Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Increase the mixing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

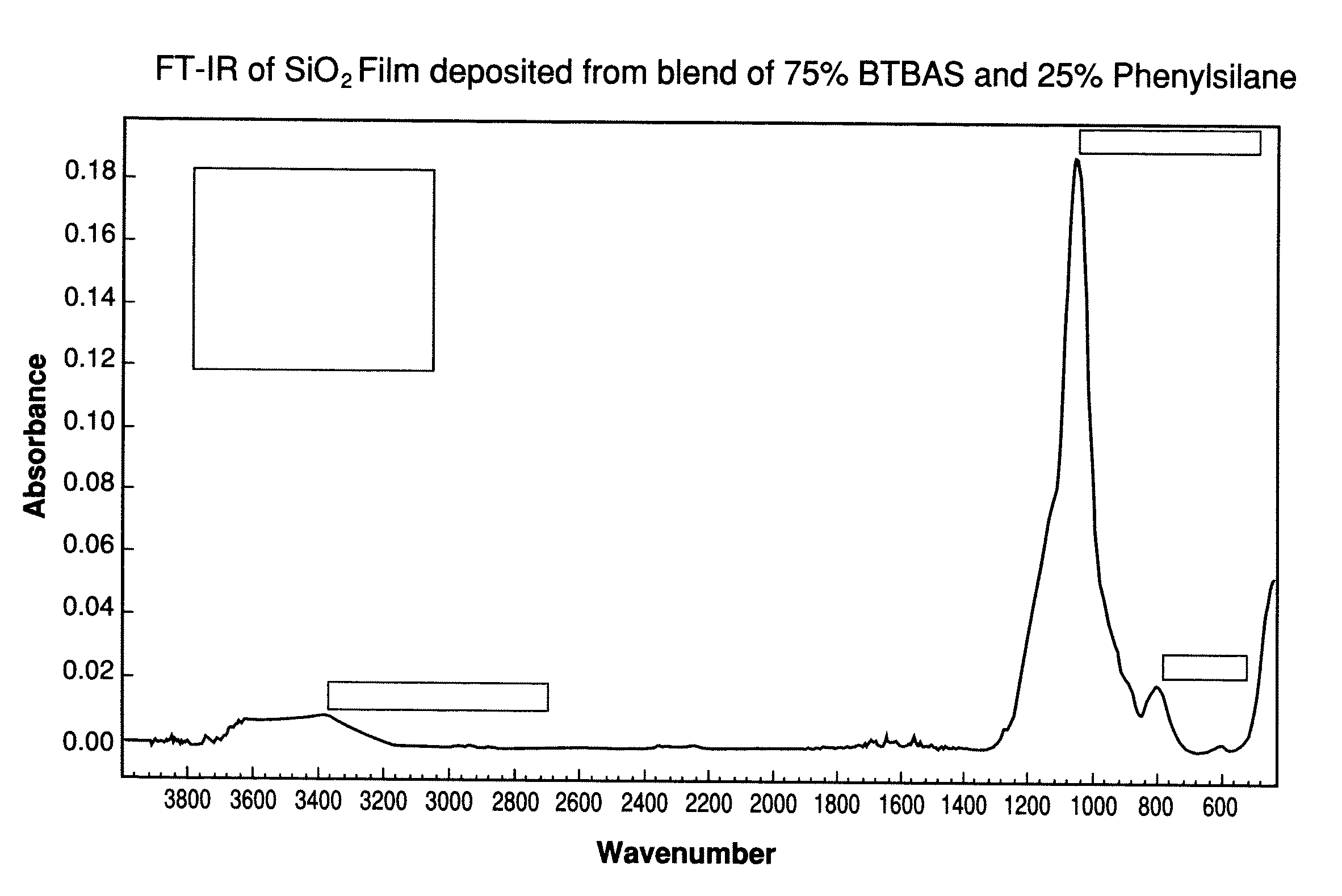

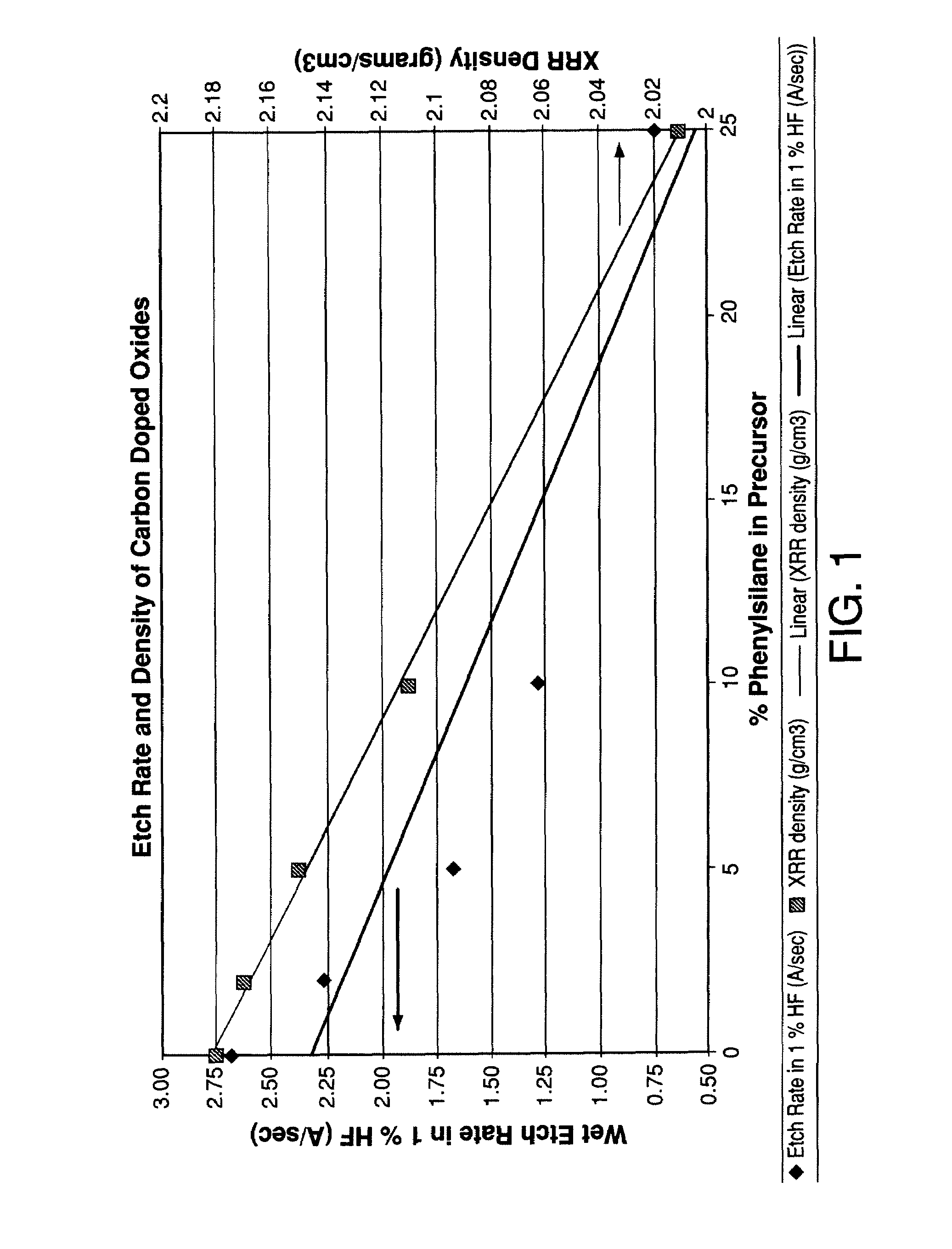

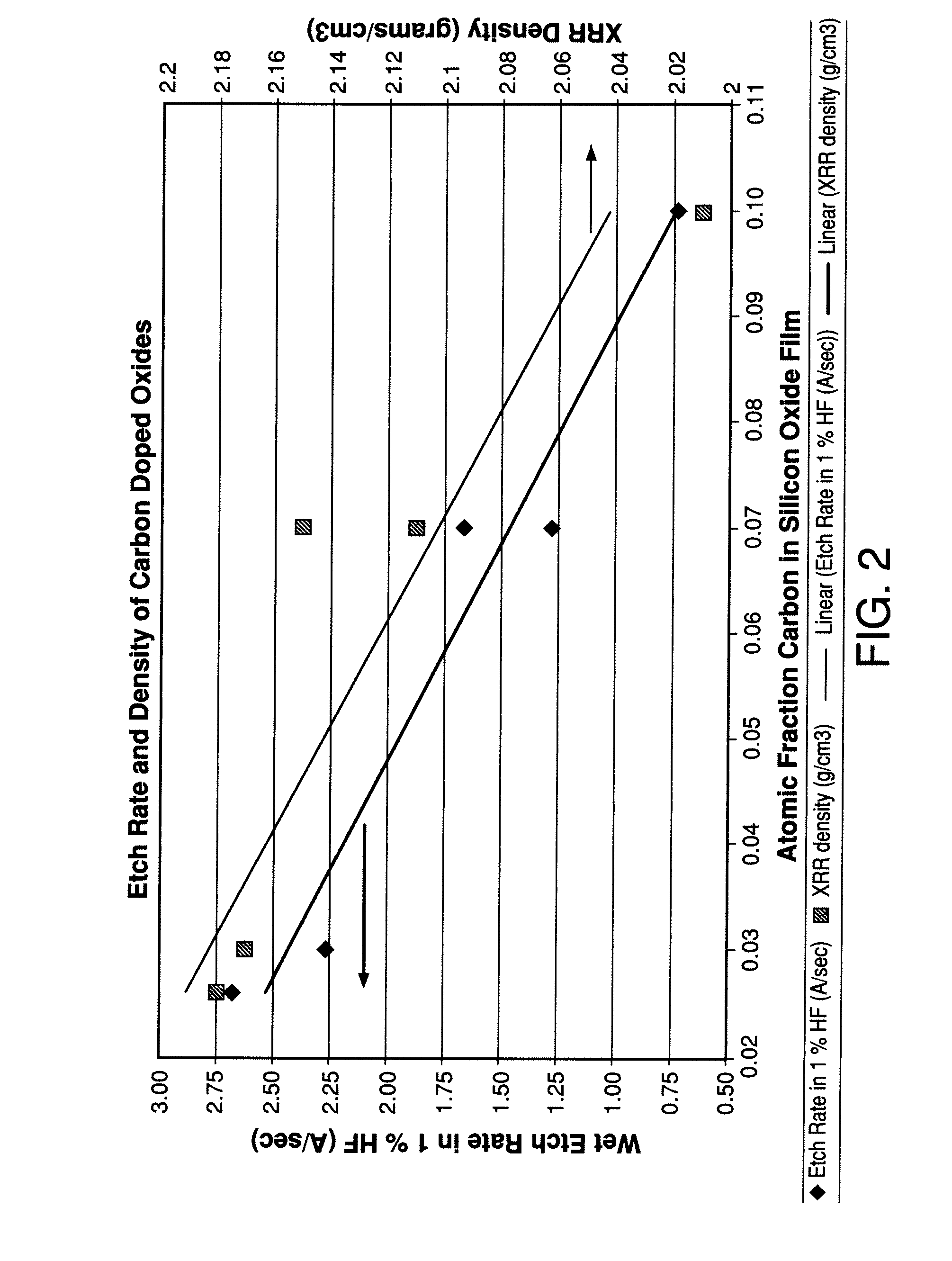

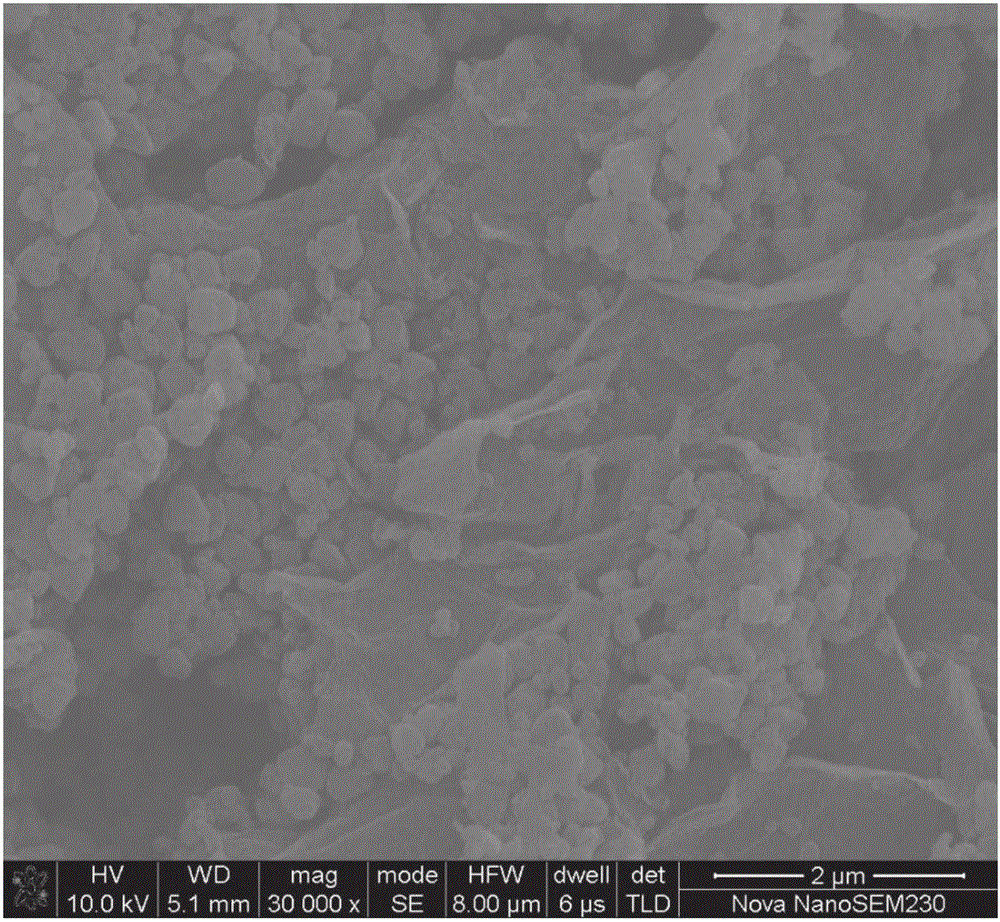

Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

InactiveUS20080124946A1Excellent etch resistanceIncreasing flow ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideChemical Modifier

The present invention discloses a process for depositing a carbon containing silicon oxide film, or a carbon containing silicon nitride film having enhanced etch resistance. The process comprises using a silicon containing precursor, a carbon containing precursor and a chemical modifier. The present invention also discloses a process for depositing a silicon oxide film, or silicon nitride film having enhanced etch resistance comprising using an organosilane precursor and a chemical modifier.

Owner:VERSUM MATERIALS US LLC

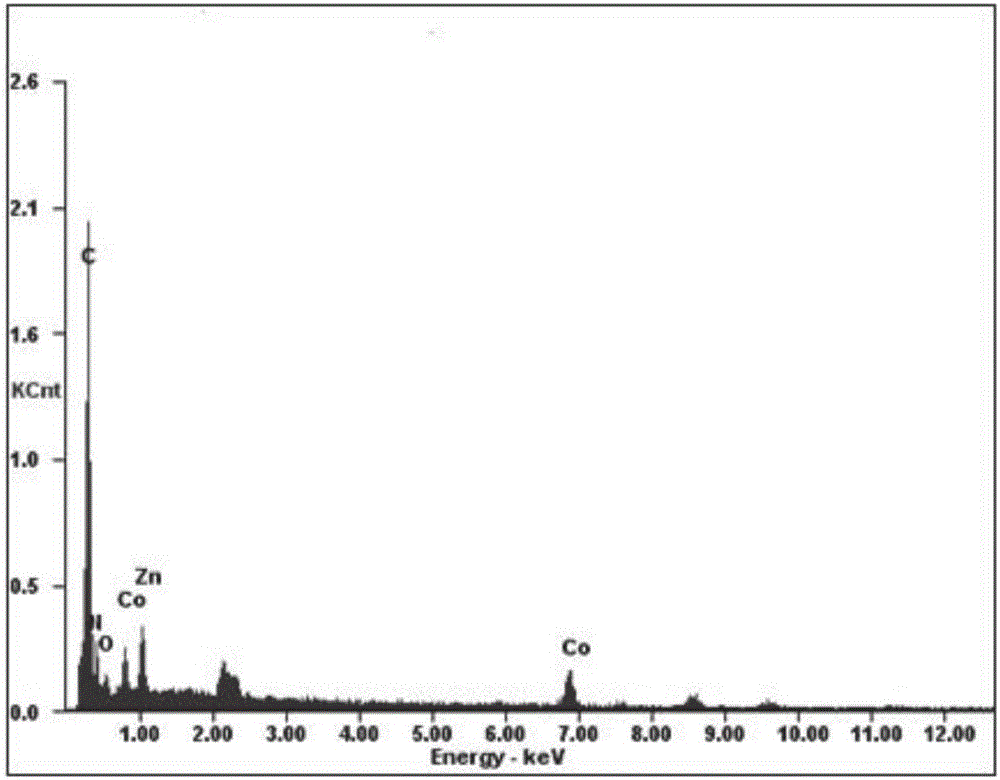

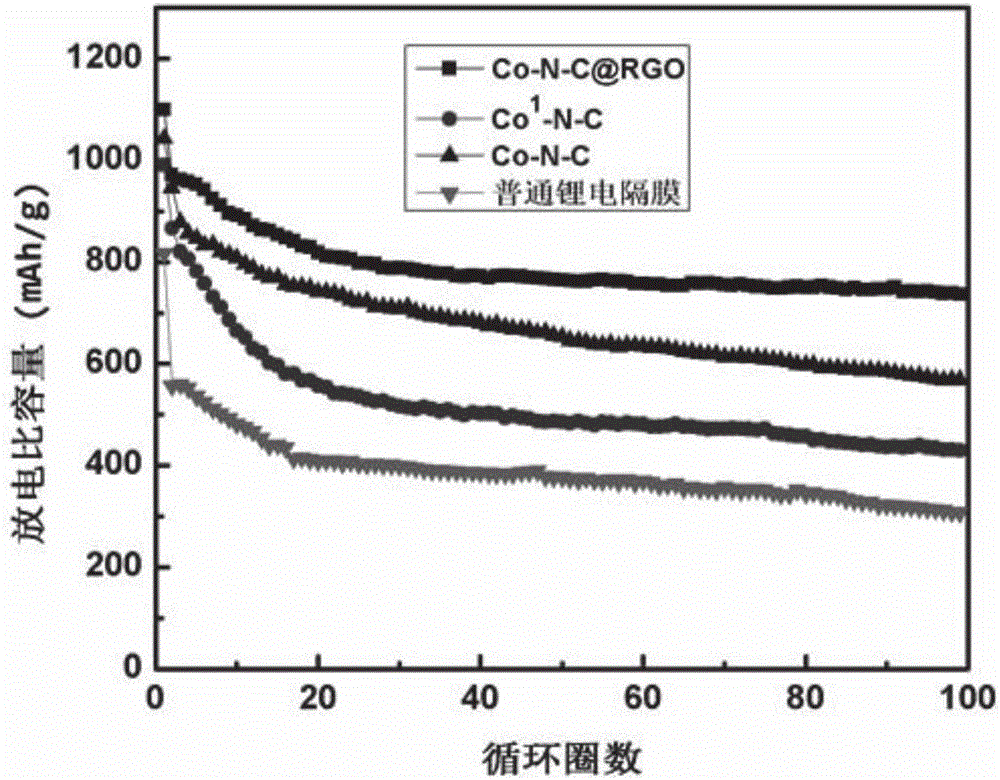

Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

ActiveCN106784525AIncrease the areaHigh porosityLi-accumulatorsCell component detailsPorous carbonElectrical battery

The invention discloses a method for preparing porous carbon@graphene composite material by taking a bimetal organic framework material as a precursor and application to modification of lithium-sulfur battery diaphragms thereof. The preparation method comprises the following steps: taking zinc salt and cobalt salt in a certain ratio as the raw materials, synthesizing a zinc / cobalt-bimetal organic framework@graphene composite material through a room-temperature liquid phase method, taking the zinc / cobalt-bimetal organic framework@graphene composite material as the precursor, carrying out high-temperature reaction under inert atmosphere, pickling and drying to obtain a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite material. Co-N-C@RGO has high conductivity; the specific surface area of Co-N-C@RGO reaches up to 750-1000m<2> / g; the content of Co is 2-4At%; the content of N is 10-20At%. When the material is applied to the modification of the lithium-sulfur battery diaphragms, the material has the function of obviously inhibiting polysulfide shuttle effect and is capable of greatly improving actual specific capacity and cyclic performance of the lithium-sulfur batteries; meanwhile, the raw materials needed for synthesizing the material are simple; the operation is convenient; the large-scale production can be achieved; the material has certain promoting effect on commercialization of lithium-sulfur battery systems.

Owner:CENT SOUTH UNIV

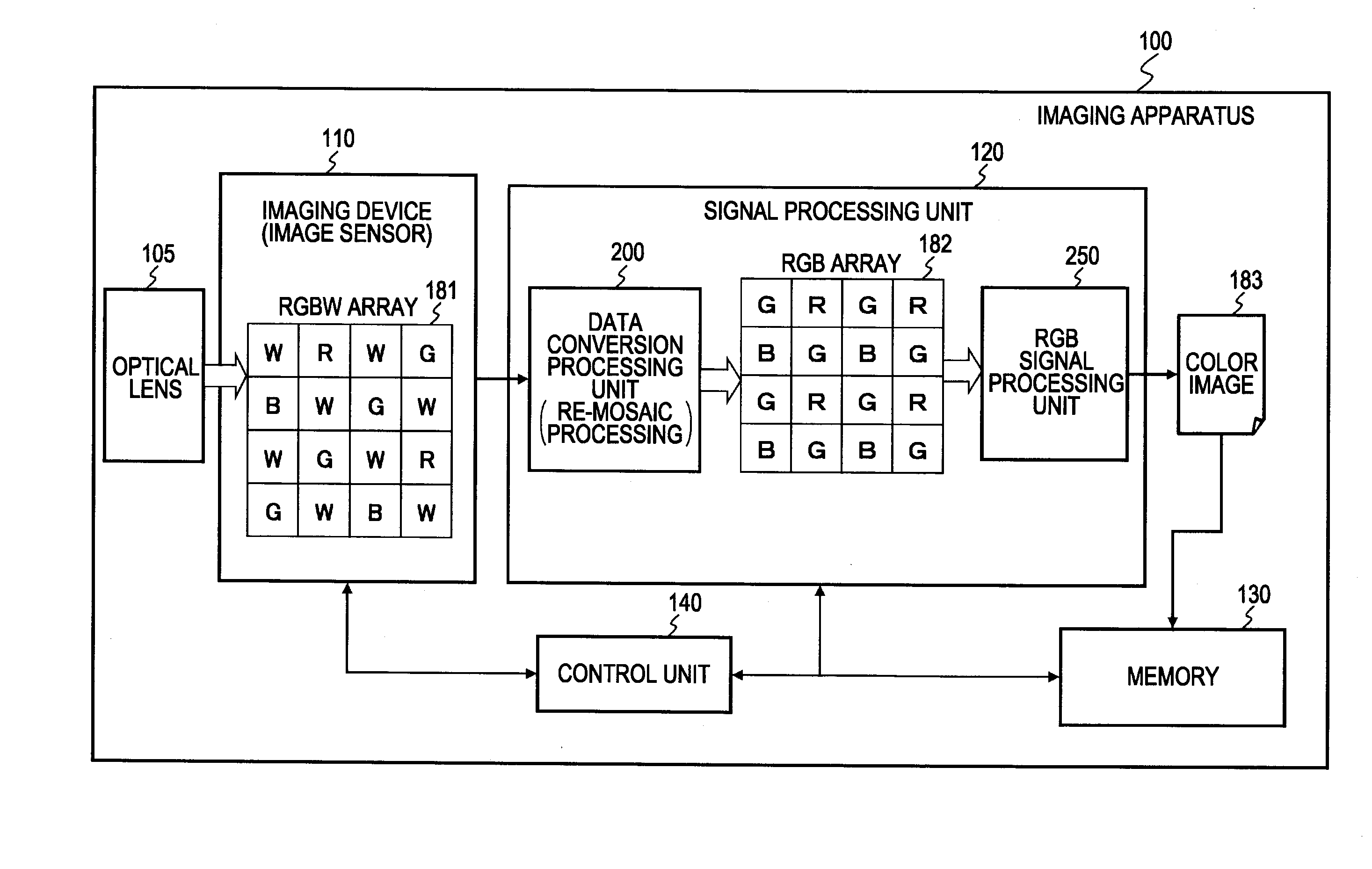

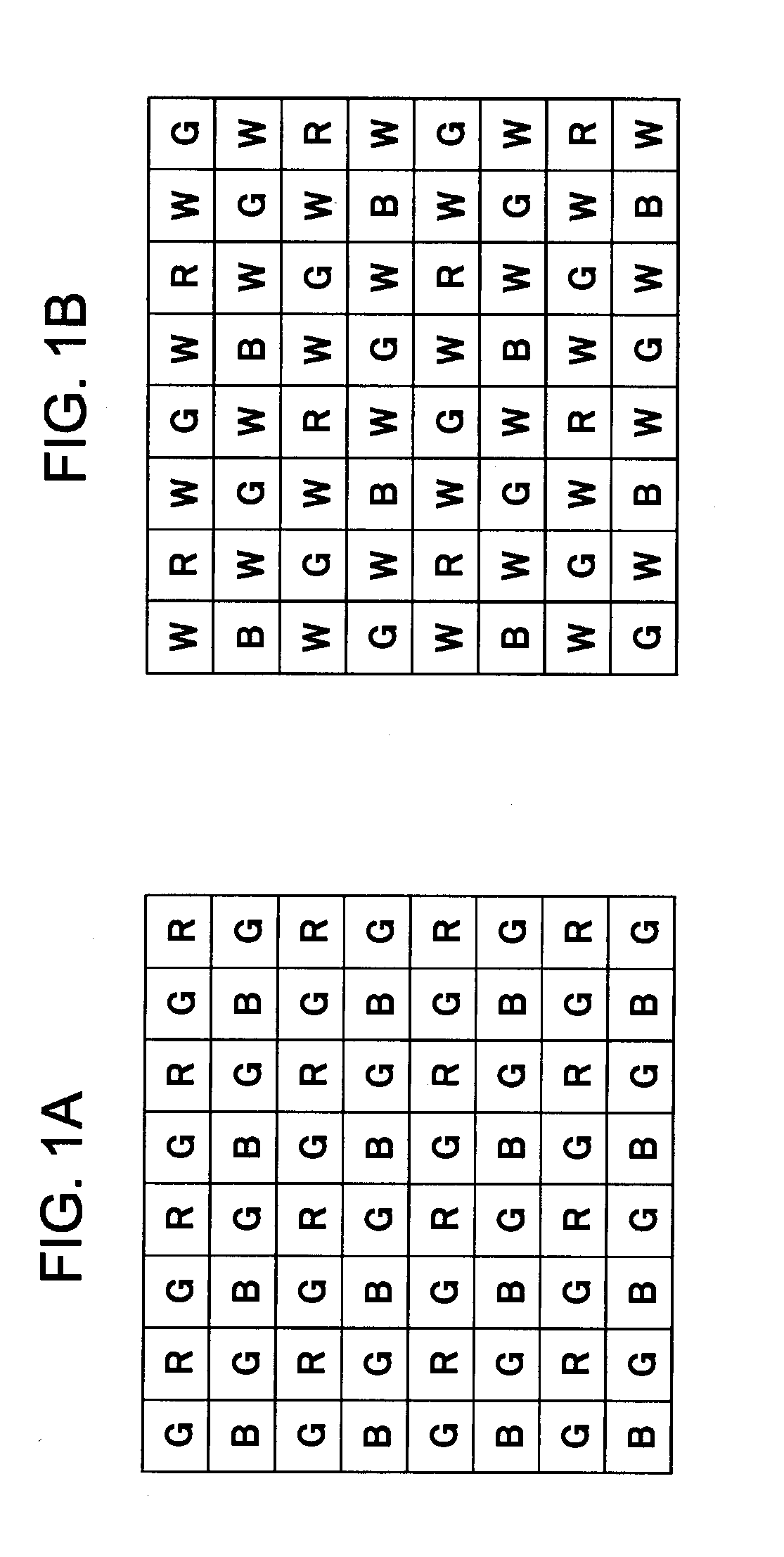

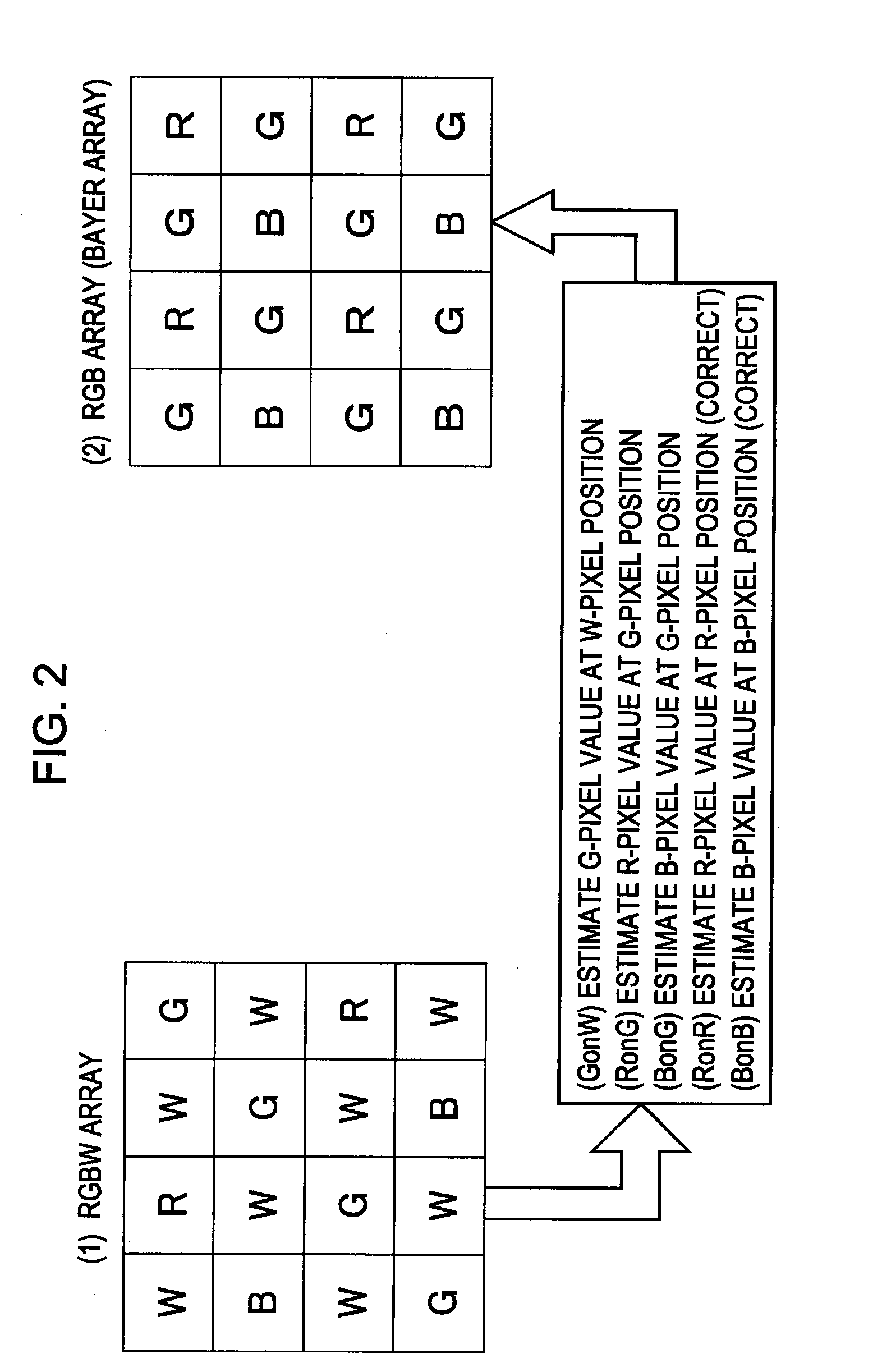

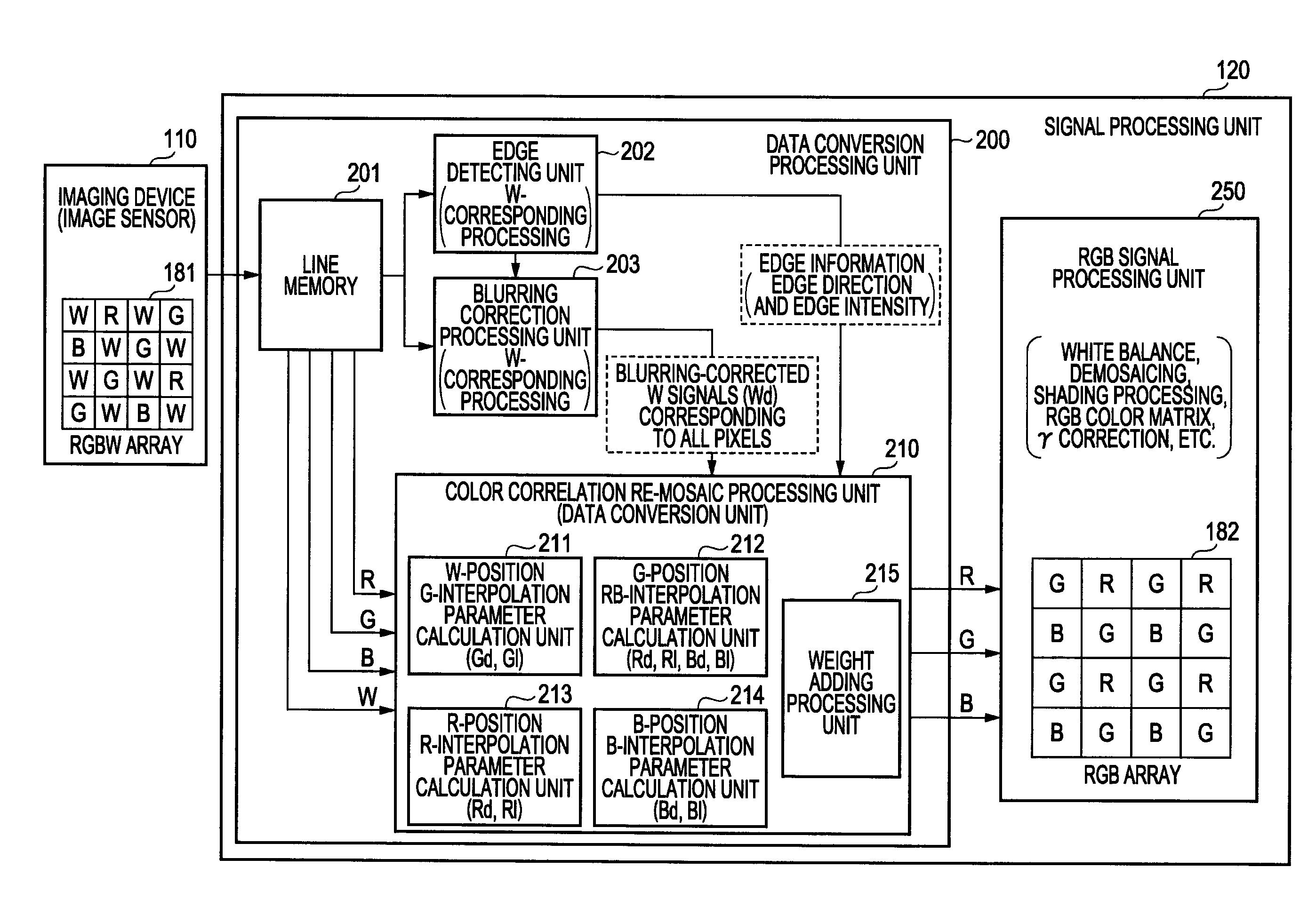

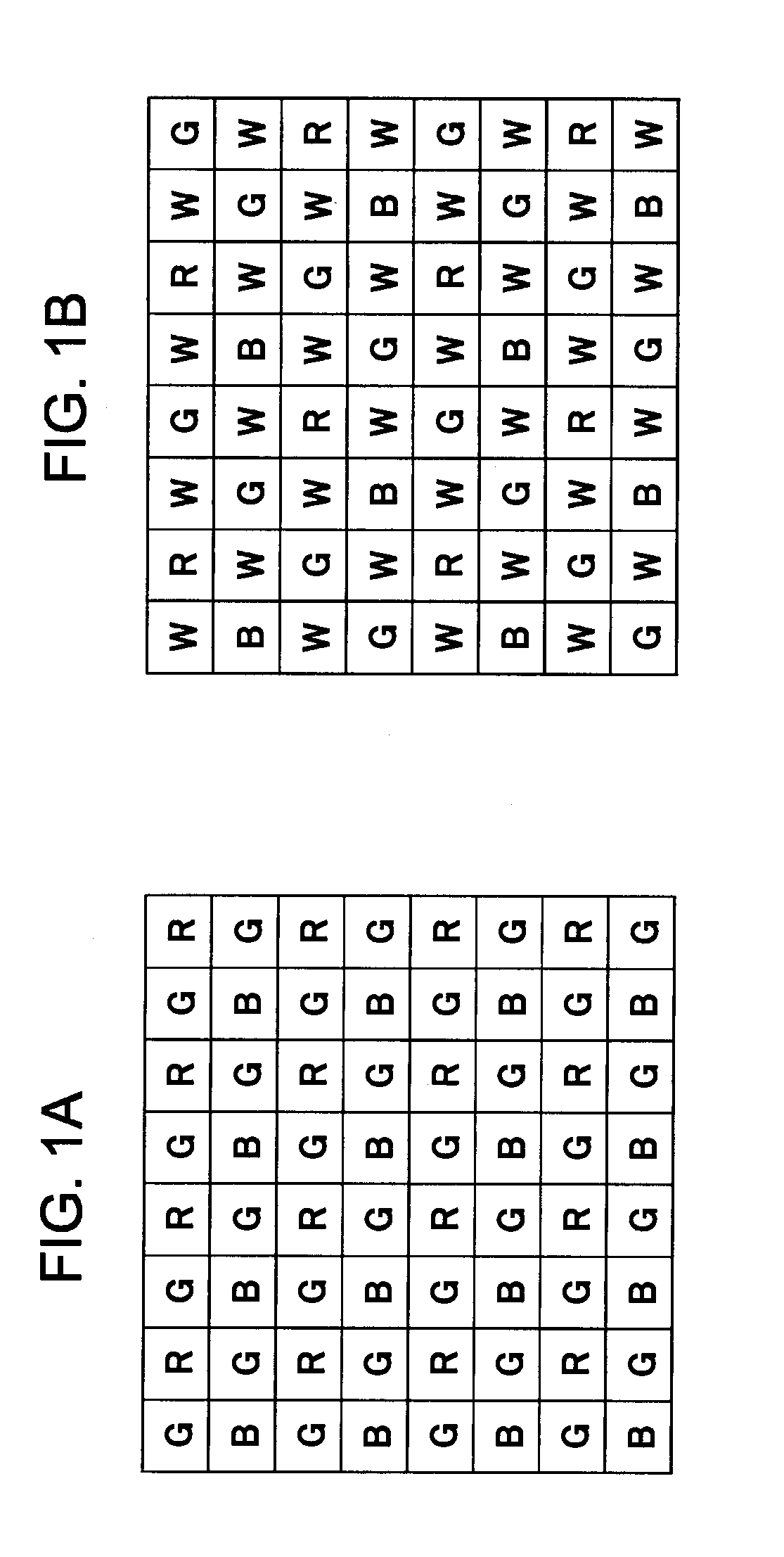

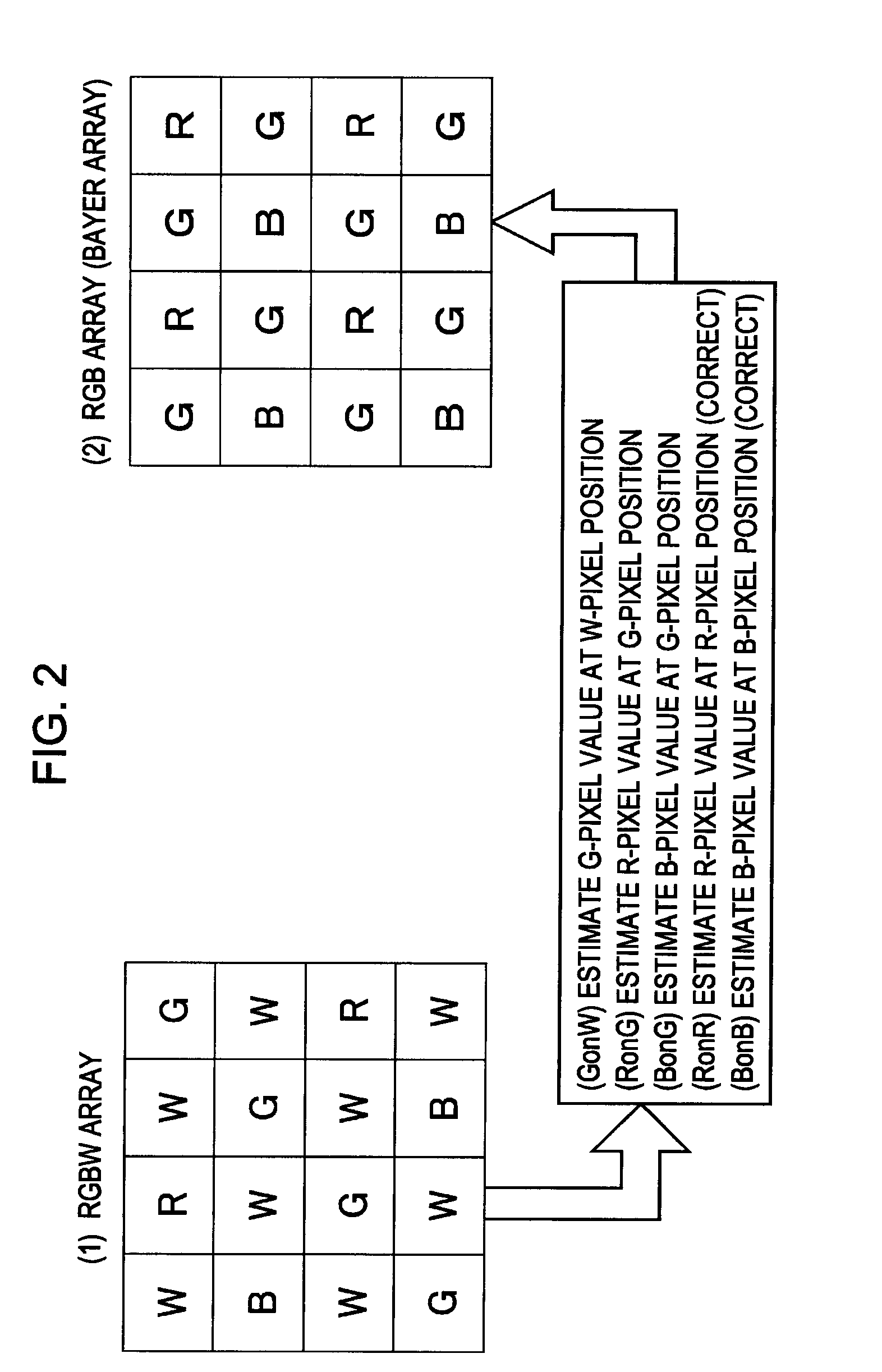

Image Processing Device, Image Processing Method, and Program

ActiveUS20110050918A1Little false colorLittle blurringTelevision system detailsImage enhancementImaging processingData conversion

An image processing device includes: a blurring correction processing unit configured to perform blurring correction processing on output signals of an imaging device having an RGBW array which includes RGB pixels and white (W) pixels, and generate blurring-corrected signals corresponding to each pixels; and a data conversion unit configured to convert the RGBW array into an RGB array; wherein the data conversion unit executes processing of generating blurring-corrected RGB signals (Rd, Gd, Bd) which are blurring-corrected signals corresponding to RGB that have been estimated from blurring-corrected signals generated by the blurring correction processing unit, and applying the blurring-corrected RGB signals (Rd, Gd, Bd) to determine RGB signals values configuring an RGB array.

Owner:SONY CORP

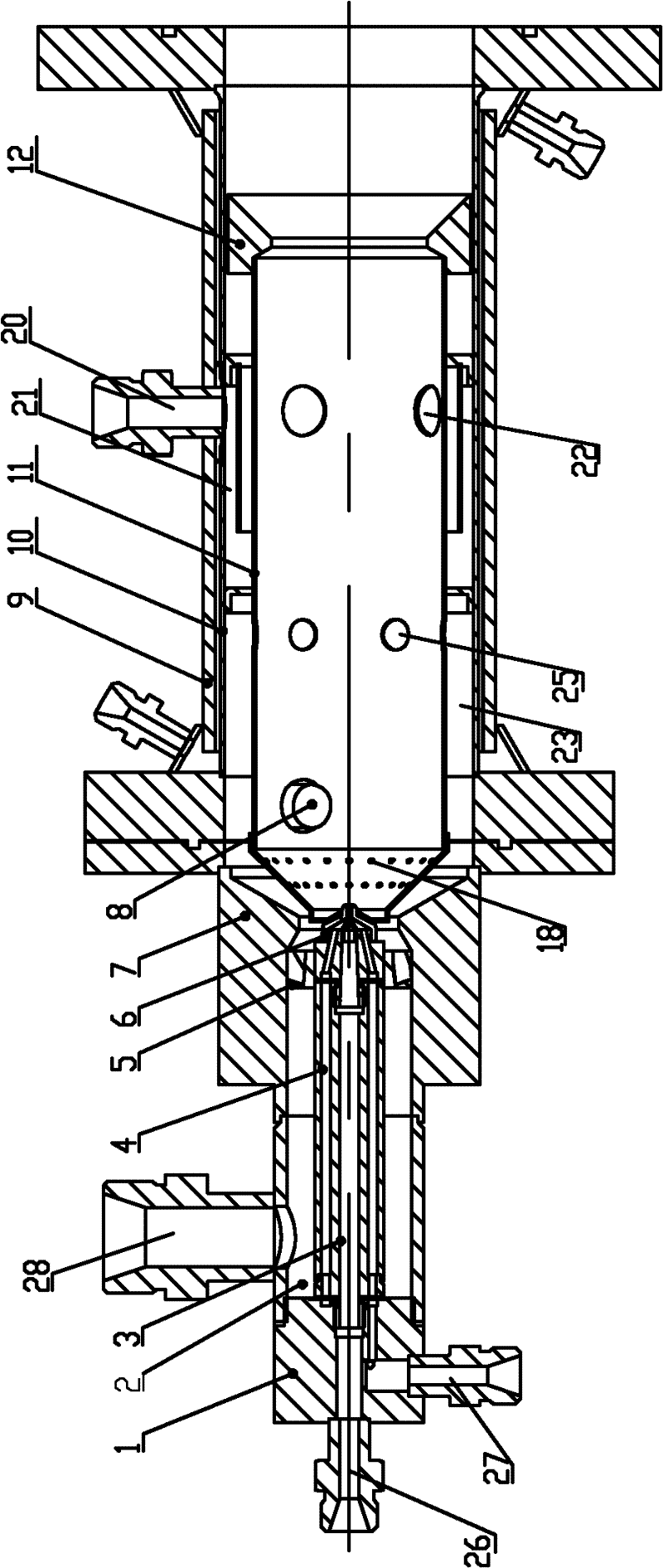

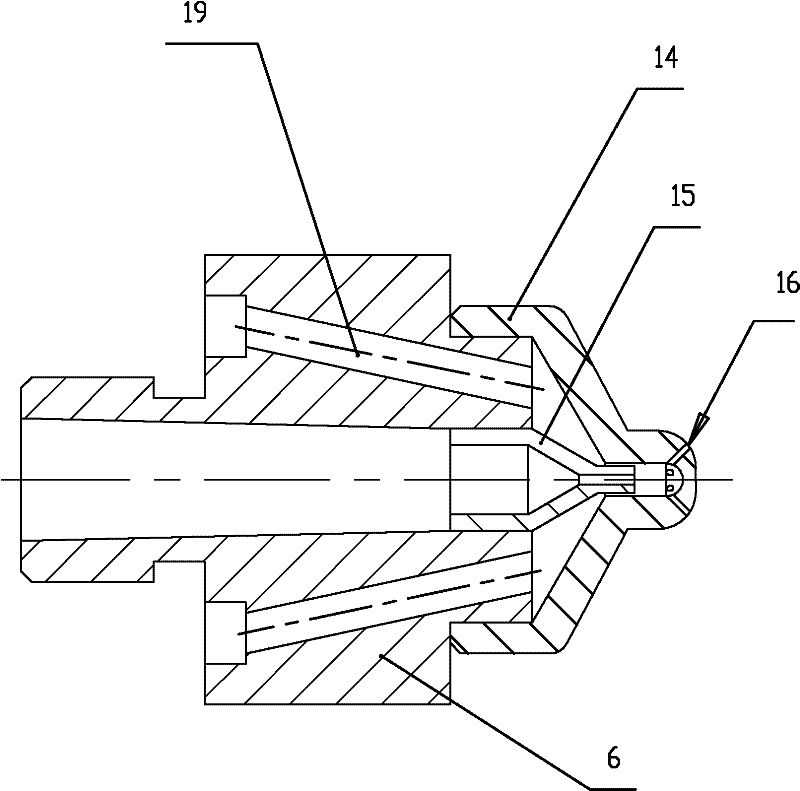

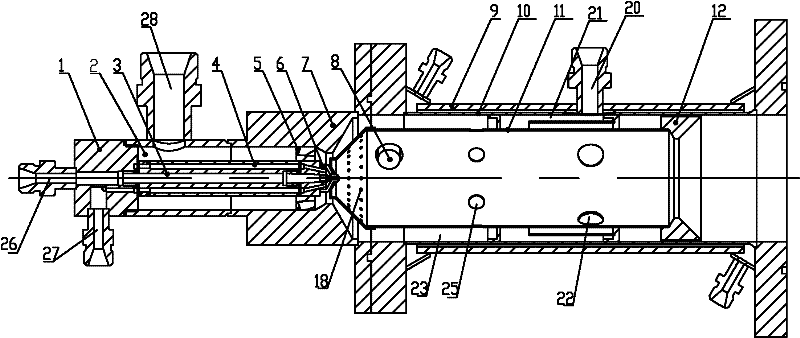

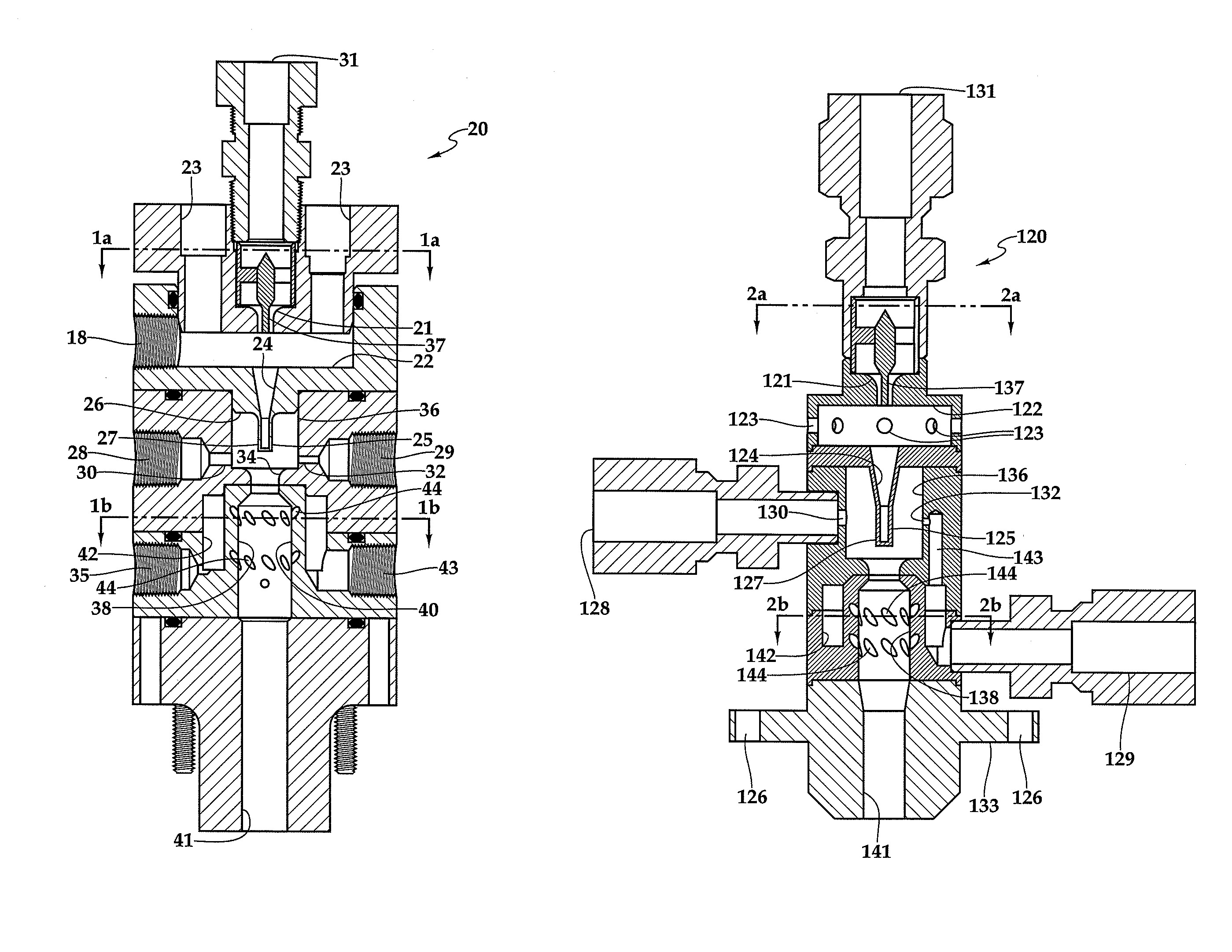

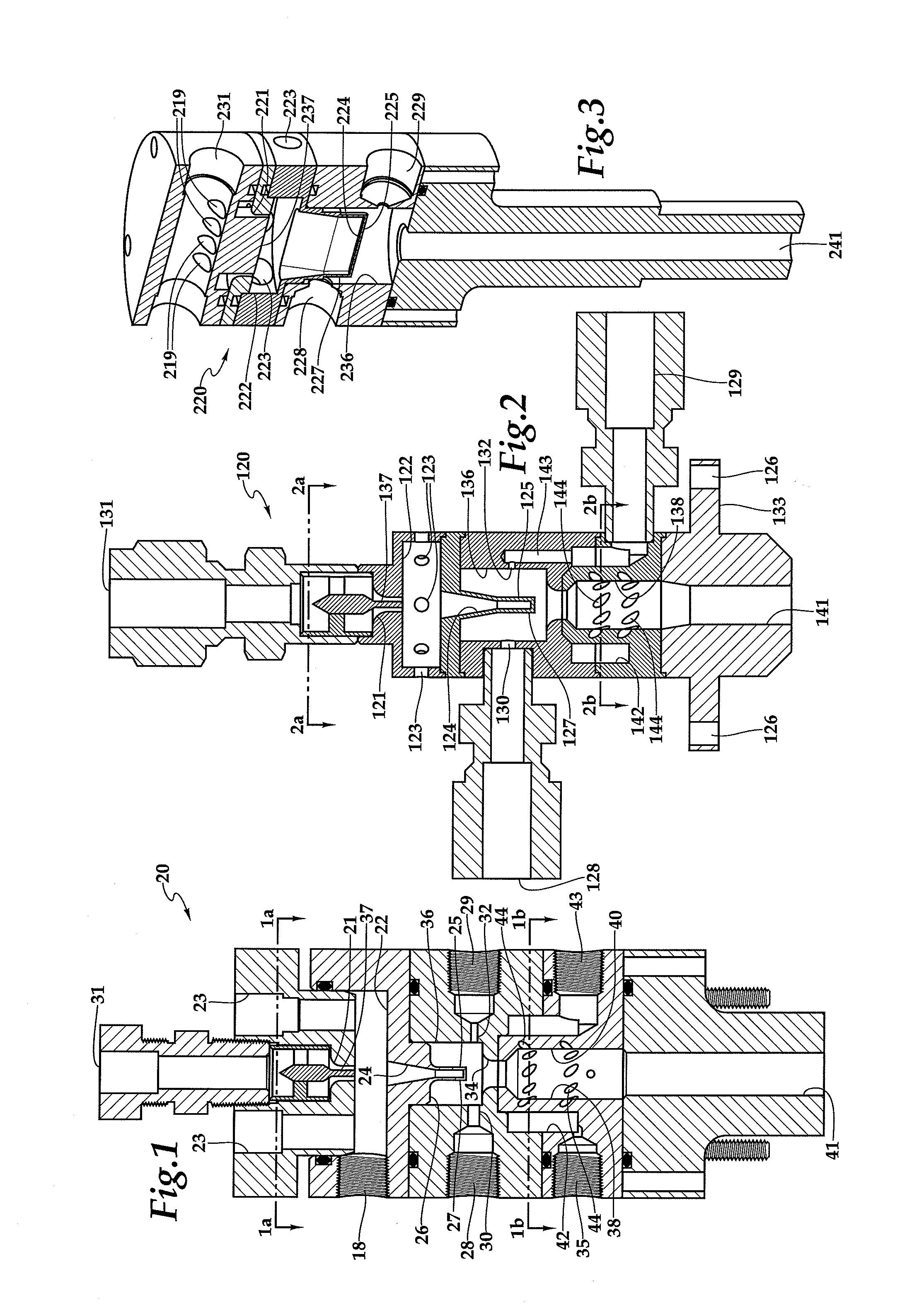

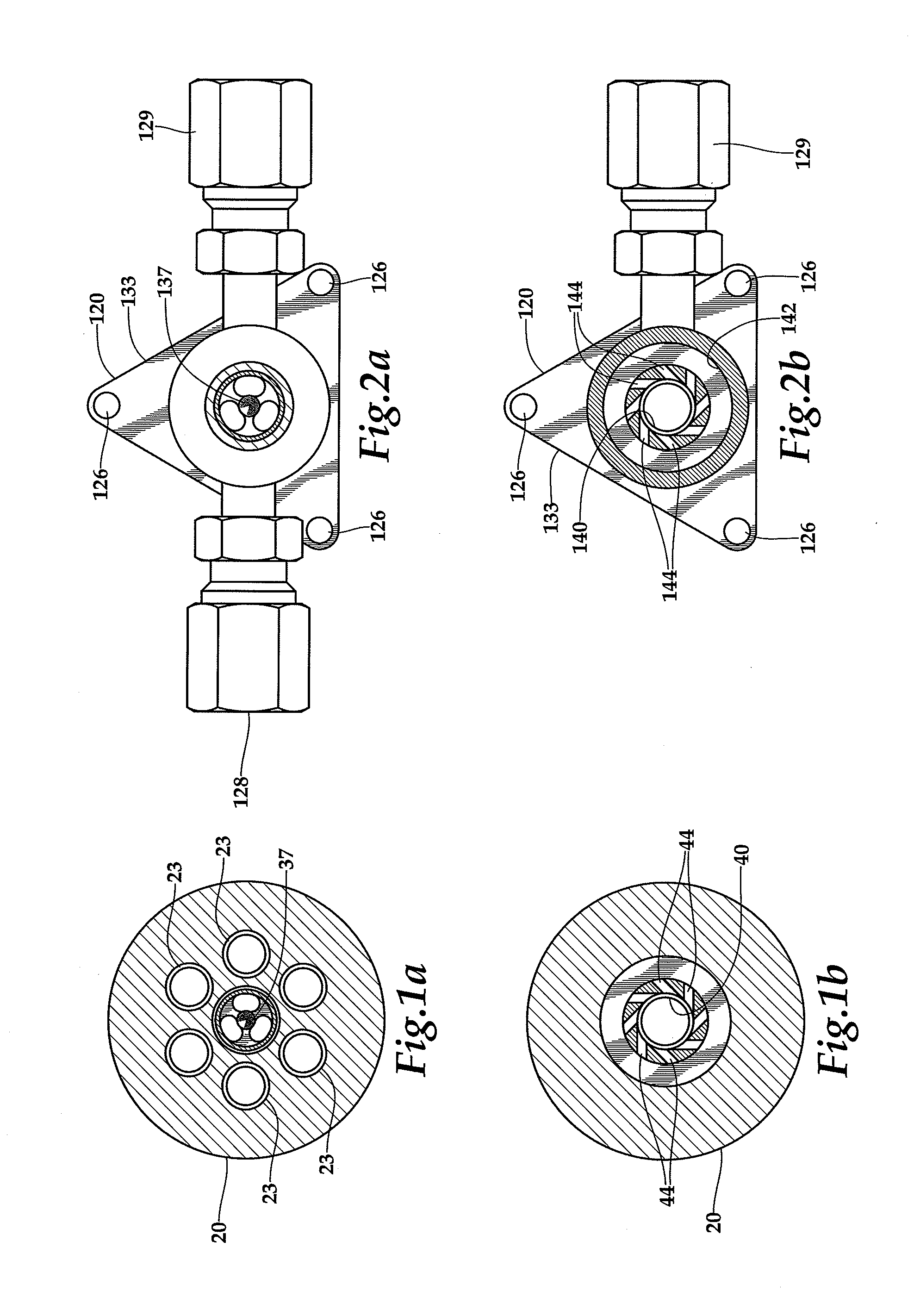

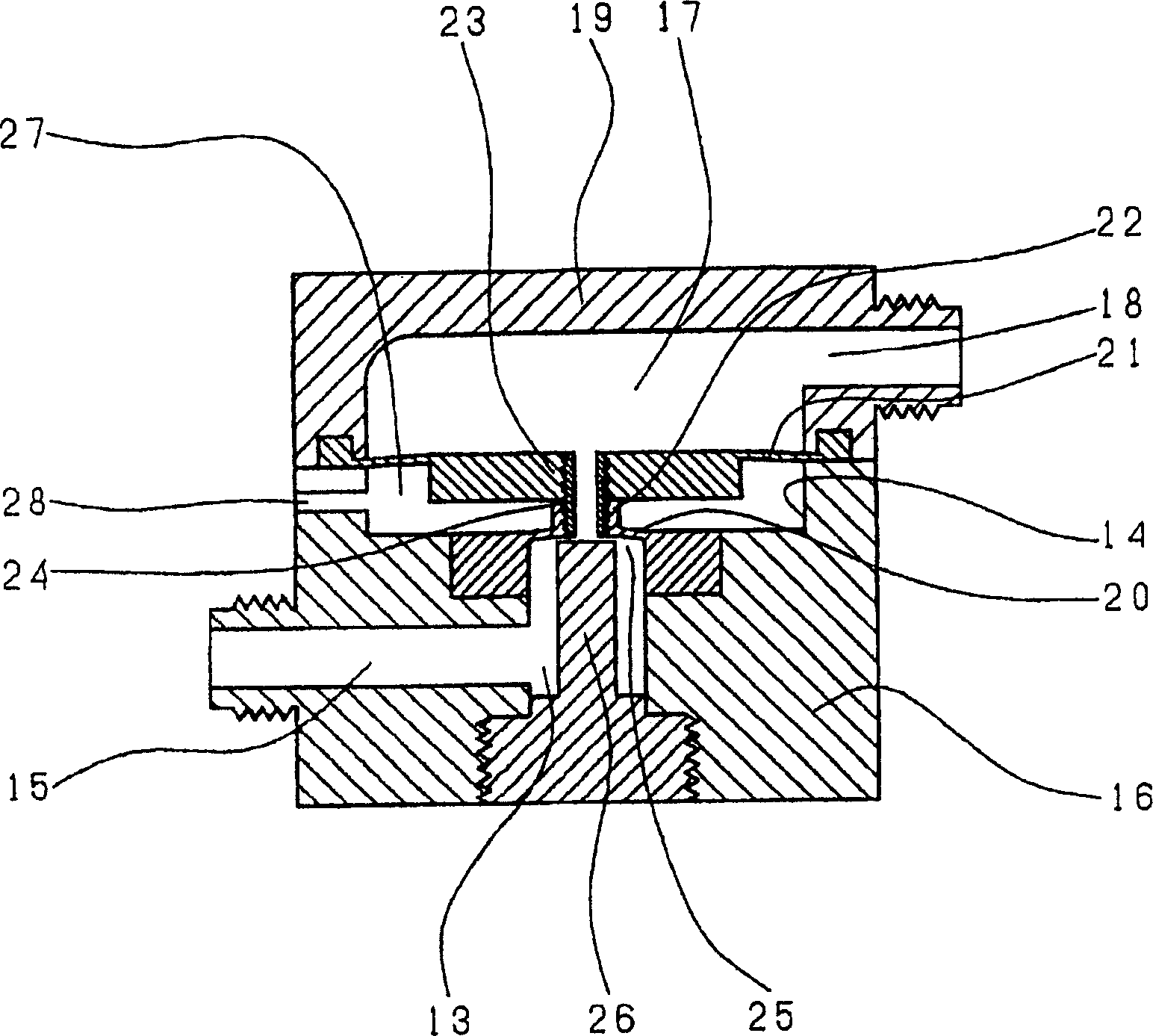

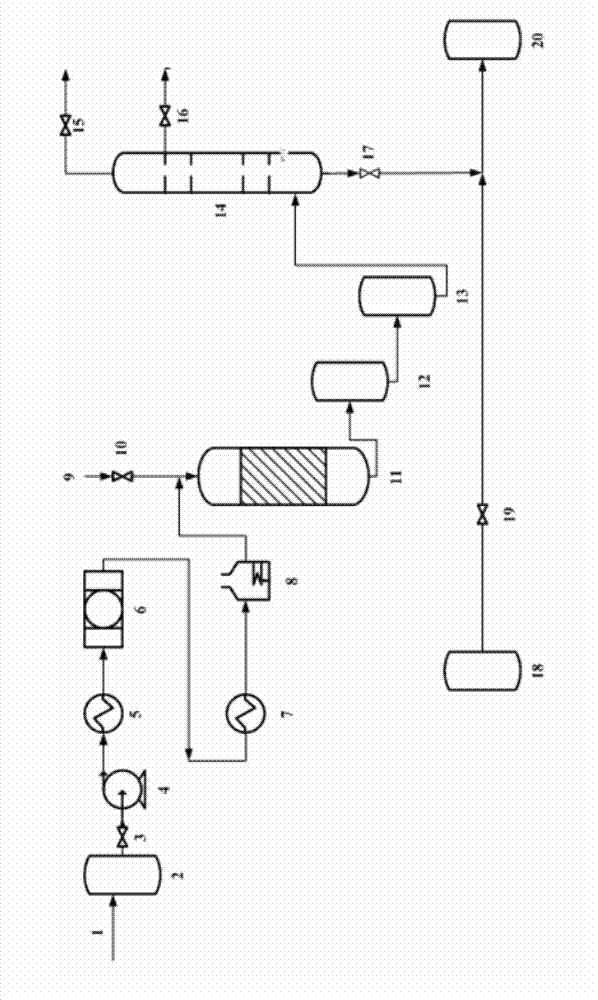

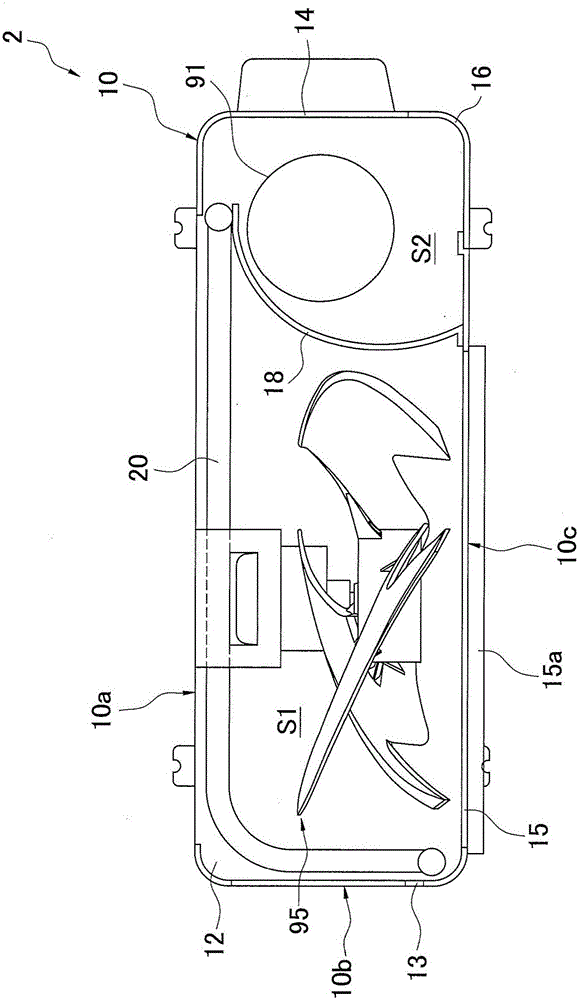

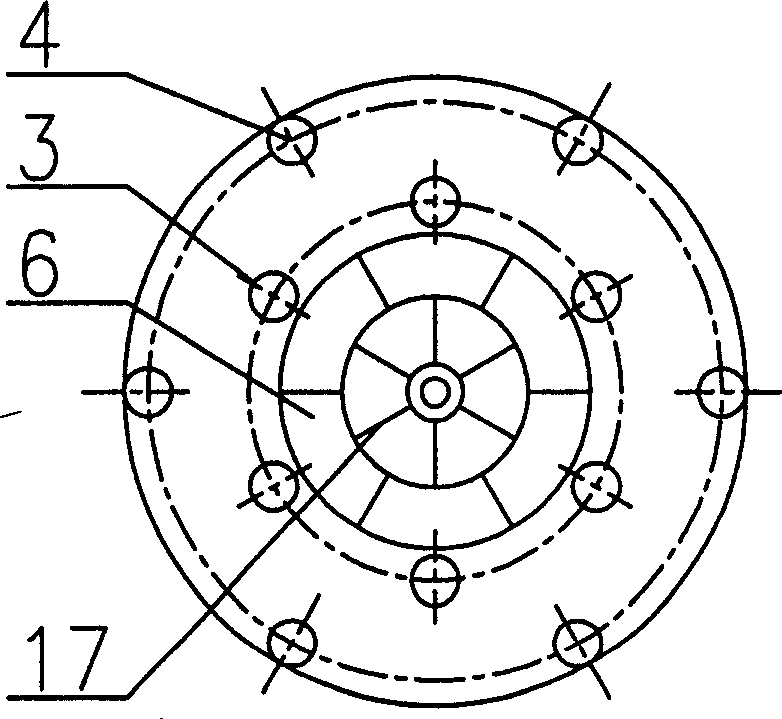

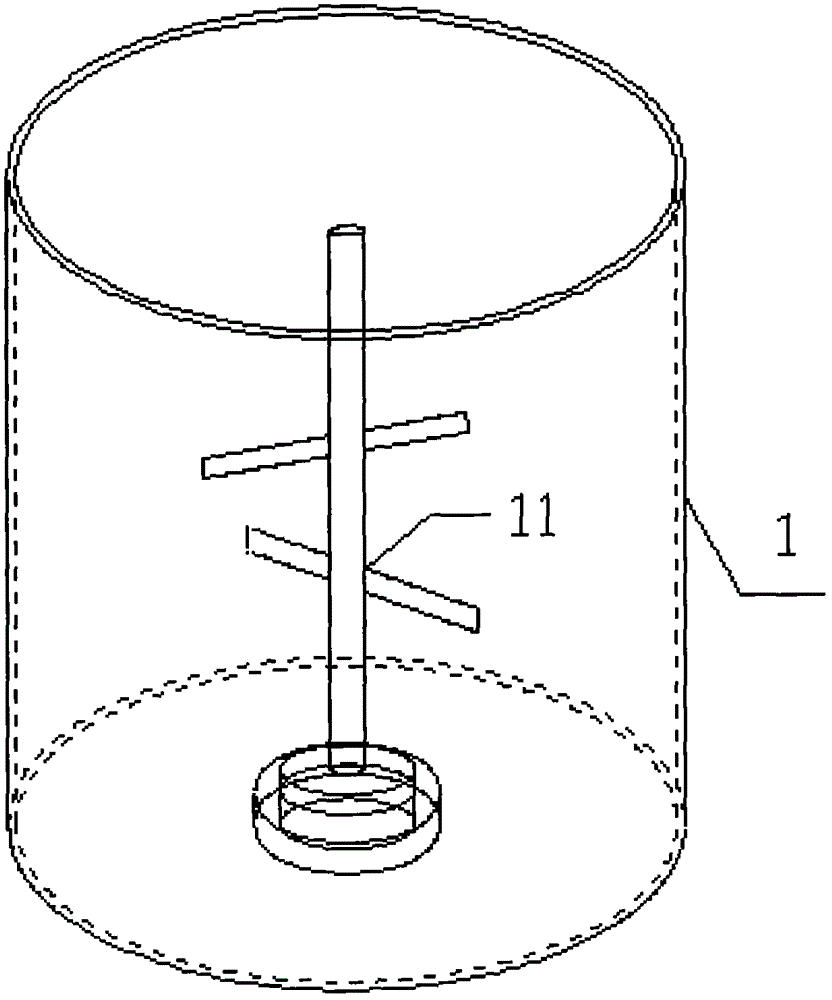

Low-flow, high-mixing ratio and stepless regulation gas-liquid mixing gas generator

InactiveCN102174338AIncrease the mixing ratioLarge adjustment rangeBurnersFuel supply regulationGas generatorEngineering

The invention relates to a low-flow, high-mixing ratio and stepless regulation gas-liquid mixing gas generator, which comprises a round mixing channel, a spray head, an igniter and a body part. The spray head is arranged between the round mixing channel and the body part, and the opening of the spray head faces the body part; the igniter is arranged in the body part; and the round mixing channel comprises a fuel channel communicated with a fuel joint, a main air channel communicated with a main air joint, and an auxiliary air channel communicated with an auxiliary air joint. The technical problem that defects exist in the prior art is solved. The gas-liquid mixing gas generator can be reliably operated and realizes large-scale stable and high-efficiency combustion and stepless regulation.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Glow plug type acoustic resonance igniter

ActiveUS9476399B1High oxygen/fuelMinimal energyGas turbine plantsRocket engine plantsCombustion chamberHydrogen

An acoustic resonance igniter uses high-pressure helium to heat a resonance cavity so a hot surface of the resonance cavity forms a source of ignition to a combustion chamber. The resonance cavity may be round or may extend linearly to increase the size of the hot surface. The combustion chamber is cooled by arranging a feed of hydrogen and oxygen which is oxygen rich and which becomes more so when ignition occurs. A second combustion chamber receives the combustion chamber output and adds additional hydrogen through ports tangential to the wall of the second combustion chamber to enrich the fuel ratio and cool the second combustion chamber. The acoustic resonance igniter is used to ignite a large rocket engine or to form a rocket thruster.

Owner:SIERRA SPACE CORP

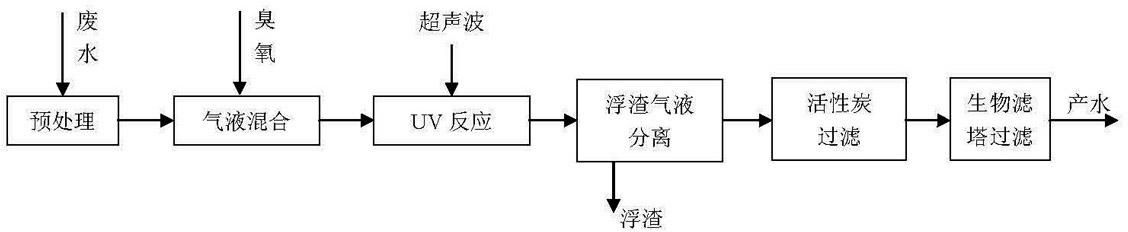

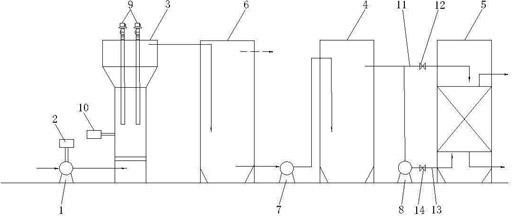

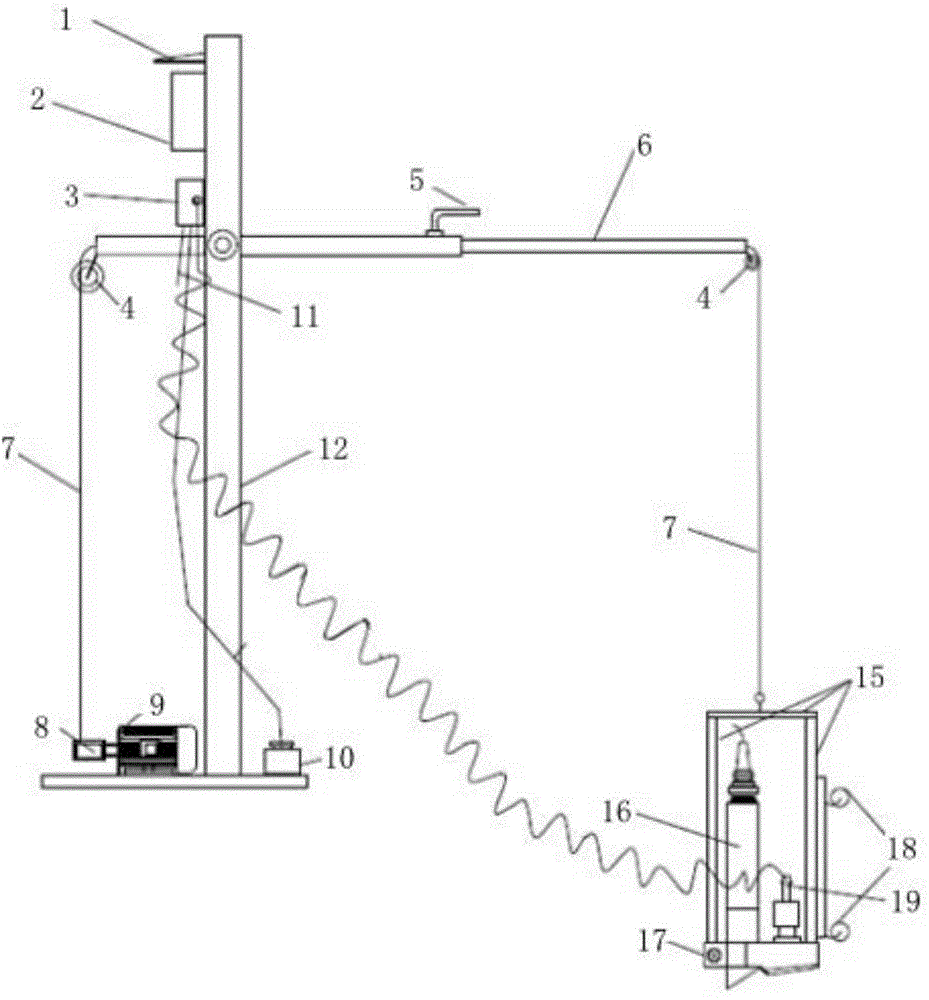

Ultraviolet light ozone reaction process and device

InactiveCN102674641AQuick responseIncrease profitWater/sewage treatment by irradiationMultistage water/sewage treatmentActivated carbon filtrationUltraviolet lights

The invention belongs to the technical field of wastewater treatment and particularly relates to an ultraviolet light ozone reaction process and an ultraviolet light ozone reaction device. The ultraviolet light ozone reaction process comprises the following steps of: a) pretreating; b) mixing gas and liquid; c) performing ultraviolet (UV) reaction; d) filtering by using active carbon; e) filtering by using a biological filter tower; and f) discharging water. By using a nano gas bubble pump, the wastewater and ozone and air in the nano gas bubble pump can be fully nixed, and countless micro gas bubbles of which the diameters are 10 to 50 microns are generated; the micro gas bubbles are stable in performance and high in gas-liquid mixing ratio, and are not aggregated easily and fractured; the gas-liquid contact area of the device is hundreds of times that of the conventional aerator and the like, so that the reaction speed of the device is hundreds of times that of the conventional aerator and the like; and the residual ozone in the wastewater is filtered by the active carbon, and treatment of tail gas is eliminated. The process and the device are high in ozone utilization rate and good in treatment effect, the reaction speed is high, and the produced water is clear.

Owner:东莞市珠江海咸水淡化研究所

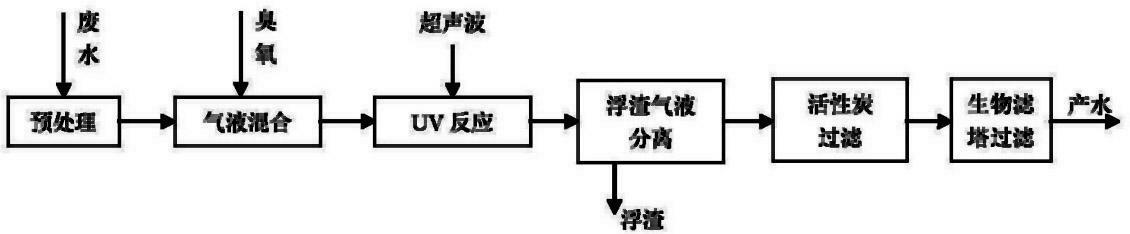

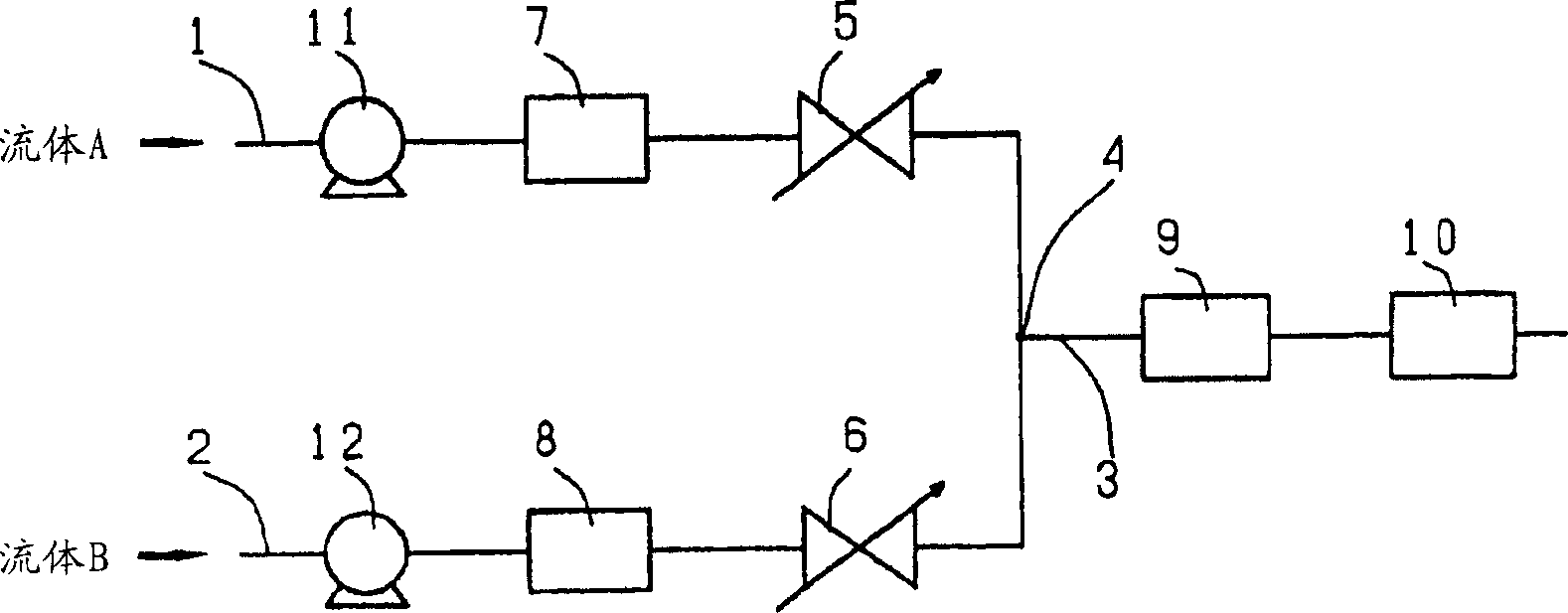

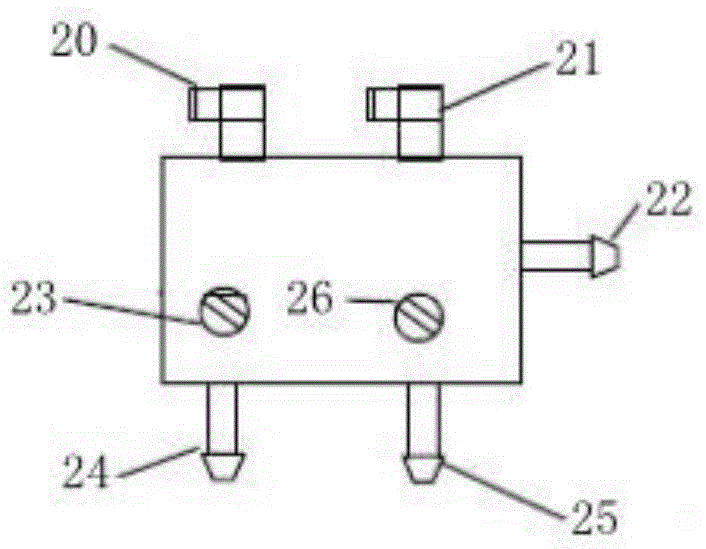

Fluid mixer

InactiveCN1767891AHigh precisionIncrease the mixing ratioControlling ratio of multiple fluid flowsFlow mixersJunction pointEngineering

A fluid mixing device in which even if the pressure on the downstream side of a back pressure valve of a mixing line fluctuates, the fluid in each supply line can always be supplied quantitatively to the mixing line, maintaining a high-precision mixing ratio, and further in making the fluid In the flowing state, the mixing ratio of the fluid supplied to the line can be changed with high precision. On the upstream side of the confluence joint (4) where at least two first supply lines (1), second supply lines (2) and mixing lines (3) meet, throttles (5, 6) for adjusting the flow rate of the fluid and Pressure reducing valves (7, 8) on the upstream side of the throttling parts (5, 6) are arranged in series in the supply lines (1, 2), and a back pressure valve (9) is arranged on the mixing line (3). In addition, the back pressure valve (9) and flow meter (10) are arranged in series on the mixing line (3), the throttling parts (5, 6) use fixed holes or regulating valves, and the pressure reducing valves (7, 8) and the back pressure Pressure valve adopts automatic valve.

Owner:ASAHI YUKIZAI KOGYO CO LTD

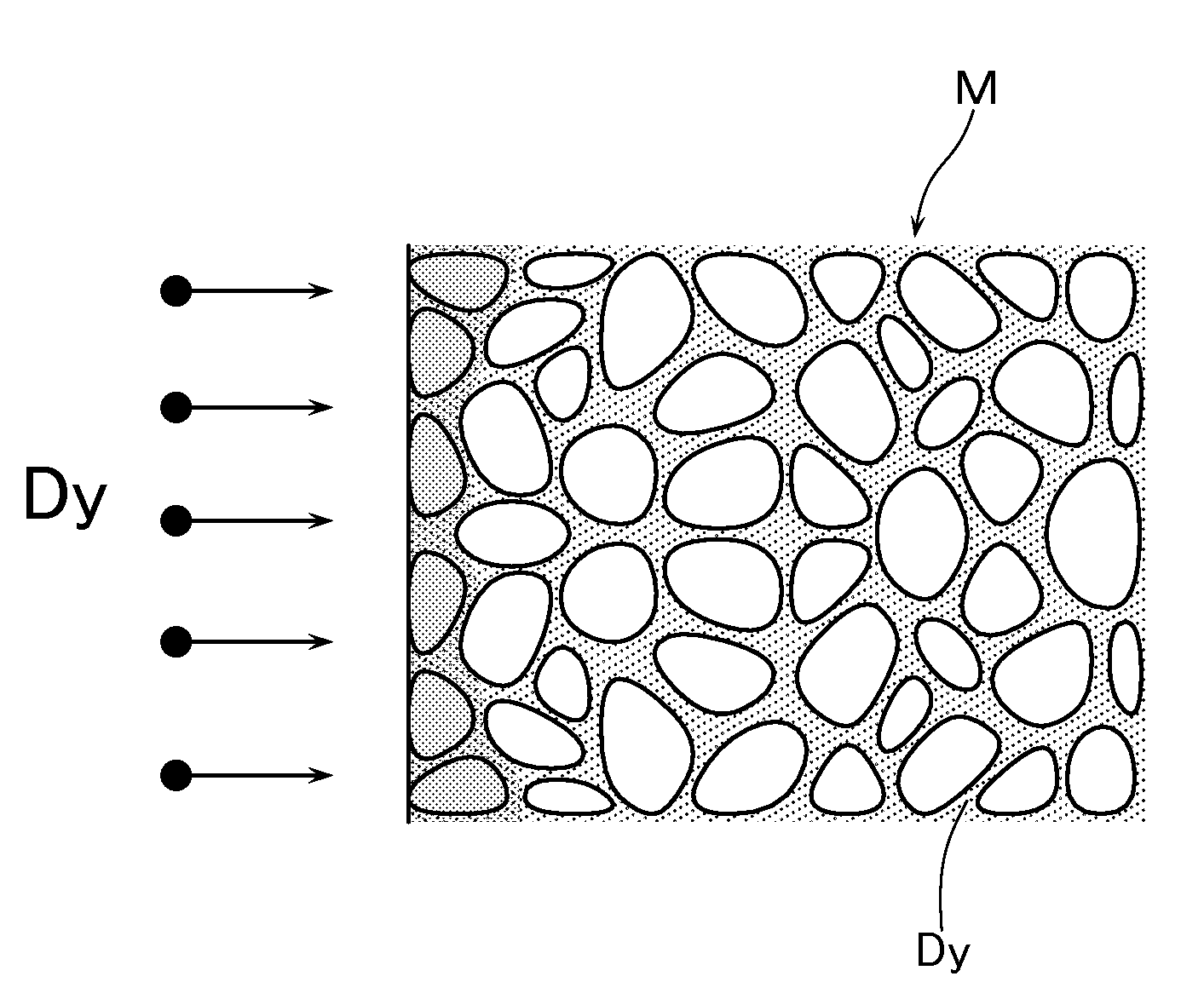

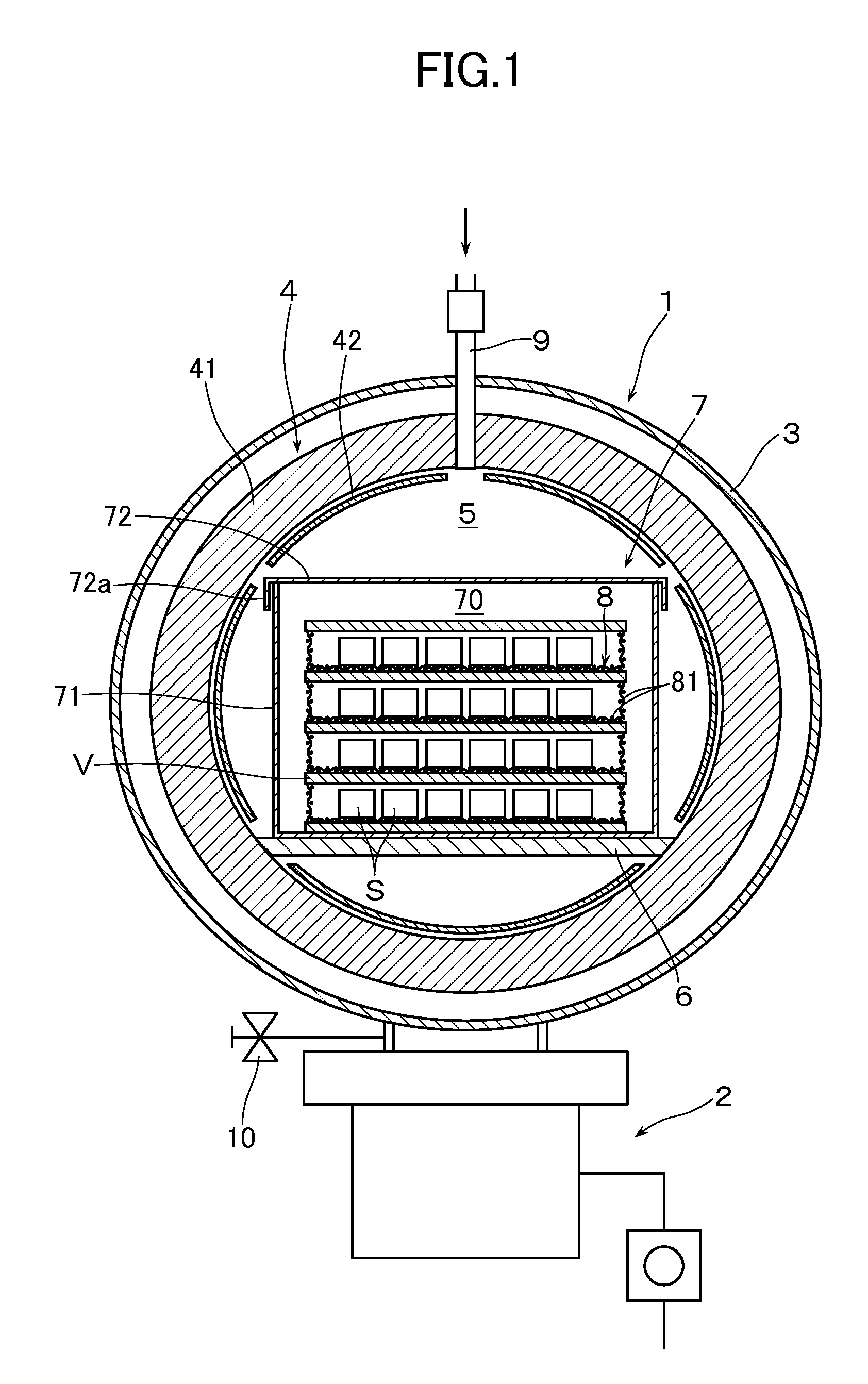

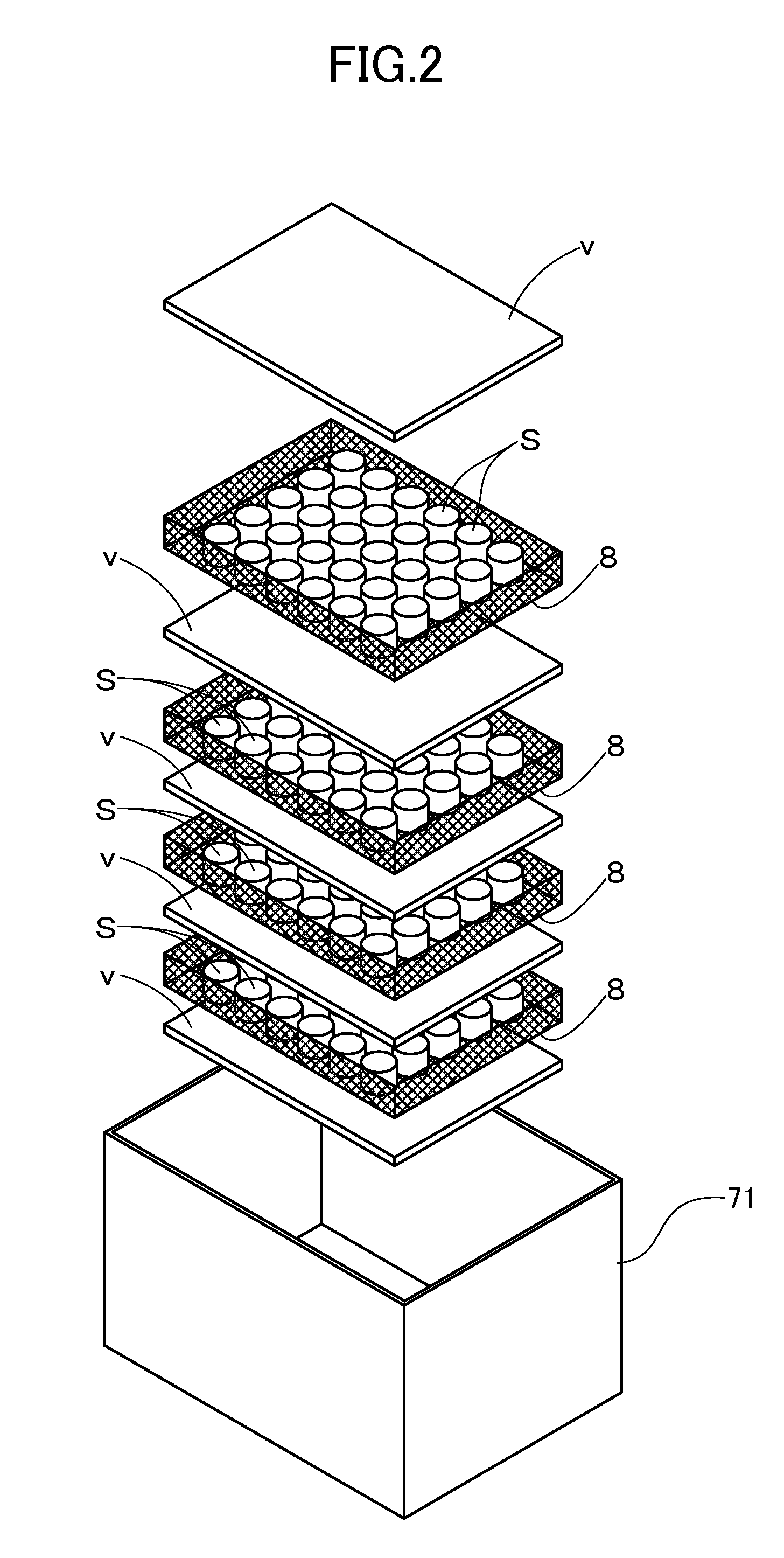

Method of recycling scrap magnet

InactiveUS20110052799A1Improve productivityImprove magnetic propertiesVacuum evaporation coatingSputtering coatingSintered magnetsRare earth

The method has the steps of: grinding a recovered scrap magnet which is an iron-boron-rare earth-based sintered magnet, thereby obtaining a scrap-derived recovered raw material powder; obtaining a sintered body from the scrap-derived recovered raw material powder by a powder metallurgy method; and processing the sintered body. The processing includes the steps of: heating the sintered body disposed in a processing chamber; evaporating a metal evaporating material containing at least one of Dy and Tb in which the metal evaporating material is disposed in the same or another processing chamber; adhering metal atoms evaporated in the evaporating step to a surface of the sintered body while controlling a supply amount of the evaporated metal atoms; and diffusing the adhered metal atoms into grain boundaries and / or grain boundary phases of the sintered body.

Owner:ULVAC INC

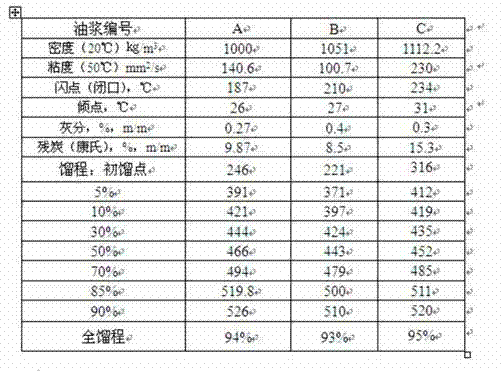

Production method of ship fuel oil

InactiveCN102888244AIncrease the mixing ratioGood compatibilityTreatment with hydrotreatment processesFractionationOil separation

The invention relates to a production method of ship fuel oil, which comprises the following steps: heating catalytic slurry oil, filtering through a precision filter to remove tiny catalyst granules in the slurry oil, mixing with hydrogen, heating, contacting the mixture with a residual oil hydrofining catalyst, a distillate hydrofining catalyst and a distillate hydrocracking catalyst to carry out catalytic hydrogenation reaction on the mixture, carrying out gas-oil separation and fractionation on the reaction product to obtain a tail oil fraction, and mixing the tail oil fraction with vacuum residual oil in different proportions to obtain the finished product. Under mild reaction conditions and lower hydrogen consumption, the method provided by the invention can greatly enhance the doping proportion of the catalytic slurry oil in the ship fuel oil by more than 75%, ensures the indexes of metals, ash and the like in the ship fuel oil to be not overproof, greatly increases the calorific value, improves the compatibility of the ship fuel oil, and ensures the production of the high-quality ship fuel oil product.

Owner:BEIJING JINHAICHANG ENERGY INVESTMENT

Image processing device, image processing method, and program pertaining to image correction

ActiveUS8314863B2Color becomes smallerIncrease the mixing ratioImage enhancementTelevision system detailsImaging processingImage correction

An image processing device includes: a blurring correction processing unit configured to perform blurring correction processing on output signals of an imaging device having an RGBW array which includes RGB pixels and white (W) pixels, and generate blurring-corrected signals corresponding to each pixels; and a data conversion unit configured to convert the RGBW array into an RGB array; wherein the data conversion unit executes processing of generating blurring-corrected RGB signals (Rd, Gd, Bd) which are blurring-corrected signals corresponding to RGB that have been estimated from blurring-corrected signals generated by the blurring correction processing unit, and applying the blurring-corrected RGB signals (Rd, Gd, Bd) to determine RGB signals values configuring an RGB array.

Owner:SONY CORP

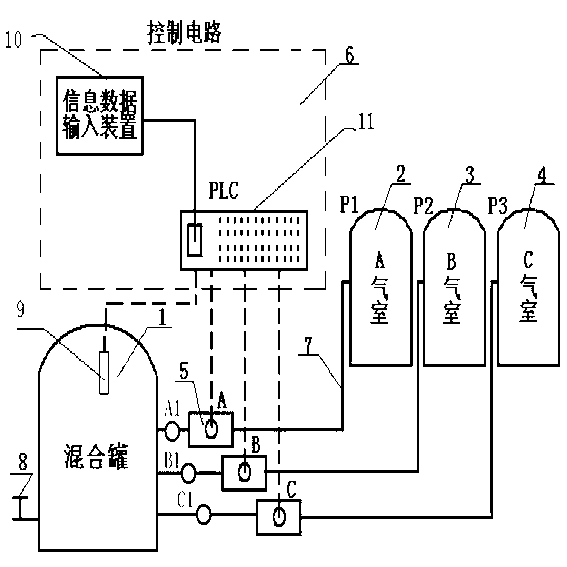

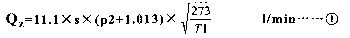

High-precision variable gas proportion mixing apparatus and gas proportion mixing method

InactiveCN103170262AReduce system errorReduce or eliminate system errorsMixer accessoriesMixing gases with gases/vapoursAutomatic controlSolenoid valve

The invention discloses a high-precision variable gas proportion mixing apparatus. The apparatus comprises a mixing tank, gas sources corresponding to the kinds of gases, and a control circuit, wherein the pressures of the gas sources are equal, the pressure of each of the gas sources is greater than the pressure of the mixing tank, the gas sources are connected with the mixing tank through pipelines, each of the pipelines is provided with a solenoid valve, each of the pipelines is also provided with a throttling device, the size sequence of the smallest effective section areas of the throttling devices is (partially) consistent with the size sequence of the proportions of the corresponding kinds of gases in a mixed gas, the control circuit comprises an information data input device and a control device having the information data and program processing functions, and the information data input device and the control end of the solenoid valve are respectively communicated with the control device. The apparatus has the advantages of simple structure, easy operation, high gas mixing proportion precision, and improvement of the market competitiveness; and additionally, the apparatus also realizes automatic control and automatic operation, so the work efficiency is improved.

Owner:SUZHOU SENRUI FRESH PRESERVATION EQUIP

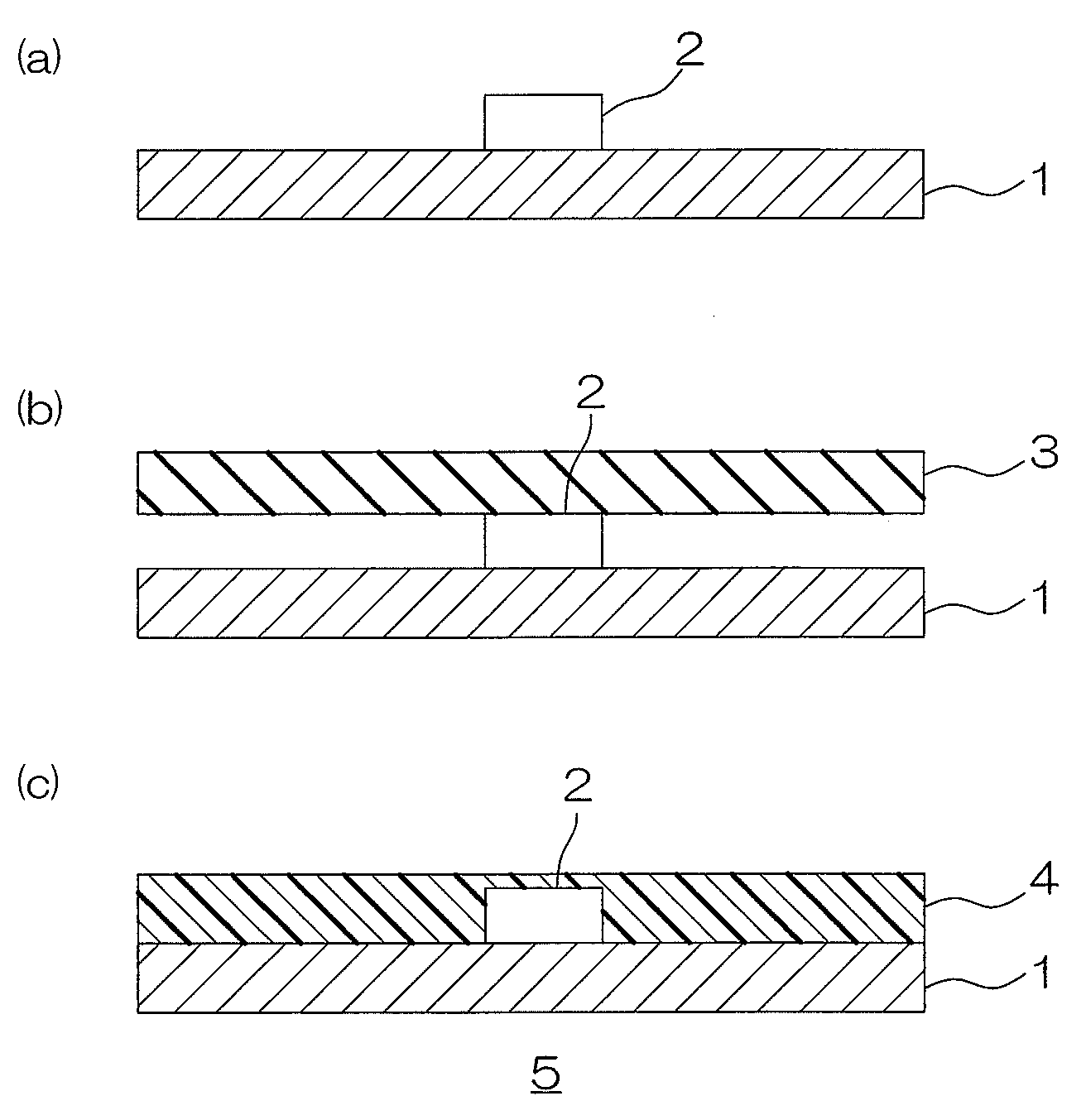

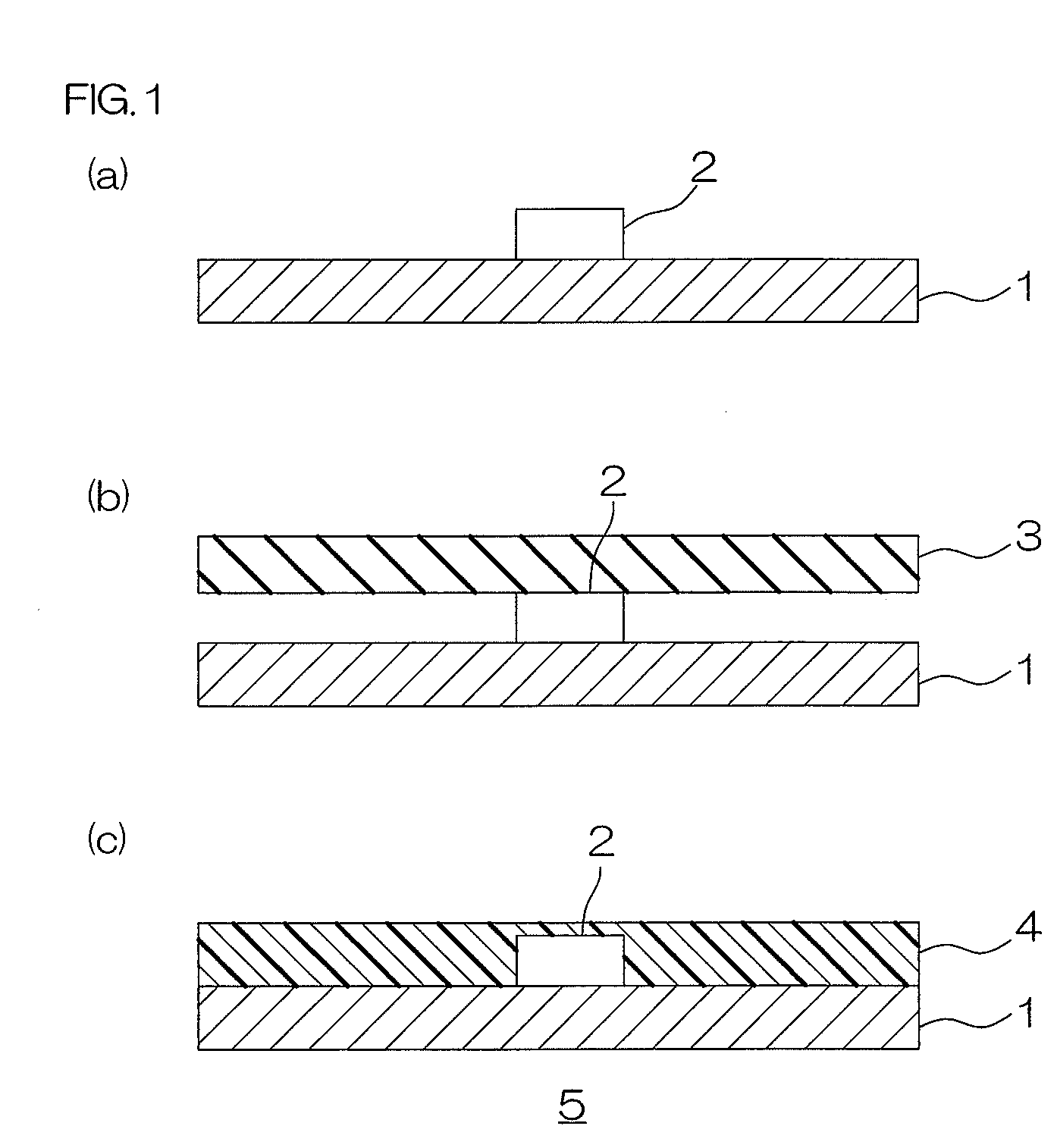

Encapsulating sheet and electronic device

An encapsulating sheet is obtained by subjecting a kneaded material to plastic working, the kneaded material including an epoxy resin represented by General Formula (1) below, a curing agent, and an inorganic filler,(where R1 to R4 are the same or different, and each represents a methyl group or a hydrogen atom; and X represents —CH2—, —O—, or —S—).

Owner:NITTO DENKO CORP

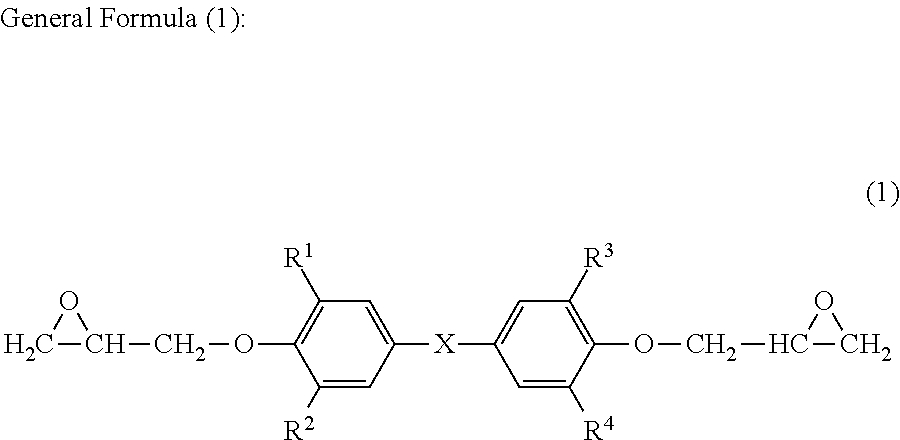

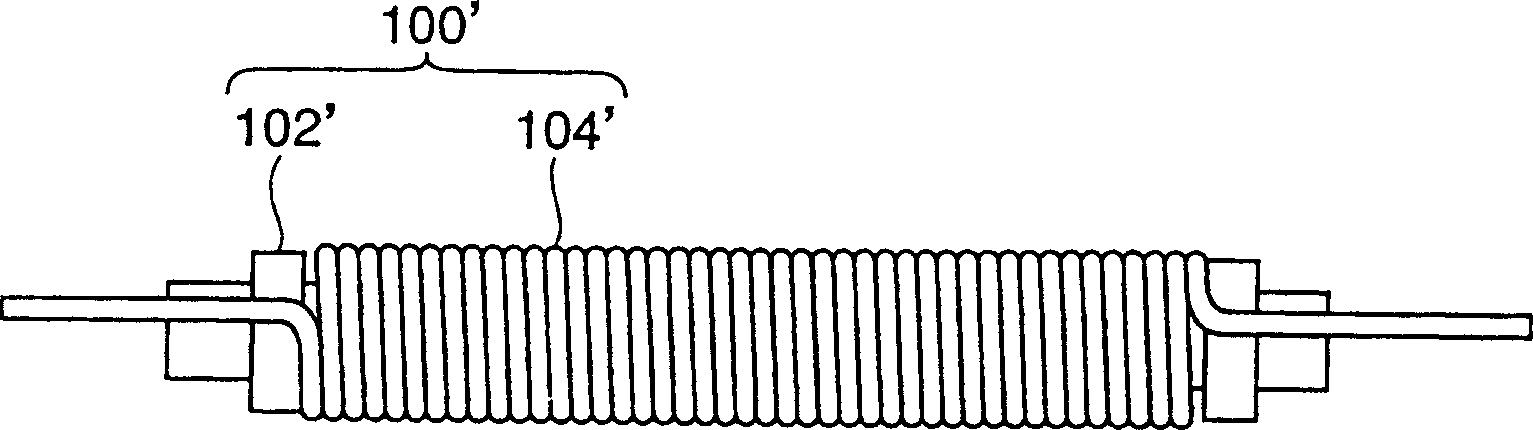

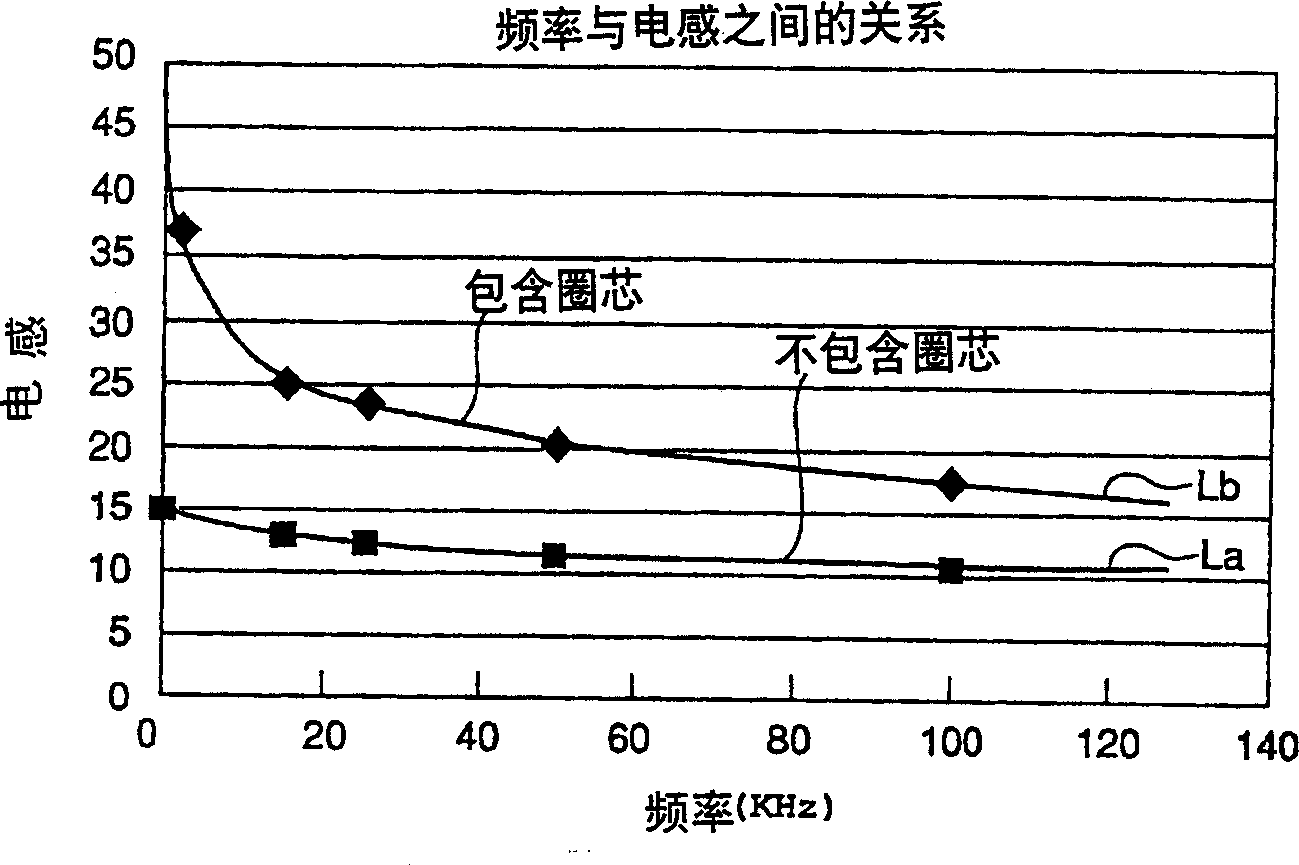

Magnetic core and magnetic field shielding component and coil, transformer, electronic apparatus and camera device

InactiveCN1490829AEasy to manufactureAvoid it happening againInduction heatingTransformers/inductances coils/windings/connectionsTransformerInductance

A magnetic core as a magnetic material that acts on an electromagnetic characteristic of the generated magnetic field and a magnetic field shield member that shields the magnetic field generated by magnetic field generation unit are structured such that magnetic particles are arranged in a base material under a dispersed state. As a result, a magnetic core in which an inductance can be set and a magnetic field shield member in which magnetic field leakage can be suppressed effectively, as well as an excitation coil, a transformer, electric equipment and an electrophotographic apparatus using them are easily provided at low costs.

Owner:FUJIFILM BUSINESS INNOVATION CORP

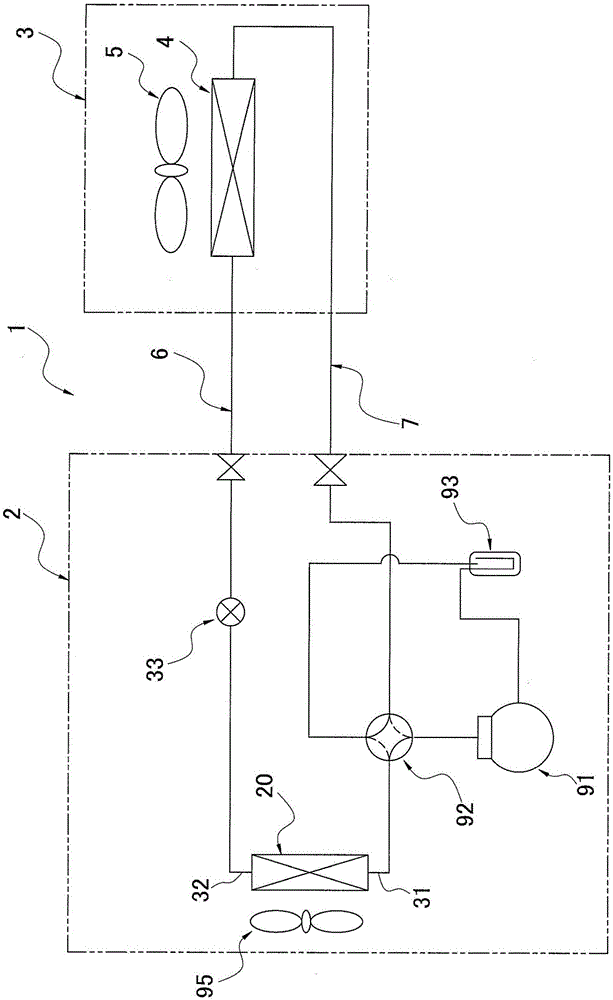

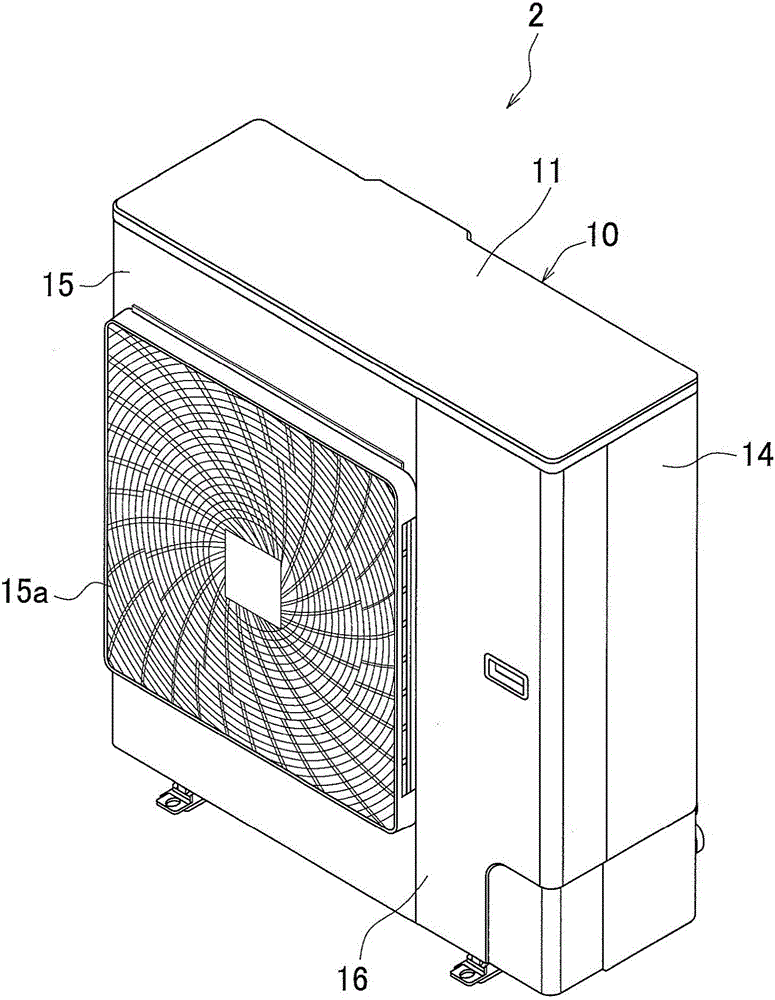

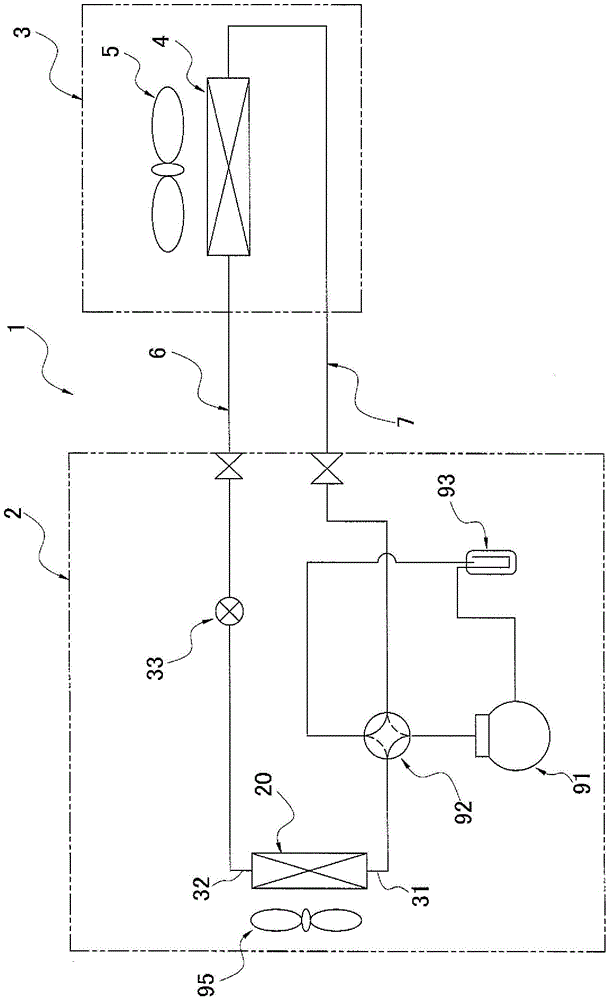

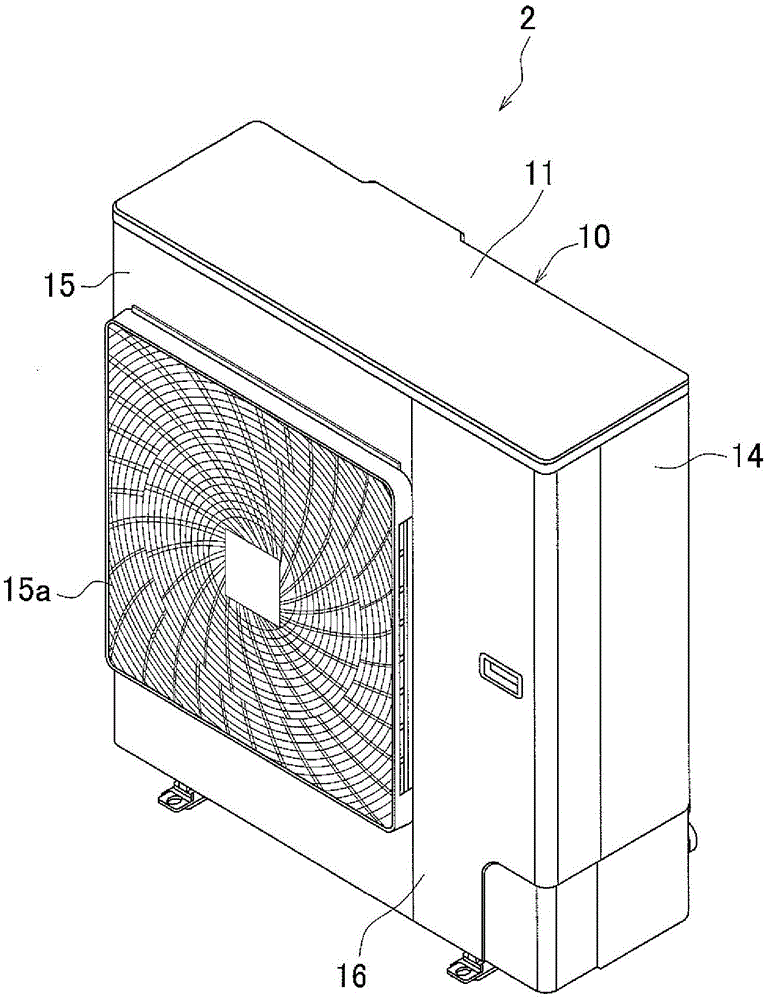

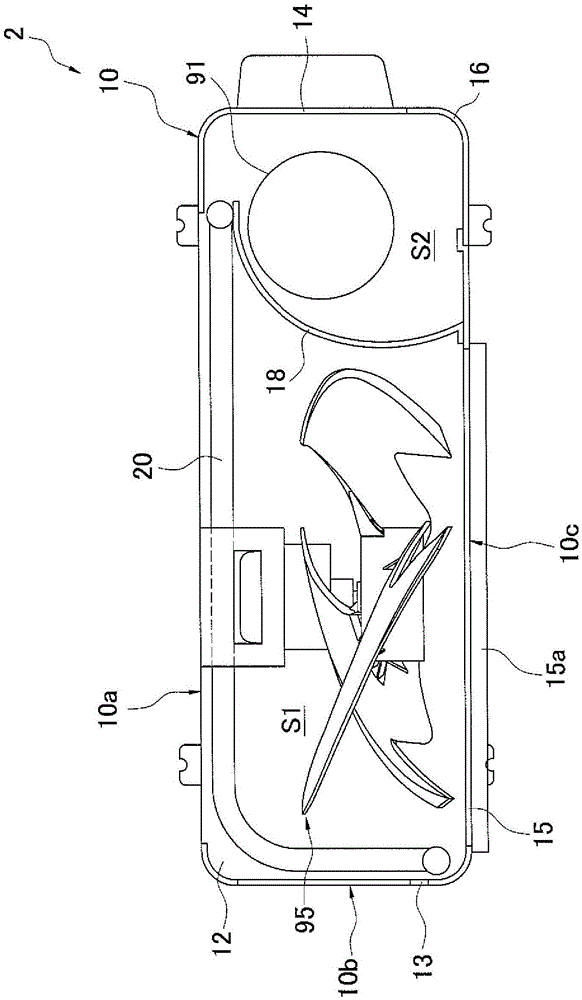

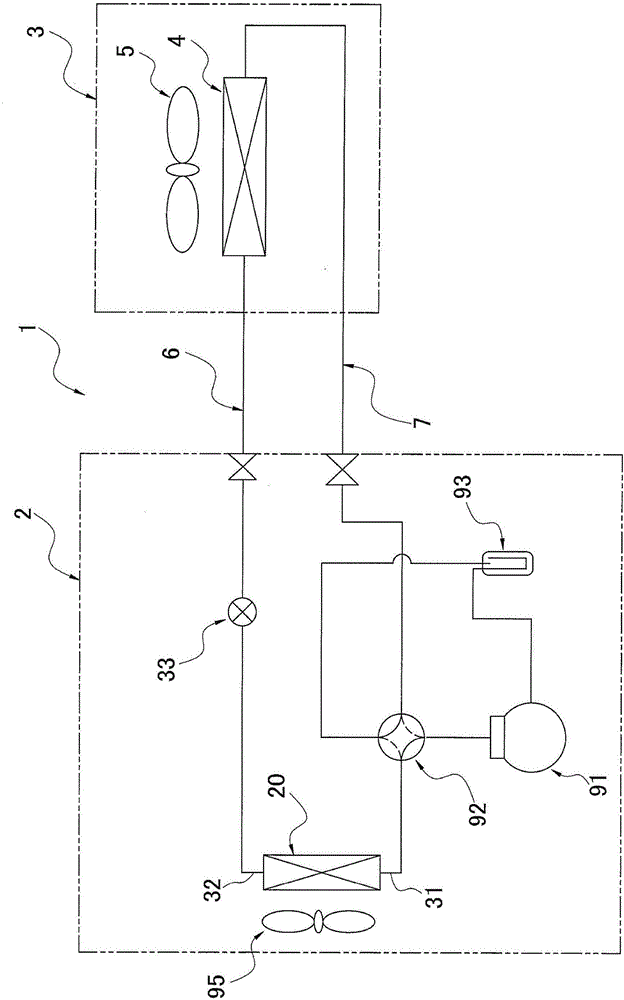

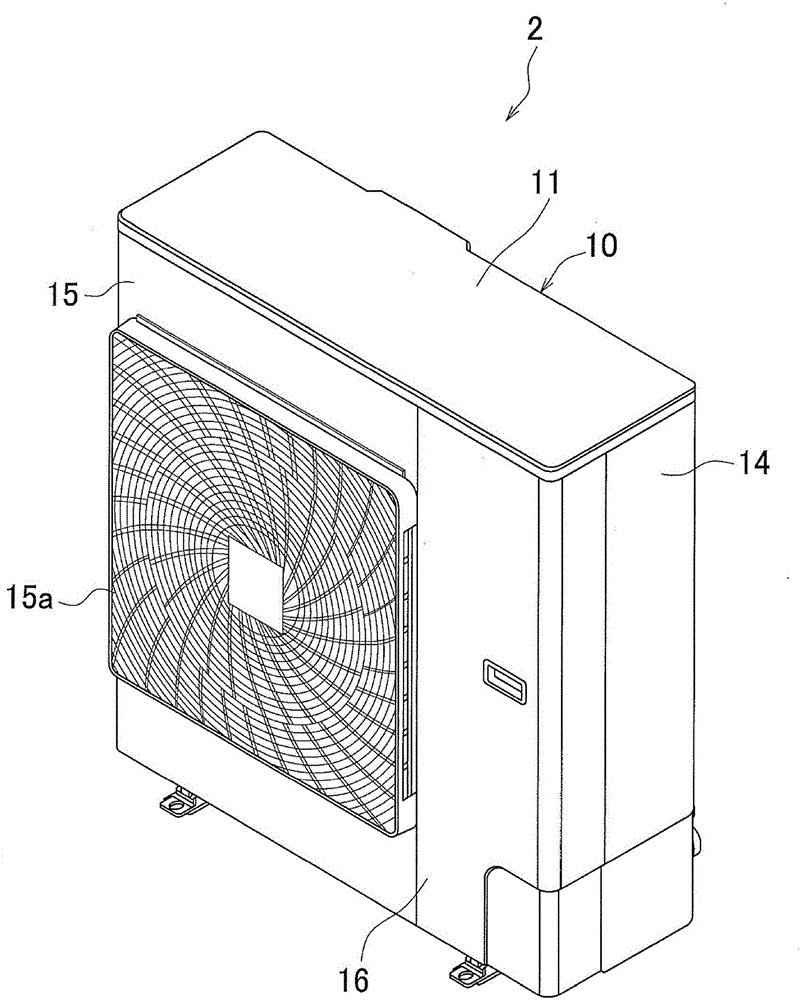

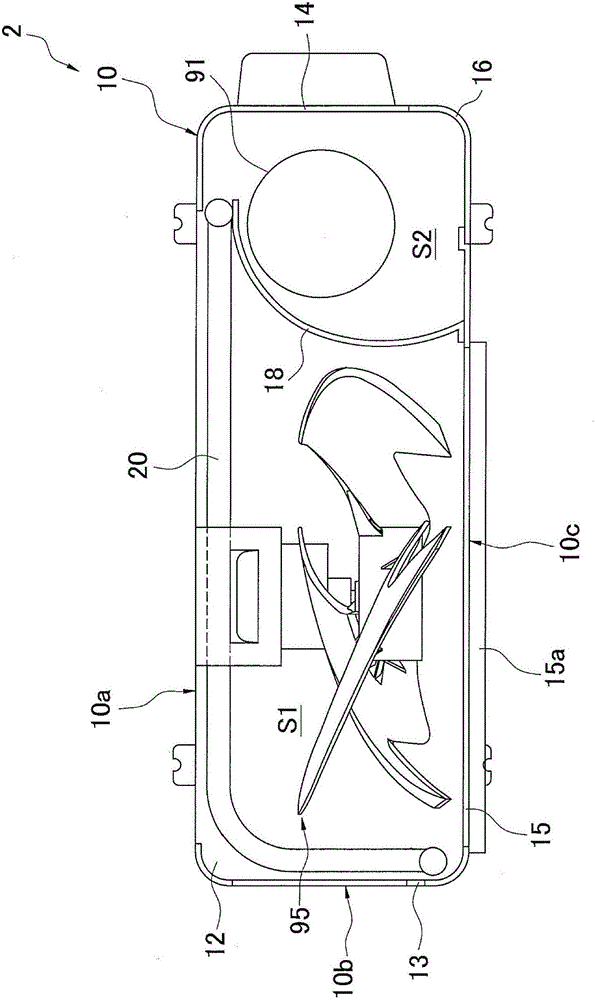

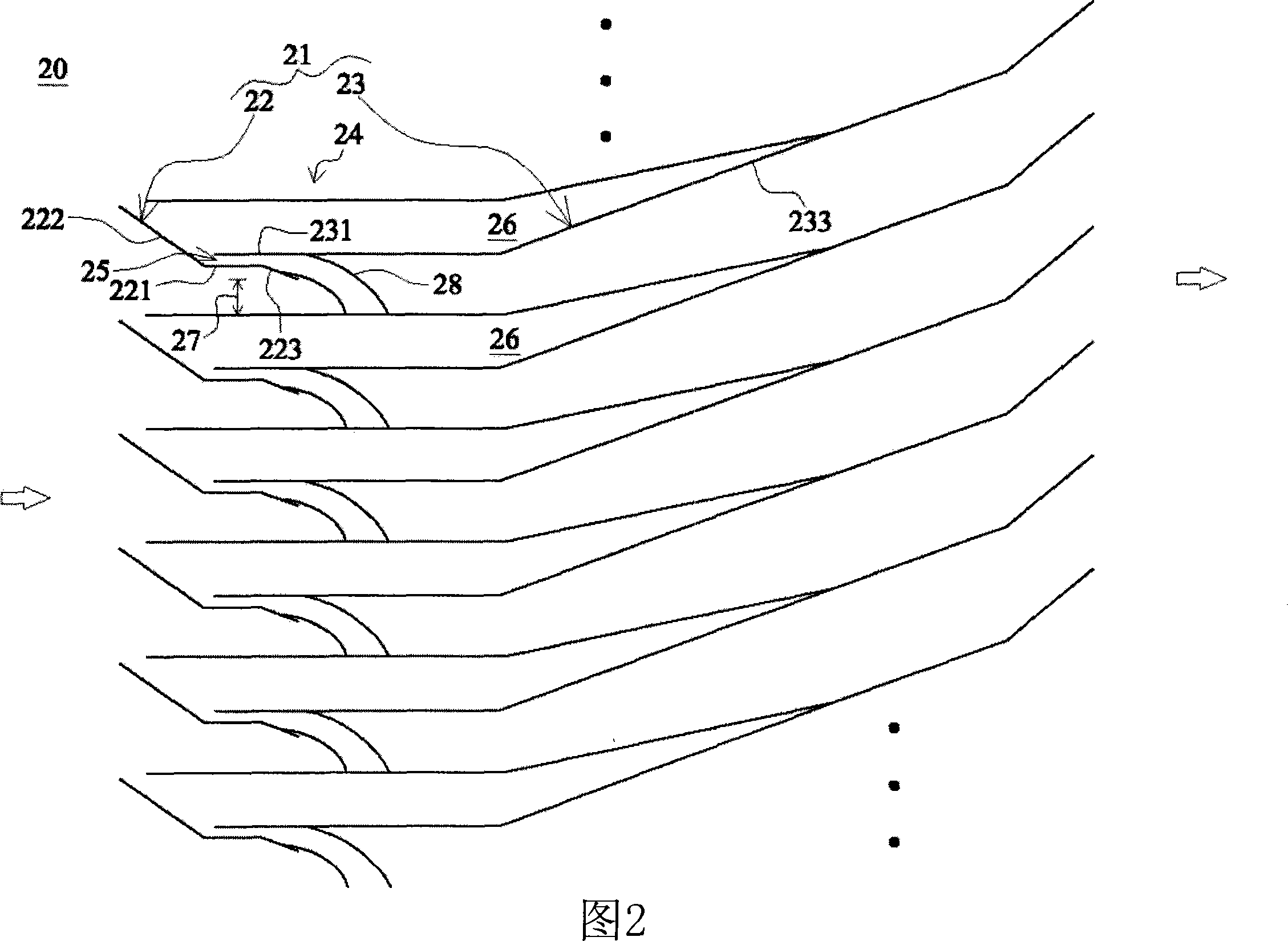

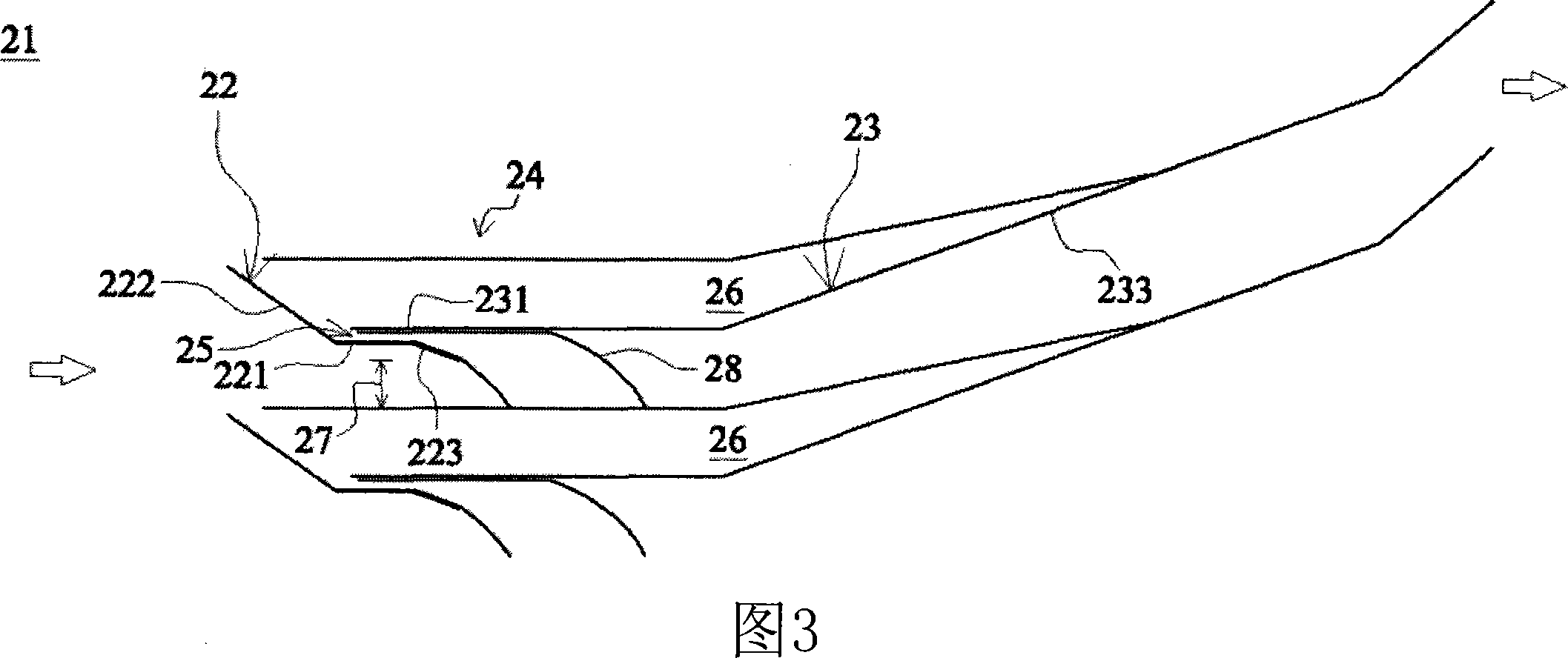

Heat exchanger and air conditioning device

ActiveCN105849498AInhibit bias currentSmall bias current suppressionEvaporators/condensersHeat exhanger finsEngineeringAir conditioning

Provided is a heat exchanger that can produce an upflow of coolant even when structured such that coolant is not directly supplied to a lower part of a space that generates a coolant upflow inside a header collecting pipe. Also provided is an air conditioning device. A plurality of flat, multi-hole pipes (21b) are connected at different heights to a first inner space (23a) of a folding-back header collecting pipe (23) of an outside heat exchanger (20). The first inner space (23a) has a loop structure that includes a first partitioning plate (51), a first inflow hole (41x) that is for causing coolant to rise into a first outflow space (51a), and a first lower passageway (51y) that causes coolant from the first upper passageway (51x) to descend through a first loop space (51b) and guides the coolant back to the first outflow space (51a). One end of the flat, multi-hole pipes (21b) is connected to either the first outflow space (51a) or the first loop space (51b). Connective piping (24) is connected to a space that is below the first loop space (51b) across a first rectifying plate (41).

Owner:DAIKIN IND LTD

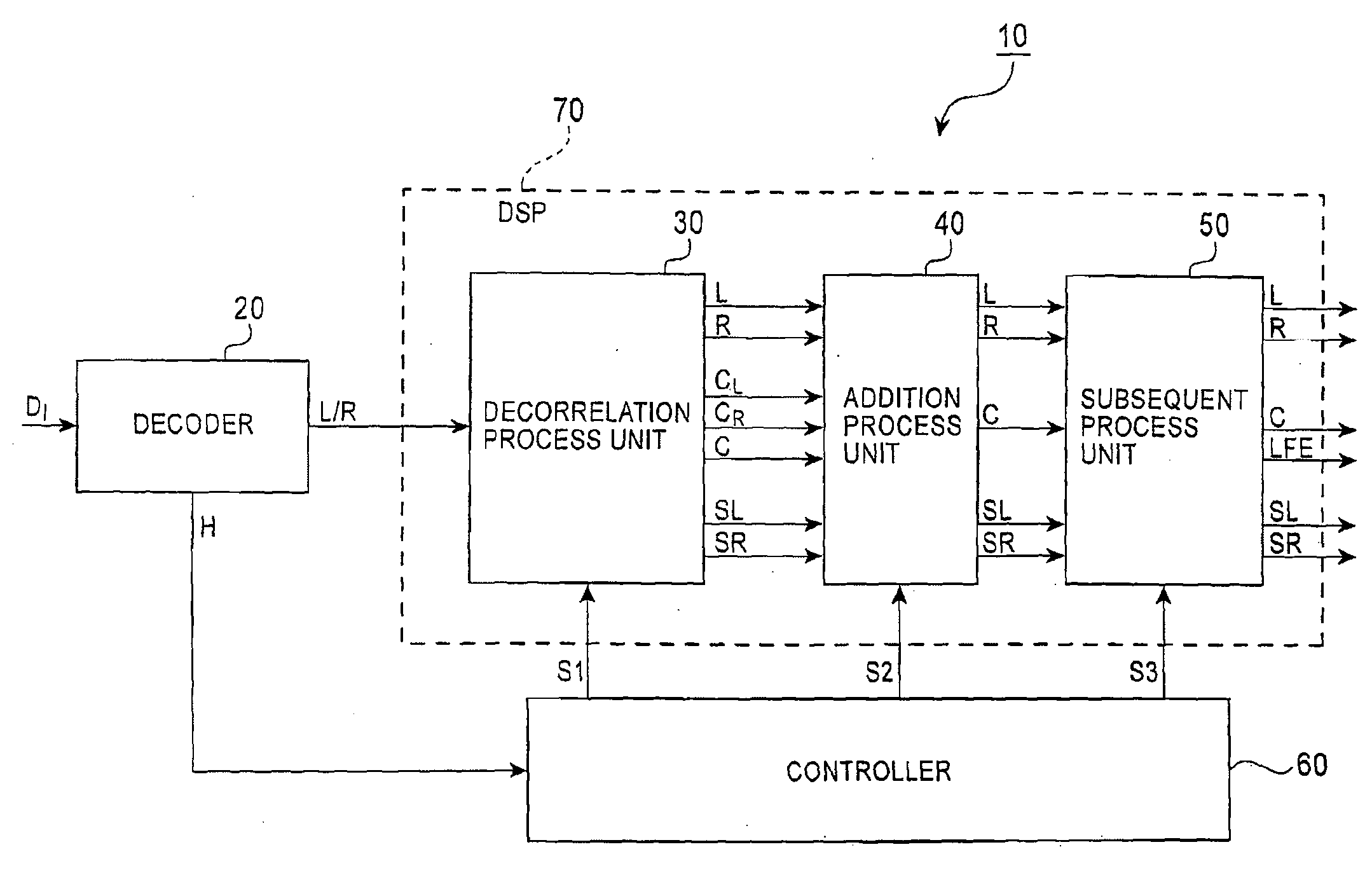

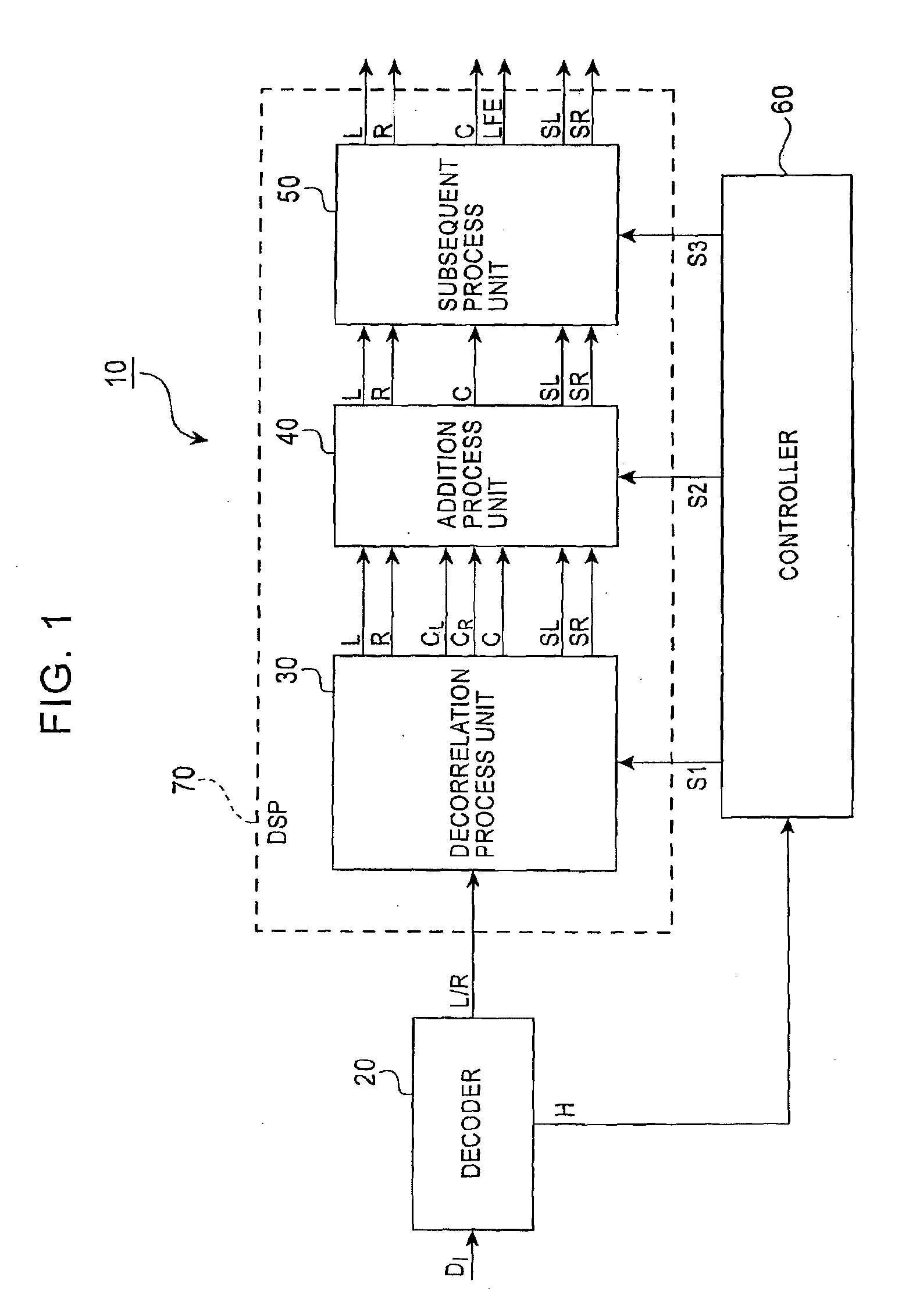

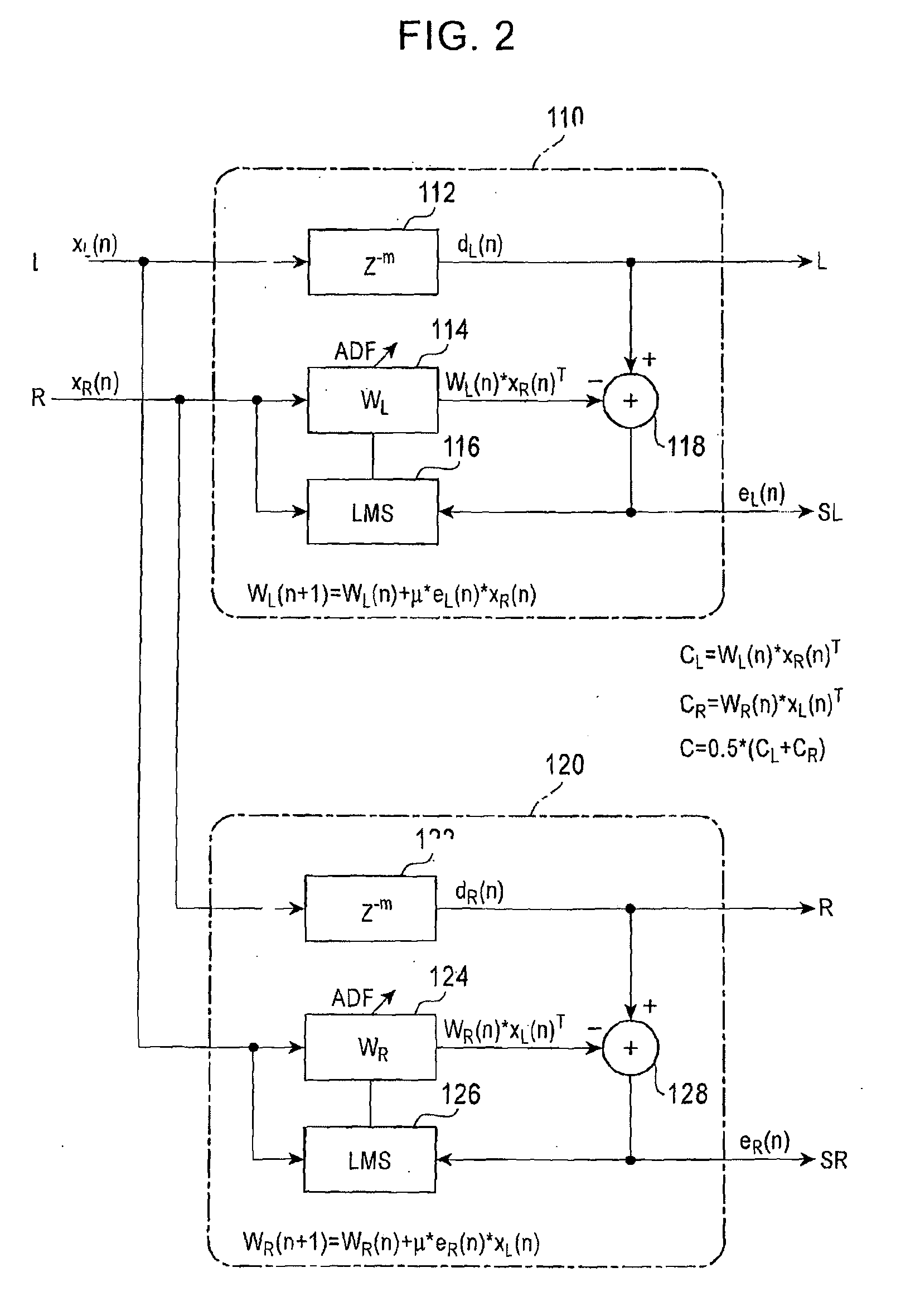

Surround generation apparatus

ActiveUS20090279706A1Increase widthSmall expansionSpeech analysisStereophonic systemsData streamComputer science

A surround system includes a decoder that decodes an encoded audio data stream, a decorrelation unit that receives and decorrelates stereo signals decoded by the decoder so as to generate surround signals having a low-correlation component, an addition unit that adds high-correlation-component signals extracted from the stereo signals to the surround signals generated by the decorrelation unit, and a controller that controls addition of the high-correlation-component signals performed by the addition unit on the basis of the bit rate of the audio data stream.

Owner:ALPINE ELECTRONICS INC

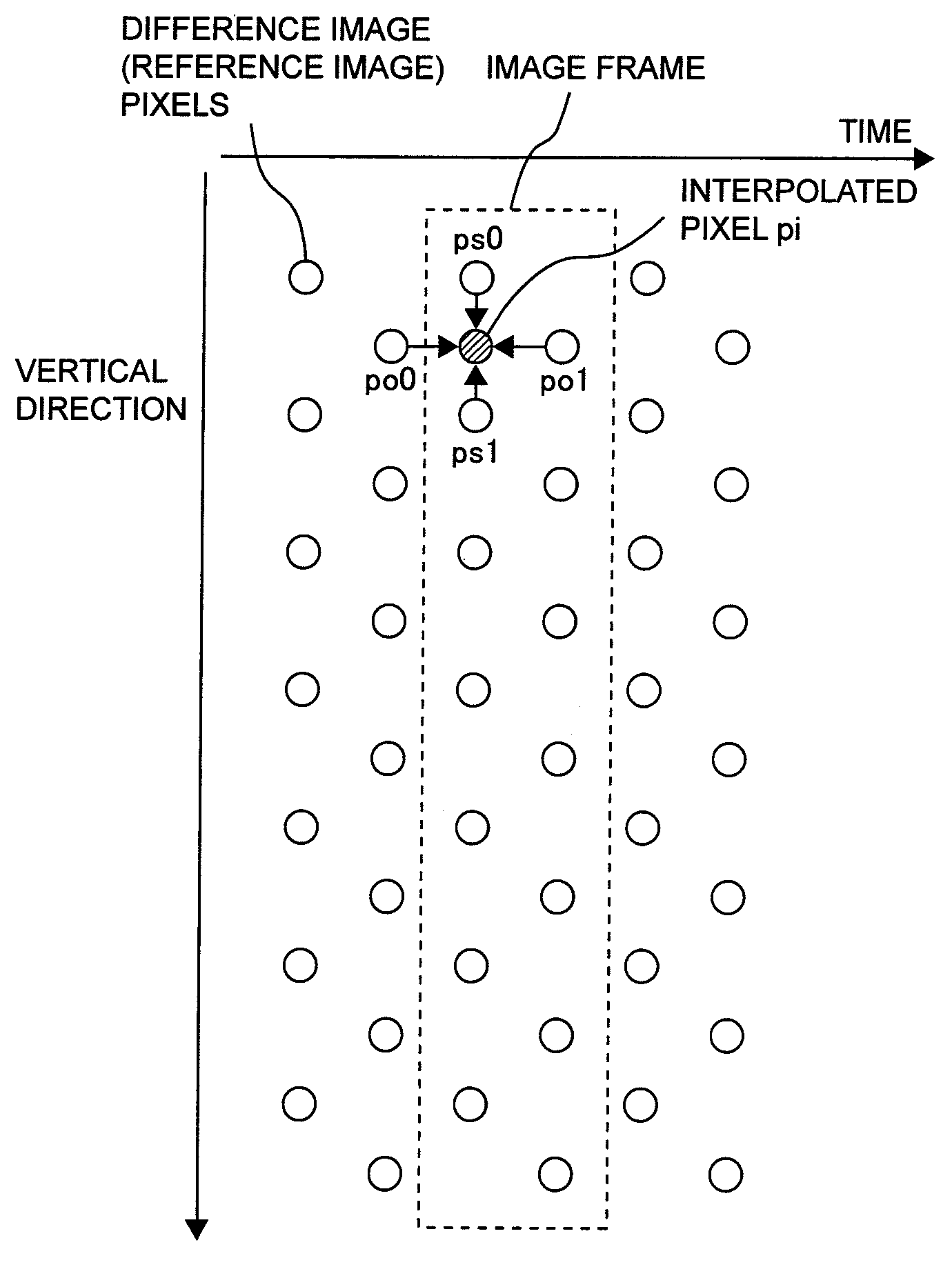

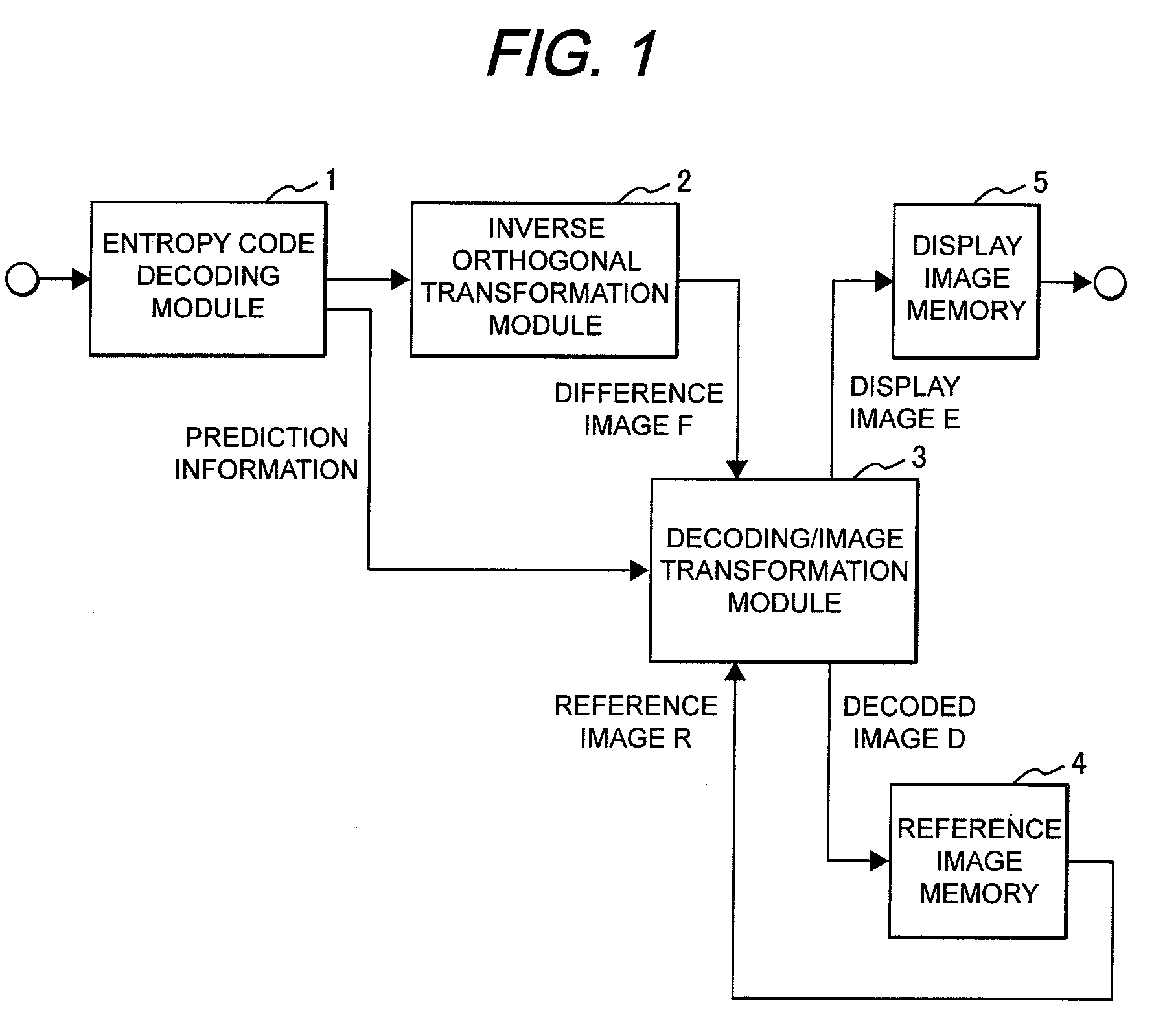

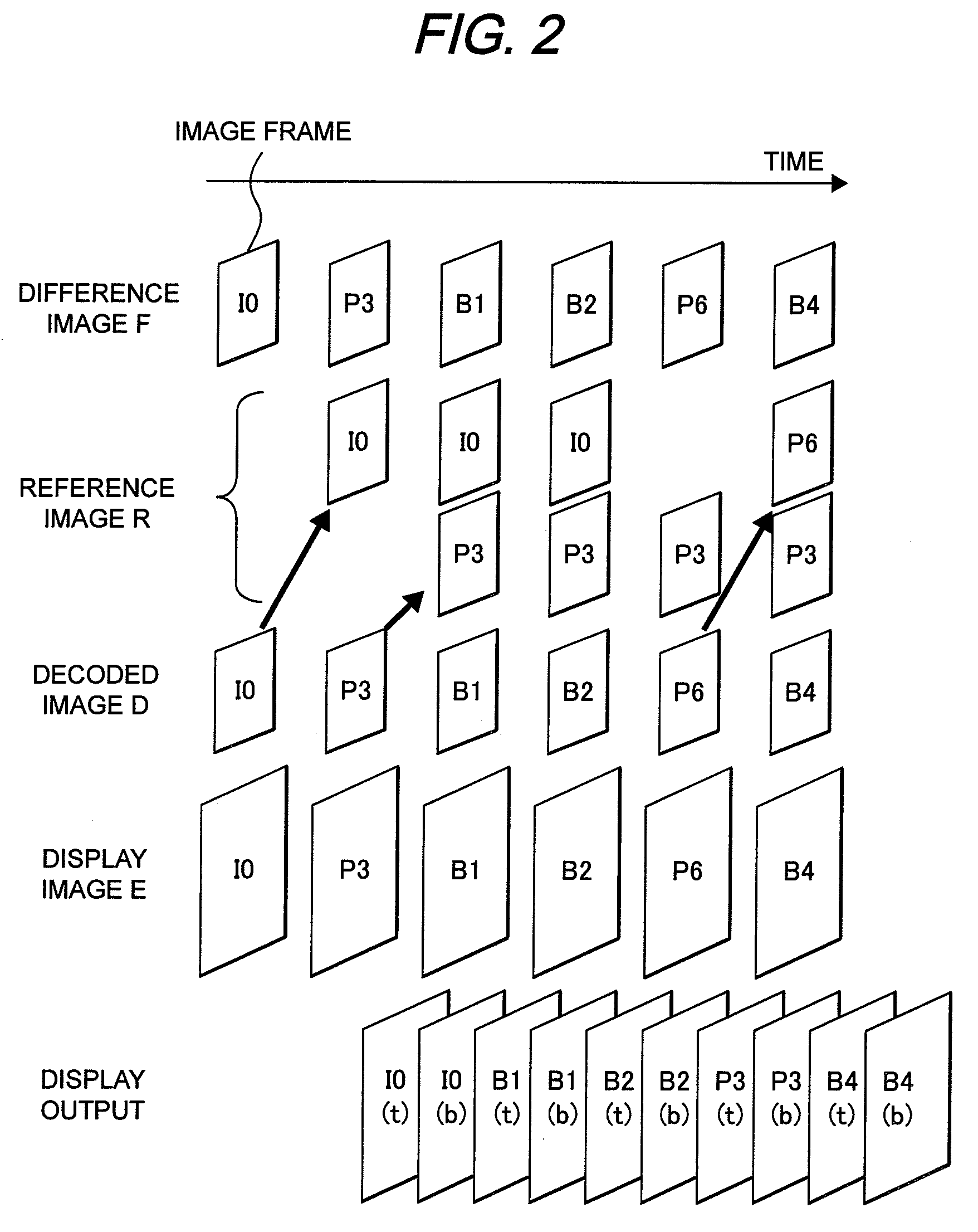

Image Decoder

ActiveUS20090003450A1Improve image qualityInfluence of deteriorationGeometric image transformationPicture reproducers using cathode ray tubesImaging qualityHigh definition

The present invention provides an image decoder which decodes a stream encoded with standard resolution and transforms it into a high-definition image with a better image quality. An intra-field pixel interpolation module generates an interpolated pixel using pixels in a field. An inter-field pixel interpolation module generates an interpolated pixel using pixels from another field. A weighted averaging module refers to the prediction mode used in predictive encoding for the coded stream. If the prediction mode is a field prediction mode, it increases the mixture ratio of interpolated pixels generated by the intra-field pixel interpolation module, and if the prediction mode is a frame prediction mode, increases the mixture ratio of interpolated pixels generated by the inter-field pixel interpolation module.

Owner:MAXELL HLDG LTD

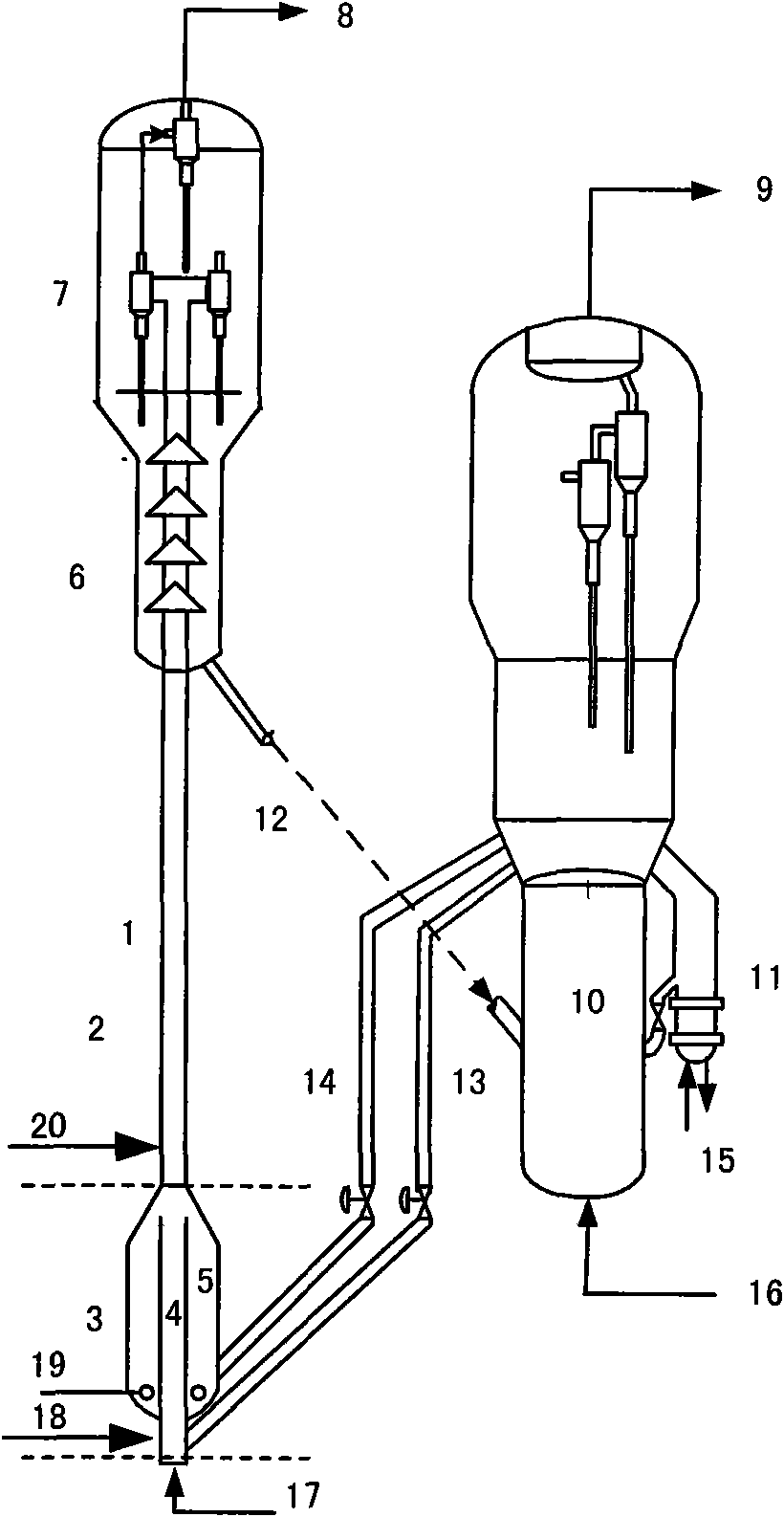

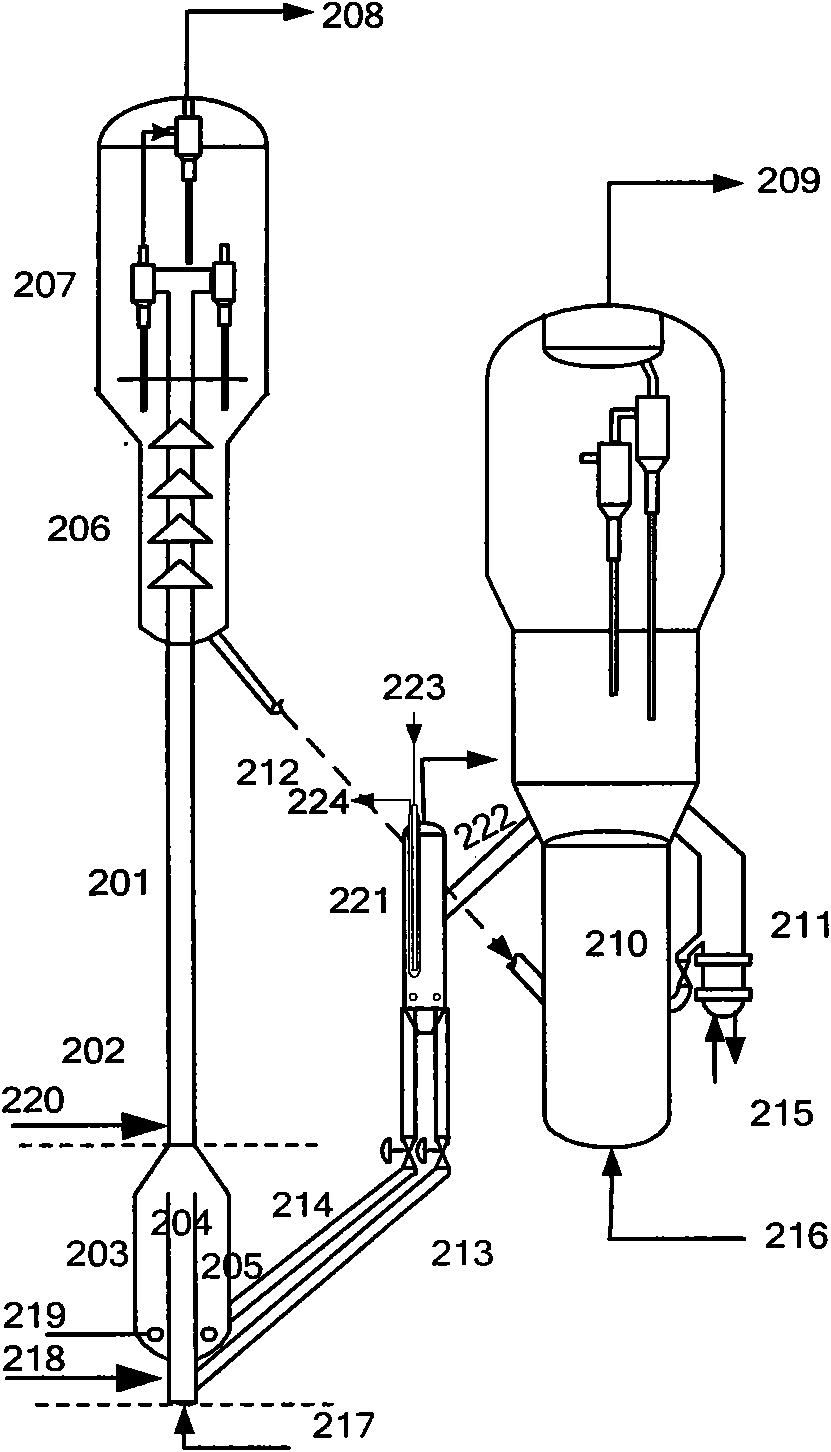

Method and device for carrying out partitioning catalytic cracking on coking waxen oil

The invention discloses method and device for partitioning catalytic cracking on coking waxen oil, which are mainly used for solving the problem that the process product distribution becomes poor because alkalic oxides preferentially absorb on the acidic activity center of a catalyst to reduce the activity and the selectivity of the catalyst when the coking waxen oil is mixed and melted in a catalytic cracking process. In the invention, a catalytic cracking lifting pipe reactor is divided into an upper reaction region and a lower reaction region, wherein the lower reaction region is in a vertical sleeve structure which is divided into an inner sleeve region and an outer sleeve region that are independent to ensure that the coking waxen oil enters the inner sleeve region for carrying out catalytic cracking reaction and conventional raw materials enter the bottom of the upper reaction region to be in contact and react with a refresh regenerable catalyst from an annular space region of the vertical sleeve structure of the lower reaction region to ensure that the refresh regenerable catalyst being in contact with the conventional raw materials are free of being damaged by pollutants of basic nitrogen and the like brought in by the coking waxen oil, so as to achieve the purposes that the conventional raw materials are fully cracked and excellent product distribution is obtained. The material flow after the coking waxen oil is subjected to the primary reaction and then joined with the conventional raw materials in the upper reaction region and then passes through the lifting pipe reactor and enters a settling and stripping system together with the conventional raw materials. Compared with the conventional catalytic cracking mixing and melting coking waxen oil, the invention remarkably improves the liquid yield while increasing the mixing amount of the coking waxen oil.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Heat exchanger and air conditioner

ActiveCN105593628ASmall bias current suppressionFully guideEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

Provided are a heat exchanger and an air conditioner capable of inhibiting uneven flow of refrigerant even when used under conditions when the circulation flow changes. A plurality of flat perforated pipes (21b) are connected at different heights to a first inner space (23a) of a return header collecting pipe (23) of an outdoor heat exchanger (20). The first inner space (23a) uses a loop structure that includes a first partitioning plate (51), a first inlet (41x), a first upper communicating route (51x), and a first lower communicating route (51y). The first partitioning plate (51) partitions the first inner space (23a) into a first outflow space (51a) and a first loop space (51b). The first inlet (41x) is provided at the bottom of the first outflow space (51a) so that the refrigerant rises in the first outflow space (51a). Refrigerant that reaches the upper end of the first outflow space (51a) is guided to the first loop space (51b) via the first upper communicating route (51x), and the refrigerant that drops from the first loop space (51b) is returned to the first outflow space (51a) in a non-vertical direction via the first lower communicating route (51y).

Owner:DAIKIN IND LTD

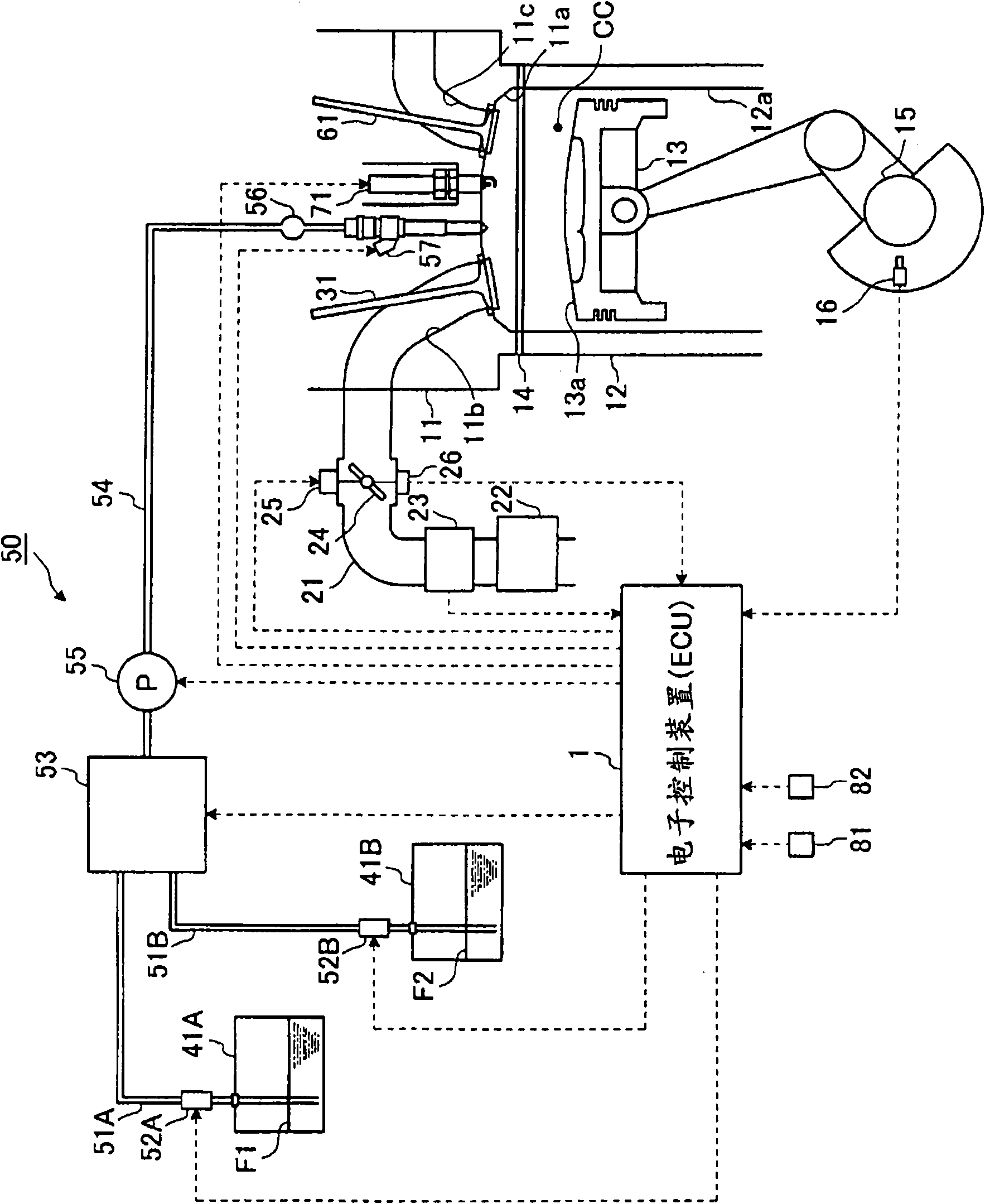

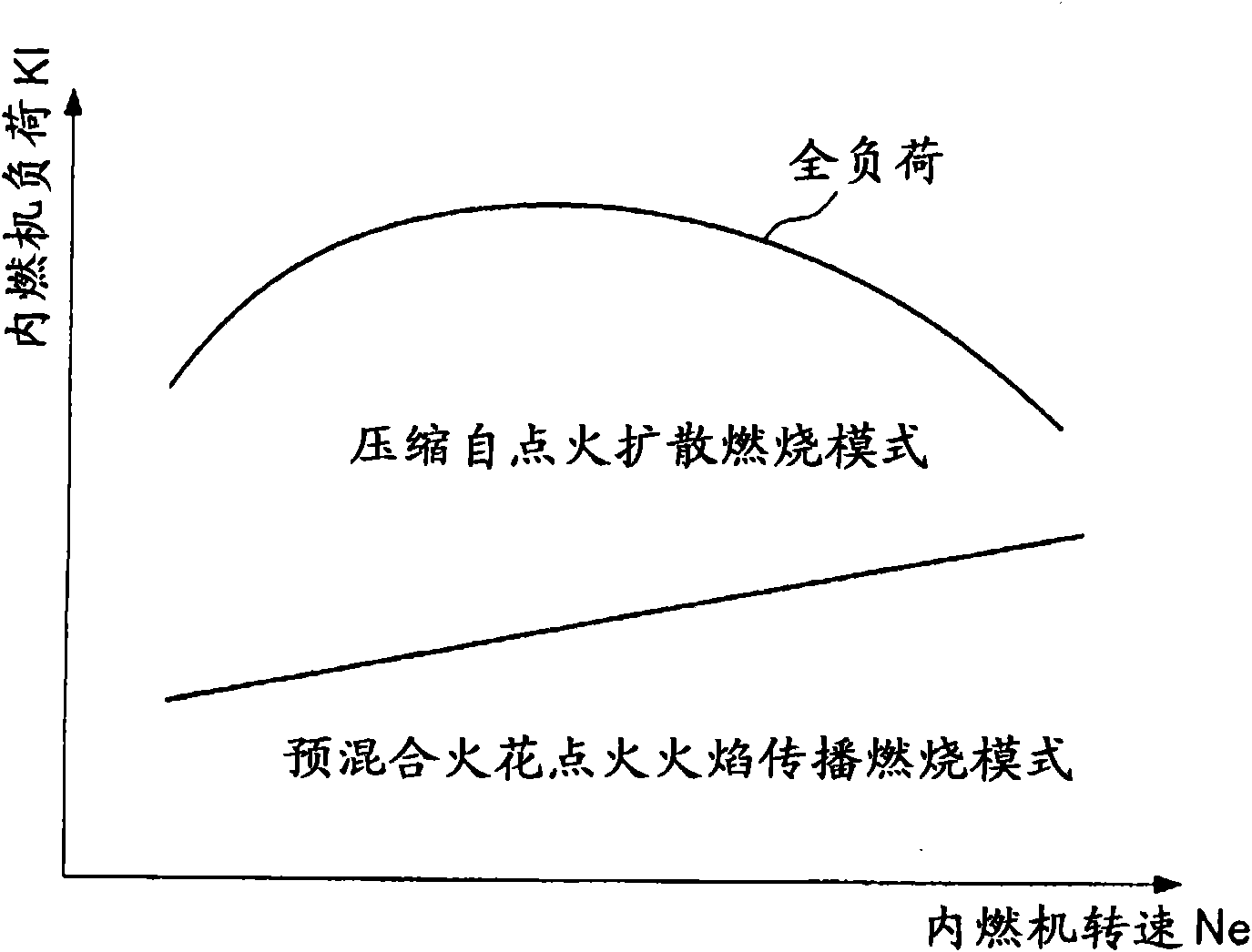

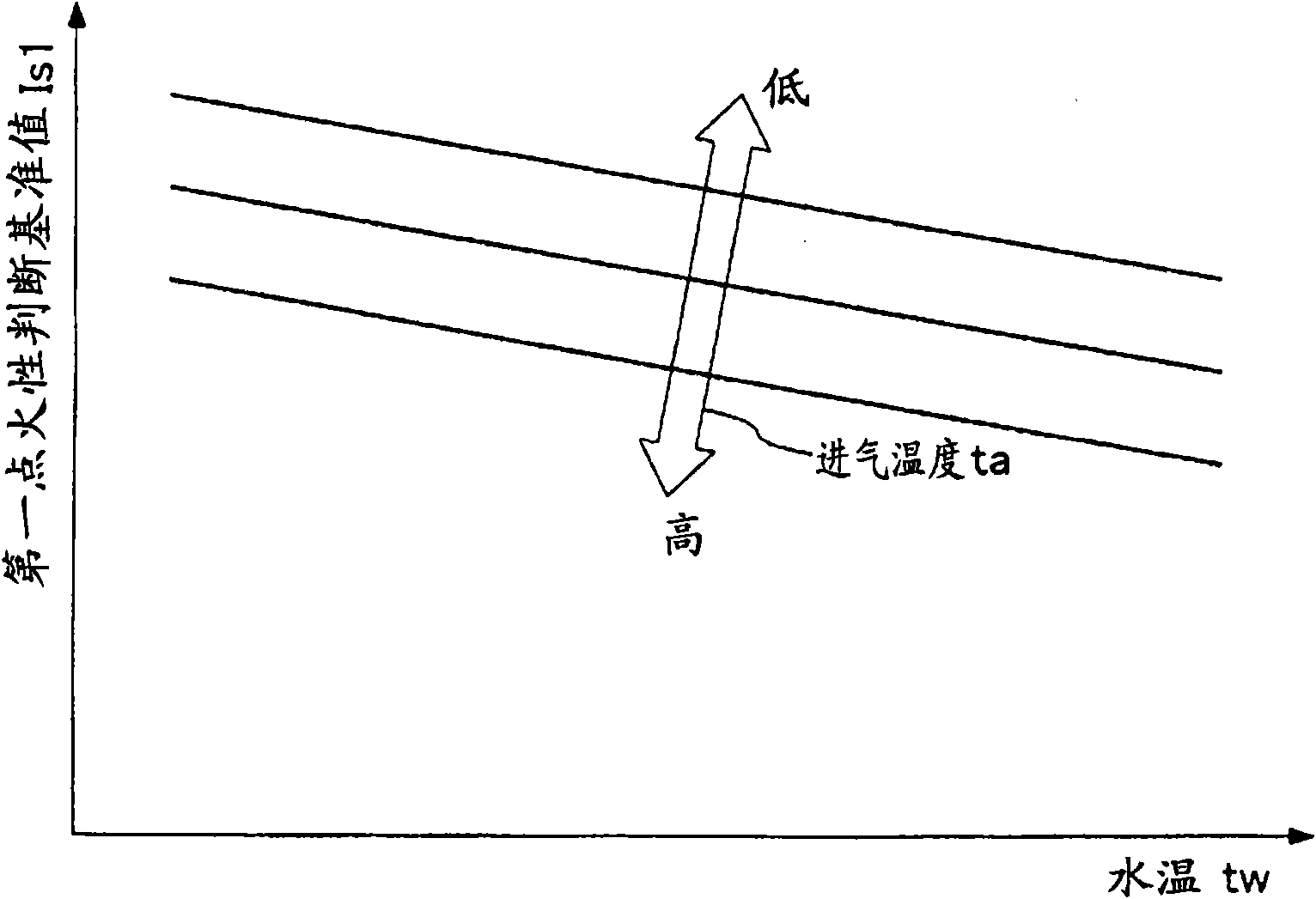

Multifuel internal-combustion engine

InactiveCN102016275AImprove ignition performanceInhibition of production increaseElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

A multifuel internal-combustion engine which improves the ignitability of low-compressed ignitable fuels inside a combustion chamber (CC) at the time of a compressed self ignition diffusive combustion mode of operation. The multifuel internal-combustion engine is operated in a manner that at least one of not less than two kinds of fuels (F1, F2) of different nature is guided into the combustion chamber (CC) or a mixed fuel composed of not less than two kinds of fuels (F1, F2) is guided into the combustion chamber (CC). An electronic controller unit (1) has a fuel characteristics detection means to detect a ignitability index value indexed for compressed ignitability of a fuel itself guided into the combustion chamber (CC), and a fuel injection control means to inject a fuel inside the combustion chamber (CC) which is judged to be low-compressed ignitable based on detected ignitability index value prior to a given time during a period from intake stroke to compression stroke at the time of the compressed self ignition diffusive combustion using such a fuel, and to guide a low-compressed ignitable fuel into the combustion chamber (CC) by subsequent main injection.

Owner:TOYOTA JIDOSHA KK

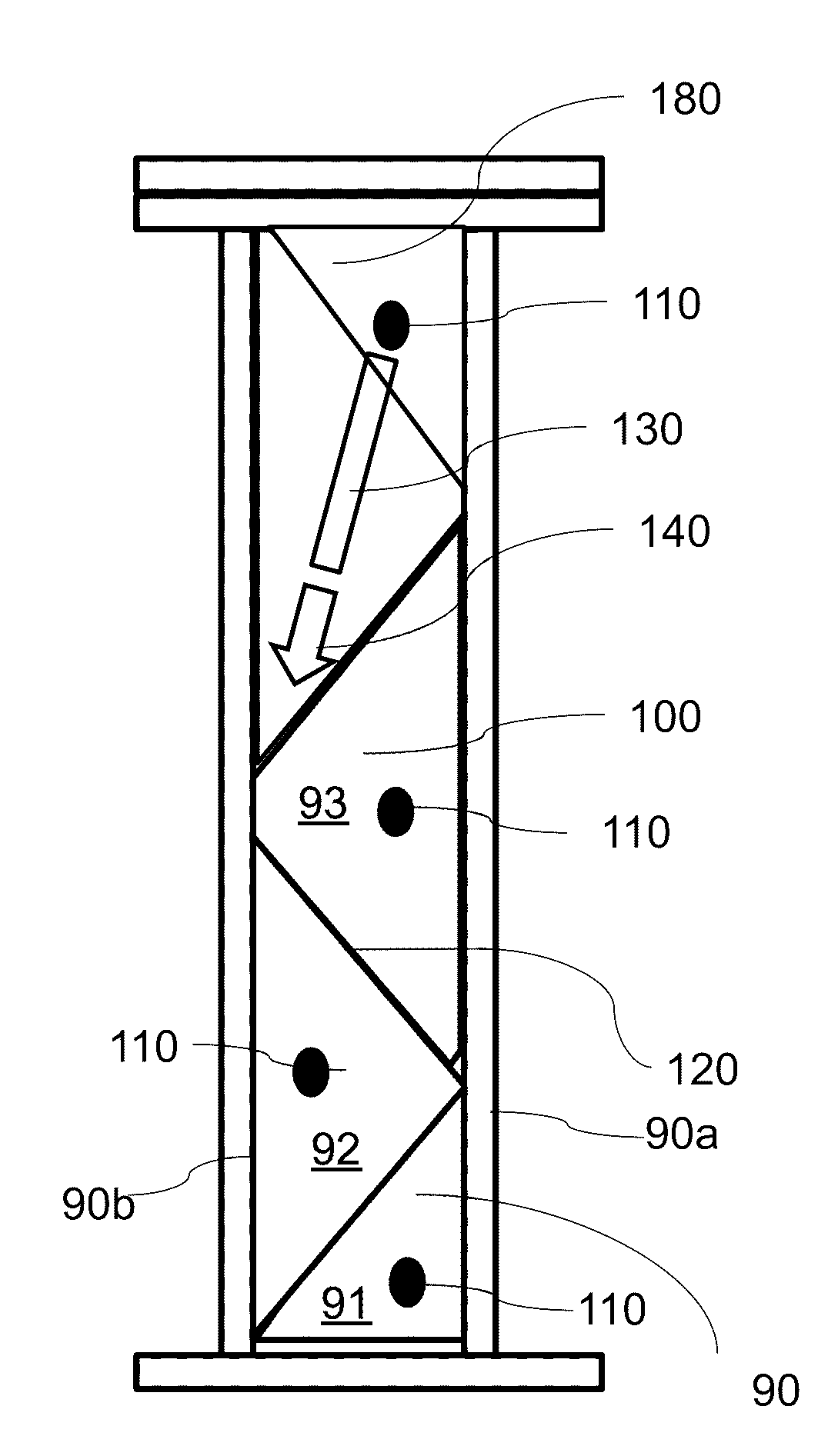

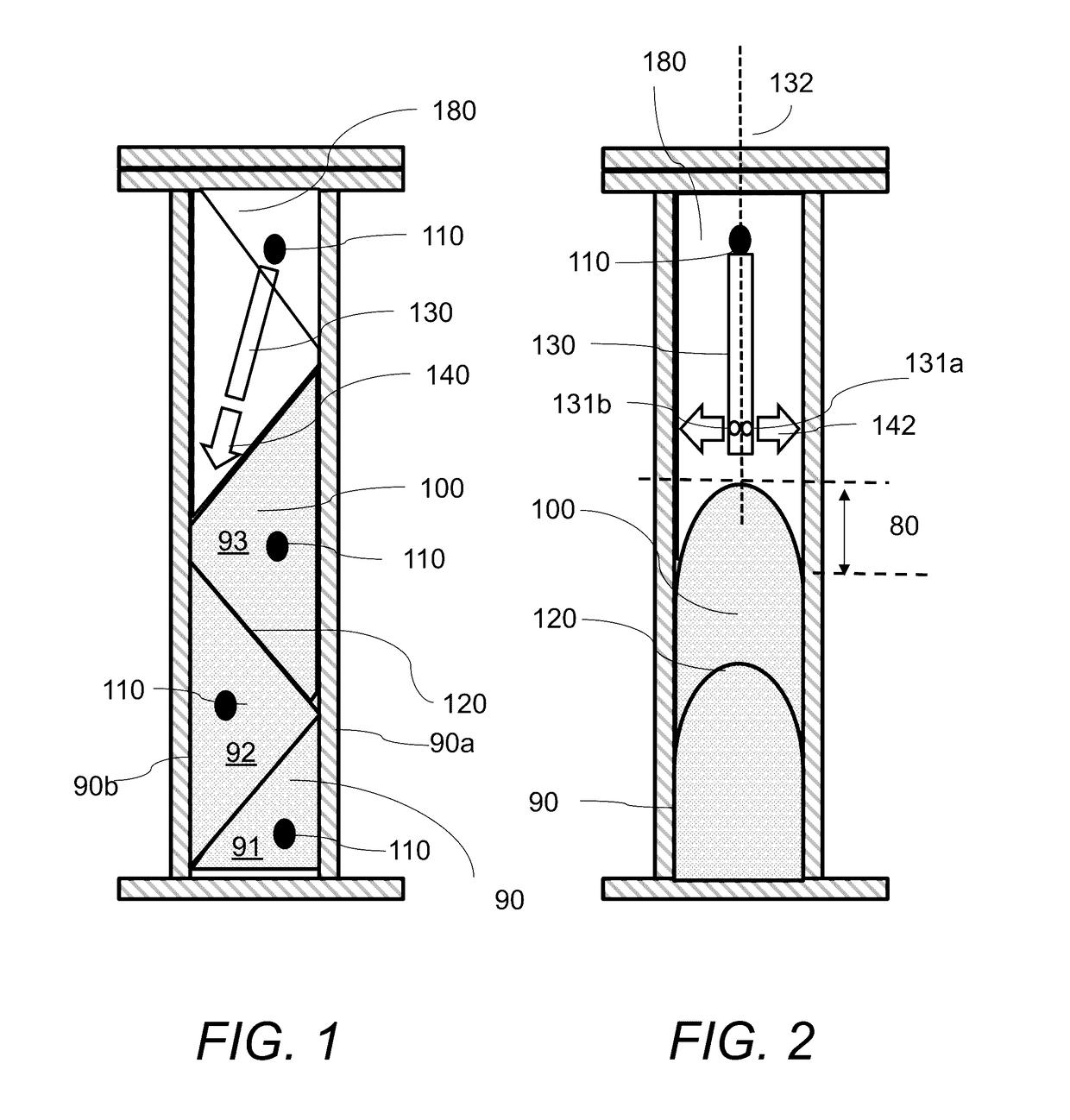

System and method for minimally invasive injection foam

InactiveUS20170080614A1Reduce pressure buildupTraining can be simplifiedHeat proofingDomestic articlesSlope angleEngineering

A method for filling a cavity with an expanding insulating foam component includes the following. First, providing a closed cavity comprising at least one elongated wall surface that extends along a first direction and includes first and second opposite sides, a top side and a bottom side. Next, forming a plurality of openings in the elongated wall surface arranged along the first direction and being alternating close to the first or the second opposite sides. Next, inserting a dispense tube through a first opening of the plurality of openings, and injecting a first portion of the expanding insulating foam into the closed cavity. The first opening is located close to the bottom side and close to the first side of the elongated wall surface. The injected foam expands along the bottom side and the first side and forms a first sloped top surface that has a positive slope angle. Next, inserting the dispense tube through a second opening of the plurality of openings located close and above the first opening and close to the opposite second side, and injecting a second portion of the expanding insulating foam into the closed cavity. The injected foam expands along the first sloped top surface and the second side and forms a second sloped top surface that has a negative slope angle.

Owner:CERTAIN TEED LLC

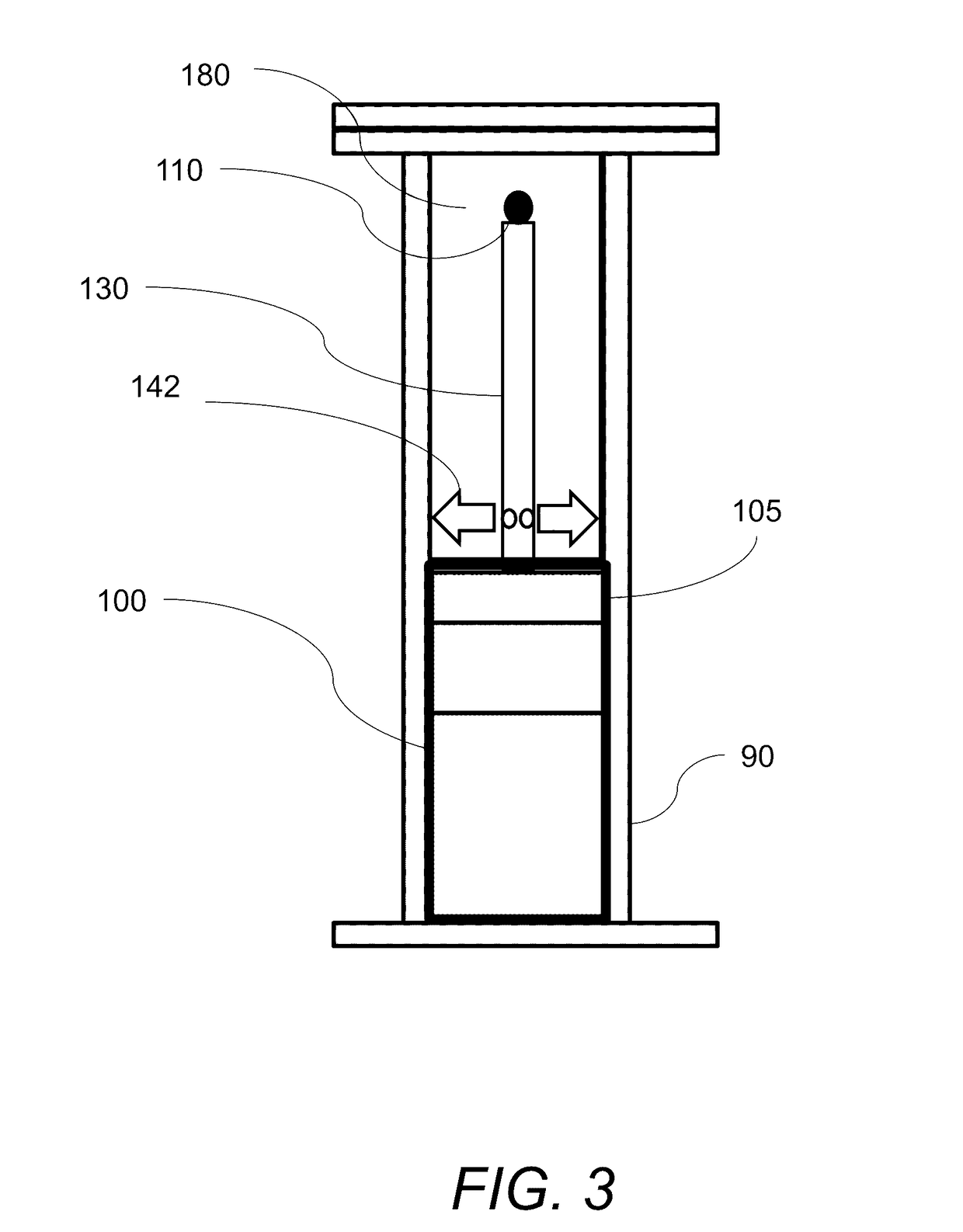

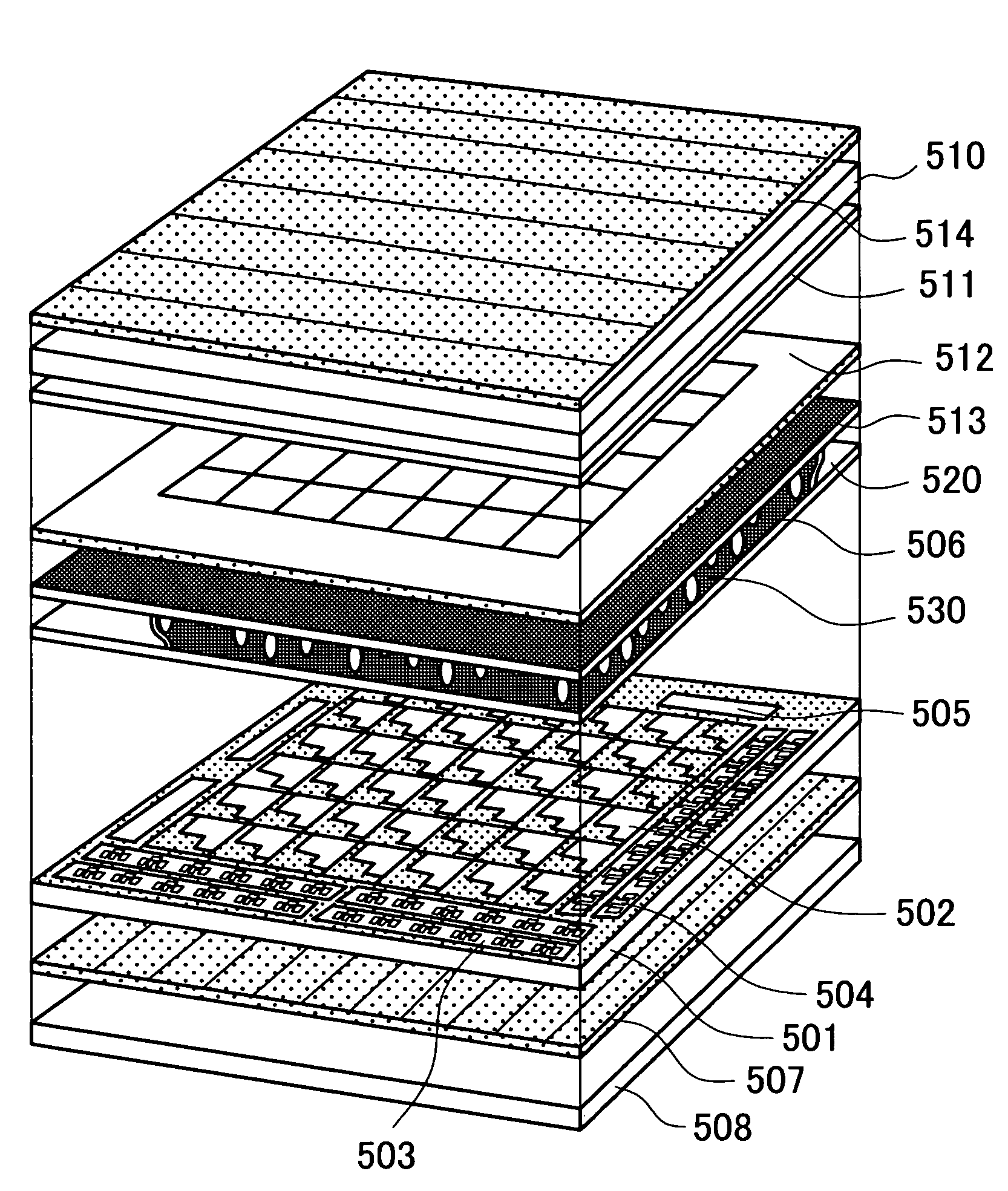

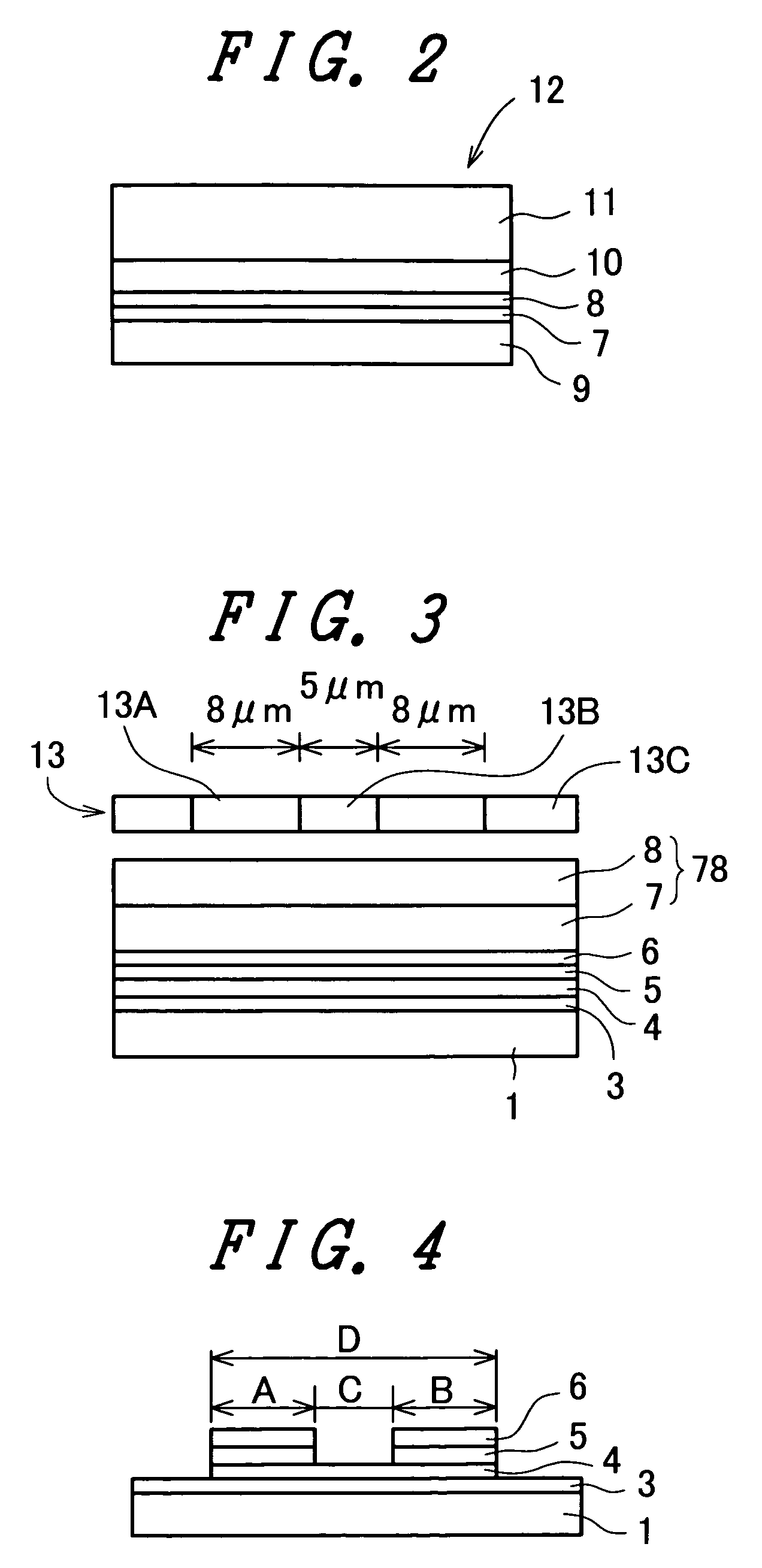

Manufacturing method of a display device using a two-layered resist

ActiveUS7460189B2Reduce stepsIncrease the mixing ratioSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusResistDisplay device

The present invention realizes the two-layered resist structure for obtaining a half exposure pattern of high sensitivity and high accuracy and a manufacturing method of a display device which includes thin film transistors which are formed using the two-layered resist. The resist is constituted of five layers, that is, a base film, a cushion layer, an upper-layer resist, a lower-layer resist and a cover film. Thicknesses of these structural members are set such that base film has a thickness of 50 to 100 μm, the cushion layer has a thickness of 10 to 30 μm, the upper-layer resist has a thickness of 0.5 to 1.0 μm, the lower-layer resist has a thickness of 0.5 to 1.0 μm, and the cover film has a thickness of 10 to 30 μm.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

Heat exchanger and air conditioning device

ActiveCN105874297AAvoid flowSmall bias current suppressionEvaporators/condensersHeat exhanger finsEngineeringAir conditioning

Provided is a heat exchanger that can suppress uneven flow of coolant even when used under conditions wherein circulation volume changes. Also provided is an air conditioning device. A plurality of flat, multi-hole pipes (21b, 121b) are connected at different heights to a first inner space (23a) of a folding-back header collecting pipe (23) of an outdoor heat exchanger (20). The first inner space (23a) has a loop structure that includes: a first partitioning plate (51); a first inflow hole (41x) that is for causing coolant to rise into a first outflow space (51a); a first upper passageway (51x); and a first lower passageway (51y). The first outflow space (51a), a first loop space (51b), a first inflow space (61b), and a first upflow space (61a) are separated by a first rectifying plate (41), the first partitioning plate (51), and a first obstructing plate (61). A coolant path of the flat pipe (121b) that is connected to the first inflow space (61b) is positioned so as not to coincide with a lower connecting hole (61x) that connects the first inflow space (61b) and the first upflow space (61a).

Owner:DAIKIN IND LTD

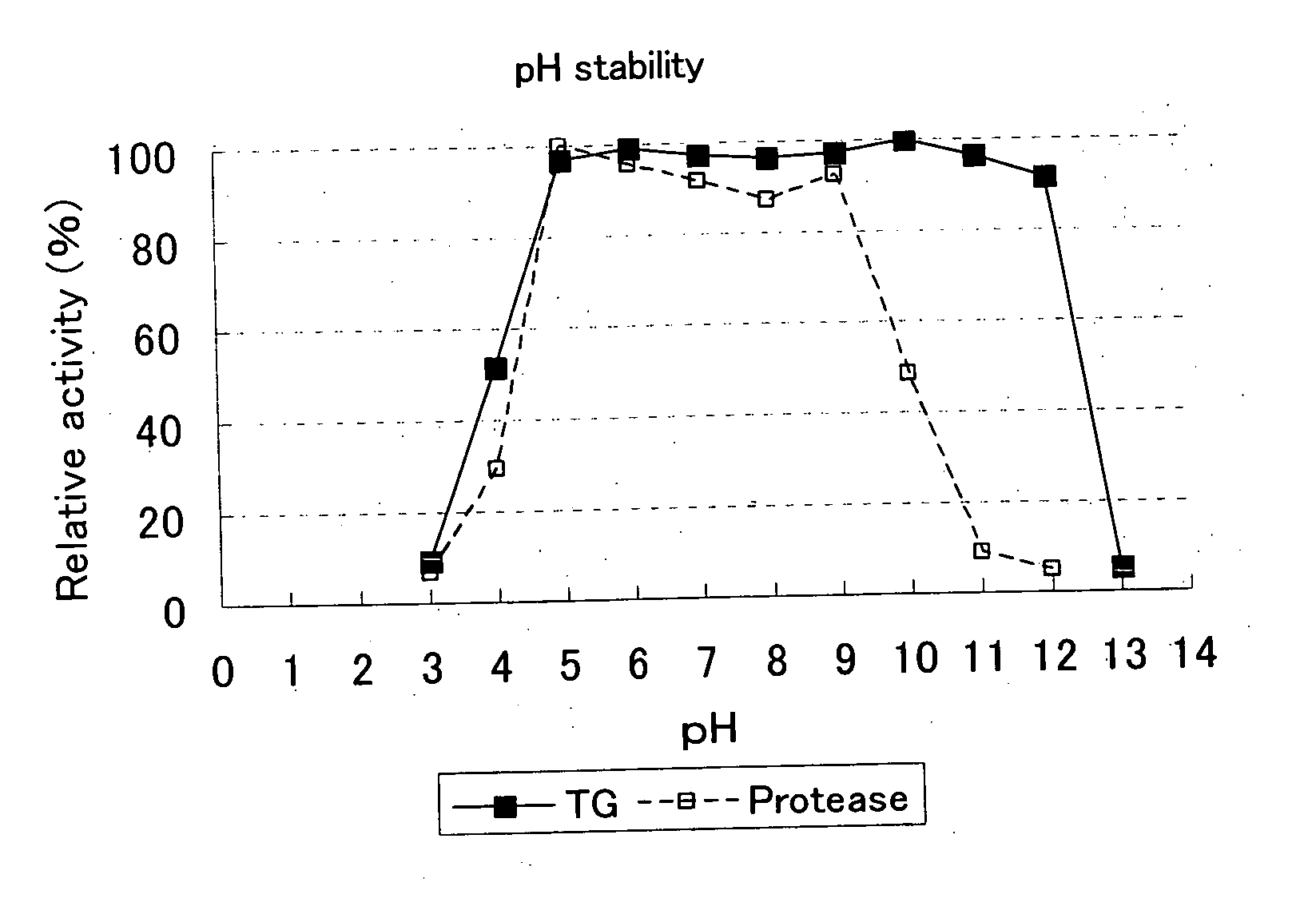

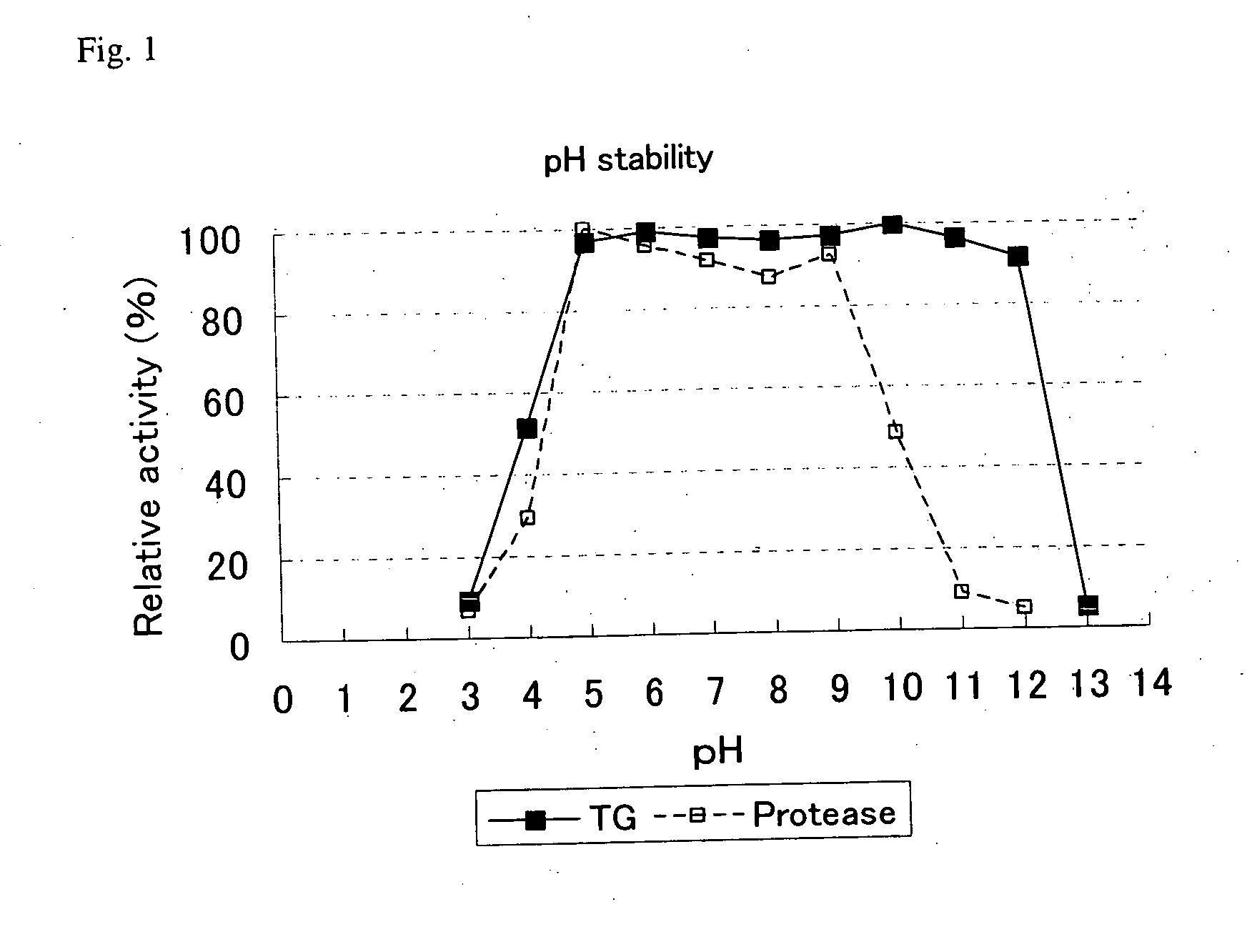

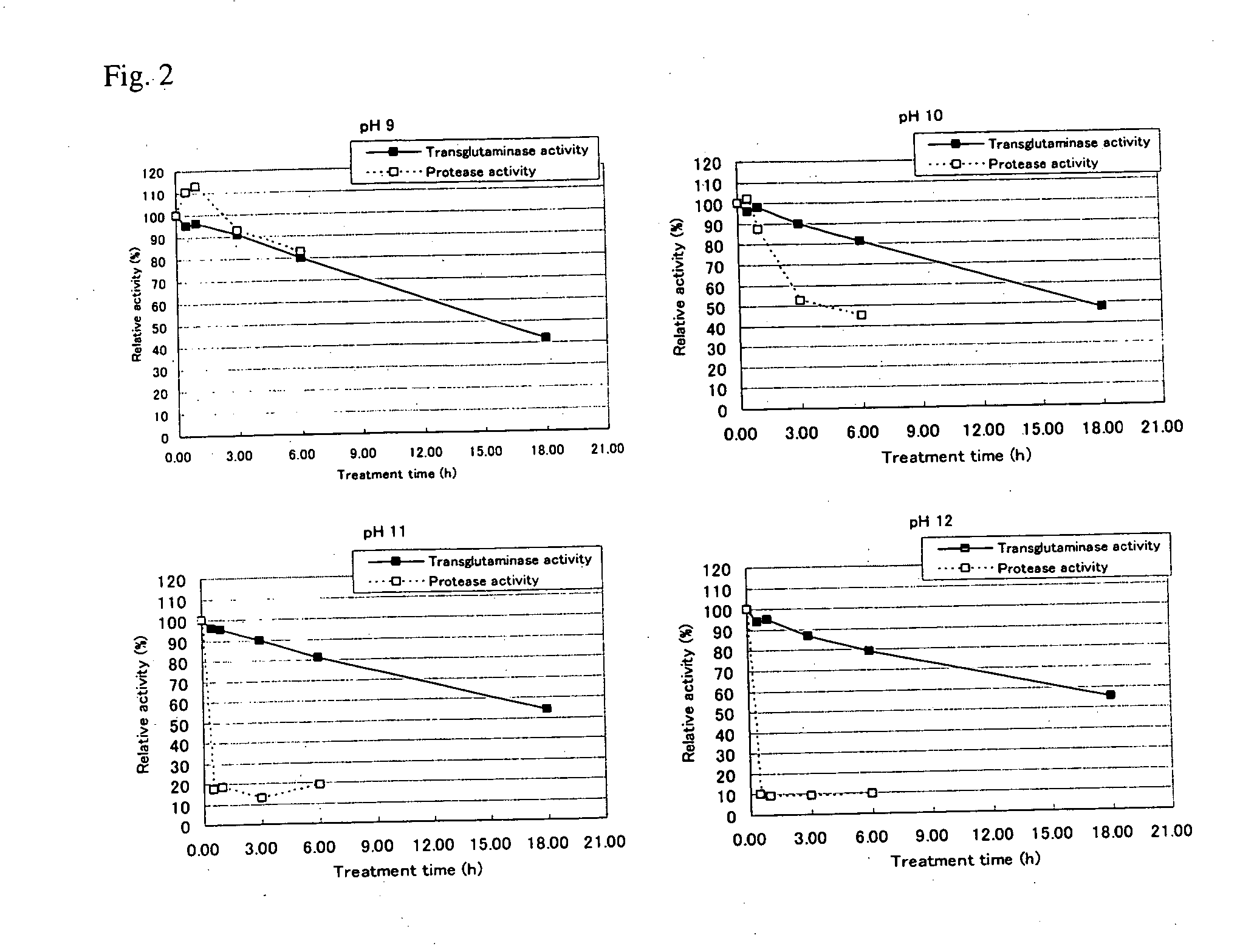

Method for producing transglutaminase composition

InactiveUS20070202213A1Reducing the protease presentReduced activityMilk preparationFood preparationProteinase activityGlutaminase

The invention provides a treatment method capable of reducing the protease present as an impurity in transglutaminase-containing products without reducing the activity of transglutaminase; a method for manufacturing transglutaminase-containing products with reduced protease activity by a treatment comprising maintaining a transglutaminase-containing product in which protease is present for 10 minutes or more but not more than 60 hours at greater than pH 9.0 but less than pH 13.0 at a temperature of 0° C. or greater but less than 50° C.; a transglutaminase-containing product obtained by this treatment method; a transglutaminase formulation in which this transglutaminase-containing product is blended, and a method for manufacturing a food by adding this transglutaminase formulation.

Owner:AJINOMOTO CO INC

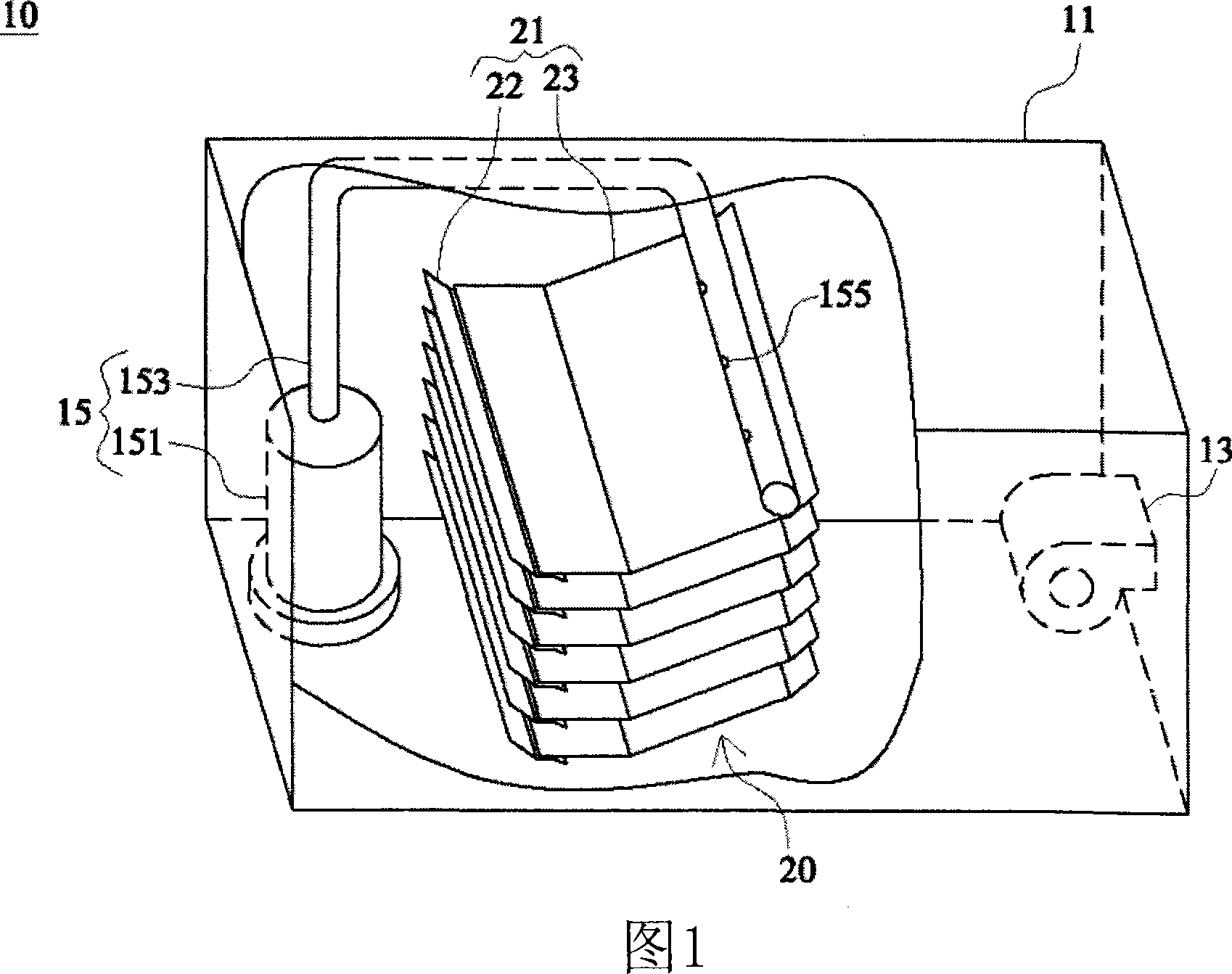

Air conditioner

InactiveCN101245940AStable temperatureIncrease humidityLighting and heating apparatusAir conditioning systemsWater storageEngineering

The invention relates to an air conditioning device, comprising at least one gas / liquid mixed module, a wind pumping component and a water supply module; each clapboard is fixedly overlapped with each other by an action clearance and comprises a first guide plate and a second guide plate; all first guide plates and all second guide plates are staggered and overlapped with each other so as to form a plurality of clearance passages and cover a water storage space, thus leading the clapboard group which is arranged above to pour a filtrated liquid in the water storage space to the water storage space of the clapboard group below so as to form a water curtain between the action clearances; therefore, the action gas which flows through the clearance of the two flow guide plates must pass through the water curtain under the guide function of the wind pumping component, and the action gas is sufficiently mixed with the filtrated liquid, thus dissolving and / or removing the impurities in the action gas and stabilizing the temperature and the moisture of the environment.

Owner:超威力有限公司

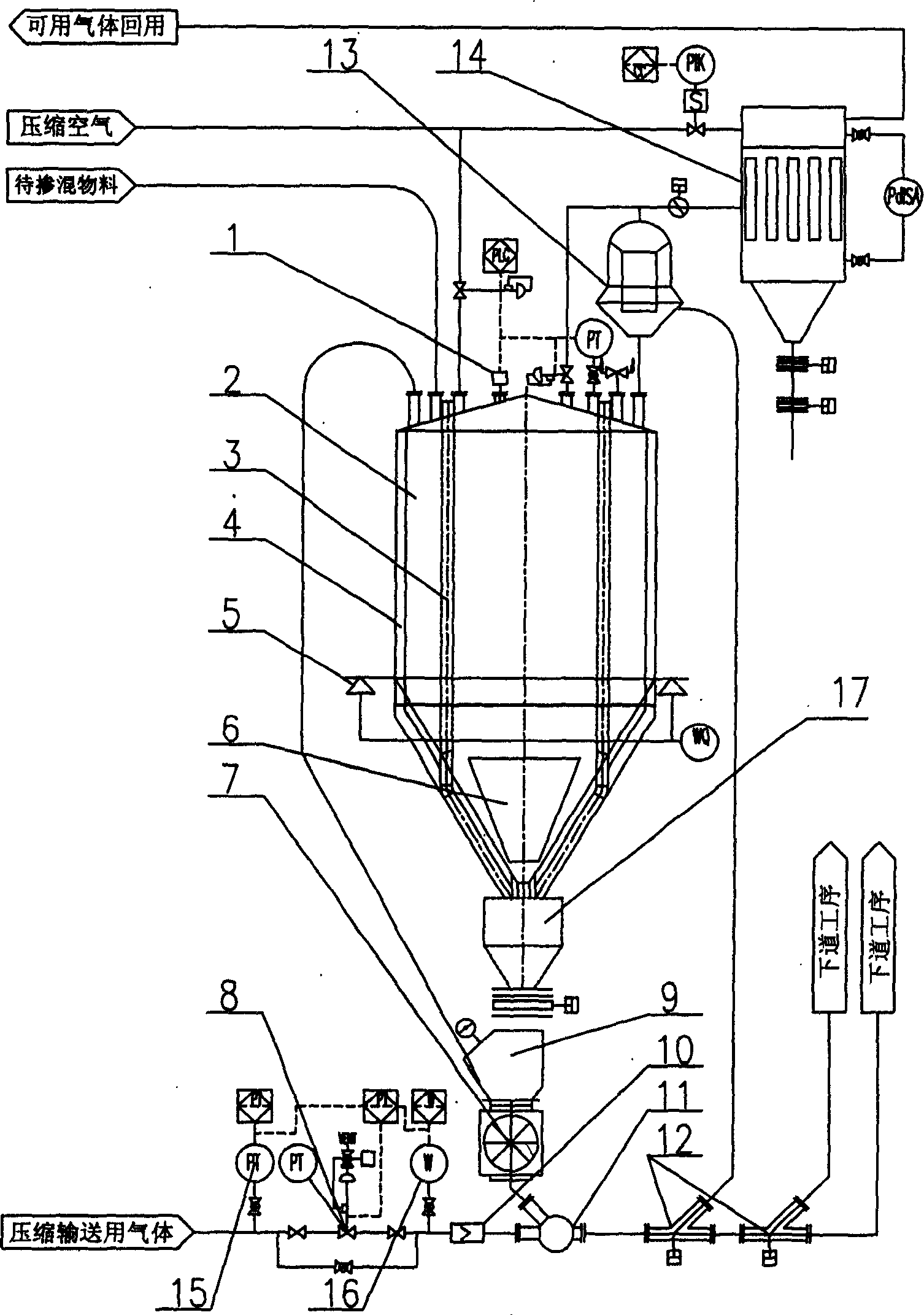

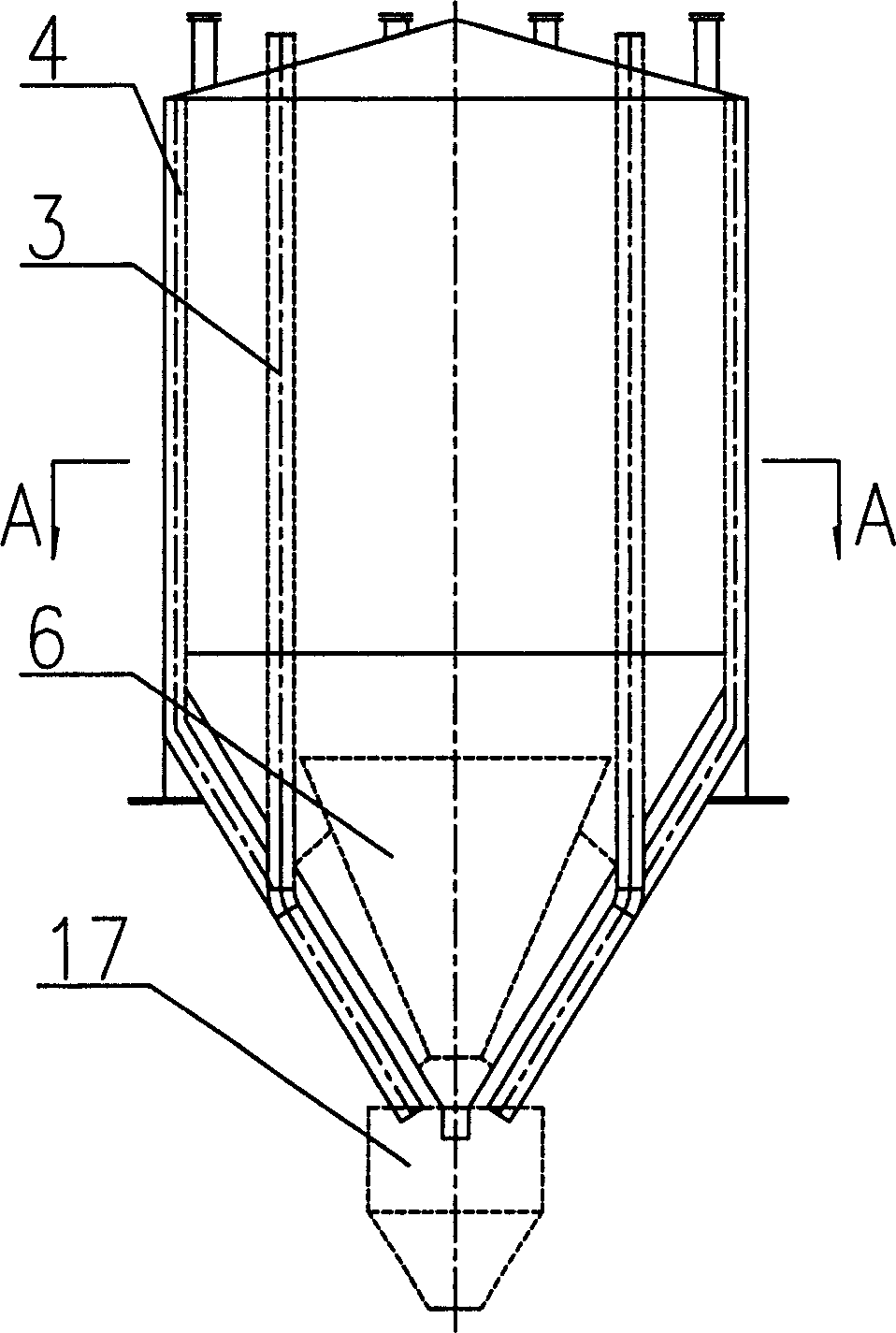

Intelligent energy mixer

InactiveCN1712117AGuaranteed fluidized movementIncrease the mixing ratioFlow mixersTransportation and packagingLine tubingEngineering

An intelligent pneumatic mixer is composed of raw material mixing cabin with multiple central pipes and multiple peripheral pipes close to wall, jet spray pipe, material delivering pipeline, high-pressure feeder, valve for high-pressure delivering pipe, multi-stage multi-conic diffusion separator with volute casing, and high-pressure pulse duster.

Owner:JIANGSU NDZ TECH

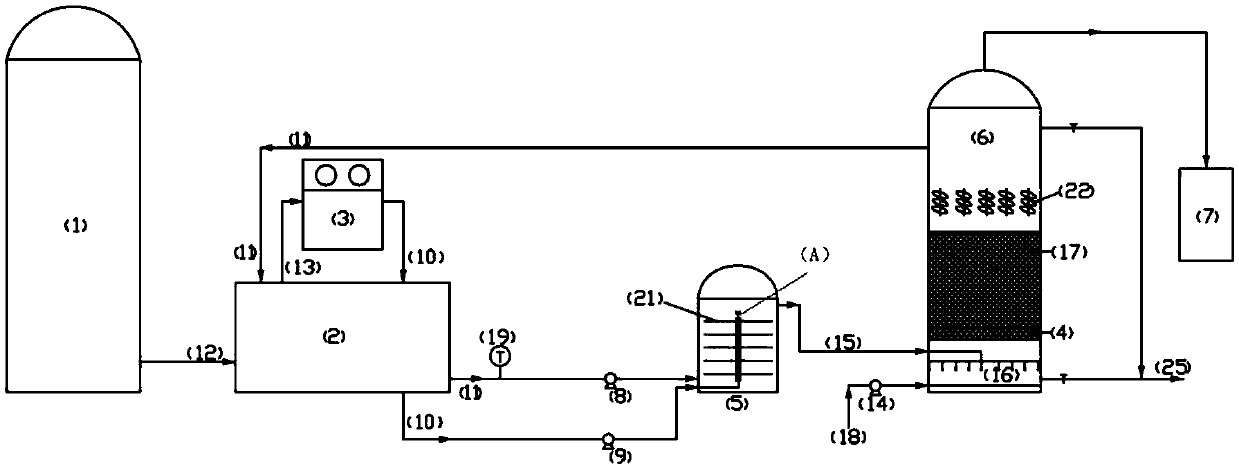

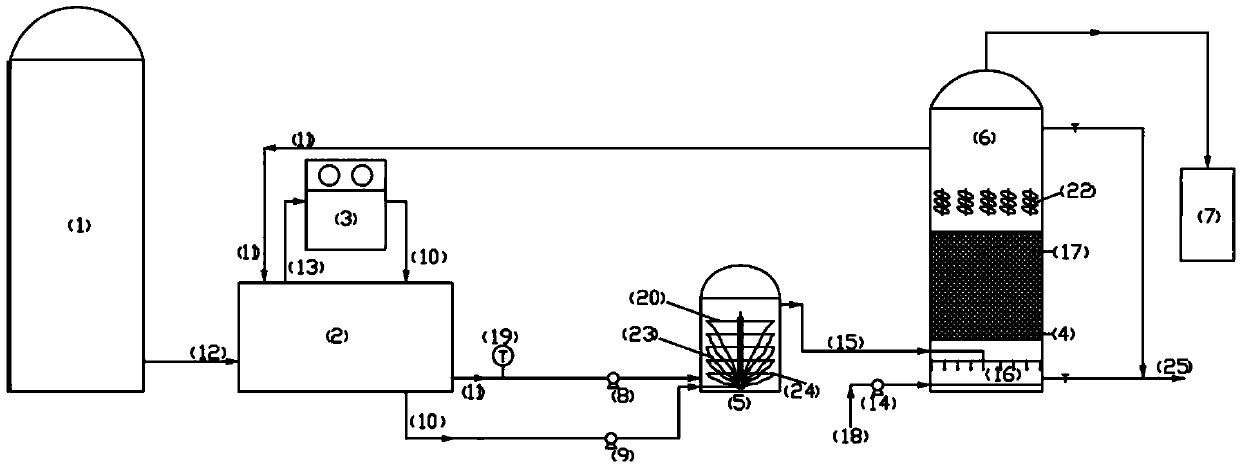

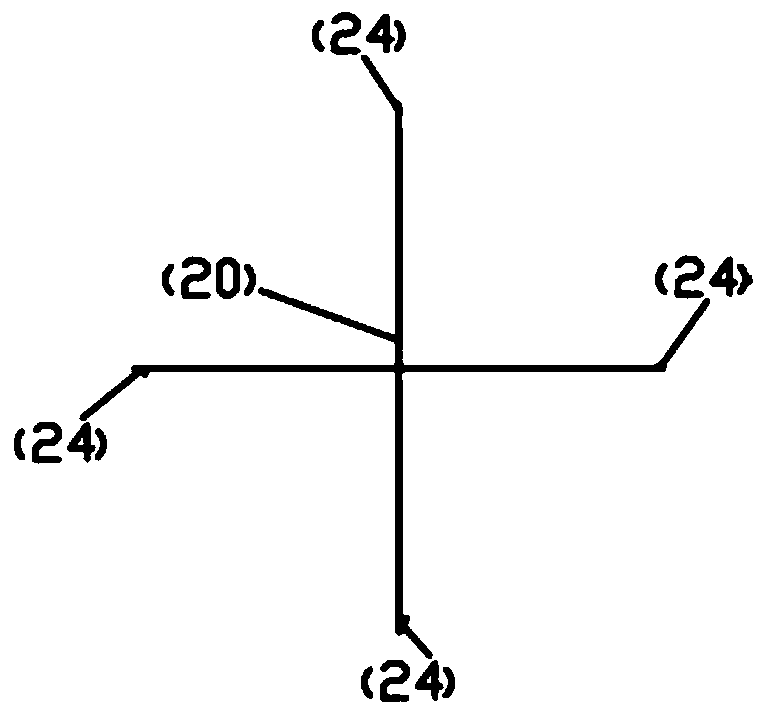

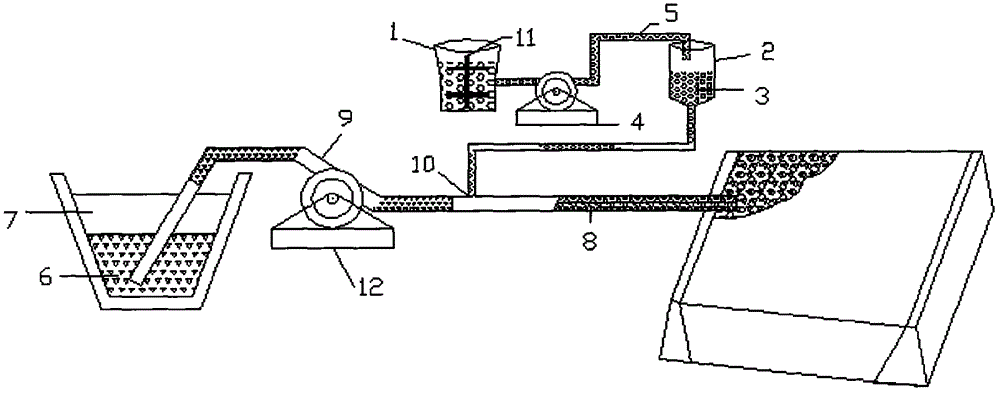

Catalytic ozonation system and method and application

ActiveCN109607745AImprove efficiencyImprove solubilityWater contaminantsWater/sewage treatment apparatusHigh concentrationSolubility

The invention provides a catalytic ozonation system and method and application. The catalytic ozonation system comprises a catalytic ozonation reaction tank (6), a bubble-free high-concentration ozonewater preparation device (5) and a low-energy-consumption refrigerating device (2); high-concentration ozone water (15) enters the catalytic ozonation reaction tank (6) through a jet flow release device (16), fine bubbles are generated, the bubbles are sufficiently mixed with pre-treated waste water (18) to generate an ozonation reaction, and part of organic pollutants in the waste water are removed. The catalytic ozonation reaction tank (6) is filled with a mineral cushion layer (4) and a catalyst (17), the mineral cushion layer (4) and the catalyst (17) act with supersaturated dissolved oxygen and remaining soluble ozone in the high-concentration ozone water respectively to generate hydroxyl radicals, and the organic matter, which is difficult to degrade, in the waste water (18) is decomposed and removed. Compared with a conventional catalytic ozonation technology, the catalytic ozonation system can more efficiently remove the organic pollutants, which are difficult to degrade, in the water.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

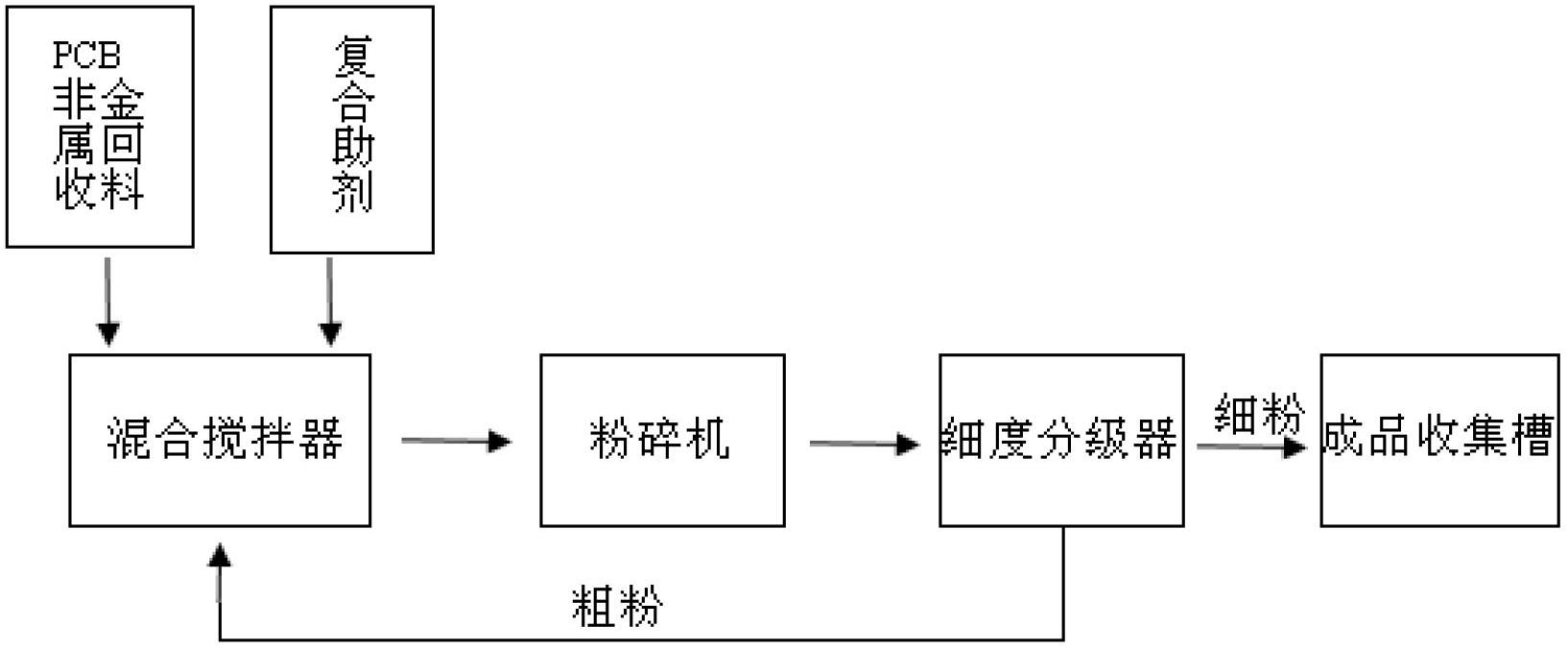

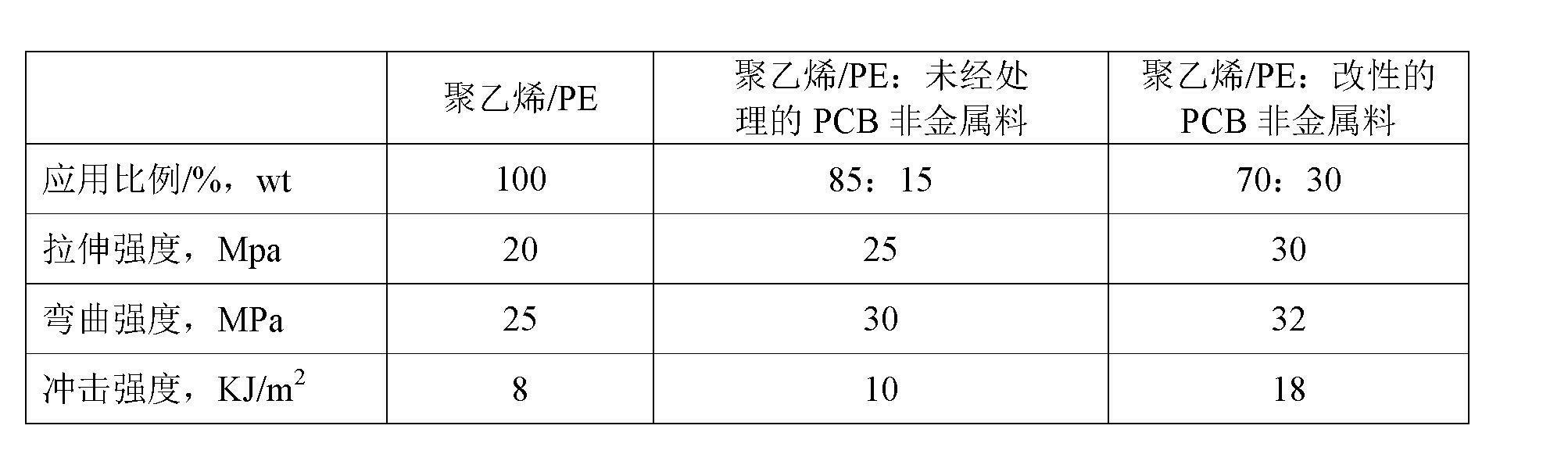

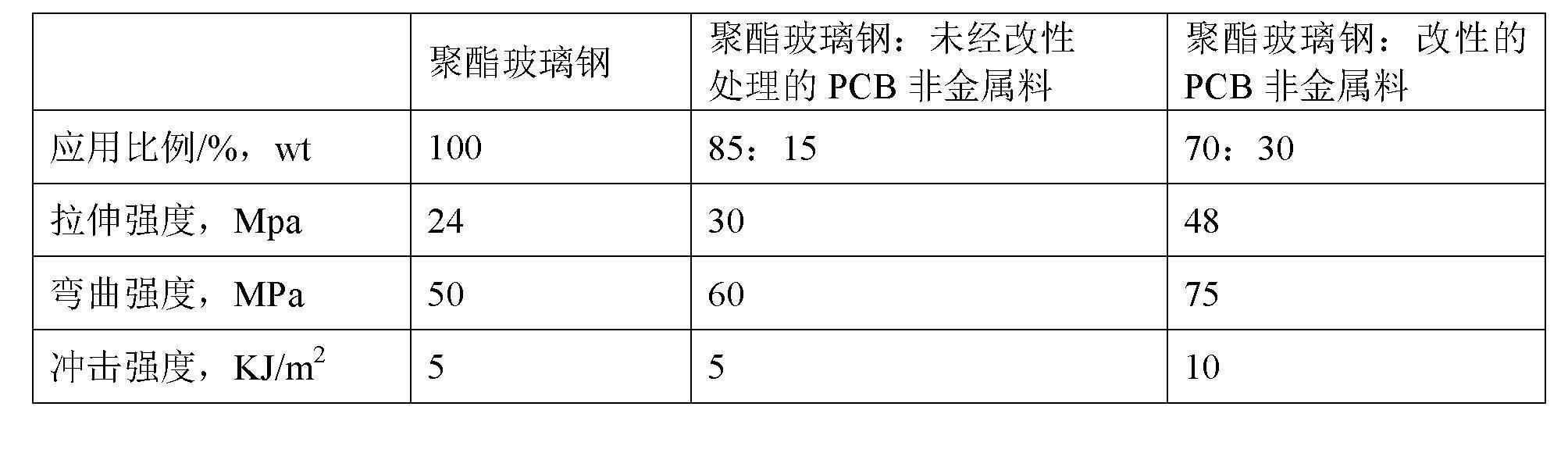

Modified nonmetallic reclaimed material of printed circuit board and preparation method thereof

ActiveCN102675717AFacilitate and intensify chemistryGood physical and mechanical propertiesChemical recyclingPigment treatment with macromolecular organic compoundsEngineeringPrinted circuit board

The invention discloses modified nonmetallic reclaimed material of a printed circuit board (PCB). The modified nonmetallic reclaimed material is prepared by a method comprising the following steps: after adding a compound assistant into nonmetallic reclaimed material of the printed circuit board and uniformly mixing, carrying out superfine crushing to obtain the modified nonmetallic reclaimed material of the printed circuit board, wherein the compound assistant comprises a crushing assistant, an active dispersing agent and a compatibilization modifier, the amount of the crushing assistant is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board, the amount of the active dispersing agent is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board, and the amount of the compatibilization modifier is 0.01%-10% of the weight of the nonmetallic reclaimed material of the printed circuit board. A finished fine power product of the modified nonmetallic reclaimed material of PCB has the advantages of effectively improved dispersion uniformity, interface compatibility and interface binding force, a mixing proportion can be increased, an application range is enlarged and application value is improved.

Owner:江苏嘉铂新材料有限公司

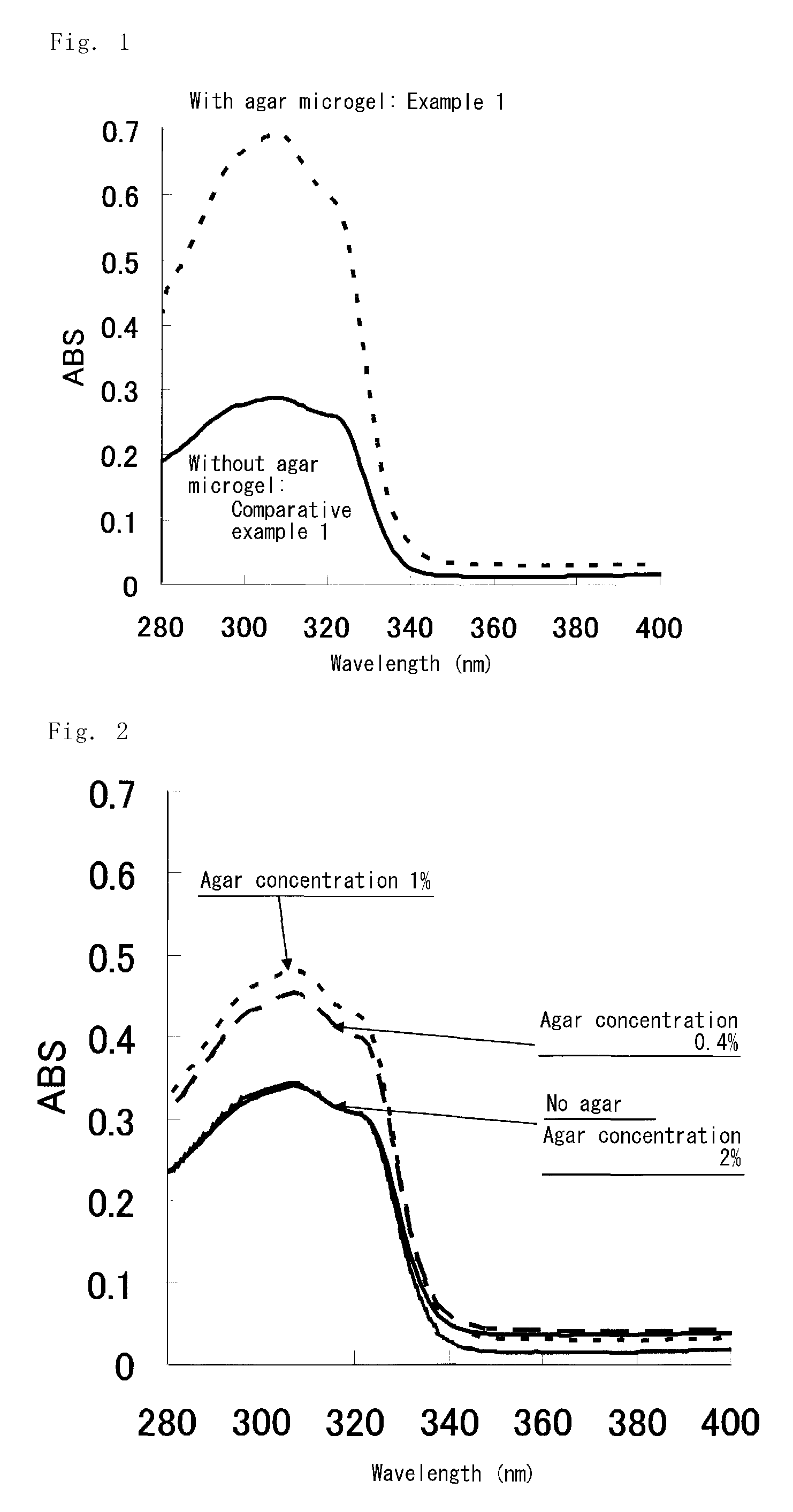

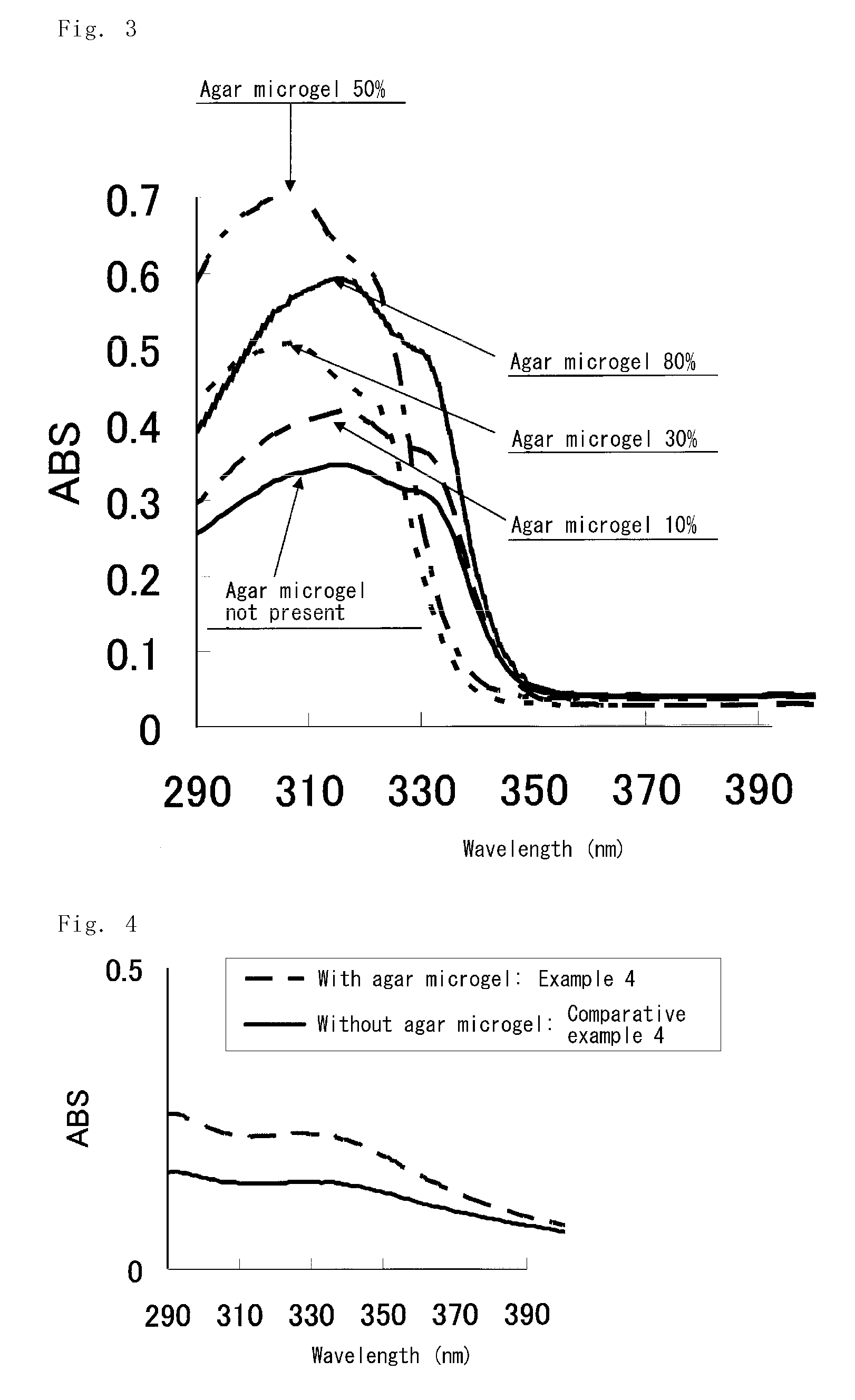

Sunscreen cosmetic

ActiveUS8367044B2Strong UV Absorbing PropertiesPromote absorptionCosmetic preparationsToilet preparationsUltravioletWater soluble

The present invention provides a sunscreen cosmetic comprising, relative to the total amount of the sunscreen cosmetic, 10-90 wt % of agar microgel (wherein the agar content in the agar microgel is 0.4-1 wt %) and 0.1-5 wt % of a water soluble ultraviolet absorbent.It was necessary to blend in an organic ultraviolet absorbent and such to give sunscreen cosmetics a high SPF value. However, there was a problem in that it was hard for a water soluble ultraviolet absorbent in the formulation to achieve the expected SPF function. Also, sunscreen cosmetics are particularly desired to give a freshing texture upon use.In view of the fact that a high blend ratio of an oil soluble ultraviolet absorbent inhibits the freshing texture upon use, the object of the present invention is to provide a sunscreen cosmetic that achieves a high SPF value and a freshing texture upon use by mainly blending in a water soluble ultraviolet absorbent.

Owner:SHISEIDO CO LTD

Input type automatic PH glass electrode adjusting device and method

ActiveCN104460414AAvoid exposureAutomatic control maintenance cleaningProgramme controlComputer controlAutomatic controlMeasurement device

The invention provides an input type automatic PH glass electrode adjusting device and method. An automatic electrode cleaning device and an automatic electrode lifting device are adopted, an electrode measuring device can be automatically controlled to be maintained and cleaned, measurement accuracy is ensured, the depth of the portion, immersed into a measuring medium, of the electrode measuring device can be automatically controlled, measuring points can be automatically adjusted according to liquid level changes, the measurement continuity is ensured, and the phenomenon that an electrode is exposed in air due to liquid level changes of the measuring medium is avoided.

Owner:NANJING CEC AUTOMATION

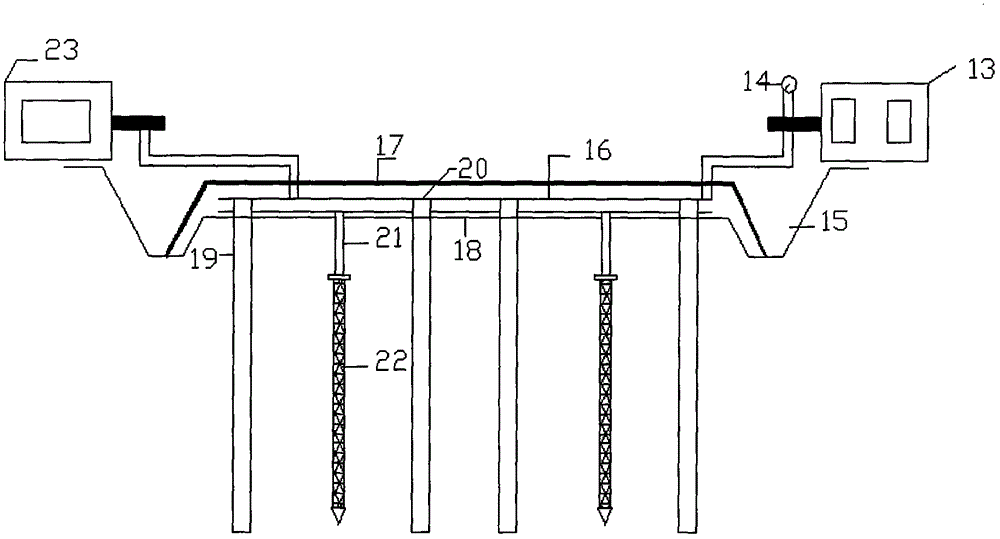

Method for treating dredger fill foundation through flocculation combined with vacuum preloading

InactiveCN104674785AIncrease the mixing ratioAchieve separationSoil preservationFlocculationCut and fill

The invention relates to a method for treating a dredger fill foundation through flocculation combined with vacuum preloading. The method includes the processes of flocculation and vacuum preloading. Property of dredger fill is changed by early-stage flocculant, so that dewatering efficiency of late-stage vacuum preloading is improved. In addition, integral strength of the dredger fill foundation can be improved effectively by combining the flocculant with the dredger fill, so that integral reinforcing effect of the dredger fill foundation can be improved effectively through flocculation combined with vacuum preloading.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com