Method used for increasing silicon dioxide antireflection film hole stability

A technology of silicon dioxide and anti-reflection coatings, which is applied in the field of improving the stability of the pores of silica anti-reflection coatings. It can solve the problems that the anti-reflection coatings cannot achieve the expected effect, the density of the film increases, and the film cracks, etc., so as to prevent the holes from collapsing. And cracking, reducing internal stress, reducing the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

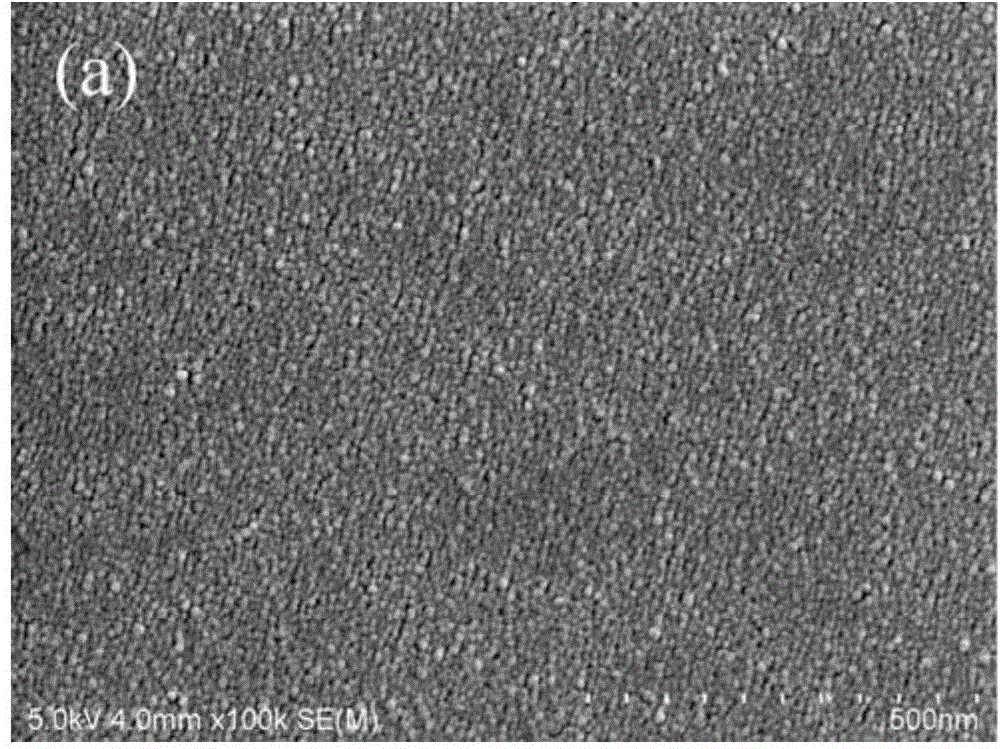

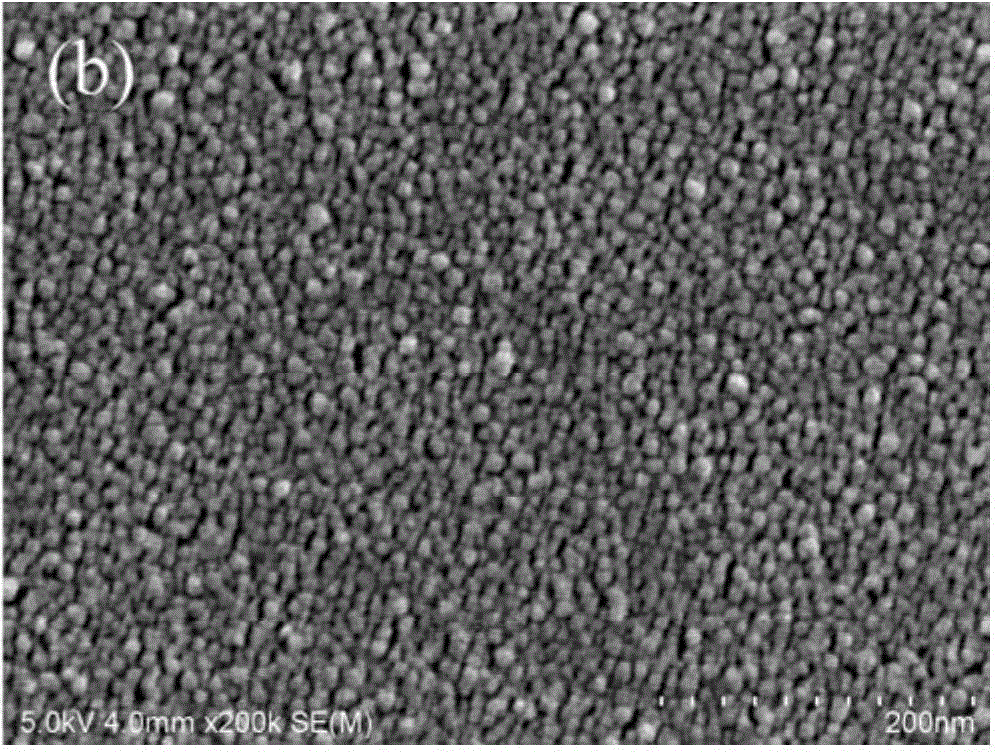

[0034] This embodiment provides a method for improving the hole stability of a silica antireflection film, which includes the following steps:

[0035] Step 1: Prepare the ready-to-use sol, the organosiloxane added in the sol is methyltriethoxysilane;

[0036] Add ethyl orthosilicate, deionized water, methyltriethoxysilane, Triton X-100 at a molar ratio of 1:4.53:0.25:0.2 to absolute ethanol, use hydrochloric acid as a catalyst, and prepare 100mL sol , Wherein the molar concentration of methyltriethoxysilane is 0.075mol / L, the sol is treated in a water bath, the temperature of the water bath is 55°C, and the time is 2 hours, and then the sol is sealed and left standing at room temperature In 2 days, the preparation of the sol to be used was completed.

[0037] Step 2: Cleaning and surface treatment of high borosilicate glass;

[0038] Use deionized water, acetone and absolute ethanol to ultrasonically clean the high borosilicate wafers. The cleaning time for each step is 15 minutes. ...

Embodiment 2

[0048] This embodiment provides a method for improving the hole stability of a silica antireflection film, which includes the following steps:

[0049] Step 1': It is basically the same as Step 1 of Example 1, except that the organosiloxane added in the sol is trimethylethoxysilane, and the concentration of trimethylethoxysilane is 0.03mol / L.

[0050] Step 2'and step 3'are the same as step 2 and step 3 of the first embodiment.

[0051] Step 4': Heat treatment of the film;

[0052] Put the high borosilicate silicon wafer with gel film prepared in step 3'into the muffle furnace, start from room temperature, heat the film at a heating rate of 0.5°C / min, at 130°C, 200°C, 250°C The four temperatures of 300℃ and 300℃ each stay for 10 minutes, and then the temperature is raised to 500℃ for heat treatment for 15 minutes, the muffle furnace is turned off, and the film is cooled to room temperature along with the furnace.

[0053] Step 5'is the same as step 5 in the first embodiment.

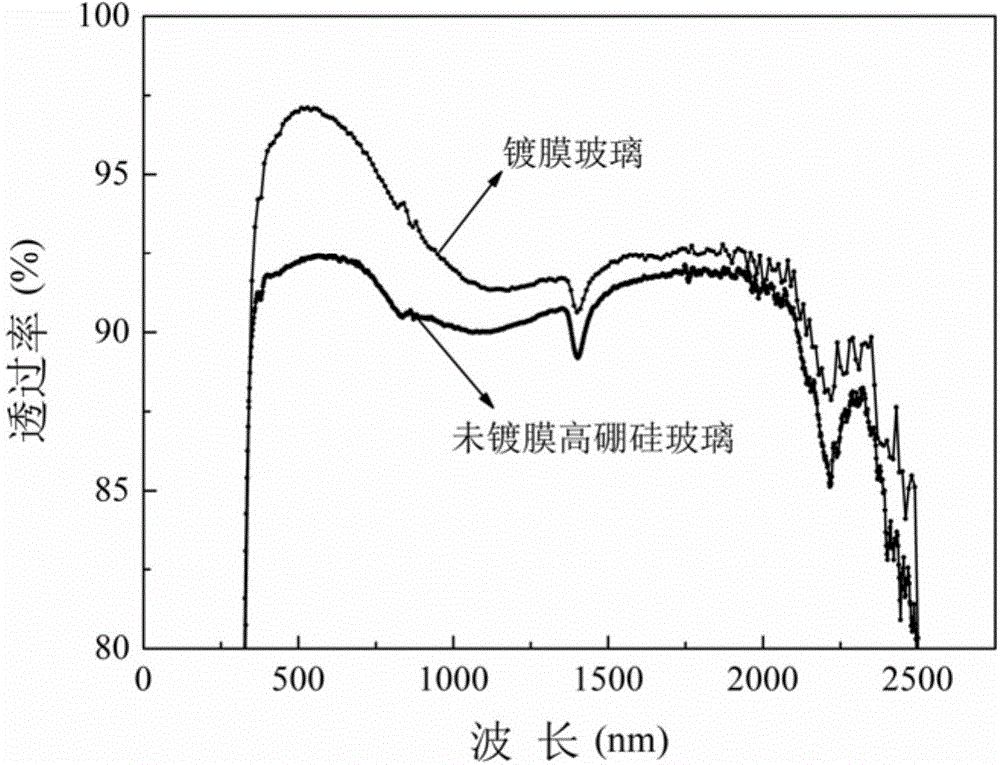

[0054] The...

Embodiment 3

[0056] This embodiment provides a method for improving the hole stability of a silica antireflection film, which includes the following steps:

[0057] Step 1'': It is basically the same as Step 1 of Example 1, except that the organosiloxane added in the sol is methyltriacetoxysilane, and the concentration of methyltriacetoxysilane is 0.2mol / L.

[0058] Step 2'' and step 3'' are the same as step 2 and step 3 of the first embodiment.

[0059] Step 4’’: Thin film heat treatment;

[0060] Put the high borosilicate silicon wafer with gel film prepared in step 3'' into the muffle furnace, start from room temperature, heat the film at a heating rate of 1℃ / min, at 145℃, 200℃, 250 The four temperatures of ℃ and 300℃ each stay for 40 minutes, and then the temperature is raised to 500℃ for heat treatment for 15 minutes, the muffle furnace is turned off, and the film is cooled to room temperature along with the furnace.

[0061] Step 5'is the same as step 5 in the first embodiment.

[0062] The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com