High-precision variable gas proportion mixing apparatus and gas proportion mixing method

A proportional mixing device and high-precision technology, which is applied in the direction of mixing methods, gas and gas/steam mixing, mixers, etc., can solve the problems that the control accuracy is easily disturbed by external factors, high maintenance costs, complex structure, etc., and achieve market improvement. Competitive, easy to operate, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

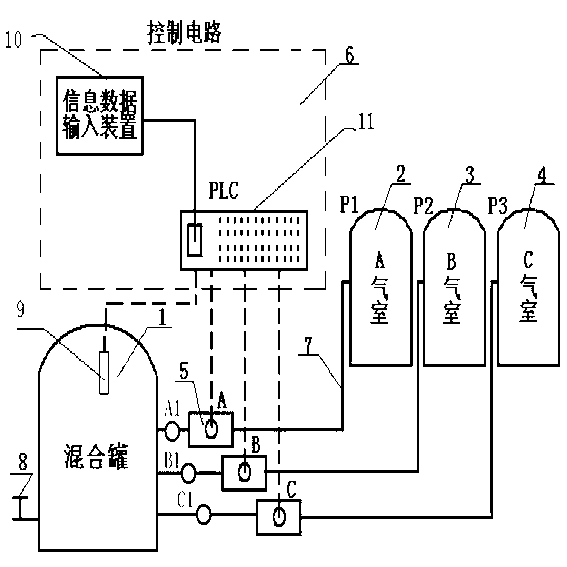

[0064] figure 1 It is a schematic cross-sectional structure diagram of an embodiment of the present invention.

[0065] like figure 1 Shown: the high-precision variable gas ratio mixing device of the embodiment of the present invention, its purpose is to mix multiple gases, such as carbon dioxide (CO 2 ), nitrogen (N 2 ) and oxygen (O 2 ) and other three kinds of gases are mixed in proportion to food fresh-keeping gas, and the gas in the food packaging is replaced and packaged, which includes a mixing tank composed of containers 1, three kinds of gas sources corresponding to the types of gases, and between each gas source The pressures are the same, and the respective pressures of the three gas sources are greater than the pressure of the mixing tank 1, and the three gas sources are respectively connected to the mixing tank 1 through three pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com