Preparing method and application of high purity and density spherical titanium zirconium alloy powder

A technology of alloy powder and titanium zirconium is applied in the field of preparation of fine-grained, high-purity and dense spherical titanium-zirconium alloy powder for 3D printing. , The effect of high density and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a preparation method of high-purity dense spherical titanium-zirconium alloy powder, comprising the following steps:

[0037] Step 1: Smelting after mixing titanium sponge particles and zirconium sponge particles to obtain high-purity titanium-zirconium alloy ingots;

[0038] Specifically, in the embodiment of the present invention, sponge titanium (Ti) and sponge zirconium (Zr) are selected as the basic raw materials, and the above raw materials are broken into small particles, and the titanium-zirconium mixture is prepared according to the required titanium-zirconium alloy composition, and mixed uniformly, The purity of the titanium sponge and zirconium sponge is not less than 99.9% by mass; in the embodiments of the present invention, the mass ratio of titanium sponge (Ti) to zirconium sponge (Zr) is preferably 1:1-9.

[0039]In the embodiment of the present invention, special smelting methods such as induction smeltin...

Embodiment 1

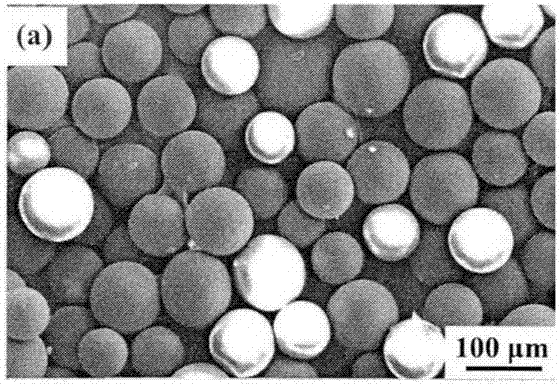

[0060] The preparation of high-purity dense spherical Ti-10%Zr alloy powder for 3D printing with an average particle size of 40 μm comprises the following steps:

[0061] In step 1, according to the composition of the Ti-10%Zr alloy, 1 part of zirconium sponge and 9 parts of titanium sponge are taken as basic raw materials. Crush the above raw materials into small particles with a particle diameter of about 3 mm and mix them uniformly.

[0062] Step 2, filling the titanium-zirconium mixture into the crucible of the vacuum induction water-cooled copper crucible suspension melting furnace; vacuumize the melting furnace, and the vacuum degree reaches 4×10 -3 Pa filled with high-purity argon to 50kPa to form a protective atmosphere; after the smelting started, first preheat the titanium-zirconium mixture with a power of 50kW to raise the temperature to 370°C; then increase the power to 160KW, and Melting for 8 minutes to completely melt and mix the titanium-zirconium mixture; aft...

Embodiment 2

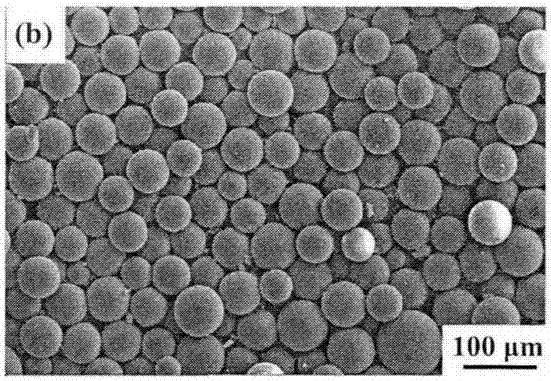

[0071] The preparation of high-purity dense spherical Ti-30%Zr alloy powder for 3D printing with an average particle size of 30 μm comprises the following steps:

[0072] In step 1, according to the composition of the Ti-30%Zr alloy, 3 parts of zirconium sponge and 7 parts of titanium sponge are taken as basic raw materials. The above raw materials are broken into small particles with a particle diameter of about 2mm and mixed uniformly.

[0073] Step 2, filling the titanium-zirconium mixture into the crucible of the vacuum induction water-cooled copper crucible suspension melting furnace; vacuumize the melting furnace, and the vacuum degree reaches 5×10 -3Fill high-purity argon at Pa to 50kPa to form a protective atmosphere; after the melting starts, firstly preheat the titanium-zirconium mixture with a power of 50KW to raise the temperature to 380°C; then increase the power to 170KW, and use a constant power Melt for 7 minutes to completely melt the titanium-zirconium mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com