Method for preparing low-carbon olefin hydrocarbon with oxocompound

A technology for low-carbon olefins and oxides, which is used in the production of hydrocarbons from oxygen-containing organic compounds, chemical instruments and methods, and ethylene production, can solve problems such as hazards and product separation difficulties, achieve good technical results, and improve stripping efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

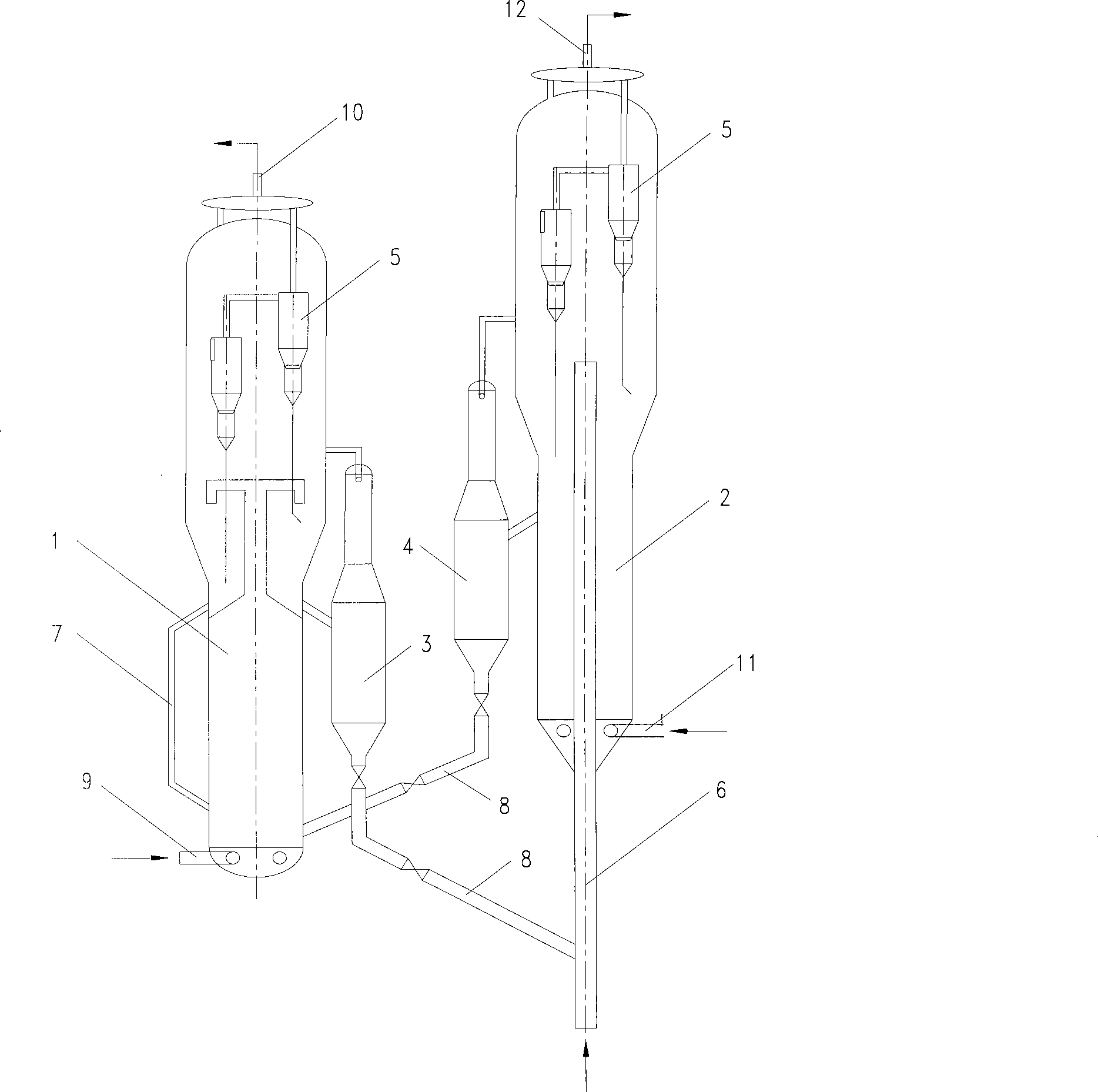

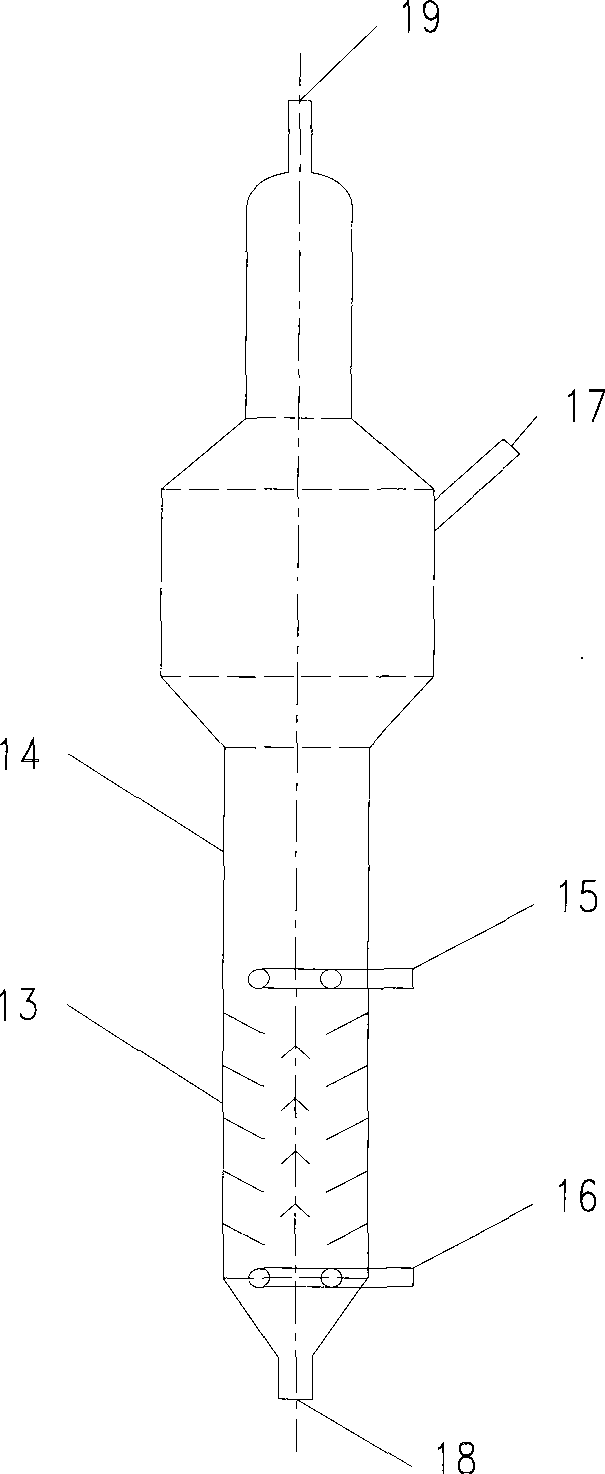

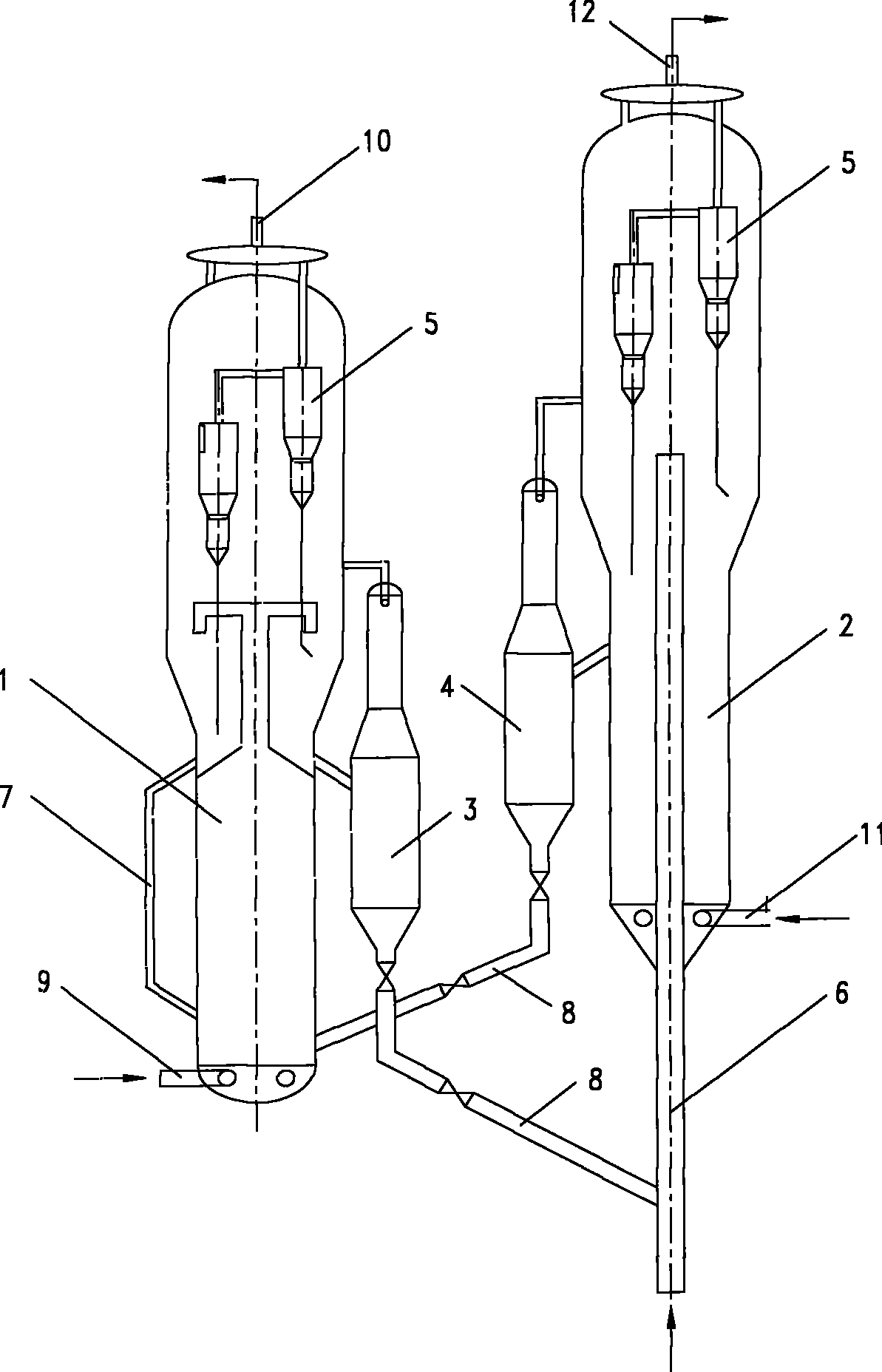

[0019] 200,000 tons / year of methanol to produce low-carbon olefins figure 1 The anti-regeneration system for the continuous regeneration of the catalyst shown and figure 2 The stripping section of the degasser is shown. Reactor diameter 3100mm, 0.06MPaG, reaction temperature 450°C, space velocity 1.0 hour -1 , the line velocity of the lower stripping section is 0.08 m / s, and the line velocity of the upper stripping section is 0.25 m / s. SAPO-34 molecular sieve catalyst is used. The reaction raw material is pure methanol. The concentration of impurities at the reactor outlet is shown in Table 1.

Embodiment 2

[0021] 300,000 tons / year of methanol production of low-carbon olefins figure 1 The anti-regeneration system for the continuous regeneration of the catalyst shown and figure 2 The stripping section of the degasser is shown. Reactor diameter 3900mm, 0.06MPaG, reaction temperature 450°C, space velocity 5.0 hours -1 , the line velocity of the lower stripping section is 0.12 m / s, and the line velocity of the upper stripping section is 0.3 m / s. SAPO-34 molecular sieve catalyst is used. The reaction raw material is pure methanol. The concentration of impurities at the reactor outlet is shown in Table 1.

Embodiment 3

[0023] 400,000 tons / year of methanol production of low-carbon olefins figure 1 The anti-regeneration system for the continuous regeneration of the catalyst shown and figure 2 The stripping section of the degasser is shown. Reactor diameter 4300mm, 0.06MPaG, reaction temperature 470°C, space velocity 3.0 hours -1 , the line velocity of the lower stripping section is 0.17 m / s, and the line velocity of the upper stripping section is 0.35 m / s. SAPO-34 molecular sieve catalyst is used. The reaction raw material is pure methanol. The concentration of impurities at the reactor outlet is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com