Service robot for the automatic suction of dust from floor surfaces

a technology of floor surfaces and cleaning robots, which is applied in the direction of carpet cleaners, distance measurement, instruments, etc., can solve the problems of requiring troublesome change of the suction nozzle, damage to delicate furniture, and time-consuming vacuum cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

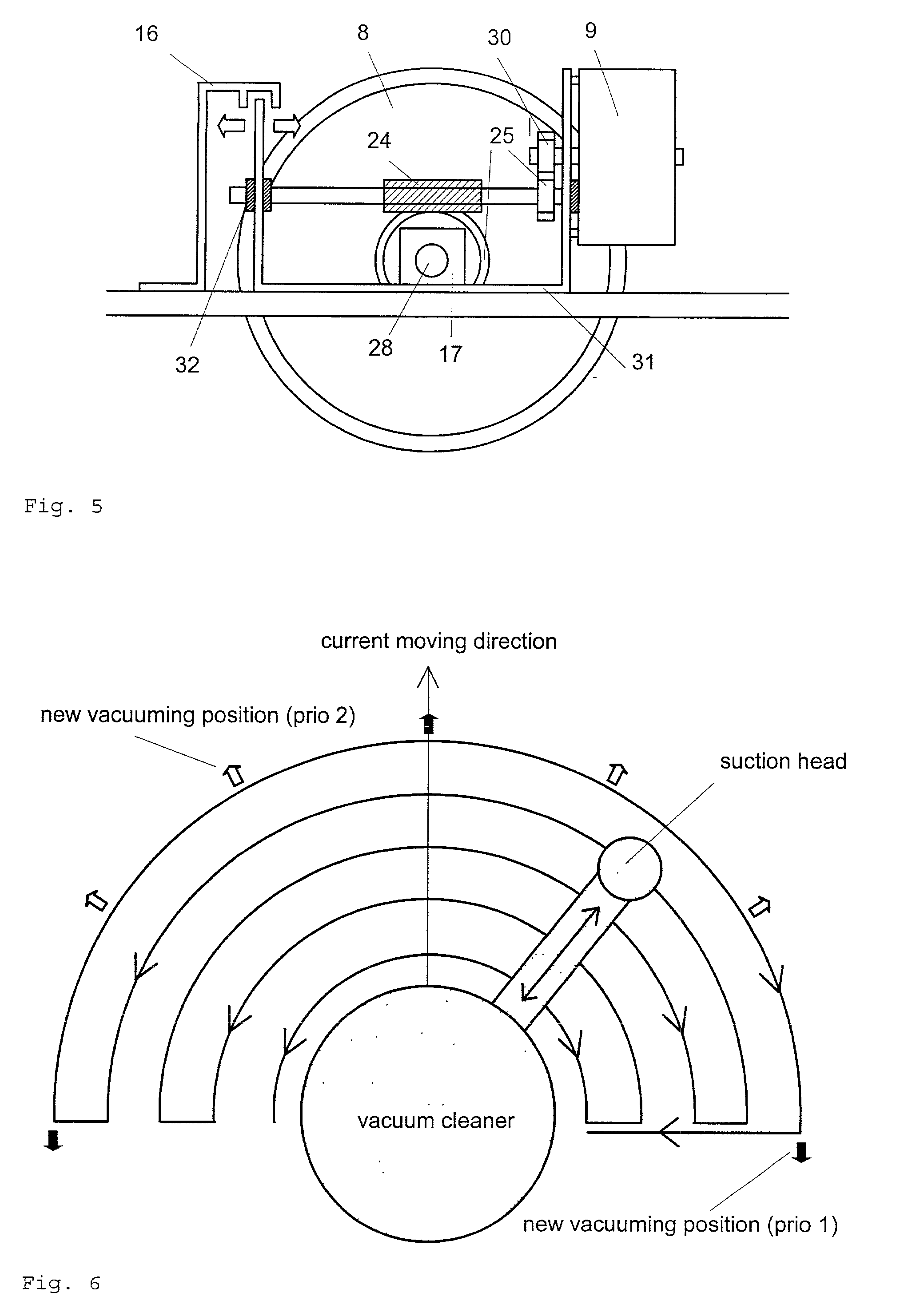

[0078] Driving means and concept of movement

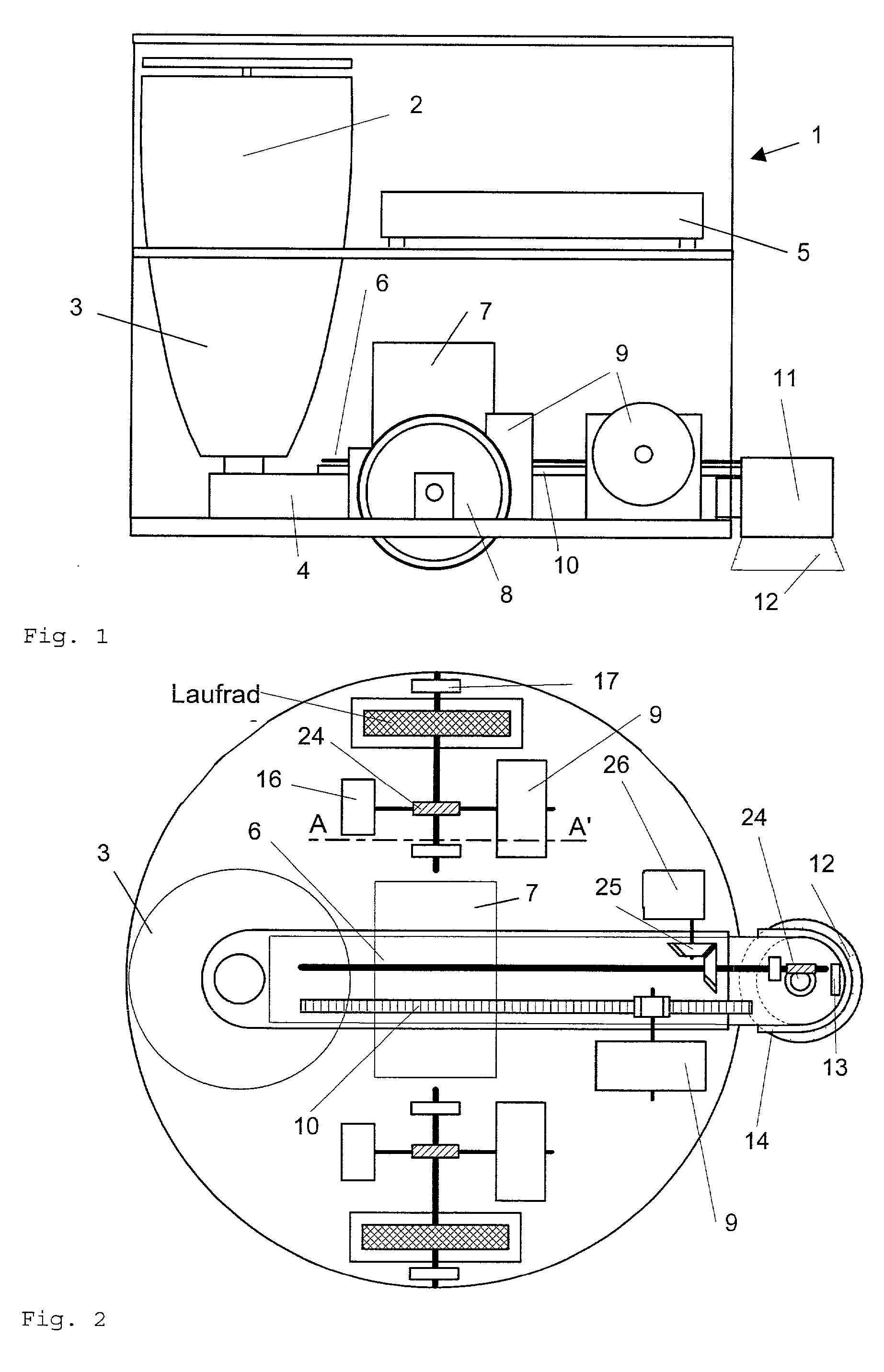

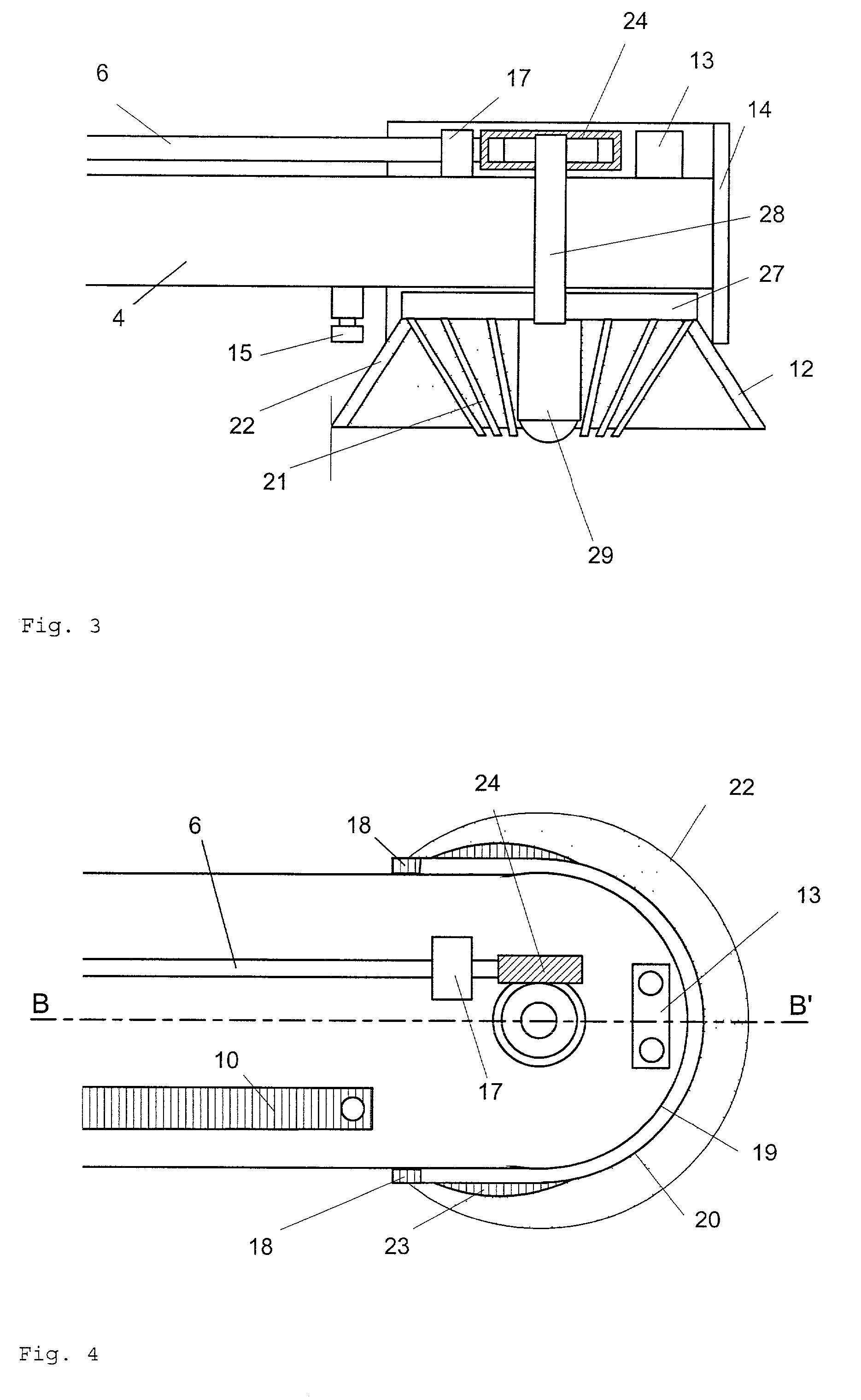

[0079] FIG. 1 shows the elevation of the vacuum cleaner 1 while FIG. 2 depicts the top plan view upon the lower level of the vacuum cleaner 1 with removed dust arrester 3.

[0080] The drive is realised by two step motors 9, each of which propelling by means of a worm drive 24 with a gear reduction of approx. 1:30 a rubber covered wheel 8. By positioning the wheels 8 on the symmetrical axis of the circular basis, by means of the two motors 9, as well the forward thrust (same direction of turning) as the turning around the centre of the vacuum cleaner 1 (opposite directions of turning) can be realised. As a third support, the cleaning brush 12 is used, which is mounted at the front end of the extensible suction arm 4.

[0081] By positioning the comparatively heavy battery 7, which provides every motor 2, 9, 26 as well as the electronic hardware 5 with energy, on the basis of the cleaner body, it is realised that the vacuum cleaner 1 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| turning frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com