Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Low concentration of sulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

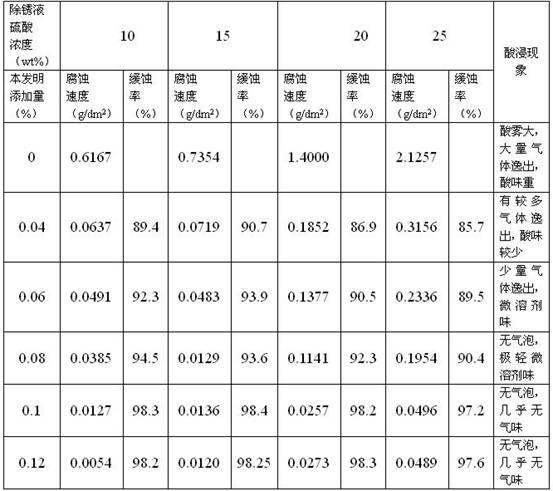

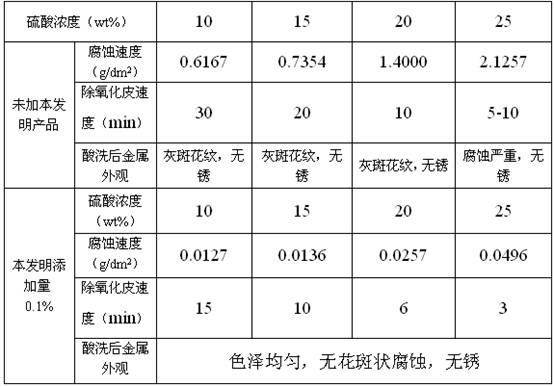

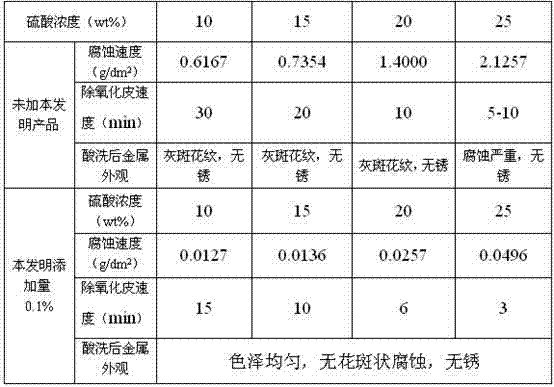

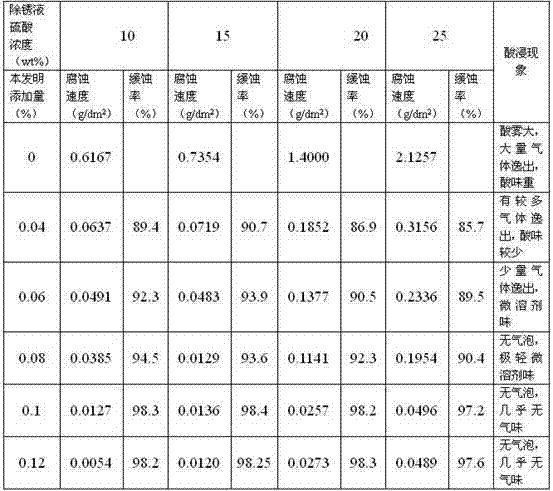

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

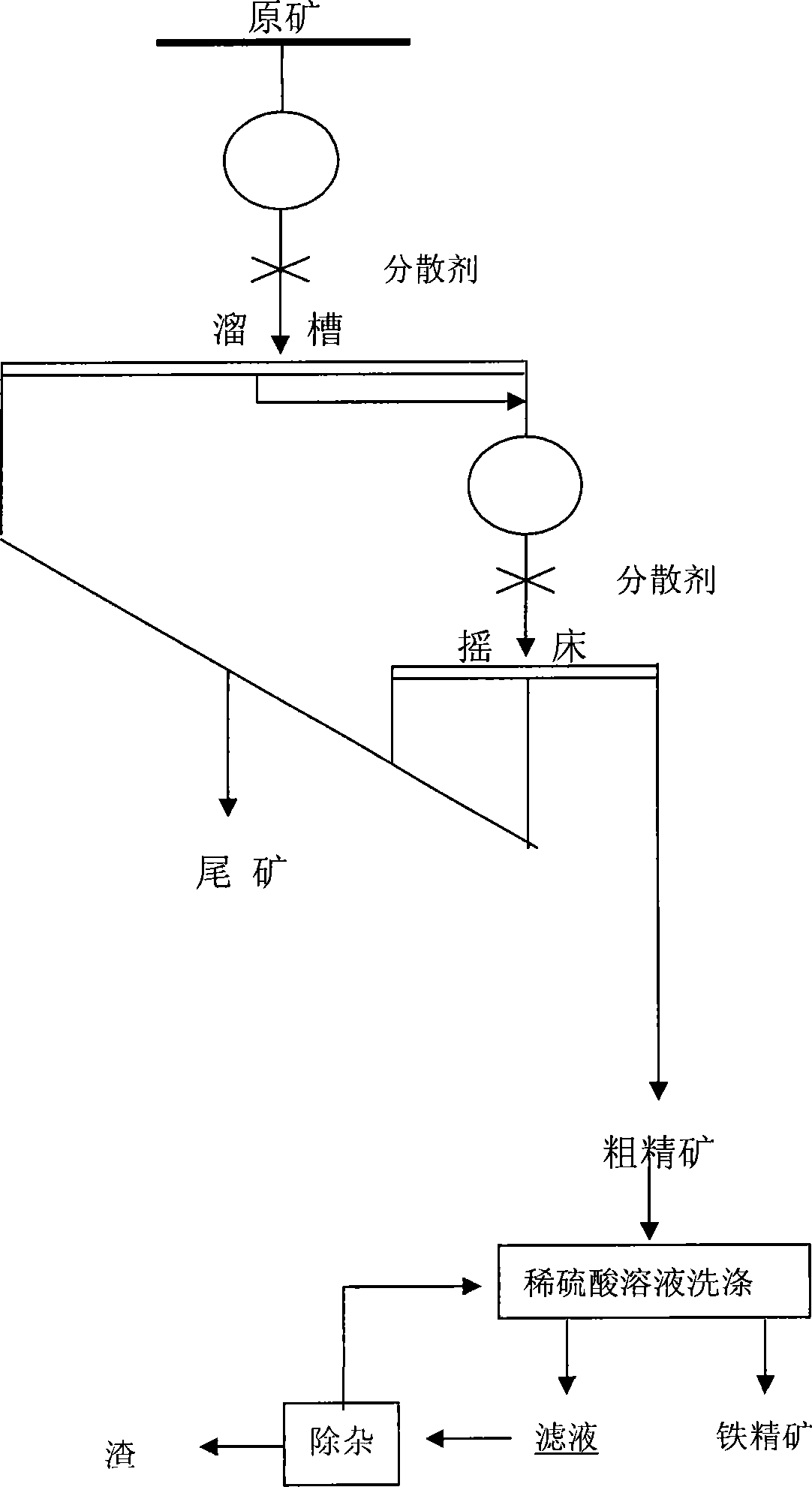

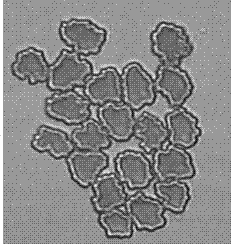

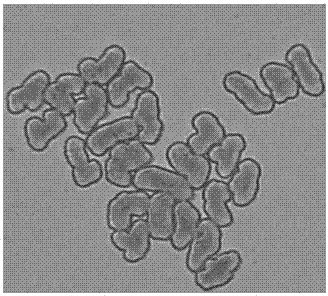

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

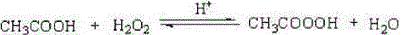

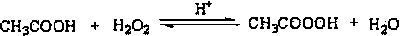

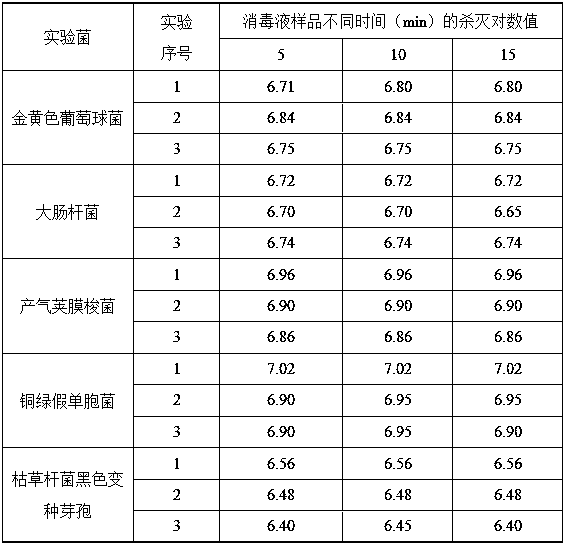

Disinfectant and preparation method thereof

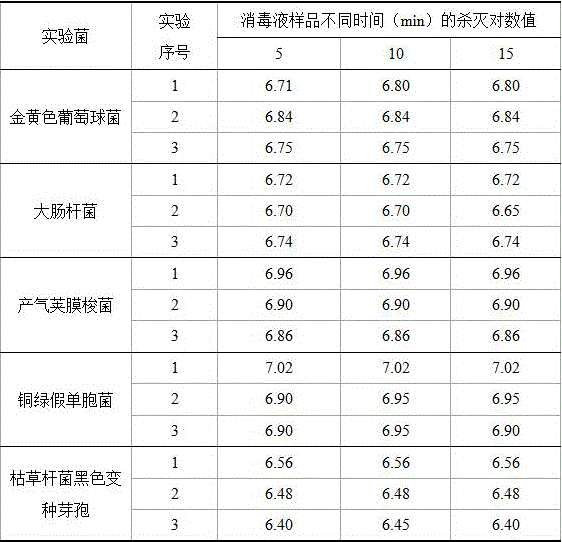

The invention discloses disinfectant. The disinfectant is characterized by being prepared from, by weight, 20%-28% of hydrogen peroxide, 3%-6% of peracetic acid, 1%-2.5% of acetic acid, 0.001%-0.02% of sulfuric acid, 0.01%-3.5% of stabilizer, 0.01%-0.2% of surface active agent and the balance deionized water or distilled water. The invention further relates to a preparation method of the disinfectant. The disinfectant has the effects of fast killing viruses, germs, fungi and spores thereof, is good in disinfection effect, and can be applied and popularized in the fields of medical treatment, food, agriculture, aquatic products, public health and the like.

Owner:连云港奥凯医疗设备科技有限公司

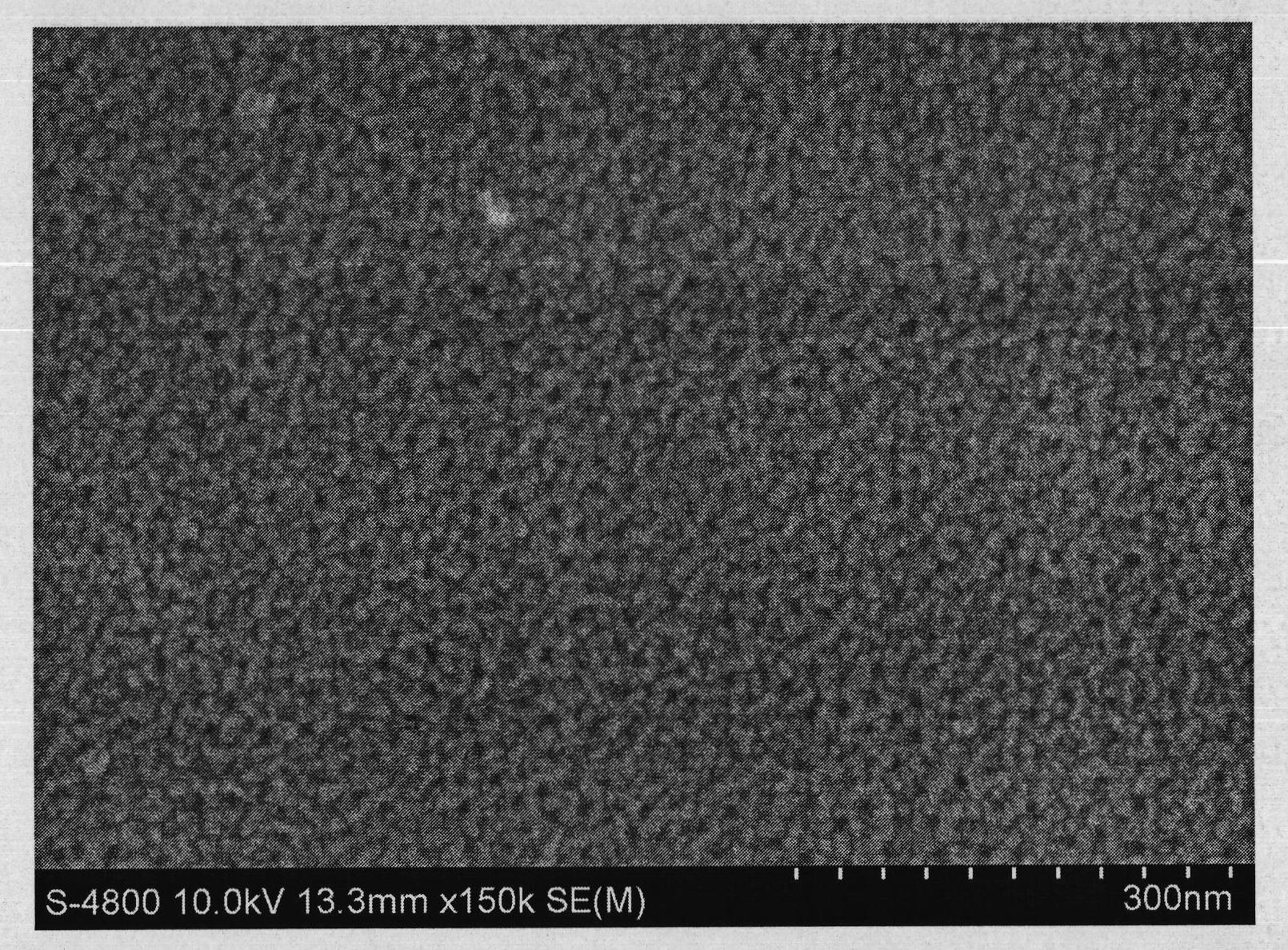

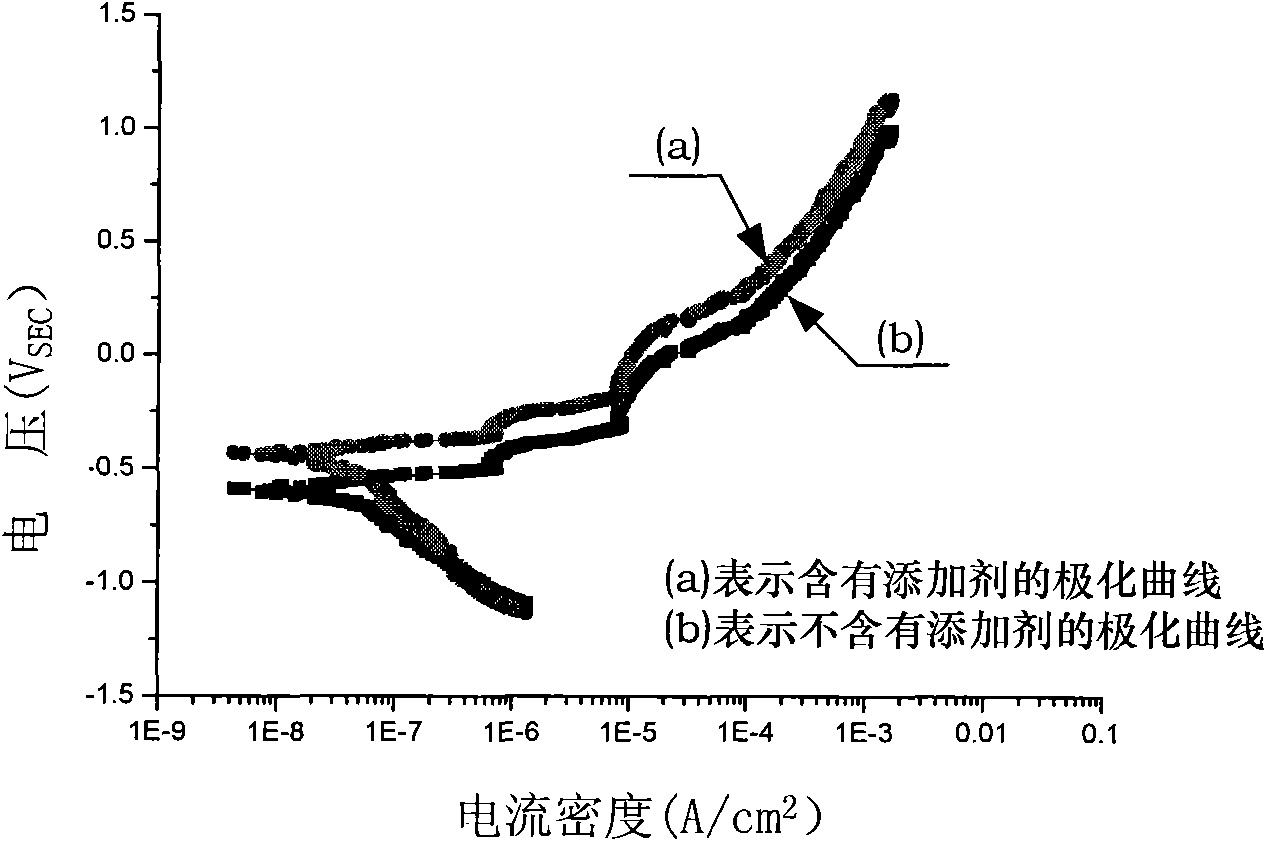

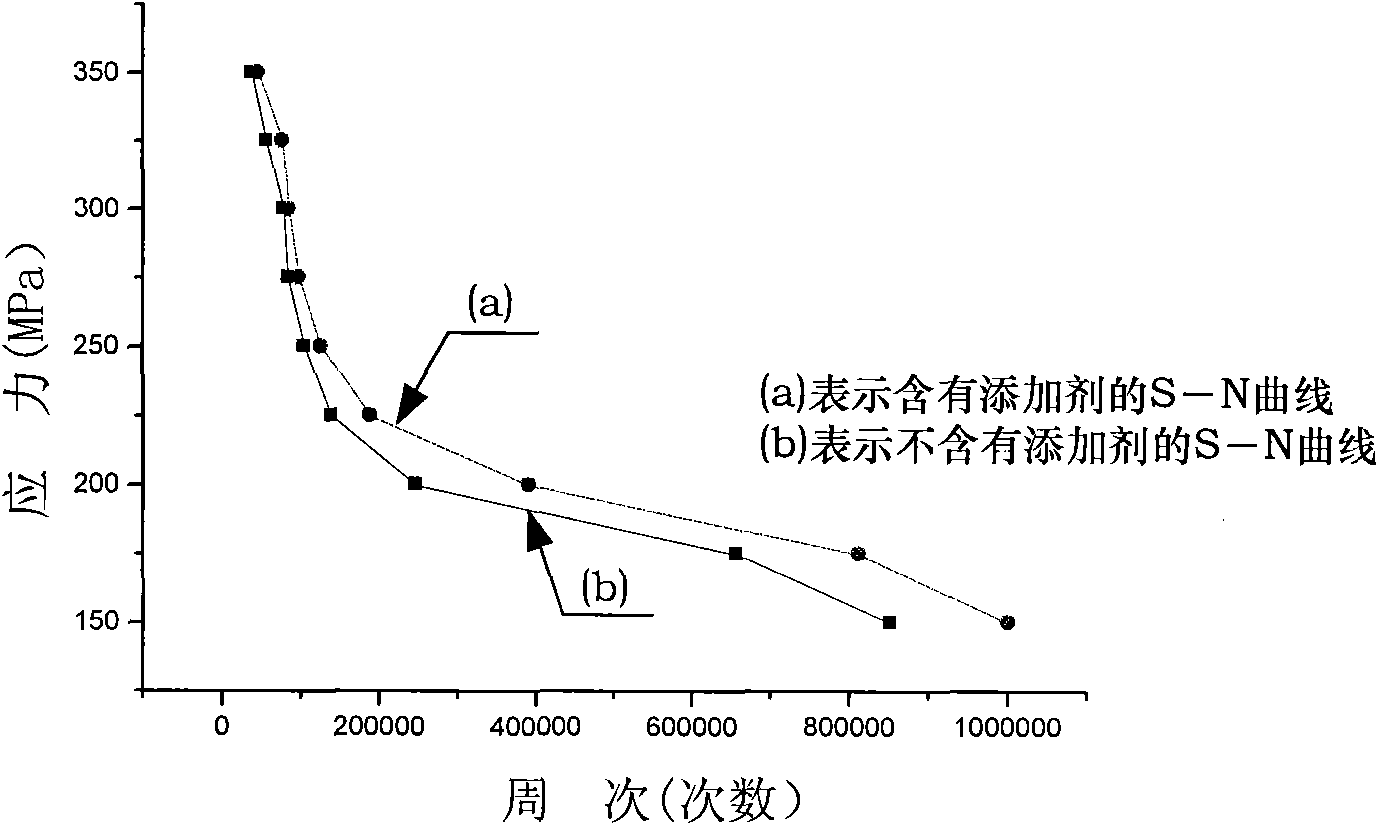

Anodic oxidation treating fluid containing corrosion inhibition additive

InactiveCN101792919AImprove fatigue lifeHigh film forming rateAnodisationAdipic acid8-Hydroxyquinoline

The invention discloses anodic oxidation treating fluid containing corrosion inhibition additive; the treating fluid is formed by adding 1.6-7.6ml of sulfuric acid, 5-30g of modifier and 10-100mg of corrosion inhibition additive in 100ml of deionized water; the modifier is adipic acid or adipate; the corrosion inhibition additive is benzotriazole, 2-mercaptobenzothiazole, dithizone or 8-oxyquinoline; the anodic oxidation treating fluid reduces the concentration of the sulfuric acid, reduces dissolving of bath solution to aerometal basal body and a generated oxidation film, and the corrosion inhibition additive is added for inhibiting excessive expansion of an oxidation film hole defect at the position of copper-bearing alloy phase particles. In the invention, the adipic acid or adipate which is environmental-protection and has low price replaces the using amount of the sulfuric acid, the film forming rate, the film layer compactness and uniformity of the anodic oxidation film are improved.

Owner:BEIHANG UNIV

Semi-dull high-strength low-elongation viscose fiber as well as preparation method and application thereof

InactiveCN104846458AGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull high-strength low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.20cN / dtex, the wet fracture strength is more than or equal to 1.70cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.6cN / dtex, the dry elongation at break is 13.0-16%, and the wet elongation at break is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, and is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows high and strong fiber characteristics and also shows skin affinity stronger than that of cotton fibers, so that the semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull high-strength low-elongation viscose fiber can be well applied to the field of producing underclothes and high-grade woven fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Method for extracting valuable metal from copper nickel sulfide through ammonium persulfate-sulfuric acid oxidation leaching

ActiveCN111411222ALow leaching temperatureLow concentration of sulfuric acidProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention discloses a method for extracting valuable metal from copper nickel sulfide through ammonium persulfate-sulfuric acid oxidation leaching. The method comprises the steps of screening low-grade copper nickel sulfide raw materials to obtain copper nickel sulfide mineral powder, according to the proportion, taking ammonium persulfate and sulfuric acid raw materials, adopting one (1) of the two manners in the ammonium persulfate to be completely mixed with sulfuric acid to form a mixture, and then uniformly mixing the mixture with mineral powder according to the proportion; and secondly, enabling the ammonium persulfate to be partly mixed with the sulfuric acid, partly making a saturated solution, under the specific temperature and system pH, performing a constant-temperature leaching reaction, in the leaching process, adding a saturated ammonium persulfate solution, finishing leaching and filtering, and obtaining leaching liquid, wherein the extraction rate of valuable metalNi in the leaching liquid is 90.4 to 97.5%, the extraction rate of Cu is 93.4 to 99.9%, and the extraction rate of Co is 92.7 to 99.6%. The method is low in leaching temperature, low in sulfuric acidconcentration, small in use amount, simple in process flow, and wide in application range, ore raw materials are limited by areas, ore, grade and the like, the extraction rate of the valuable metal ishigher, and no SO2 is emitted.

Owner:东北大学秦皇岛分校

Production technology of FDN superplasticizer

The invention discloses a production technology of an FDN superplasticizer, and solves the problems that by a method for reducing the sodium sulfate content of a product through reduction in the addition amount of concentrated sulfuric acid, the amount of naphthalene participating in a sulfonation reaction is reduced, a large amount of unreacted naphthalene participates in a condensation reaction,thus sulfonated groups on unit naphthalene are reduced, and after the sulfonated groups on unit naphthalene are reduced, the product performance is easily affected. The production technology mainly comprises the following steps: melting refined naphthalene or industrial naphthalene, performing the sulfonation reaction, performing a hydrolysis reaction, performing a condensation reaction and performing a neutralization reaction. In the sulfonation process, an excessive amount of waste material containing a polynaphthalene sulfonate-based compound is added as a reaction raw material, so that the purposes of avoiding easy influence of reduction in the concentration of the sulfuric acid on the normal reaction, performing the reaction more fully and increasing the yield are achieved.

Owner:ZHEJIANG JISHENG CHEM BUILDING MATERIALS

Strengthened leaching method of nickel in molybdenum sulfide nickel ores

InactiveCN104278161AAchieve separationLow concentration of sulfuric acidProcess efficiency improvementPregnant leach solutionGranularity

The invention relates to a strengthened leaching method of nickel in molybdenum sulfide nickel ores. The method comprises the following steps: roasting; molybdenum and nickel separation, namely crushing roasted sands until the granularity is below 0.1mm, carrying out water leaching in a liquid solid ratio of (2:1)-(8:1), and filtering and washing to obtain dark grey filter residues, wherein the leaching temperature is 70-100 DEG C, the time is at least 1 hour; and strengthened leaching of nickel, namely in a leaching mixed liquid, carrying out ultrasonic oscillation for at least 4 hours, thereby obtaining nickel from the leaching liquid, wherein the liquid solid ratio of the liquid and the filter residues is (3:1)-(8:1), the concentration of sulfuric acid is 10-20wt% and the leaching temperature is 70-100 DEG C. The method provided by the invention is used for effectively separating molybdenum and nickel and the leaching rate of nickel can reach 85%; and moreover, in the test, the concentration of sulfuric acid is relatively low, so that not only are the raw materials saved, but also the method is less in pollution, low in dangerousness and not high in requirements on equipment and has certain using value.

Owner:WUXI CHENGBO SCI & TECH DEV

Semi-dull low-extensibility viscose fiber as well as preparation method and application thereof

InactiveCN104846456AGood air permeabilityImprove dye uptakeArtificial filament washing/dryingArtificial filaments from viscoseWoven fabricViscose fiber

The invention provides a semi-dull low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, the dry elongation at break is 12-14.5%, and the wet fracture extensibility is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, shows high and strong fiber characteristics, and also shows skin affinity stronger than that of cotton fibers, so that the viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull low-elongation viscose fiber can be well applied to the field of production of jean fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

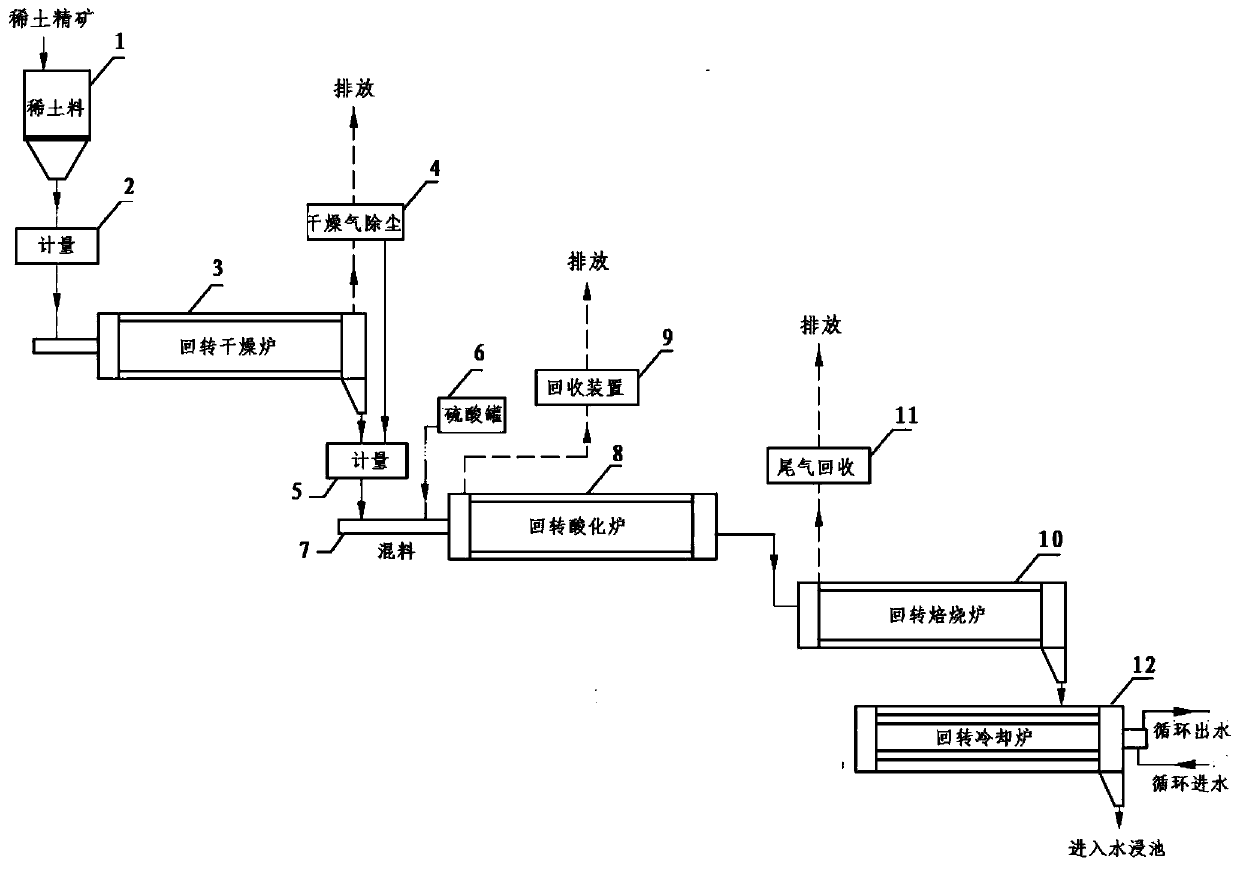

System and method for acidizing and roasting rare earth concentrate through multi-section external heating rotary furnace

The invention discloses a method and system for acidizing and roasting rare earth concentrate through a multi-section external heating rotary furnace. The method comprises the following steps of metering and putting the rare earth concentrate into an external heating rotary drying furnace, controlling heating temperature of materials and staying time in the furnace, exhausting tail gas, conveyingdust and sulfuric acid into a rotary acidifying furnace, and controlling the temperature of the materials and the staying time in the furnace; exhausting the tail gas entering an acidified tail gas recovery device after the tail end reaches the standard; enbaling acidified materials to enter a rotary roasting furnace to be roasted, controlling the temperature of the materials and the staying timein the furnace, and exhausting roasted tail gas entering a roasting tail gas recycling device after the roasted tail gas reaches the standard; and enabling high-temperature roasted materials to entera rotary cooling furnace to be cooled and be conveyed to a water leaching procedure so as to obtain the acidified roasted rare earth concentrate with the roasted material leaching rate being 93%-98%.According to the method, the tail gas treatment amount and operation cost are greatly reduced, the fluidity of the dried rare earth concentrate is good, the corrosion rate of equipment and pipelines is reduced, and equipment pipeline blockage is reduced.

Owner:西安三瑞实业有限公司

Titaniferous slag recrystallization-reselection titanium recovery method

ActiveCN104928485ARealize mineral phase reconstructionLow costProcess efficiency improvementRecovery methodIron sulfate

The invention relates to a titaniferous slag recrystallization-reselection titanium recovery method and belongs to the technical field of complex resource recovery and comprehensive utilization of the metallurgical industry. According to the method, titaniferous slag with 24-42wt% of TiO2 is subjected to recrystallization through a hydrothermal method, and a new ilmenite phase and a new non-titanium ore phase are formed; remaining iron sulfate water solution is filtered out, diiron trisulfate is supplemented, and the hydrothermal method is conducted circularly, recrystallization is conducted for utilization; reselection is conducted on the filtered solid-phase matter which is subjected to recrystallization, and the ilmenite (the heavy phase) rich in titanium and the waste slag (the light phase) with little titanium are separated. According to the method, the reaction temperature is low, the reaction time is short, the technological process is simple, operation is easy, the titaniferous slag can be processed on a large scale, and the problem that the titaniferous slag is stacked and is hard to utilize is solved.

Owner:KUNMING UNIV OF SCI & TECH

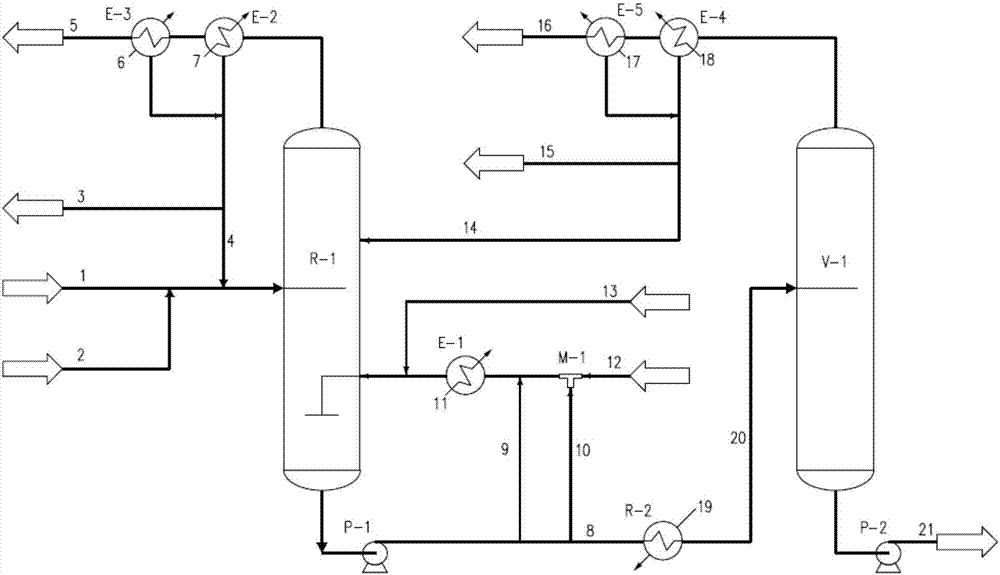

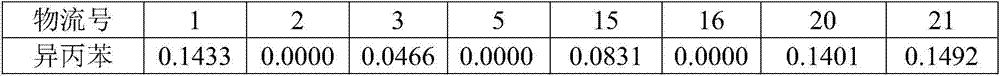

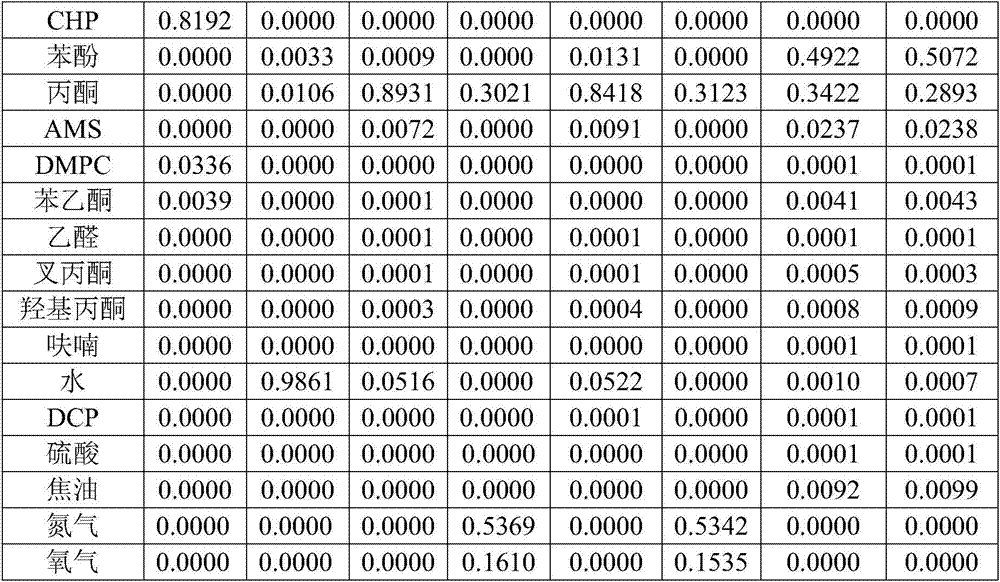

Method of raising decomposition yield of cumyl hydroperoxide

ActiveCN105669367AReduce energy consumptionReduce generationOxygen-containing compound preparationOrganic compound preparationReaction temperaturePhenol

The invention relates to a method for raising the decomposition yield of cumyl hydroperoxide of a phenol-acetone unit.The method includes the steps that 1, first-level decomposition liquid is recycled to a decomposer through a special distributor after being cooled; 2, a concentrated sulfuric acid catalyst is added into a decomposition liquid recycling system from two different points; 3, the concentration of sulfuric acid in the decomposer is lowered; 4, standing time of decomposition liquid in the decomposer is increased, and the reaction temperature of the decomposer is lowered; 5, standing time of the decomposition liquid in a second-level composer is increased; 6, the reaction temperature of second-level decomposition is increased; 7, flash evaporation is conducted on materials discharged through second-level decomposition to recycle energy, total or part of flash evaporation condensate liquid is recycled to the decomposer, and the remaining part is sent to a crude acetone tower on the downstream of the phenol-acetone unit; 8, part of decomposer steam condensate liquid is sent to a fine acetone tower on the downstream of the phenol-acetone unit or fed into a feeding tank.The method mainly solves the problems that by means of an existing phenol acetone production technology, the decomposition yield is low, a great number of tar by-products are generated, and a distilled fed material is high in salt content.

Owner:张殿豪

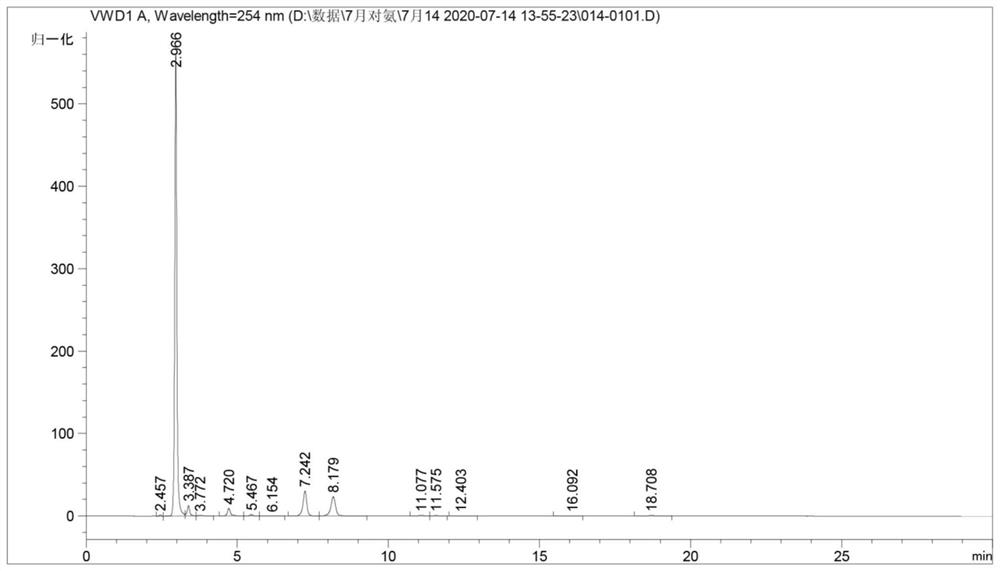

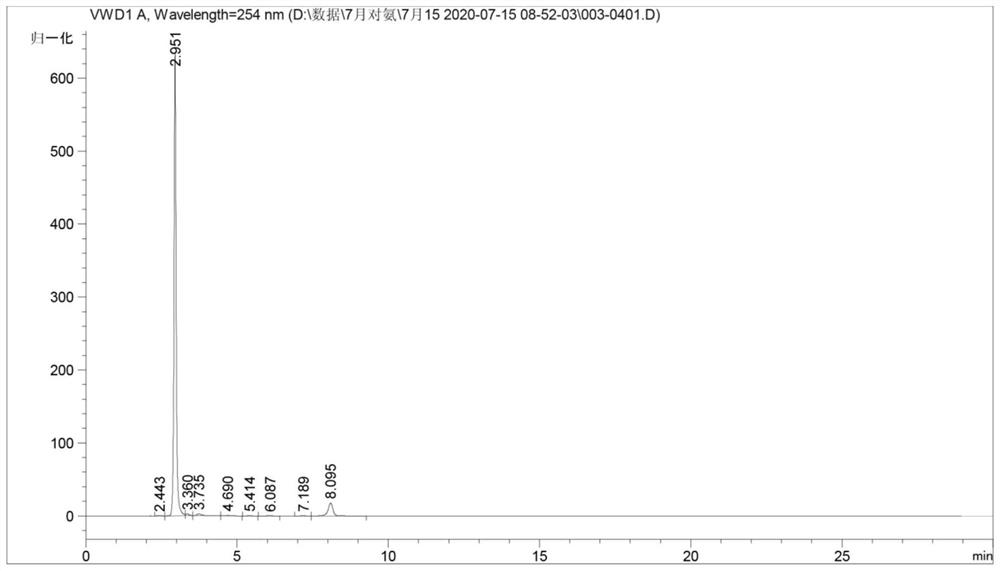

Preparation method of special catalyst for nitrobenzene hydrogenation production of p-aminophenol

PendingCN112138650AHigh activityHigh selectivityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonM-aminophenol

The invention discloses a preparation method of a special catalyst for nitrobenzene hydrogenation production of p-aminophenol. The preparation method comprises the following steps: pretreating cocoanut active charcoal, preparing a Pt / C catalyst and adding a modifier. The catalyst produced by the method has the advantages of high activity, high selectivity, high stability and the like. The catalystconsumption can be greatly reduced, the production cost of enterprises is reduced, and the method has good market value. Meanwhile, the catalyst can improve nitrobenzene hydrogenation reaction conditions, so that the sulfuric acid concentration of a medium is reduced to below 8% from 15%-20% in the prior art, and the material cost and the wastewater treatment cost are further reduced.

Owner:张国良 +2

Semi-dull high-intensity low-elongation viscose fiber and preparing method thereof

ActiveCN104846460AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentBleaching apparatusFiberPolymer science

The invention provides semi-dull high-intensity low-elongation viscose fiber and a preparing method of the semi-dull high-intensity low-elongation viscose fiber. The viscose fiber is obtained through sequentially carrying out soaking, grinding, pressing and crushing, kneading, polymerization reduction, yellowing, dissolution, filtering, defoaming, aging, spinning traction and post treatment on pulp raw materials. The viscose fiber has the following indexes that the fiber number is 1.11 to 1.67 dtex, the dry fracture intensity is greater than or equal to 3.10cN / dtex, the wet fracture intensity is higher than or equal to 1.60cN / dtex, the intensity required for generating the 5-percent elongation rate in the wet state is higher than or equal to 0.55N / dtex, and the dry fracture elongation rate is 11.0 to 19.0 percent. The high-intensity low-elongation viscose fiber related by the invention is a novel fiber variety realized through technical innovation, an index system is different from that of ordinary viscose fiber and modal fiber; a product shows the high-intensity and low-elongation fiber features of the modal fiber, and also shows the higher skin affinity than cotton fiber; the existing differentiated viscose fiber can be effectively replaced; the downstream work procedure processing performance of the viscose fiber is improved; meanwhile, the development and the industrial updating of downstream novel textiles can also be promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

Delustering high-strength viscose fiber and preparation method and application thereof

InactiveCN104831393AImprove dye uptakeGuaranteed multiple responsesMonocomponent cellulose artificial filamentBleaching apparatusSocial benefitsBreaking strength

The invention discloses a delustering high-strength viscose fiber and a preparation method and application thereof. The delustering high-strength low-elongation viscose fiber is obtained by subjecting pulp materials to dipping, grinding, squeezing smashing, rubbing, depolymerizing, yellowing, dissolving, filtering, deaerating, ripening, spinning drawing and post-processing sequentially. The delustering high-strength viscose fiber meets the technical indexes that the dry breaking strength is not smaller than 3.15cN / dtex, the wet breaking strength is not smaller than 1.70cN / dtex, the strength for generating 5% of elongation in a wet condition is not smaller than 0.55cN / dtex, the dry breaking elongation is 15.0%-19.0%, the wet breaking elongation is 16.0%-21.0%, radial water swelling capacity is 22%-26%, and the content of a delustering agent is 0.8%-5%. The delustering high-strength viscose fiber is a novel viscose fiber, is lower than a modal fiber in production cost, has great economic benefit and social benefit, and is mainly applied to the field of dense siro-spinning.

Owner:YIBIN GRACE GROUP CO LTD +2

Ultrafine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846462AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceSpinning

The invention provides an ultrafine semi-dull high-strength low-elongation viscose fiber and a preparation method thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has the following indexes that the fineness is 0.8-1.11dtex, the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The ultrafine high-strength low-elongation viscose fiber is a novel fiber variety realized by virtue of technical innovation, and has an index system which is different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows the fiber characteristics of high strength and low elongation of the Modal fibers and also shows skin affinity stronger than that of cotton fibers, so that the ultrafine semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, and while the processability of the downstream process of the viscose fiber is improved, the development and the industrial upgrading of downstream novel textiles are promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of preparation method of solvent-free green styrene series cation exchange resin

ActiveCN108102032BStrong extensionImprove stress resistanceCation exchangersIon exchangeSolvent free

The invention relates to a method for preparing no-solvent green styrene-series cation exchange resin and belongs to the field of preparation of cation exchange resin. A crosslinking agent is adoptedto improve the elasticity and the pressure resistance of a styrene resin framework; a secondary polymerization method is adopted to increase the strength of the frameworl; high-concentration sulfuricacid is adopted to quicken a reaction and to improve the efficiency; and a multi-gradient concentration step-by-step acid nesting method to reduce intense heat release of sulfuric acid during cleaning. Disadvantages of a process which adopts dichloroethane as a swelling agent for a synthetic reaction are avoided, resin with the same performance and indexes as ion exchange ion which is prepared bynot taking dichloroethane as the swelling agent, and owing to frequent use of a water phase, environmental pollution of the water phase can be reduced. Resin prepared by the method is a dichloroethane-residue-free green product, and can be more deeply applied to industries including drinking water, food, medicines and the like.

Owner:江苏国创新材料研究中心有限公司

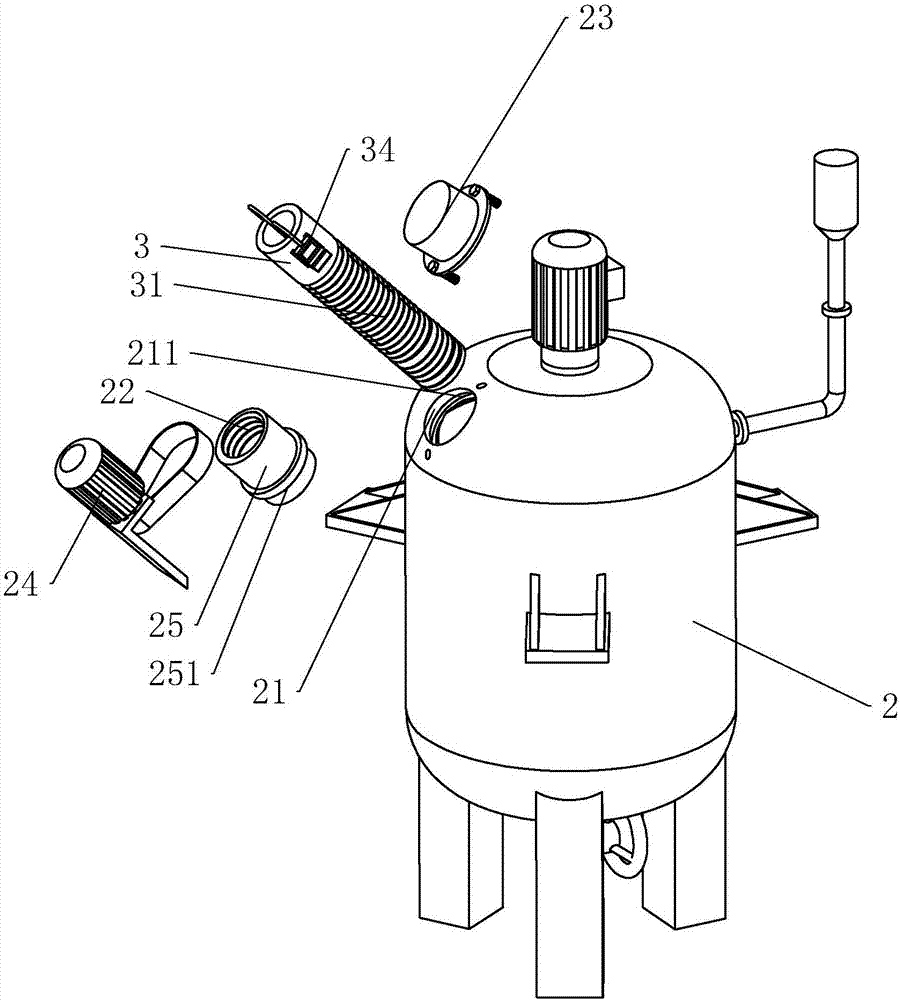

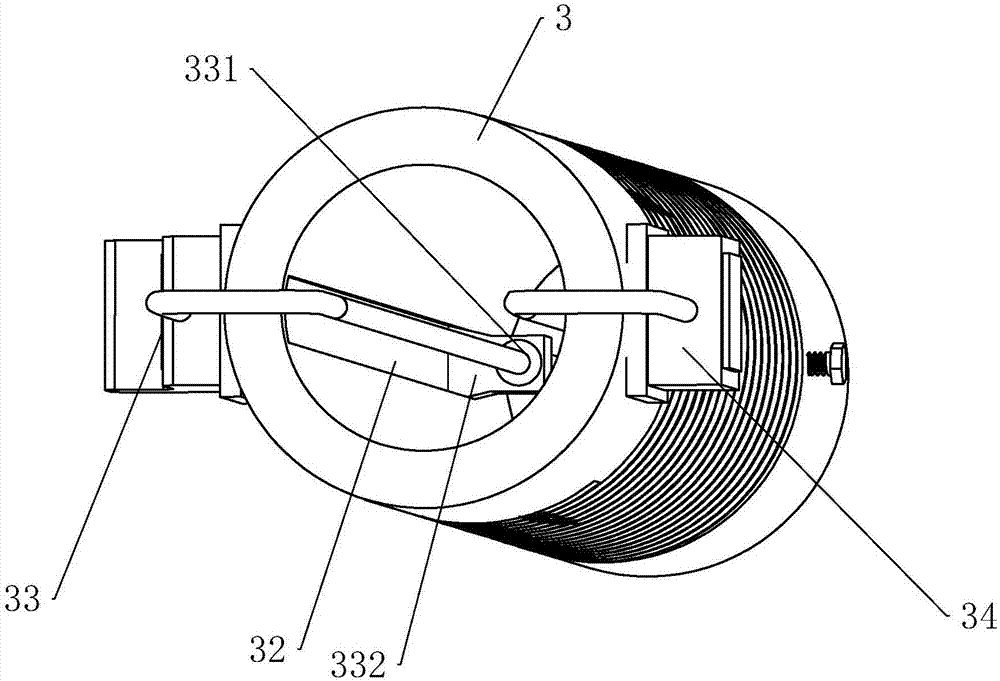

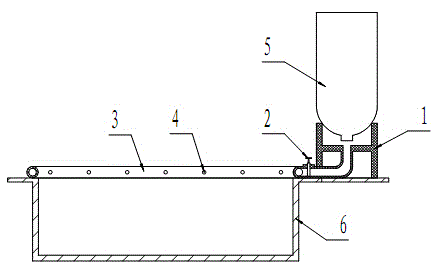

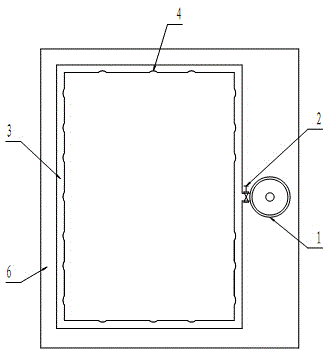

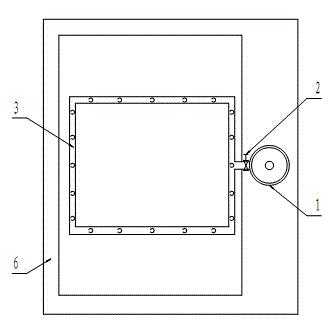

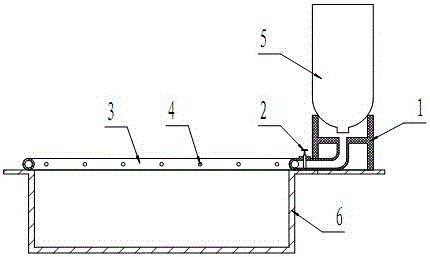

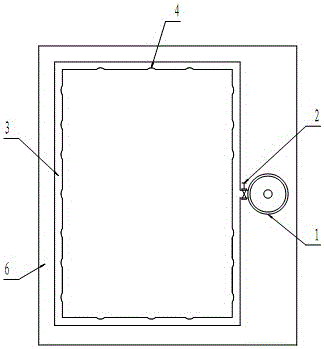

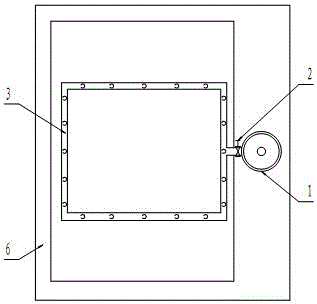

Low-maintenance storage battery positive plate cleaning and alkalizing device and cleaning method

ActiveCN104485486AReduce water consumptionImprove cleaning efficiencySecondary cells servicing/maintenanceBiochemical engineeringCleaning methods

The invention discloses a low-maintenance storage battery positive plate cleaning and alkalizing device and a cleaning method and belongs to the technical field of storage batteries. The low-maintenance storage battery positive plate cleaning and alkalizing device is arranged on a storage battery plate cleaning tank, and comprises an alkali liquor containing barrel, an alkali liquor tank and an alkali liquor conveying pipe, wherein the alkali liquor containing barrel is inverted above the alkali liquor tank; the alkali liquor tank is arranged on the peripheral table board of the storage battery plate cleaning tank; the bottom surface of the alkali liquor tank is communicated with the alkali liquor conveying pipe; a control valve is arranged between the alkali liquor conveying pipe and the alkali liquor tank; and a group of liquid leakage holes is formed in the pipe wall of the alkali liquor conveying pipe. According to the device disclosed by the invention, the water consumption in the storage battery positive plate cleaning process is reduced, the cleaning time is shortened, the storage battery positive plate cleaning efficiency is improved, and the storage battery positive plate cleaning effect is improved.

Owner:唐山风帆宏文蓄电池有限公司

Copper nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals

ActiveCN111411222BLow leaching temperatureLow concentration of sulfuric acidProcess efficiency improvementPregnant leach solutionSulfate

The copper-nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals of the present invention comprises the following steps: sieve the low-grade copper-nickel sulfide raw material to obtain copper-nickel sulfide mineral powder, and take ammonium persulfate and sulfuric acid raw materials in proportion , ammonium persulfate adopts one of two methods (1) after mixing all of it with sulfuric acid, mix it with mineral powder in proportion; (2) mix part of ammonium persulfate with sulfuric acid, and partly make a saturated solution; The constant temperature leaching reaction is carried out under the temperature and system pH. The saturated ammonium persulfate solution is added during the leaching process, and the leaching and filtration are completed to obtain a leaching solution. The extraction rate of valuable metal Ni in the leaching solution is 90.4-97.5%, and the extraction rate of Cu is 93.4-99.9%. The Co extraction rate is 92.7‑99.6%. This method has low leaching temperature, low concentration of sulfuric acid, less dosage, simple process flow, wide application range, ore raw materials are not limited by region, ore position, grade, etc.; the extraction rate of valuable metals is high, and there is no SO 2 emission.

Owner:东北大学秦皇岛分校

A semi-dull high-strength low-elongation viscose fiber and its preparation method

ActiveCN104846457BGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull, high-strength, low-elongation viscose fiber and a preparation method thereof. The viscose fiber is prepared by impregnating pulp raw materials, grinding, crushing, kneading, depolymerizing, yellowing, dissolving, and filtering in sequence. , defoaming, ripening, spinning and drawing and post-treatment, the viscose fiber has the following indicators: dry breaking strength ≥ 3.10 cN / dtex, wet breaking strength ≥ 1.60 cN / dtex, 5% elongation in wet state The strength required for elongation is ≥0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

A method for recrystallization-gravity recovery of titanium-containing slag

ActiveCN104928485BRealize mineral phase reconstructionLow costProcess efficiency improvementIron sulfateRecovery method

Owner:KUNMING UNIV OF SCI & TECH

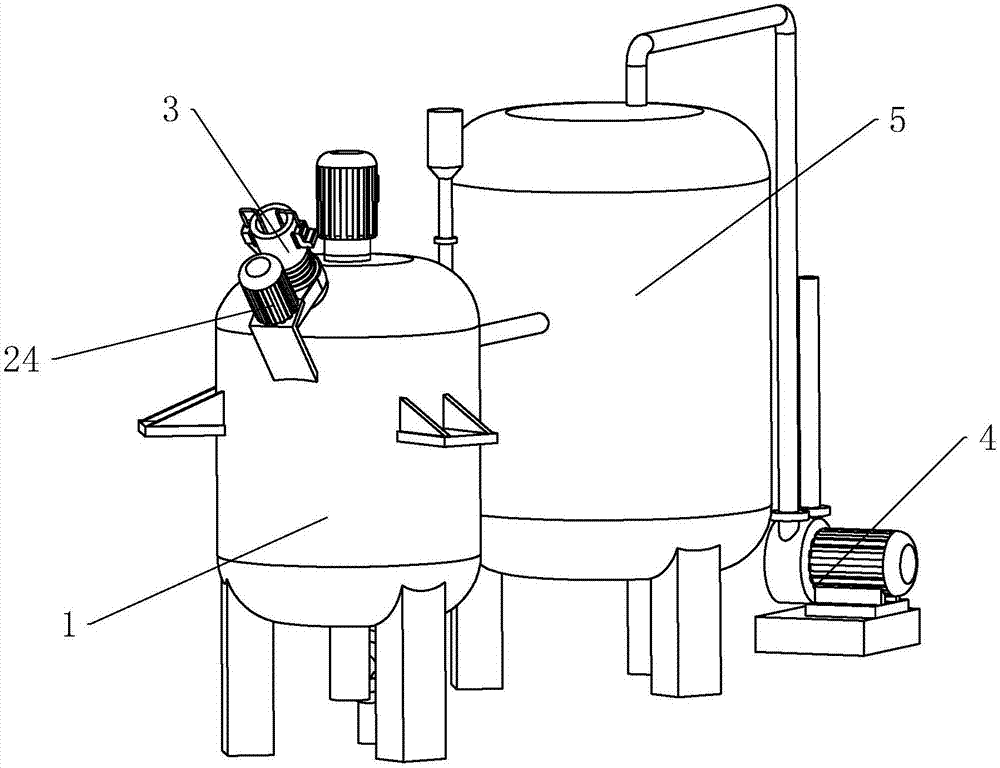

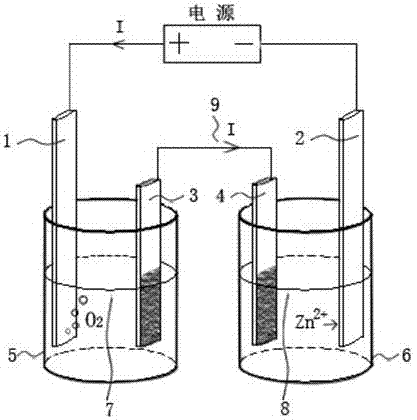

Device for extracting zinc by electrodeposition with double electrolytic baths and application of device

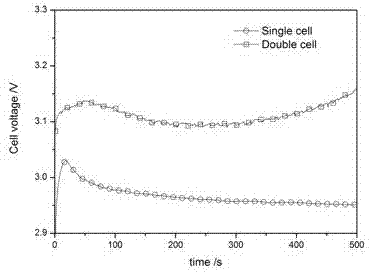

ActiveCN107268026ASolve the problem of acid mistAvoid miscibilityPhotography auxillary processesProcess efficiency improvementSulfateAuxiliary electrode

The invention relates to a device for extracting zinc by electrodeposition with double electrolytic baths and application of the device, and belongs to the technical field of wet metallurgy. The device comprises an inert anode, a pure aluminum or zinc cathode, an auxiliary electrode I, an auxiliary electrode II, an anode bath, a cathode bath, sulfur-acid-containing electrolyte and zinc-sulfate-containing electrolyte, wherein the inert anode and the sulfur-acid-containing electrolyte are arranged in the anode bath; the aluminum or zinc cathode and the zinc-sulfate-containing electrolyte are arranged in the cathode bath; the inert anode is connected with the positive pole of a power supply; the pure aluminum or zinc cathode is connected with the positive pole of the power supply; the auxiliary electrode I and the auxiliary electrode II are respectively arranged in the anode bath and the cathode bath; and the auxiliary electrode I is connected with the auxiliary electrode II through a wire. The double electrolytic baths are used in the device, and decoupling of a metal zinc electrodeposition extracting process and a cathode and anode reaction process is realized, namely, cathode deposition and anode oxygen evolution of metal zinc are separately implemented in the different electrolytic baths.

Owner:KUNMING UNIV OF SCI & TECH

Semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846460BGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsBreaking strengthPolymer science

The invention provides a semi-dull, high-strength, low-elongation viscose fiber and a preparation method thereof. The viscose fiber is prepared by impregnating pulp raw materials, grinding, crushing, kneading, depolymerizing, yellowing, dissolving, and filtering in sequence. , defoaming, ripening, spinning and drawing, and post-treatment. The viscose fiber has the following indicators: fineness 1.11-1.67dtex, dry breaking strength ≥ 3.10 cN / dtex, wet breaking strength ≥ 1.60cN / dtex, The strength required to produce 5% elongation in wet state is ≥0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

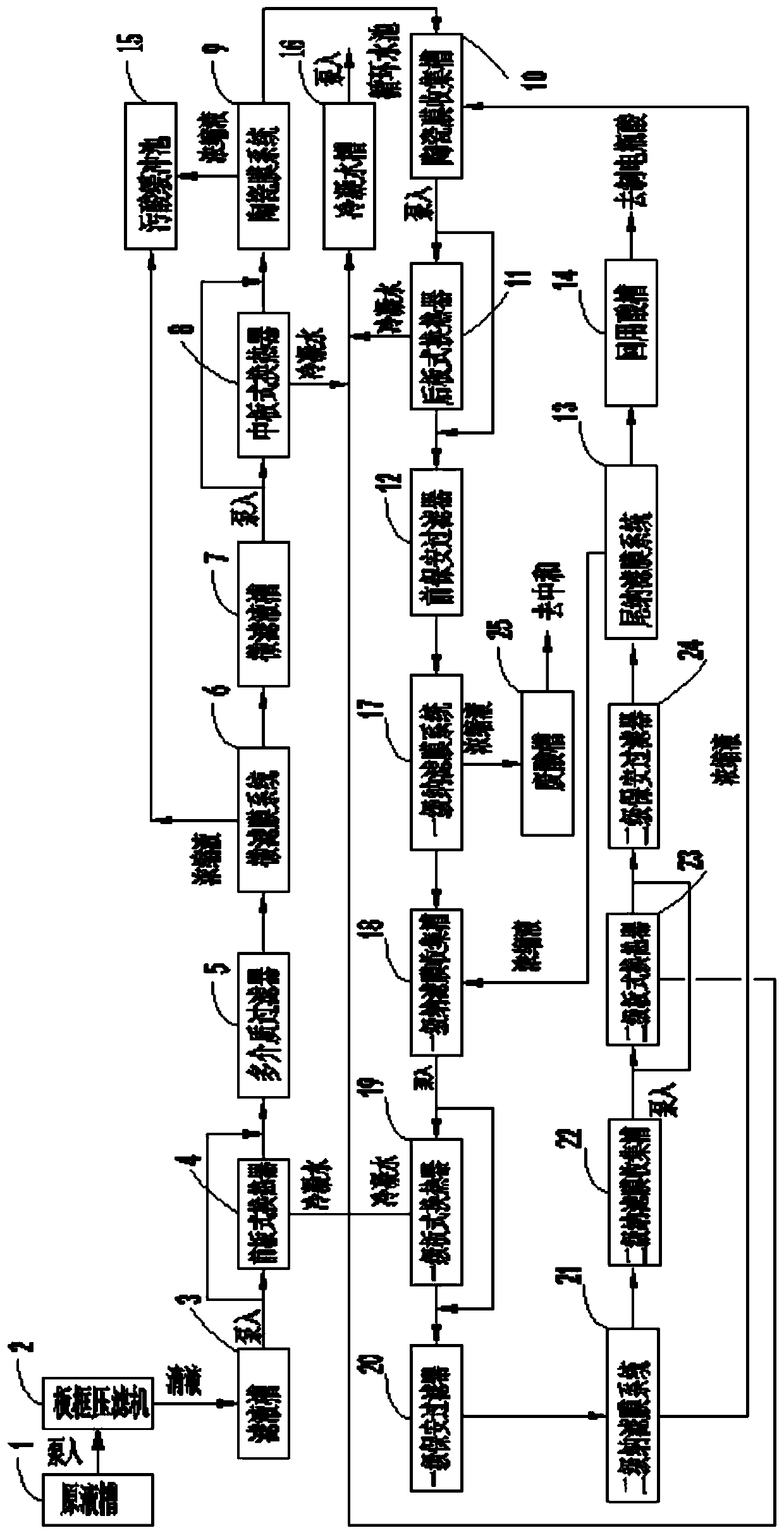

Waste lead-acid storage battery disassembling waste acid treatment system

InactiveCN110563231ALow concentration of sulfuric acidHigh recovery rateWater contaminantsTreatment involving filtrationNanofiltrationWaste treatment

Owner:WUHAN FEIBOLE ENVIRONMENTAL PROTECTION ENG

A low-maintenance battery positive plate cleaning and adding alkali device and cleaning method

ActiveCN104485486BReduce water consumptionImprove cleaning efficiencySecondary cells servicing/maintenanceEngineeringProcess engineering

The invention discloses a low-maintenance storage battery positive plate cleaning and alkalizing device and a cleaning method and belongs to the technical field of storage batteries. The low-maintenance storage battery positive plate cleaning and alkalizing device is arranged on a storage battery plate cleaning tank, and comprises an alkali liquor containing barrel, an alkali liquor tank and an alkali liquor conveying pipe, wherein the alkali liquor containing barrel is inverted above the alkali liquor tank; the alkali liquor tank is arranged on the peripheral table board of the storage battery plate cleaning tank; the bottom surface of the alkali liquor tank is communicated with the alkali liquor conveying pipe; a control valve is arranged between the alkali liquor conveying pipe and the alkali liquor tank; and a group of liquid leakage holes is formed in the pipe wall of the alkali liquor conveying pipe. According to the device disclosed by the invention, the water consumption in the storage battery positive plate cleaning process is reduced, the cleaning time is shortened, the storage battery positive plate cleaning efficiency is improved, and the storage battery positive plate cleaning effect is improved.

Owner:唐山风帆宏文蓄电池有限公司

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761BThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

Ultra-fine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846462BGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceAfter treatment

The invention provides an ultrafine semi-dull high-strength low-elongation viscose fiber and a preparation method thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has the following indexes that the fineness is 0.8-1.11dtex, the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The ultrafine high-strength low-elongation viscose fiber is a novel fiber variety realized by virtue of technical innovation, and has an index system which is different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows the fiber characteristics of high strength and low elongation of the Modal fibers and also shows skin affinity stronger than that of cotton fibers, so that the ultrafine semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, and while the processability of the downstream process of the viscose fiber is improved, the development and the industrial upgrading of downstream novel textiles are promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

A method for improving the decomposition yield of cumene hydroperoxide

ActiveCN105669367BReduce consumptionReduce parkingOxygen-containing compound preparationOrganic compound preparationReaction temperaturePhenol

Owner:张殿豪

A kind of production technology of fdn superplasticizer

The invention discloses a production technology of an FDN superplasticizer, and solves the problems that by a method for reducing the sodium sulfate content of a product through reduction in the addition amount of concentrated sulfuric acid, the amount of naphthalene participating in a sulfonation reaction is reduced, a large amount of unreacted naphthalene participates in a condensation reaction,thus sulfonated groups on unit naphthalene are reduced, and after the sulfonated groups on unit naphthalene are reduced, the product performance is easily affected. The production technology mainly comprises the following steps: melting refined naphthalene or industrial naphthalene, performing the sulfonation reaction, performing a hydrolysis reaction, performing a condensation reaction and performing a neutralization reaction. In the sulfonation process, an excessive amount of waste material containing a polynaphthalene sulfonate-based compound is added as a reaction raw material, so that the purposes of avoiding easy influence of reduction in the concentration of the sulfuric acid on the normal reaction, performing the reaction more fully and increasing the yield are achieved.

Owner:ZHEJIANG JISHENG CHEM BUILDING MATERIALS

A kind of disinfectant and preparation method thereof

The invention discloses disinfectant. The disinfectant is characterized by being prepared from, by weight, 20%-28% of hydrogen peroxide, 3%-6% of peracetic acid, 1%-2.5% of acetic acid, 0.001%-0.02% of sulfuric acid, 0.01%-3.5% of stabilizer, 0.01%-0.2% of surface active agent and the balance deionized water or distilled water. The invention further relates to a preparation method of the disinfectant. The disinfectant has the effects of fast killing viruses, germs, fungi and spores thereof, is good in disinfection effect, and can be applied and popularized in the fields of medical treatment, food, agriculture, aquatic products, public health and the like.

Owner:连云港奥凯医疗设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com