Semi-dull low-extensibility viscose fiber as well as preparation method and application thereof

A viscose fiber, semi-dull technology, applied in the direction of stretch spinning, cellulose/protein artificial filament chemical post-treatment, wet spinning, etc., can solve the problem that the market share of viscose fiber is reduced and there is no greater limit Satisfies the problems of downstream new textile development and industrial upgrading, and achieves the effects of good color fastness of finished products, small deformation of finished fabrics and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

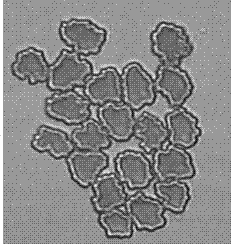

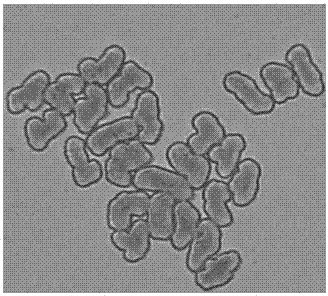

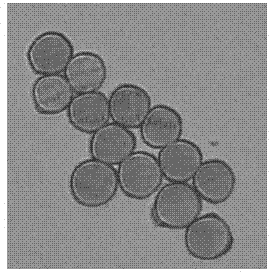

Image

Examples

Embodiment 1

[0061] The semi-dull low elongation stretched viscose fiber of the present embodiment is prepared by the following method:

[0062] A: Immerse the pulp raw material in an immersion barrel filled with lye, and grind it with a grinder to make a pulp porridge with a concentration of 3%;

[0063] B: Send the porridge prepared in step A to a press machine, and then send it to a pulverizer for crushing to obtain alkali cellulose, and then send the alkali cellulose to a kneading machine for kneading treatment, and obtain a concentration of 35% after treatment porridge;

[0064] C: Mix the porridge prepared in step B with lye and send it to the reactor, add pure oxygen to the reactor for directional depolymerization, after depolymerization, the degree of polymerization is 400-600, and the purity of cellulose is 98.0-98.5 % alkali cellulose;

[0065] D: The alkali cellulose prepared in step C is sent to the yellowing machine, and carbon disulfide is added in the yellowing machine to ...

Embodiment 2

[0076] The difference between the semi-dull low elongation elongation viscose fiber of this embodiment and embodiment 1 is: the semi-dull low elongation viscose fiber detected by random sampling in this embodiment has the following performance indicators different from embodiment 1 system:

[0077] The dry breaking strength is 3.10 cN / dtex, the wet breaking strength is 1.62cN / dtex,

[0078] The strength required to produce 5% elongation in wet state is 0.6cN / dtex,

[0079] The dry elongation at break is 13%, and the wet elongation at break is 20.8%.

[0080] The crystallinity is 40%, the radial water swelling degree is 22.5%, and the matting agent content is 0.45%.

[0081] The whiteness is 84.6%, the linear density deviation rate is -1.0%, the residual sulfur is 7.0mg / 100g,

[0082] The length deviation rate is +1.0%, the ultra-long fiber rate is 0.5%,

[0083] The double-length fiber is 1.0mg / 100g, and the defect is 1.0mg / 100g.

Embodiment 3

[0085] The difference between the semi-dull low elongation elongation viscose fiber of this embodiment and embodiment 1 is: the semi-dull low elongation viscose fiber detected by random sampling in this embodiment has the following performance indicators different from embodiment 1 system:

[0086] The dry breaking strength is 3.25cN / dtex, the wet breaking strength is 1.65cN / dtex,

[0087] The strength required to produce 5% elongation in wet state is 0.65cN / dtex,

[0088] The dry elongation at break is 12.8%, and the wet elongation at break is 20%.

[0089] The crystallinity is 43%, the radial water swelling degree is 22.5%, and the matting agent content is 0.75%.

[0090] The whiteness is 84%, the linear density deviation rate is -1.5%, the residual sulfur is 5.5mg / 100g,

[0091] The length deviation rate is +2.0%, and the ultra-long fiber rate is 0.5%,

[0092] The double-length fiber is 0.95mg / 100g, and the defect is 1.0mg / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com