Method for recovering and recycling waste lithium ion battery cathode material

A lithium-ion battery and cathode material technology, which is applied in the field of lithium-ion battery material preparation and waste resource recycling, can solve the problems of low-cost metal loss environment, single battery material system, and narrow adaptability, so as to save resources, Effect of high added value and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

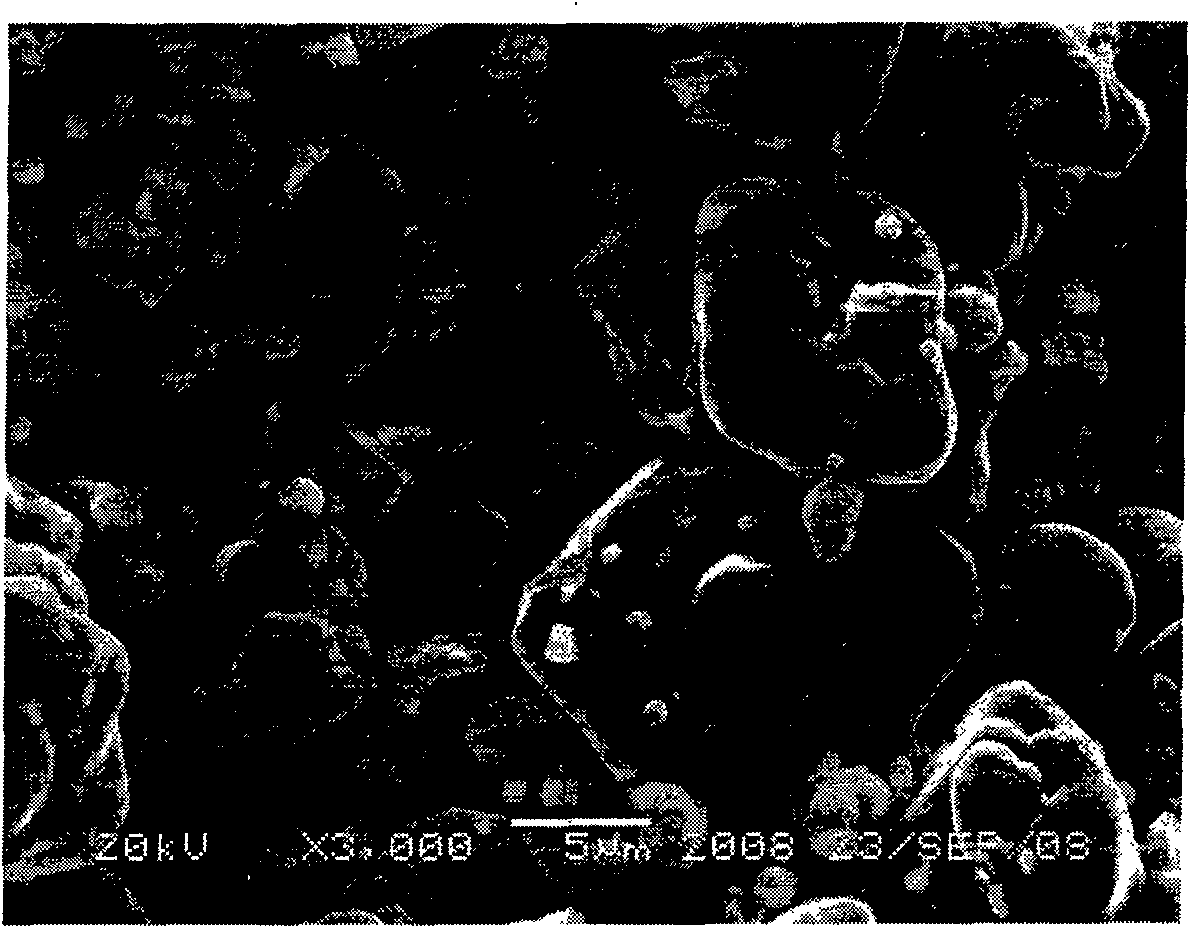

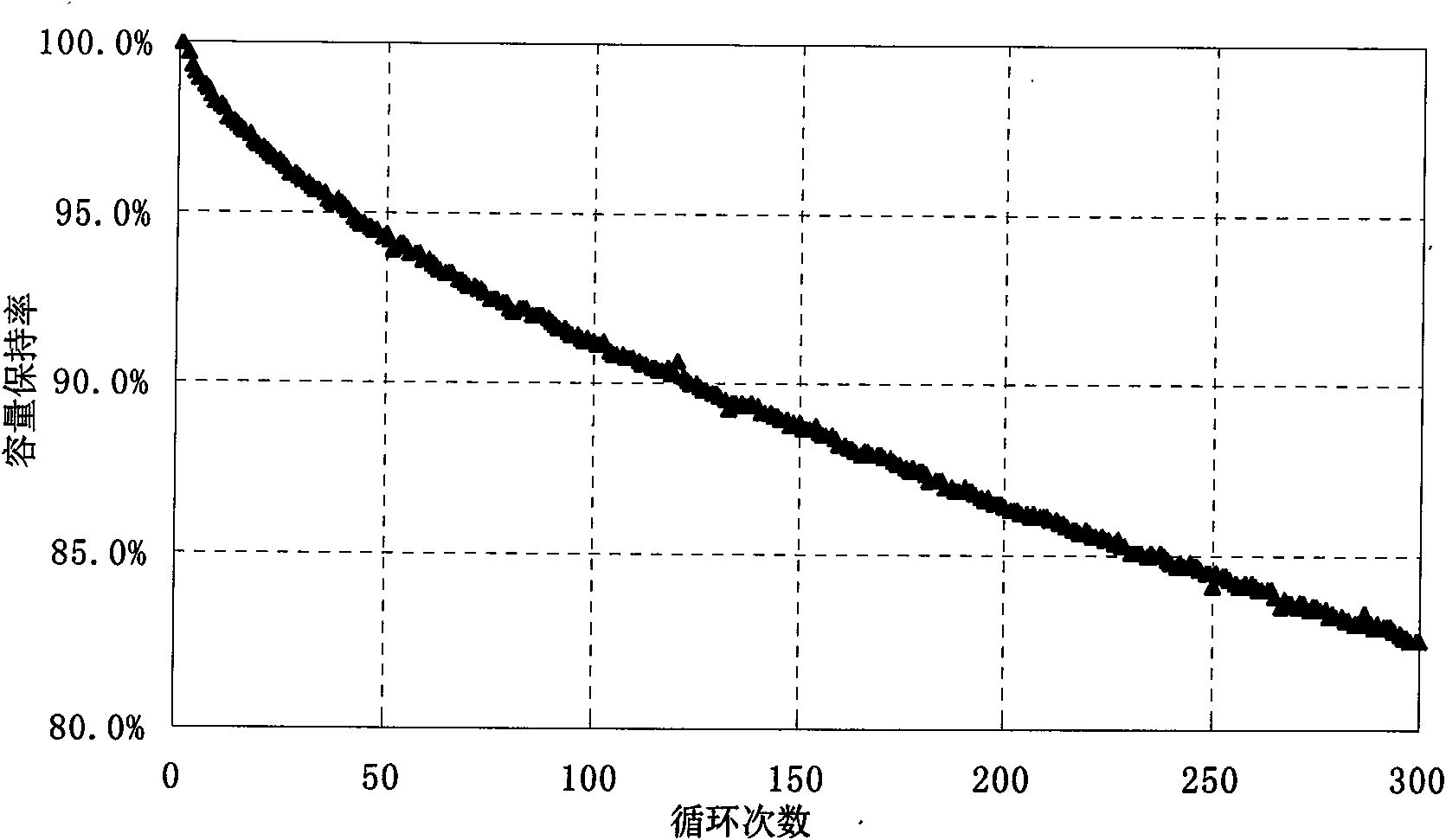

[0035] After drying the lithium cobalt oxide cathode waste at 120°C for 5 hours, use a crusher to crush the waste until the maximum particle size is less than 100 μm, and then heat-treat the powder in an air atmosphere furnace at a constant temperature of 400°C for 5 hours, and then sieve to control the particle size range: D10 ≥3μm, D90≤35μm, D50 is 8μm~20μm, complete the recovery of lithium cobalt oxide cathode material. figure 2 It is the SEM image of the recycled lithium cobalt oxide cathode material. Using this recycled material to make 053450 full battery, the measured 1C discharge specific capacity of the recycled material is 144mAh / g, which is about 2mAh / g lower than the normal product. The recycled material has good cycle performance, and the capacity retention rate reaches about 82.5% after 300 1C cycles. image 3 It is the cycle performance graph of the recycled lithium cobalt oxide cathode material.

Embodiment 2

[0037] The experimental conditions are the same as in Example 1, except that lithium cobaltate cathode waste is replaced by LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode waste. Figure 4 LiNi for recycling 1 / 3 co 1 / 3 mn 1 / 3 o 2 SEM images of cathode waste. LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The 1C discharge specific capacity of recycled materials is 143mAh / g, which is about 1.5mAh / g lower than that of normal products. The recycled material has good cycle performance, and the capacity retention rate reaches about 87% after 300 1C cycles. Figure 5 LiNi for recycling 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cycling performance graph of the cathode material.

Embodiment 3

[0039] The experimental conditions were the same as in Example 1, except that the lithium cobaltate cathode waste was replaced with lithium manganate cathode waste. Figure 6 It is the SEM image of the recycled lithium manganate cathode waste. The 1C discharge specific capacity of recycled lithium manganate is 105mAh / g, which is about 3mAh / g lower than normal products. Recycled materials have qualified cycle performance, and the capacity retention rate reaches about 80% after 300 1C cycles. Figure 7 It is the cycle performance diagram of the recycled lithium manganese oxide cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com