Polymerizable deep eutectic solvent

A technology of deep eutectic solvent and hydrogen bond donor, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, compounds of group 5/15 elements of the periodic table, etc., can solve the problem of less polymerizable deep eutectic solvents, etc. , to achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

[0039] A kind of preparation method of polymerizable deep eutectic solvent, the steps are as follows:

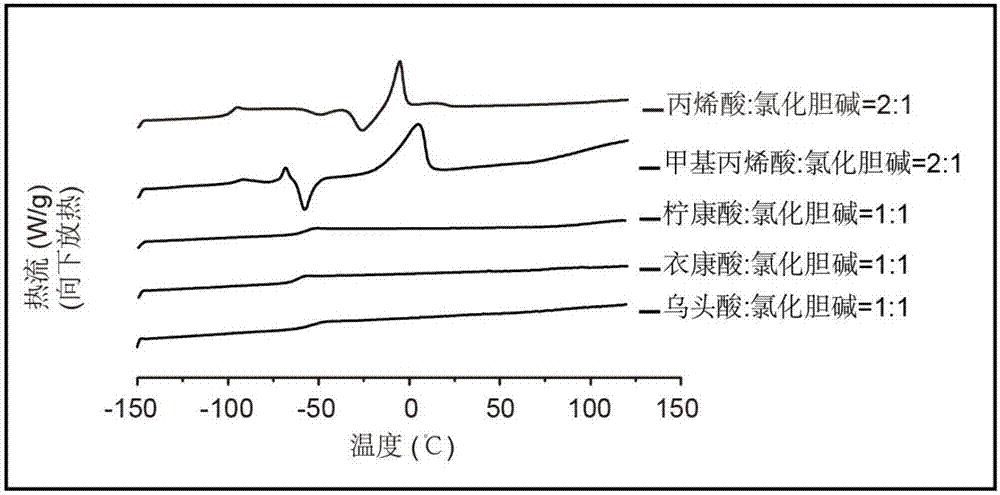

[0040] Mix 13.96g of choline chloride with acrylic acid, methacrylic acid, crotonic acid, citraconic acid, itaconic acid and aconitic acid respectively, and stir in an oil bath at 90°C for 4 hours to obtain a clear and transparent polymerizable eutectic solvent. See Table 1 for specific ratios.

Embodiment 21~24

[0042] A kind of preparation method of polymerizable deep eutectic solvent, the steps are as follows:

[0043] Mix 11.72 g of anhydrous betaine with crotonic acid and citraconic acid respectively, and stir in an oil bath at 90°C for 4 hours to obtain a clear and transparent polymerizable deep eutectic solvent. See Table 2 for the specific ratio.

Embodiment 25~43

[0045] A kind of preparation method of polymerizable deep eutectic solvent, the steps are as follows:

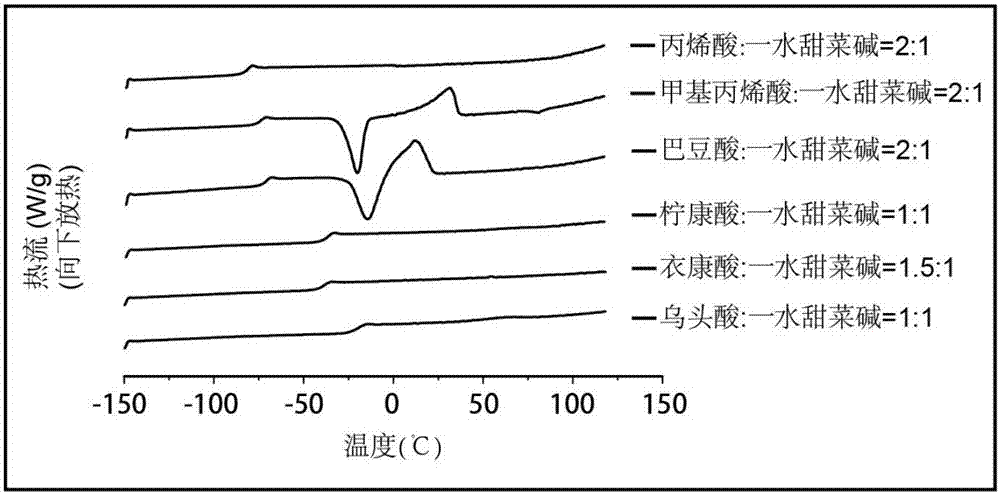

[0046] Mix 13.52 g of betaine monohydrate with acrylic acid, methacrylic acid, crotonic acid, citraconic acid, itaconic acid, aconitic acid, and sorbic acid respectively, and stir in an oil bath at 90°C for 4 hours to obtain clear and transparent polymerizable Deep eutectic solvent. See Table 3 for specific ratios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com