Cyclone type dust collecting apparatus for a vacuum cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

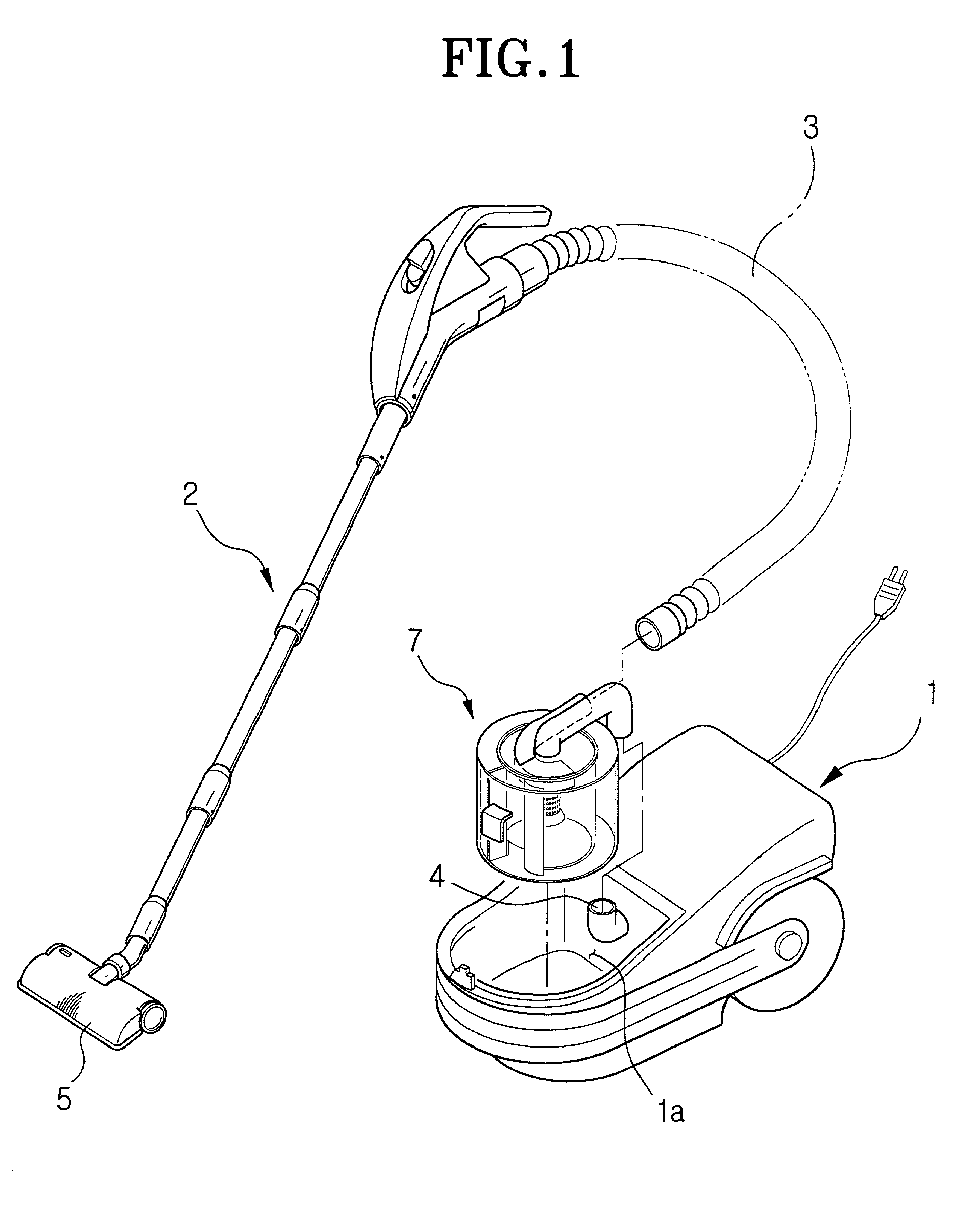

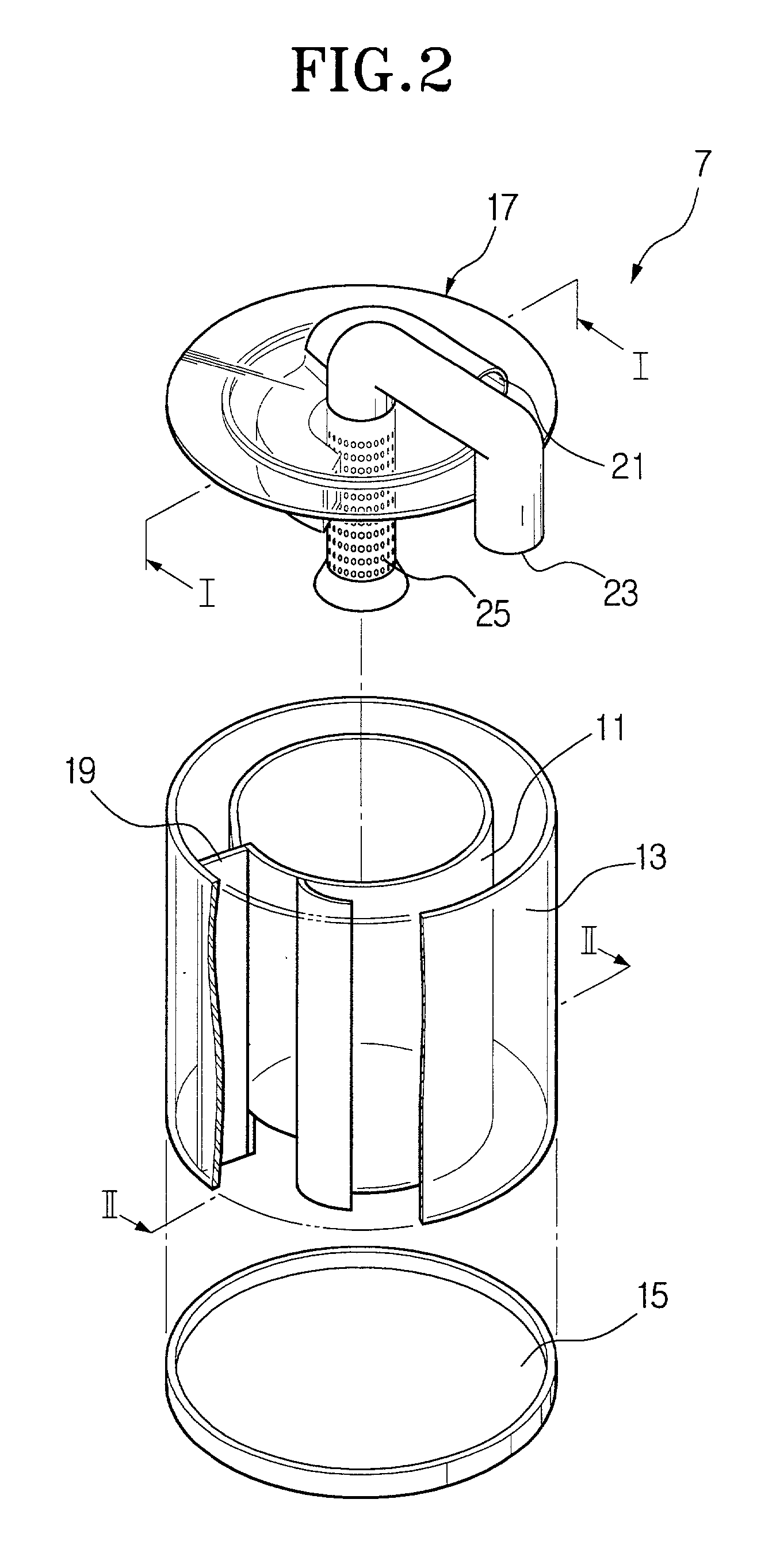

[0013] The present invention of a cyclone type dust collecting apparatus for a vacuum cleaner will be described in greater detail below with reference to the accompanying drawings.

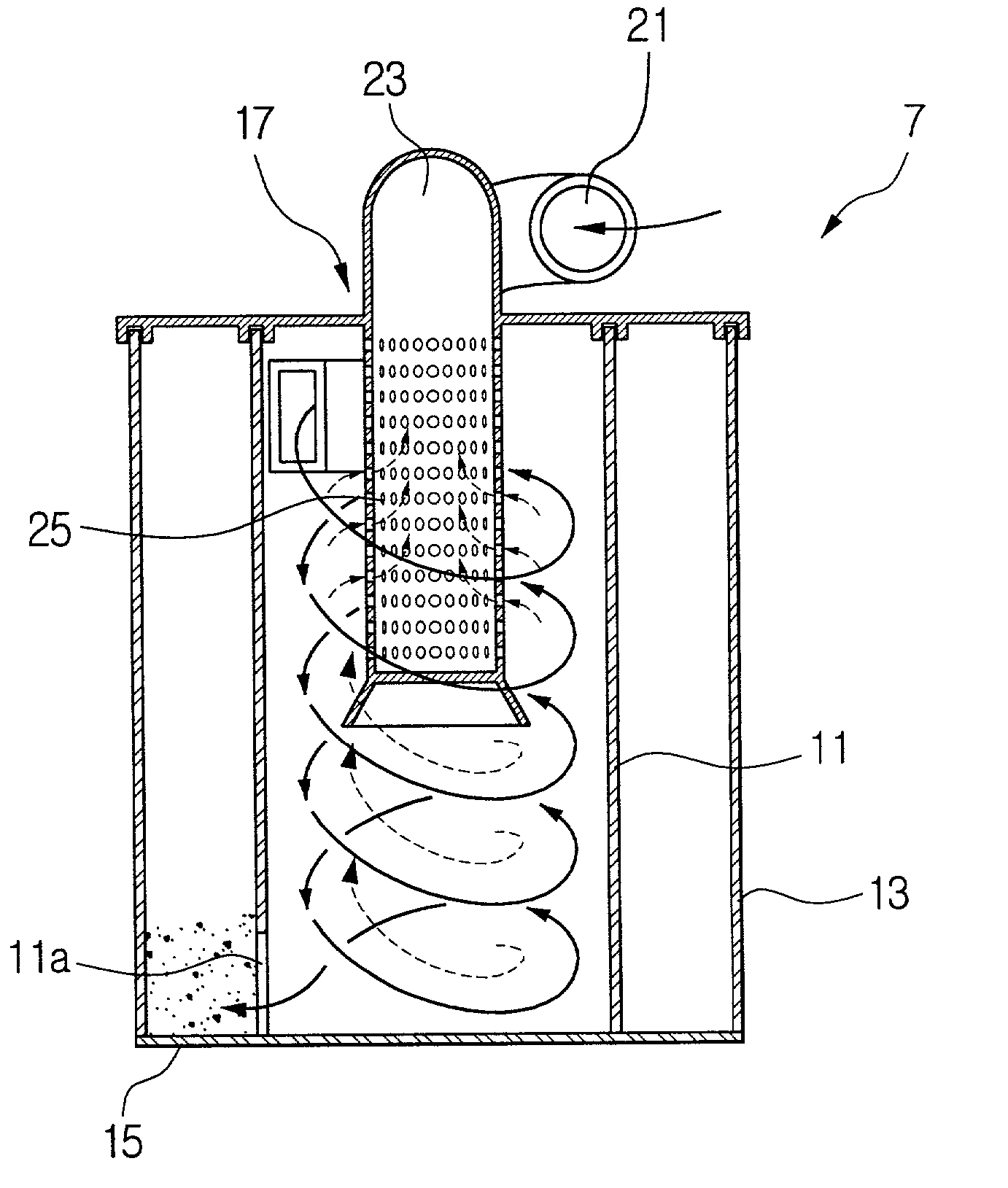

[0014] FIG. 1 is a schematic exploded perspective view of a vacuum cleaner having a cyclone type dust collecting apparatus in accordance with a preferred embodiment of the present invention.

[0015] Referring to FIG. 1, the vacuum cleaner includes a body 1, a suction brush 5 that is connected to the body 1 through a connecting tube 2 and a connecting hose 3, and a cyclone type dust collecting device 7.

[0016] The cleaner body 1 includes a dust collecting chamber 1a, in which the cyclone dust collecting device 7 is nested, and a motor driving chamber (not shown), in which a motor (not shown) is nested. According to the preferred embodiment of the present invention, the motor driving chamber and the dust collecting chamber 1a communicate with each other through an air passage tube 4. The motor generates a stron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com