Preparation method for spherical titanium or titanium alloy powder

The technology of titanium alloy powder and titanium alloy wire is applied in the field of preparation of spherical titanium or titanium alloy powder, which can solve the problems of high equipment requirements and electrode pollution, and achieve the effects of good fluidity, high sphericity and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

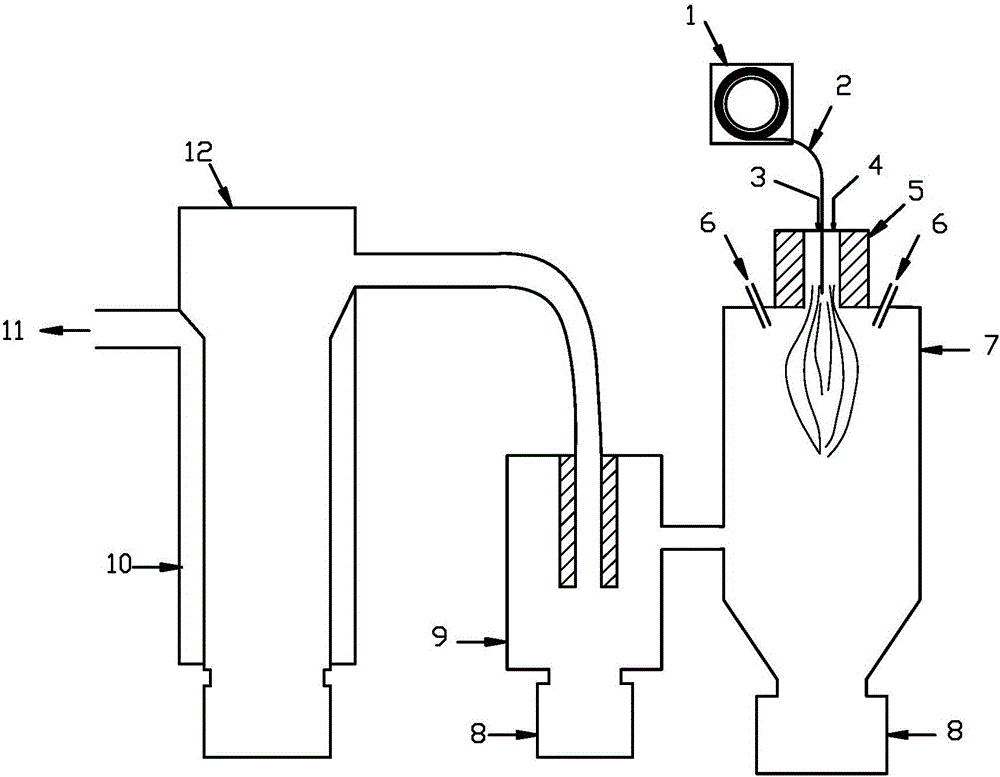

Method used

Image

Examples

Embodiment 1

[0032] 1) Take a titanium wire with a diameter of 0.2mm and put it into the feeder, and then use argon to flush and leak the preparation system;

[0033] 2) Pass sheath gas (argon flow rate is 30slpm, hydrogen flow rate is 2slpm) and center gas (argon gas flow rate is 2slpm) into the plasma generator, adjust the system pressure to 27.6Kpa, turn on the high-frequency power supply and excite the plasma, and then Introduce the auxiliary air flow and adjust the flow rate to 25slpm, gradually adjust the system air pressure to 103.4Kpa, and adjust the system power to 15KW;

[0034]3) After the system stabilizes, turn on the feeder and start feeding at a rate of 12g / min, and feed the carrier gas (argon gas, the flow rate is 2slpm) into the feeder, and the titanium wire is sent into the plasma generator under the protection of the carrier gas Medium vaporization smelting, melting rapidly in the plasma high-temperature area, the formed melt is broken up into tiny metal droplets in the ...

Embodiment 2

[0040] 1) Take a titanium alloy wire with a diameter of 2mm (the composition is Ti+6wt.%Al+4wt.%V) and put it into the feeder, and then flush and leak check the preparation system with argon;

[0041] 2) Pass sheath gas (argon gas flow rate is 75slpm, hydrogen gas flow rate is 6slpm) and center gas (argon gas flow rate is 6slpm) into plasma generator, adjust system pressure to be 34.5Kpa, open high-frequency power supply and excite plasma, then Introduce the auxiliary air flow and adjust the flow rate to 45slpm, gradually adjust the system air pressure to 110.2Kpa, and adjust the system power to 60KW;

[0042] 3) After the system is stable, open the feeder and start feeding at a rate of 50g / min, and feed carrier gas (argon gas, flow rate of 4 slpm) into the feeder, and the titanium alloy wire is sent into the plasma for generation under the protection of the carrier gas Vaporization and smelting in the vessel, and rapid melting in the plasma high-temperature area, the formed m...

Embodiment 3

[0046] Repeat Example 1, the difference is:

[0047] In step 1), the diameter of the titanium wire is 6mm;

[0048] In step 2), the sheath gas to be fed is: the flow rate of argon gas is 300 slpm, the flow rate of hydrogen gas is 80 slpm; the flow rate of argon gas in the center gas is 100 slpm, and the auxiliary gas flow is introduced and the flow rate is adjusted to 100 slpm, and the system pressure is gradually adjusted to 130.9Kpa , adjust the system power to 200KW;

[0049] In step 3), the feeder feeds at a rate of 200 g / min and feeds carrier gas (argon, with a flow rate of 6 slpm) into the feeder.

[0050] In step 4), the powder is sequentially passed through -150 mesh and +325 mesh sieves under the protection of argon to obtain spherical titanium powder with a main particle size range of 45-106 μm, and the average particle size of the spherical titanium powder is 72.5 μm.

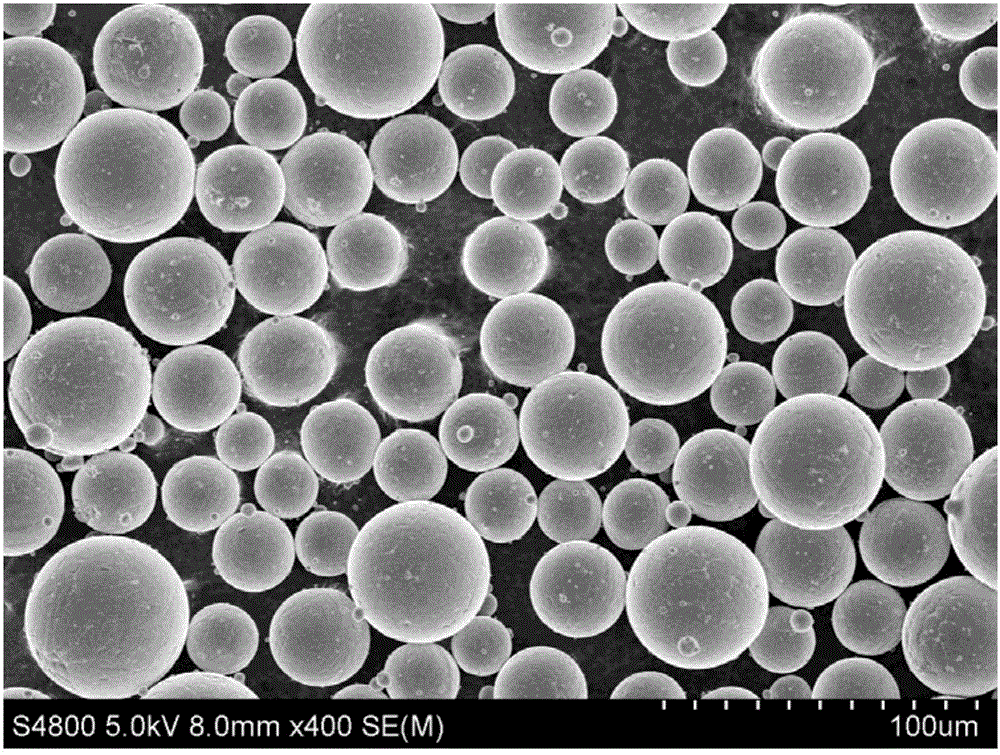

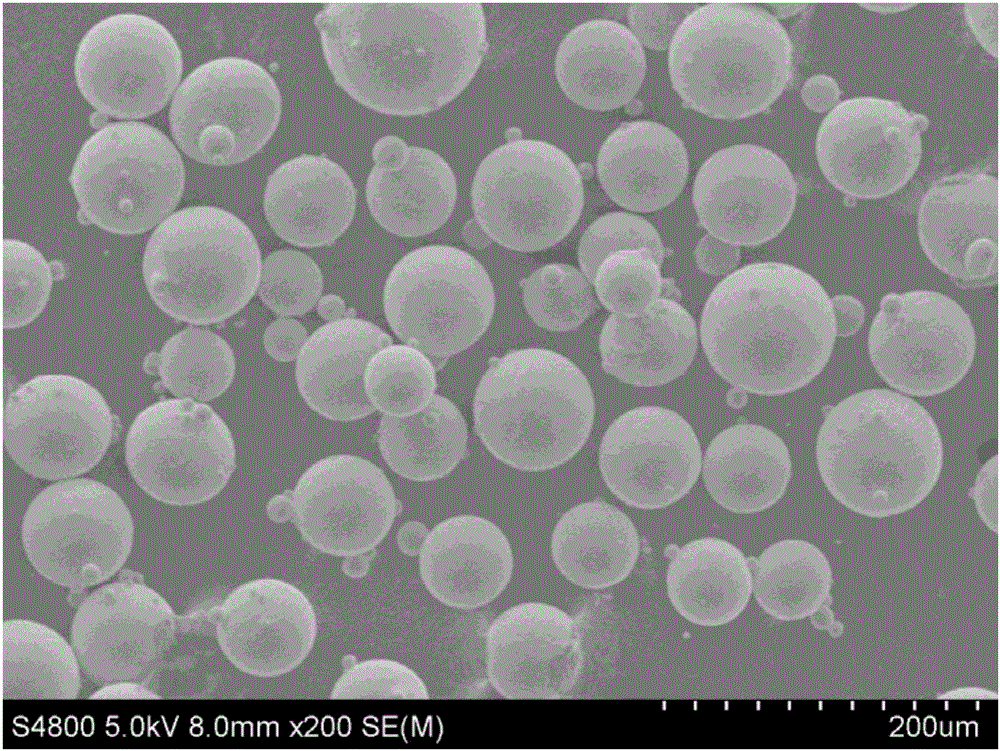

[0051] The microscopic appearance of the spherical titanium alloy powder prepared in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com