Method for mfg. diamondoid composite diaphragm of loudspeaker

A technology of diamond-like film and diamond, which is applied in the field of depositing diamond-like film, can solve the problems that the quality and performance of the diamond-like film are not particularly good, it is difficult to prepare a transition layer, and the deposition time is long, and the cost is low, the deposition area is small, The effect of high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

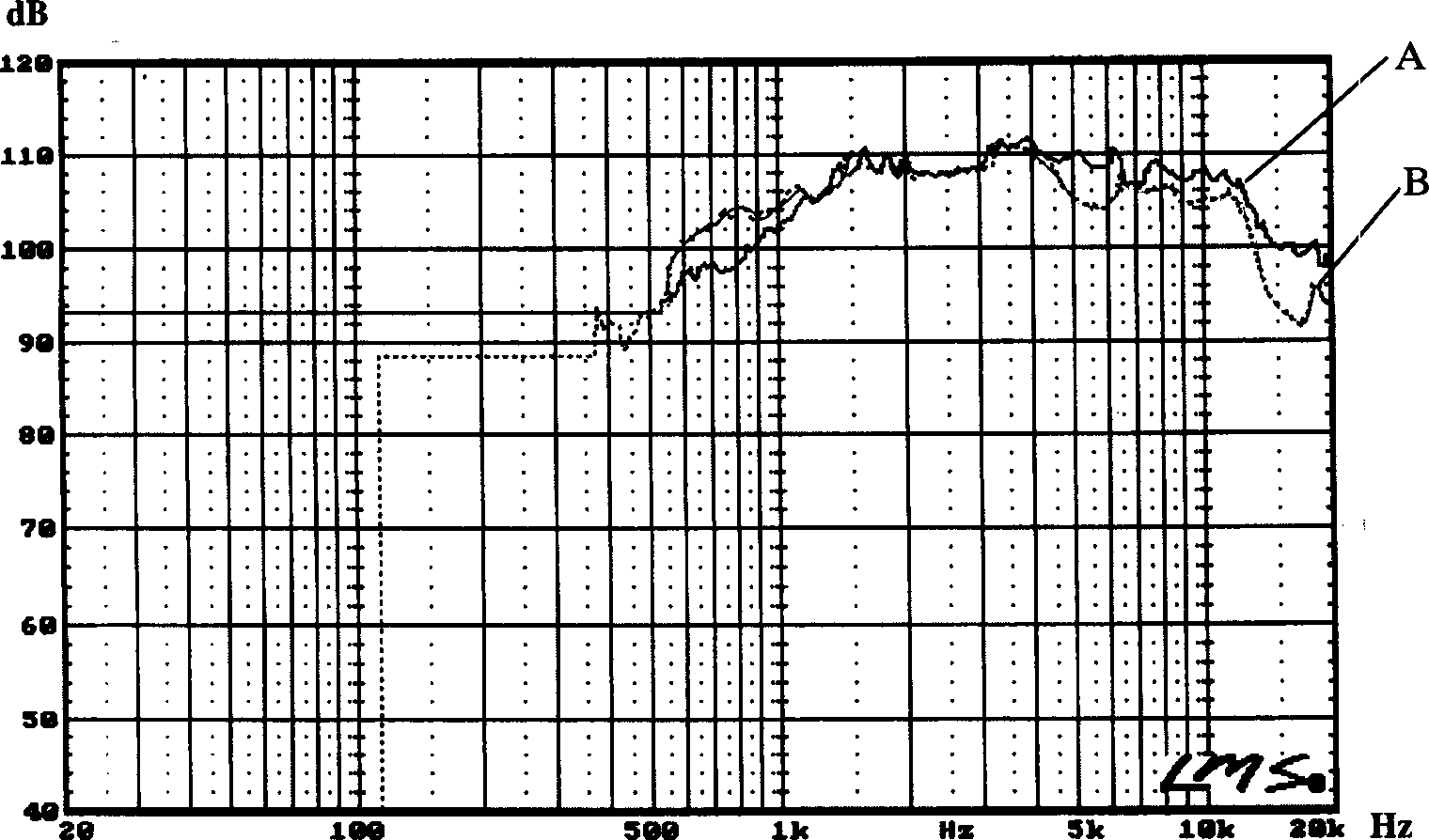

Image

Examples

Embodiment

[0019] The preparation of the diamond-like carbon film is carried out on an eight-arc source vacuum cathodic arc deposition equipment. The outer diameter of the deposited titanium diaphragm is Φ62mm, and the diameter of the voice coil is Φ44.5mm. Before loading into the furnace, it is strictly cleaned to remove surface grease, dust and other pollutants. After dehydration in alcohol, it is dried. The diaphragm is fixed with a clamp and hung On the workpiece rack of the coating machine, the loading capacity is about 150 pieces.

[0020] Vacuum down to 4×10 -3 After Pa, pass argon gas to start the titanium arc source, at a bias voltage of 800V, and an air pressure of 1×10 -2 Under Pa, perform ion bombardment cleaning for 10 minutes.

[0021] At bias voltage 200V, hydrogen pressure 1×10 -2 Under Pa, start titanium and graphite cathode arcs, and deposit titanium and titanium carbide transition layers for 10 minutes.

[0022] At hydrogen pressure 1×10 -2 Under Pa, the graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com