Air Flow Losses in a Vacuum Cleaners

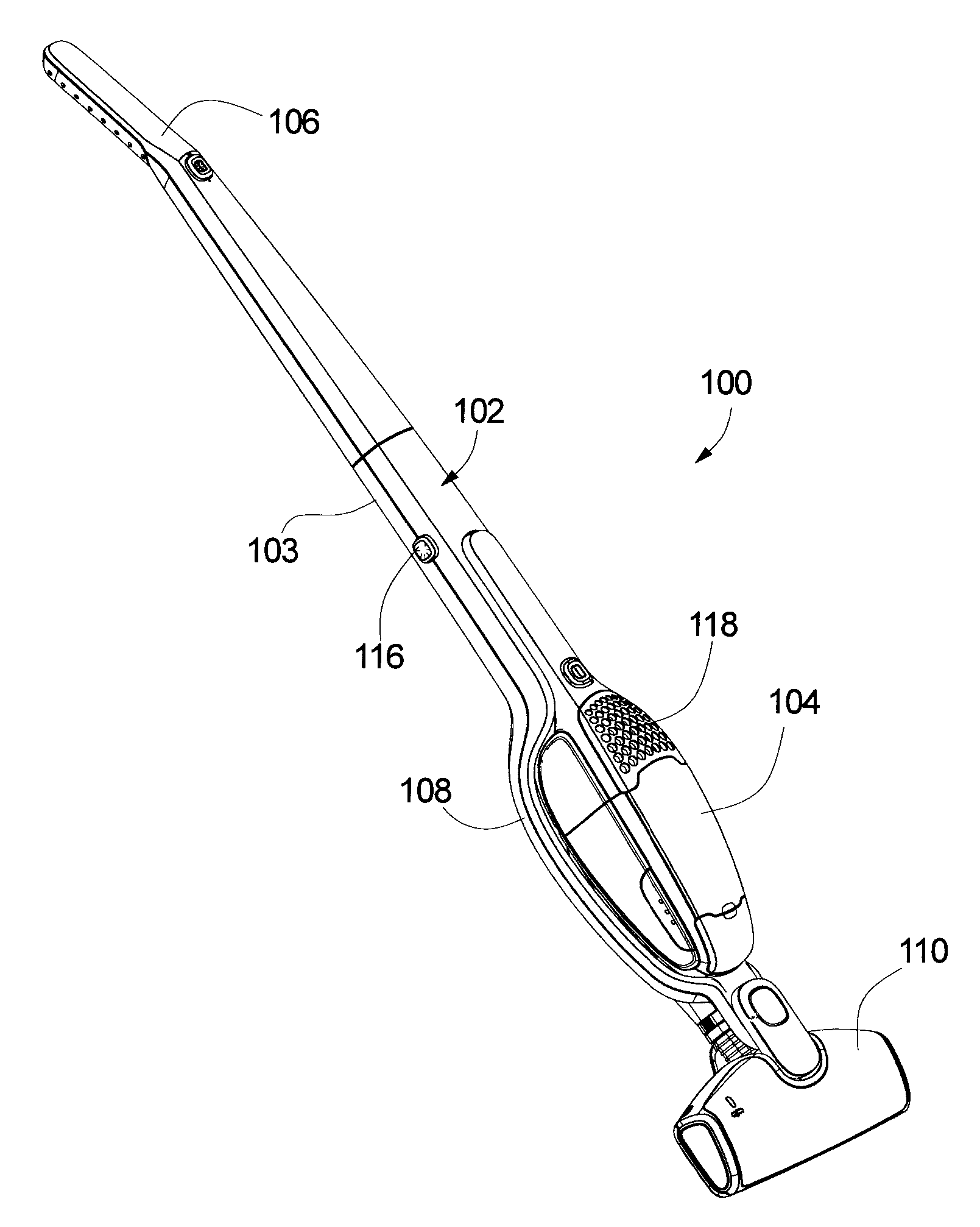

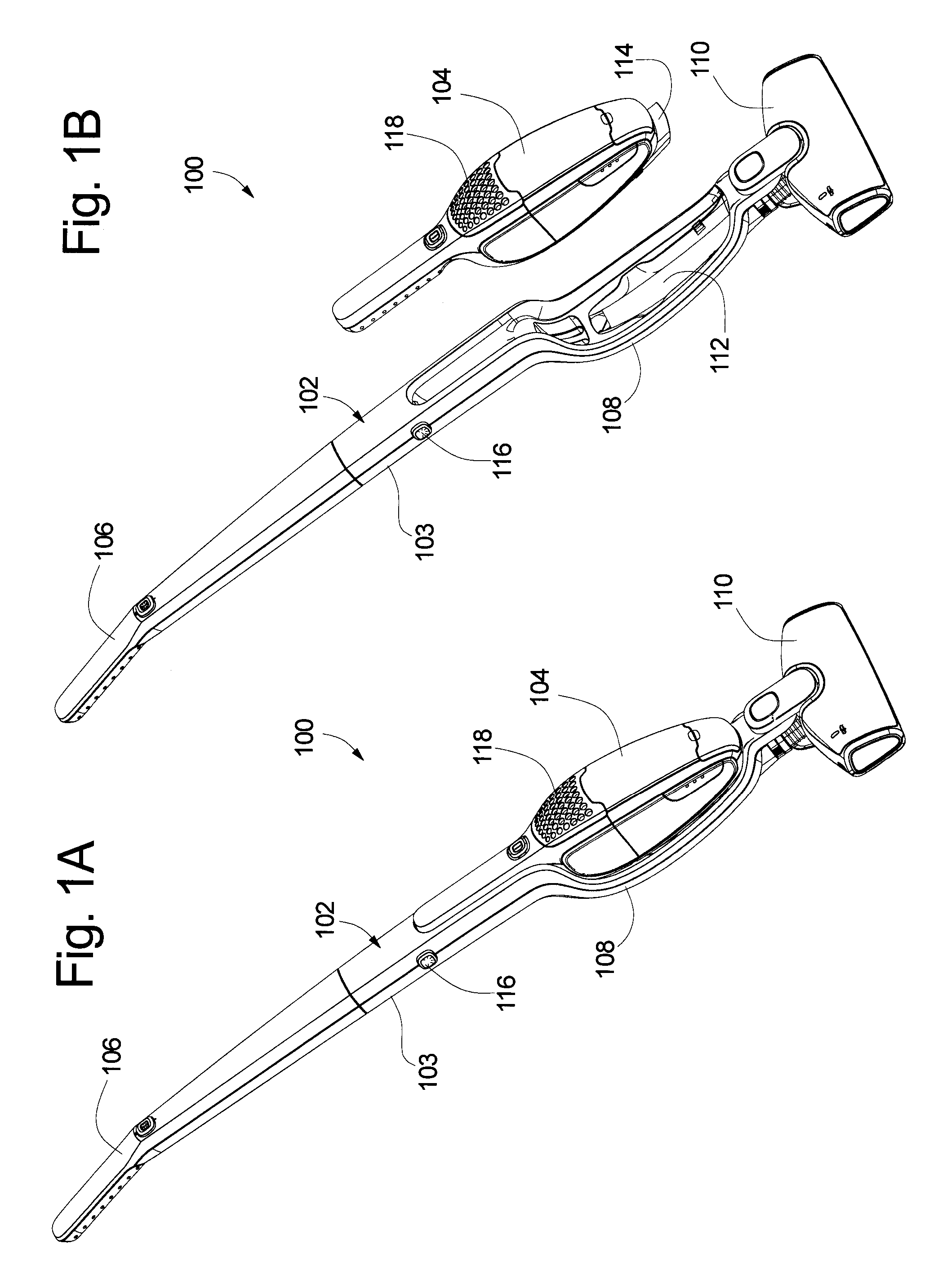

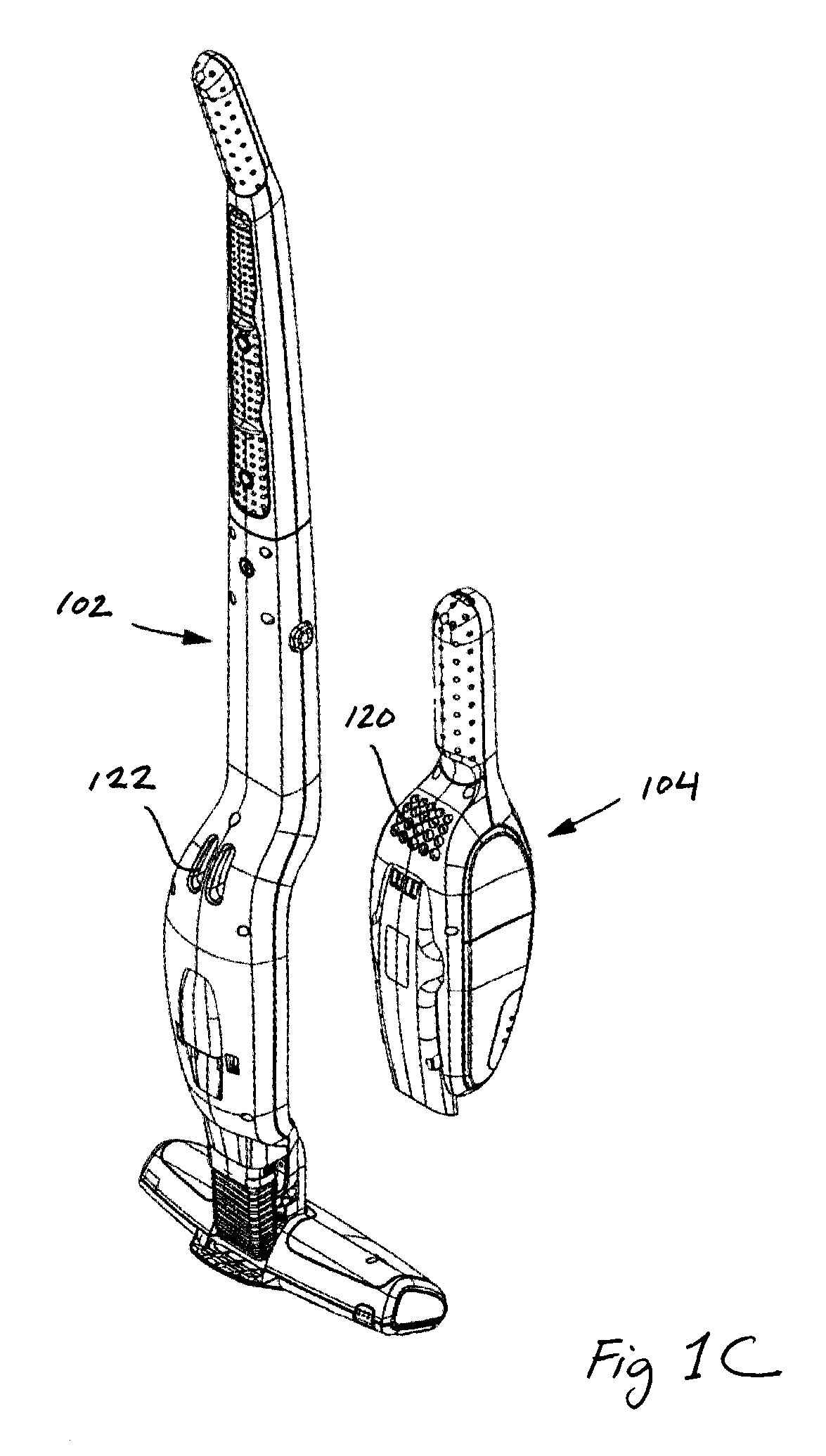

a vacuum cleaner and air flow technology, applied in the direction of vacuum cleaners, cleaning filter means, domestic applications, etc., can solve the problems of increasing the cost and weight of the vacuum cleaner, shortening the battery life,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0121] Turning now to FIGS. 11B and 11C, a filter unit 1116 is illustrated. The filter unit 1116 comprises an air permeable and flexible filter body 1126 having the form of a tubular bag with an open end, or top portion 1128, integrated with a filter attachment member 1130. A dust removing assembly 1132 comprising a rod 1134 and a spring 1136 is arranged inside the filter body 1126, and an end portion 1138 of the rod 1134 is connected to a closed portion 1140 of the filter body 1126. The rod 1134 is supported by a support part 1142 integrated with the filter attachment member 1130 via at least one arm 1146. Preferably, the support part 1142 forms a hole for the rod 1134. The filter body 1126 is straightened by a biasing force applied by the spring 1136 which is arranged around the rod 1134 between a rod protrusion 1148 and the support part 1142 of the attachment member 1130.

[0122] The attachment member 1130 comprises holes 1150 that are configured to receive therethrough correspond...

second embodiment

[0126] Turning now to FIG. 11E, a filter unit 1116 is illustrated. The filter unit 1116 comprises an air permeable and flexible fine particle-filter body 1158 having the form of a tubular bag with its open end, or top portion 1160, integrated with a filter attachment member 1130. A flexible cleaning and / or sealing part 1162 is attached to a closed portion 1164 of the particle-filter body 1158. The filter unit 1116 further comprises a coarse pre-filter body 1166 which has an opening 1168 in an end portion, encloses the particle-filter body 1158, and is connected to the attachment member 1130. It should be noted that the coarse pre-filter body 1166 filters large particles such as hair and fibers, while the particle-filter body 1158 filters smaller particles that pass through the coarse filter 1166.

[0127] Preferably, the coarse pre-filter body 1166 is detachable from the attachment member 1130, and the coarse filter body 1166 may incorporate a separate attachment member (not shown) fo...

third embodiment

[0131]FIG. 11G illustrates a filter unit 1116 according to a The filter unit 1116 comprises a spring 1170 arranged inside the filter body 1126 to support the filter body 1126. The spring 1170 is at one end connected to a bottom portion 1140 of the filter body 1126 and is at its other end connected to the attachment member 1130. Preferably, the spring 1170 has a conical shape corresponding to the straightened shape of the filter body 1126, as illustrated in the figure.

[0132] Other variations of the filter systems above are contemplated. For example, the rod 1134 of the third embodiment may be omitted and replaced by a weight (not shown) arranged in a bottom portion 1140 of the filter body 1126. In this case the filter unit 1116 is to be shaken for contracting and straightening the filter body 1126. Such a weight may be used in any combination of the first and second embodiment.

[0133] The spring 1170 according to the third embodiment may also be combined with any of the filters acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com