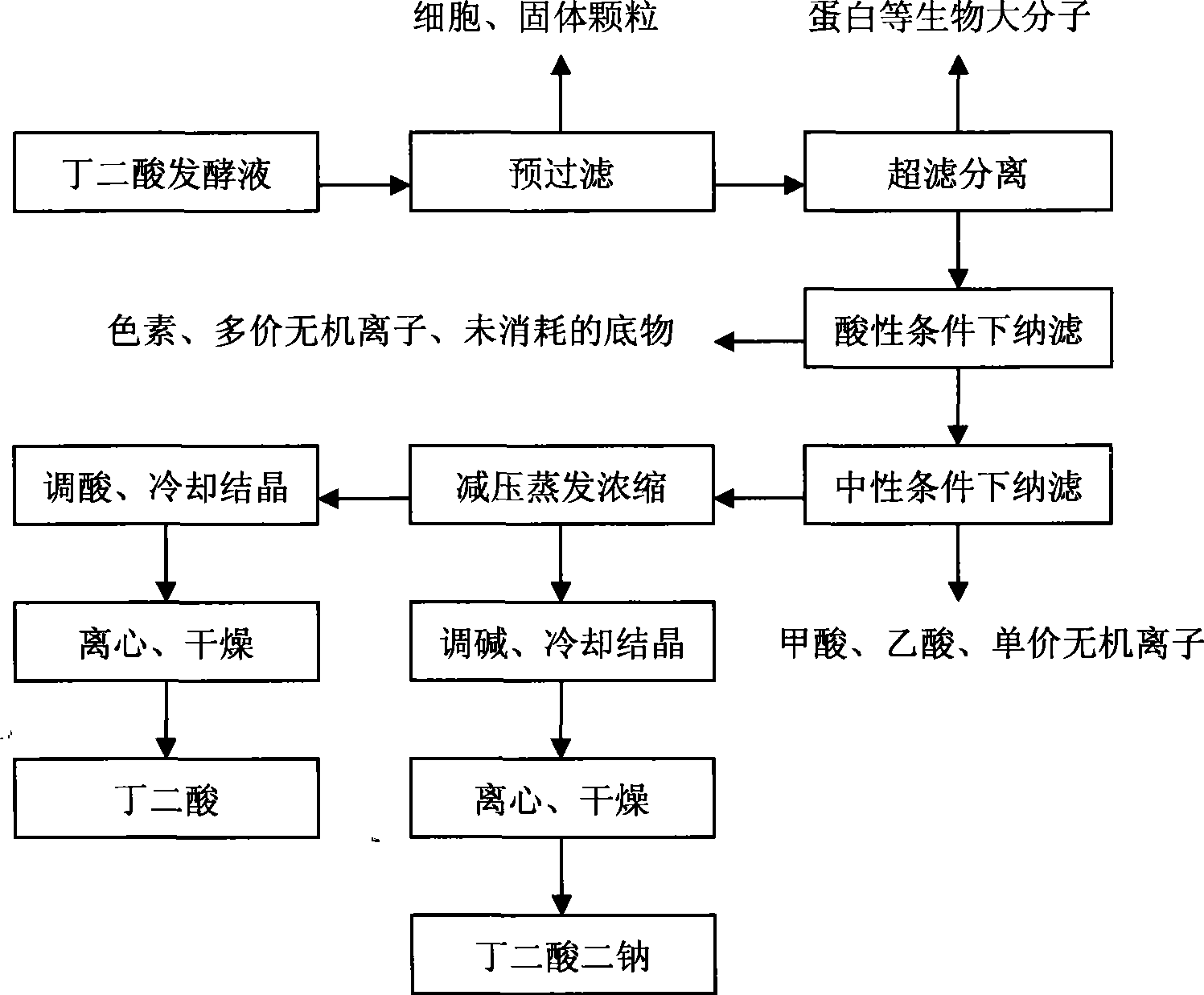

Method for separating and extracting amber acid from amber acid fermentation liquor by nanofiltration

A technology of succinic acid and fermentation broth, applied in the separation/purification of carboxylic acid compounds, ultrafiltration, carboxylate preparation and other directions, can solve the problems of difficult product quality control, large sewage, and many steps, and save equipment investment. , The effect of good separation selectivity and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The succinic acid fermentation broth prepared with glucose as carbon source contains 67g / L succinic acid, 12g / L acetic acid, 6g / L formic acid, 9g / L glucose, pH6.7.

[0027] Anionic flocculants were added to the fermentation broth, and diatomaceous earth was used as a filter aid for plate-and-frame pressure filtration. The filtration temperature was 70°C, the sterilization rate was 91%, and the protein removal rate was 27%. The filtrate was collected; the filtrate was adjusted to pH5 with sulfuric acid .0, using a tubular inorganic membrane with a molecular weight cut-off of 150,000 Daltons for ultrafiltration, temperature 35°C, operating pressure 0.3Mpa, protein removal rate 75%, ultrafiltrate collection, decolorization rate 27%; two nanofiltration processes The molecular weight cut-off of the nanofiltration membrane adopted is 150 Daltons, the ultrafiltrate is adjusted to pH 3.0 with sulfuric acid, and the nanofiltration separation is carried out, the temperature is 25 ...

Embodiment 2

[0030]The succinic acid fermentation broth prepared with glucose as carbon source contains succinic acid 45g / L, acetic acid 9g / L, formic acid 5g / L, glucose-free, pH 6.5.

[0031] Use sulfuric acid to adjust the fermentation broth to pH 4.5 for microfiltration. The pore size of the tubular inorganic microfiltration membrane used is 0.175 μm, the operating temperature is 40 ° C, the operating pressure is 0.1 Mpa, the sterilization rate is 99.8%, and the protein removal rate is 41%. , collect the filtrate; adjust the filtrate to pH 4.5 with sulfuric acid, use a roll-type organic membrane with a molecular weight cut-off of 10,000 Daltons for ultrafiltration, the temperature is 25°C, the operating pressure is 0.25Mpa, and the protein removal rate is 90%. liquid, the decolorization rate is 68%; the molecular weight cut-off of the nanofiltration membrane used in the two nanofiltration processes is 160 Daltons, and the ultrafiltrate is adjusted to pH4. Mpa, succinic acid transmission ...

Embodiment 3

[0034] Succinic acid fermentation broth prepared by using straw hydrolyzed sugar solution as carbon source, containing 51g / L succinic acid, 11g / L acetic acid, 7g / L formic acid, no glucose, pH6.4,

[0035] Use sulfuric acid to adjust the fermented liquid to pH 4.0 for microfiltration. The hollow fiber organic microfiltration membrane used has a pore size of 0.1 μm, an operating temperature of 20° C., a sterilization rate of 99.5%, and a protein removal rate of 35%. The filtrate is collected; Sulfuric acid was used to adjust the filtrate to pH 4.0, and ultrafiltration was carried out with a roll-type organic membrane with a molecular weight cut-off of 5000 Daltons. The temperature was 40°C, the operating pressure was 0.3Mpa, the protein removal rate was 95%, and the ultrafiltrate was collected with a decolorization rate of 80%; The molecular weight cut-off of the nanofiltration membrane used in the two nanofiltration processes is 160 Daltons, the ultrafiltrate is adjusted to pH 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com