obtain good hydrophobicity and oleophobicity, and lower fly height in HDD.

Owner:SAE MAGNETICS (HK) LTD

In-situ preparation method of metal fiber reinforced composite film

InactiveCN111501010ASolve reunionImprove efficiencyVacuum evaporation coatingSputtering coatingPlatinumComposite film

The invention provides an in-situ preparation method of a metal fiber reinforced composite film. Metal fibers (silver, copper, aluminum, tin, platinum and the like) are generated while the thin film is formed through sputtering by means of a plasma assisted chemical vapor deposition method and the catalytic action of carbon plasmas, thereby achieving in-situ preparation of the metal fiber reinforced composite film. The method realizes one-dimensional metal fiber sputtering synthesis and in-situ preparation of the fiber reinforced composite film. The composite structure can adjust the stress state in the thin film and the film toughness, and simultaneously endows the film with excellent electrical conductivity, abrasion reduction performance and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com