Production technology of large-specification extraordinary isotropic graphite material

A graphite material and production process technology, which is applied in the production process field of large-scale special homogeneity graphite materials, can solve the problems of difference in volume shrinkage of filler and binder, poor structural uniformity, reduced mechanical strength, etc., to shorten production cycle, The structure is fine and dense, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail with examples below.

[0023] In this example, the binder is modified asphalt, and its main performance indicators are: carbon residue rate: 53%, softening point: 79.5°C, volatile matter: 58.6%.

[0024] The impregnating agent is medium-temperature asphalt and high-temperature asphalt, and its main properties are as follows:

[0025] Medium temperature asphalt: carbon residue rate: 50.2%; softening point: 79.5°C; volatile matter: 58.6%;

[0026] High-temperature asphalt: carbon residue rate: 56.6%; softening point: 97.0°C; volatile matter: 54.1%.

[0027] The filler is calcined petroleum coke, and its main performance indicators are: ash content: 0.26%; moisture: 0.38%.

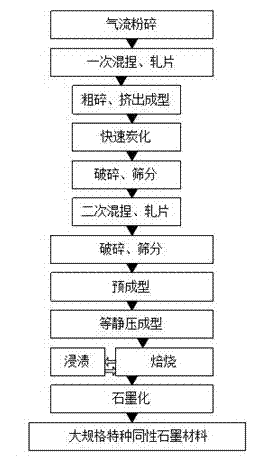

[0028] see figure 1 , the production process is carried out in the following steps:

[0029] 1. Jet crushing: after coarse crushing, the calcined petroleum coke or pitch coke is crushed with a jet mill to make coke powder with an average particle size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com