Anodic oxidation treating fluid containing corrosion inhibition additive

An anodic oxidation and additive technology, applied in anodic oxidation and other directions, can solve problems such as fatigue fracture, achieve the effects of fatigue life protection, increase film formation rate, and reduce sulfuric acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

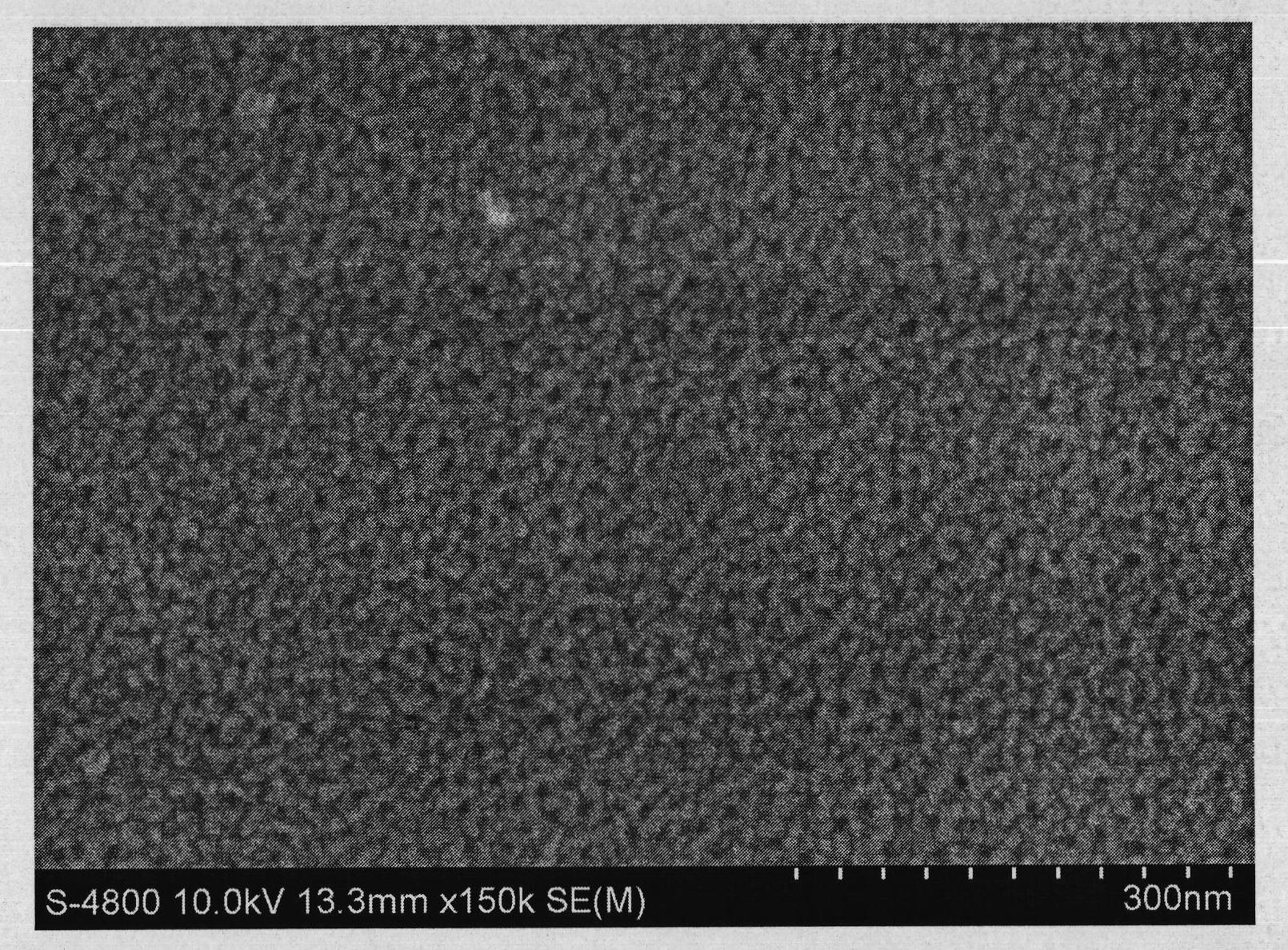

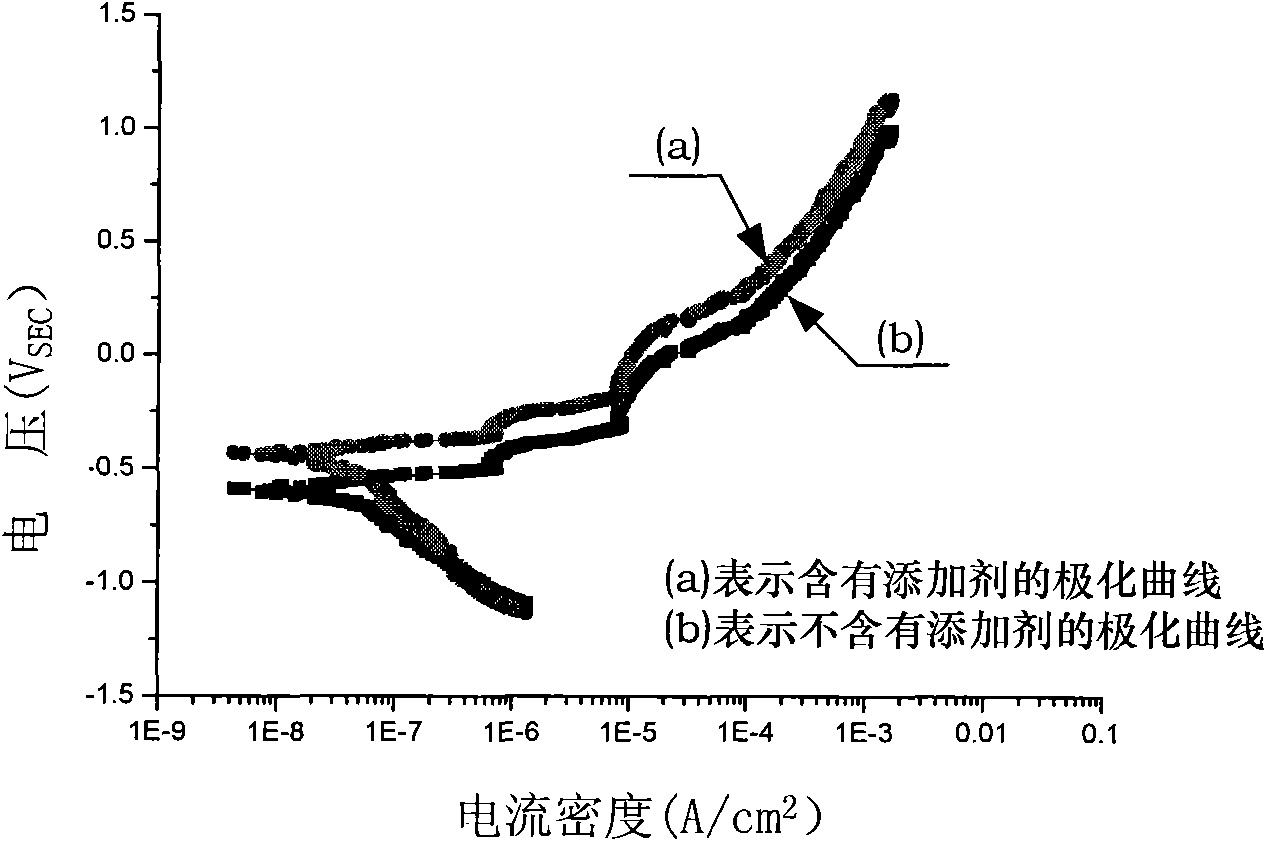

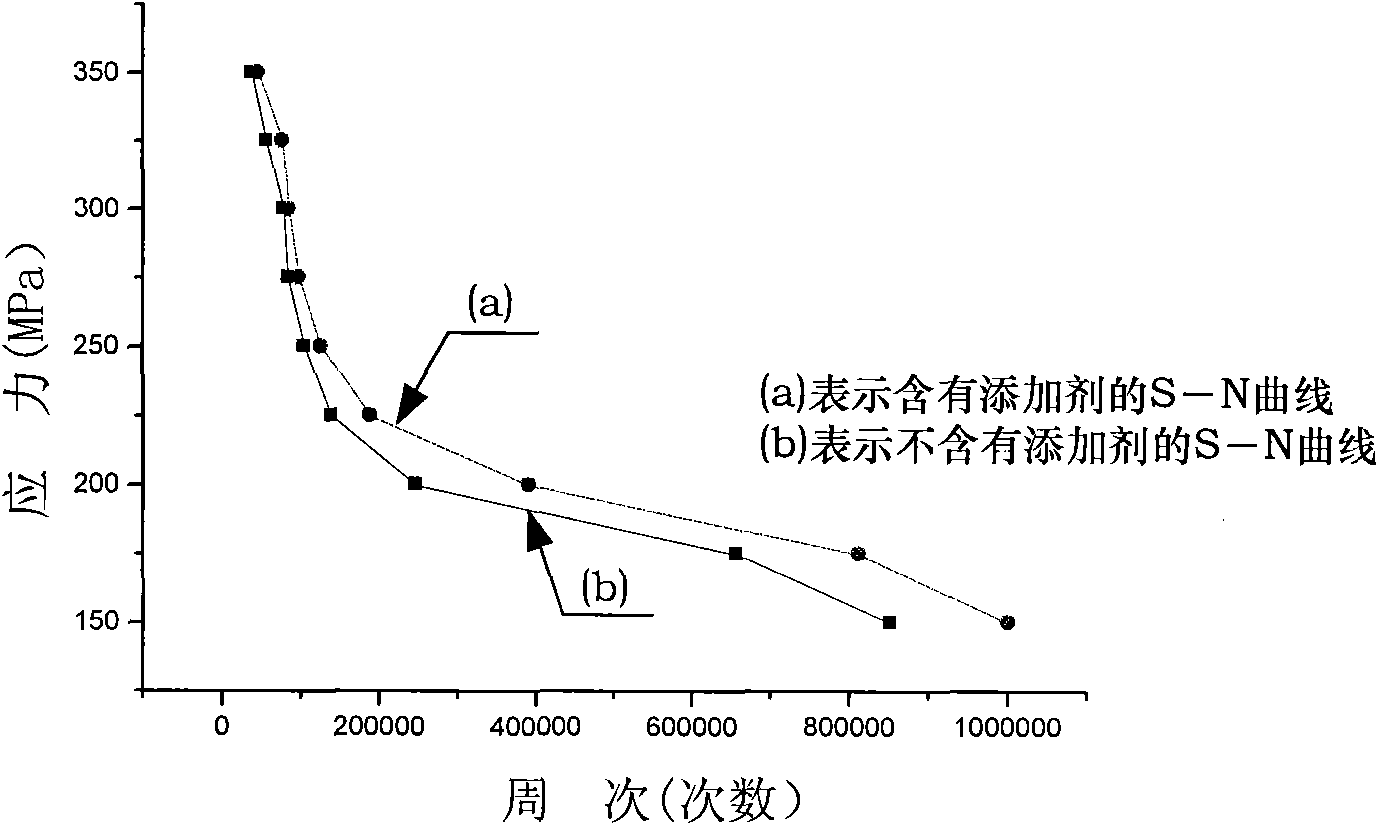

Image

Examples

Embodiment 1

[0034] 1. The test material is brand 2024 bare aluminum plate, the heat treatment system is T3 (2024-T3), and the size is 100mm×50mm×2.5mm;

[0035] 2. The anodic oxidation bath solution is 100ml of deionized water, adding 2.5ml of H with a mass percentage concentration of 98%. 2 SO 4 , 5g of adipic acid (fatty acid) modifier and 10mg of benzotriazole corrosion inhibitor;

[0036] Three, the specific steps are

[0037] Alkali washing step: immerse in NaOH aqueous solution at a temperature of 50°C for 1.5min to take it out, and rinse the surface of the sample with water; the NaOH aqueous solution is 100ml of tap water with 5.5g of NaOH added;

[0038] Light-emitting step: put the sample treated by the alkali washing step into the three-acid light-emitting solution at 20°C for 2 minutes, take it out, and rinse the surface of the sample with deionized water; add 5g of CrO to 100ml of the three-acid light-emitting solution 3 , 8ml of HNO 3 , 1 ml of HF. CrO 3 For analytical ...

Embodiment 2

[0048] 1. The test material is brand 2024 bare aluminum plate, the heat treatment system is T3 (2024-T3), and the size is 100mm×50mm×2.5mm;

[0049] 2. The anodizing bath solution is 100ml of deionized water, adding 5ml of H with a mass percentage concentration of 98%. 2 SO 4 , 10g of ammonium adipate modifier and 20mg of 2-mercaptobenzothiazole corrosion inhibitor;

[0050] Three, the specific steps are

[0051] Alkali washing step: immerse in NaOH aqueous solution at a temperature of 60°C for 1min to take it out, and rinse the surface of the sample with water; NaOH aqueous solution is 100ml of tap water with 6g of NaOH added;

[0052] Light-emitting step: put the sample treated by the alkali washing step into the tri-acid light-emitting solution at 25°C for 1 min, take it out, and rinse the surface of the sample with deionized water; add 6g of CrO to 100ml of the three-acid light-emitting solution 3 , 6ml of HNO 3 , 0.8ml of HF. HNO 3 The mass percent concentration is ...

Embodiment 3

[0062] 1. The test material is 7050 bare aluminum plate, the heat treatment system is T7451 (7050-T7451), and the size is 100mm×50mm×4mm;

[0063] Two, the anodic oxidation tank solution is the 8-hydroxyquinoline corrosion inhibitor of 6ml of H2SO4, 30g of sodium adipate modifier and 50mg of mass percent concentration added in the deionized water of 100ml;

[0064] Three, the specific steps are

[0065] Alkali washing step: immerse in NaOH aqueous solution at a temperature of 55°C for 2 minutes to take it out, and rinse the surface of the sample with water; NaOH aqueous solution is 100ml of tap water with 5.5g of NaOH added;

[0066] Light-emitting step: put the sample treated by the alkali washing step into the three-acid light-emitting solution at a temperature of 15°C for 3 minutes, take it out, and rinse the surface of the sample with deionized water; add 4g of CrO 3 , 7ml of HNO 3 , 1.2ml of HF. HNO 3 The mass percent concentration is 65%. The mass percent concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| film density | aaaaa | aaaaa |

| film density | aaaaa | aaaaa |

| film density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com