Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "High corrosion inhibition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

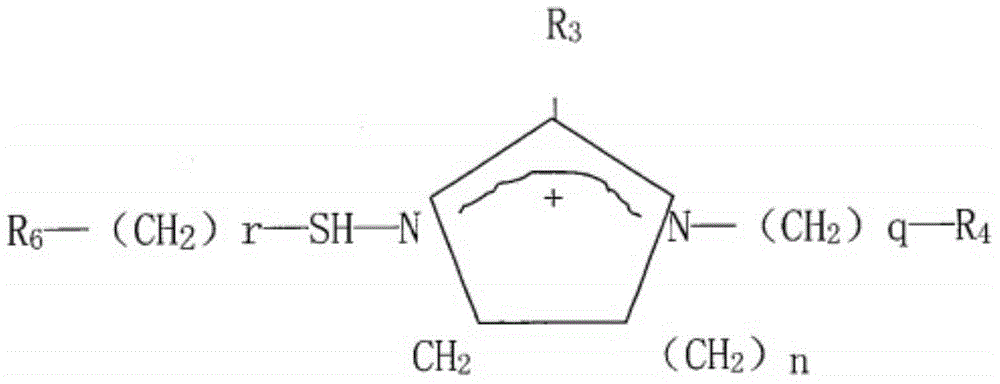

Method for synthesizing water-soluble imidazoline quaternary ammonium salt corrosion inhibitor

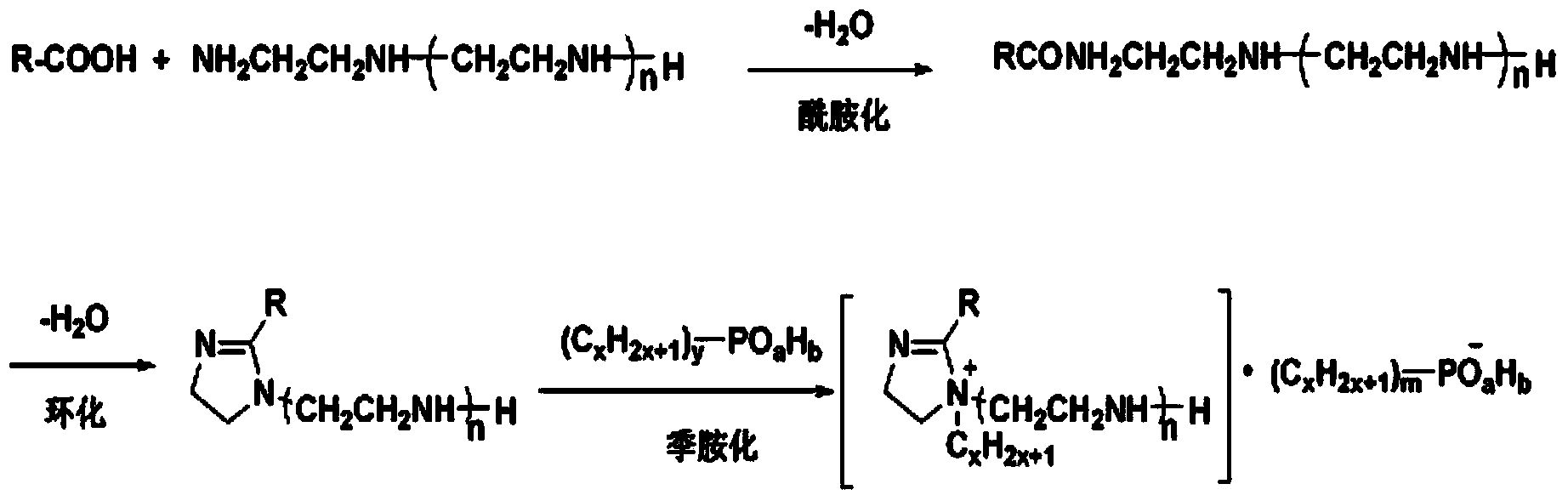

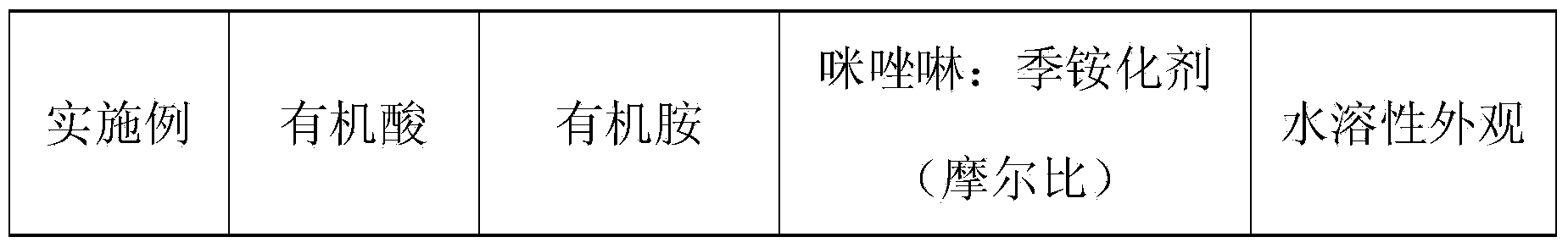

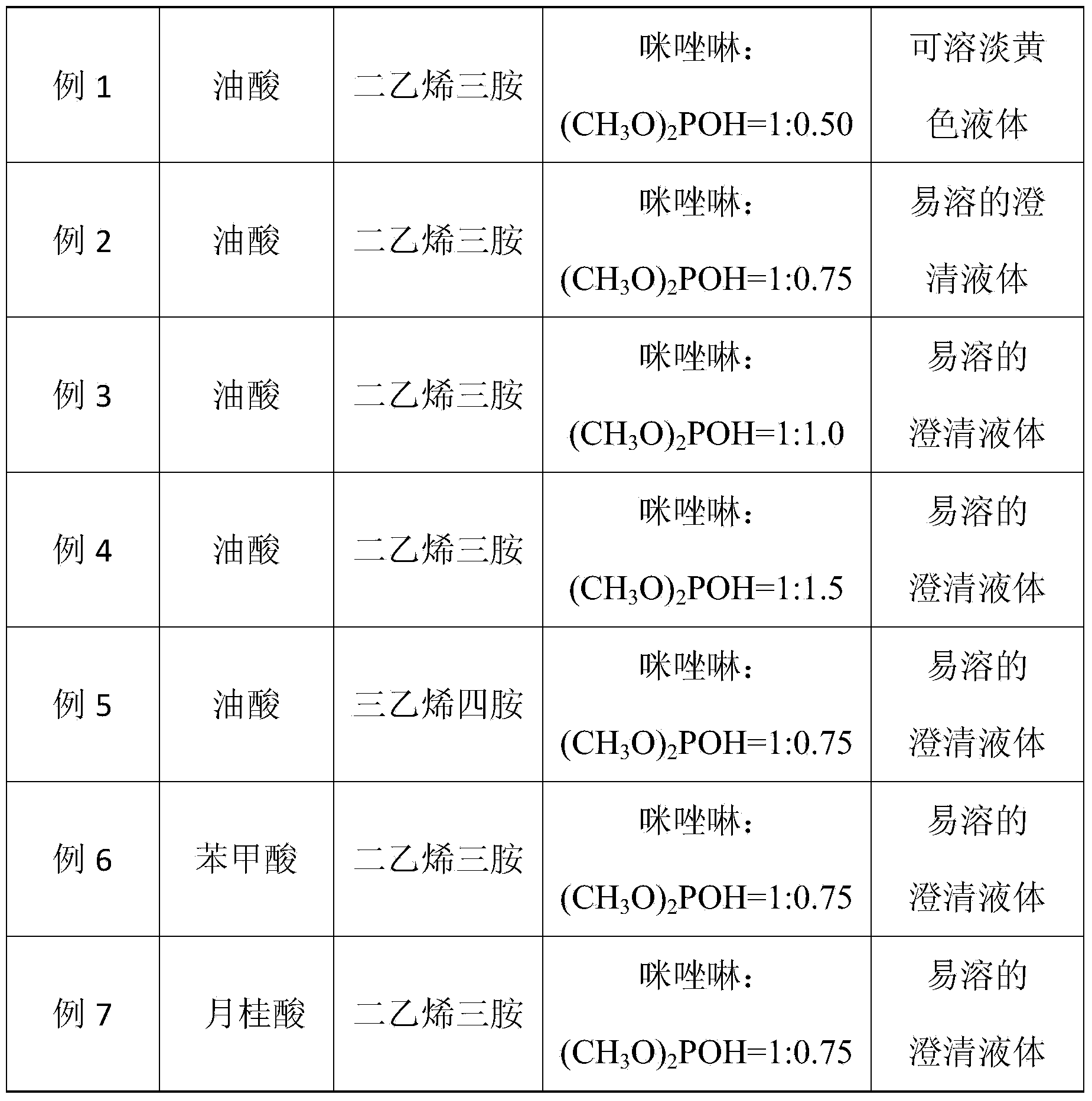

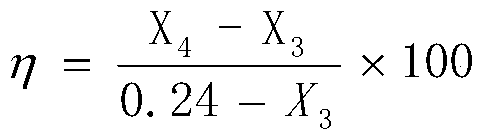

ActiveCN103554027ALow freezing pointGood water solubilityGroup 5/15 element organic compoundsSolubilityOrganic acid

The invention discloses a method for synthesizing a water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. The method is characterized by comprising the following steps of performing amidation reaction on reaction raw materials organic acid and organic amine to synthesize amide, performing amide cyclization reaction to obtain imidazolidine, and quaternizing the oil-soluble imidazolidine by using a quaternizing agent such as dimethyl phosphite to synthesize the water-soluble imidazoline quaternary ammonium salt corrosion inhibitor. Evaluation tests show that an obtained product is high in water solubility and corrosion inhibition rate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Composite corrosion-retarding antisludging agent for treating high-concentration multiple circulating water

InactiveCN101125715AGrowth inhibitionLimit metabolismScale removal and water softeningHigh concentrationCarboxylic acid

A compound inhibition antisludging agent is used for treating high-concentration circulation water, comprising a liquid part and a solid part. Based on that the total weight of the liquid part is deemed to be 100 percent, percentages of each component by weight are: organic phosphonic acid 5-40 percent, organic carboxylic acid 5-40 percent and water 20-90 percent; and based on that the total weight of the solid part is deemed to be 100 percent, percentages of each component by weight are: polymer with antisludging effect 5-35 percent, alkaline agent 45-80 percent, azoles 1-10 percent and zinc salt 1-10 percent. The concentrations of the liquid part and the solid part in the circulating water are that: the solid part: the dosage of the agent added into make-up water is 20-200mg / L; the liquid part: total phosphine kept in the circulating water system is 10-15mg / L. The invention has effects of inhibition, antisludging, sterilization and algae removal upon meeting the requirements of the state, can promote the concentration multiple of the circulating water system up to 7.5 or more and can be operated at normal temperature with good effect and without pre-membrane treatment.

Owner:上海潓溱环保科技股份有限公司

Pickling and passivating treatment process for stainless steel pipes

InactiveCN102220591AImprove surface qualityImprove efficiencyMetallic material coating processesGramPotassium dichromate

The invention discloses a pickling and passivating treatment process for stainless steel pipes, which comprises the steps of pretreatment, liquid preparation and pickling and passivating treatment, wherein the pickling and passivating liquid consists of 20 to 22 percent of nitric acid (with specific gravity of 1.42), 30 to 50 grams per liter of potassium dichromate, 30 to 50 grams per liter of additive and the balance of water. In the pickling and passivating treatment process, pickling and passivating are accomplished in one step to form silvery white bright beautiful surfaces of the stainless steel pipes and form high-quality passivated films, so that the surface quality of the treated metal pipes is improved and the treated metal pipes have high corrosion resistance; the descaling speed and the descaling efficiency are high; the corrosion of the metal substrates is small and the corrosion inhibition rate is high; and acid mist in a cleaning operation process is avoided, and the long-existing NOx and HF serious pollution problem of stainless steel continuous pickling and passivating is solved.

Owner:扬州华宇管件有限公司

Compound corrosion and scale inhibitor

InactiveCN105502704AHigh water saving rateReduce pollutionSpecific water treatment objectivesScale removal and water softeningHigh concentrationAzole

The invention provides a compound corrosion and scale inhibitor. The compound corrosion and scale inhibitor is a liquid preparation which is prepared by mixing a first liquid preparation with a second liquid preparation according to the ratio of 1:1; a compound preparation prepared from organic phosphonic acid, polycarboxylic acid, a dispersing agent and water is adopted as the first liquid preparation; a compound preparation prepared from solid agentia and water according to the weight ratio of 1:1 is adopted as the second liquid preparation, wherein a compound preparation which has the scale inhibition effect and is prepared from polymers, an alkaline agent, azoles and zinc salt is adopted as the solid agentia. The compound corrosion and scale inhibitor can achieve the effects of corrosion inhibition, scale inhibition and sterilization and algae removal which meet the national requirements, can be applied to a circulating cooling water system with the high concentration multiple, is convenient to put, does not need to be prefilmed, can be used at normal temperature and is good in using effect.

Owner:HEBEI AGRICULTURAL UNIV. +1

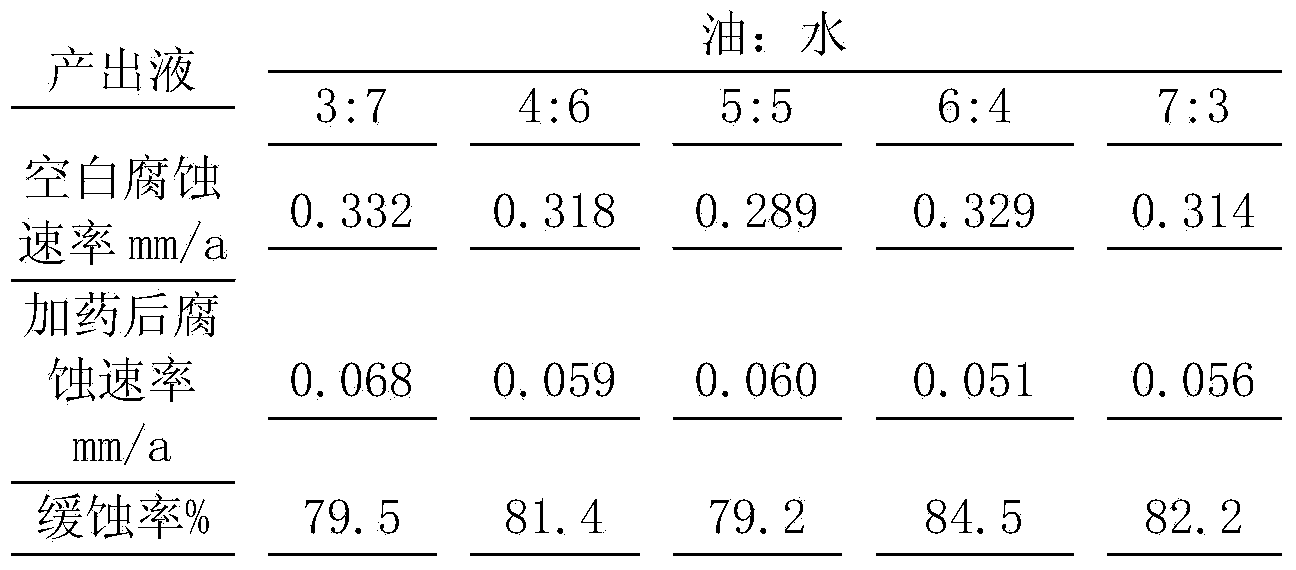

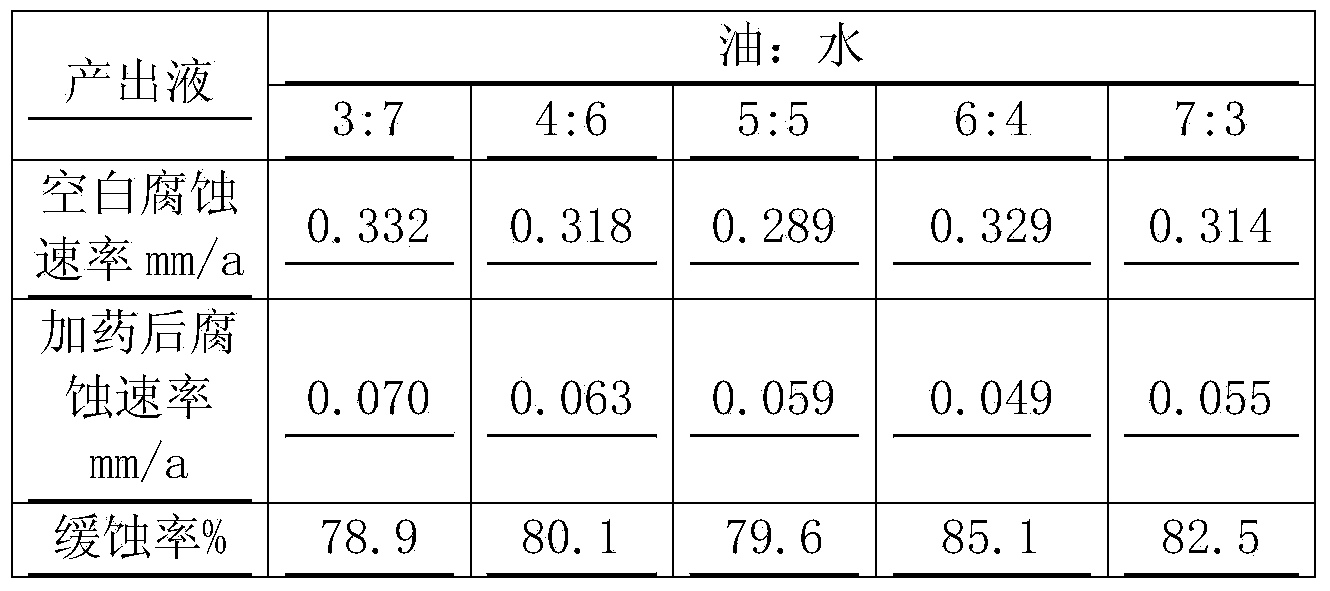

Oil-water medium corrosion inhibitor for corrosion control on oilfield-production oil gas water collection and transmission system

ActiveCN104073810AWide adaptabilityGood compatibilityBorehole/well accessoriesAlkylphenolFatty alcohol

The invention relates to an oil-water medium corrosion inhibitor for corrosion control on an oilfield-production oil gas water collection and transmission system, which comprises 1-25% of bis quaternary ammonium salts of imidazoline and alkyl-tert ammonium, 0.5-10% of sulfhydryl alkyl acid, 1-15% of organic urea compound, 1-10% of thiocyanide, 1-15% of alkyl quaternary ammonium salts, 0-10% of fatty alcohol polyethenoxy ether, 0-10% of alkylphenol polyoxyethylene and the balance of water. The corrosion inhibitor can control the corrosion of the oilfield-production oil gas water collection and transmission system with different oil-water ratio media; and when the charging amount reaches 100 mg / L, the corrosion inhibition rate can reach 75% above, and the corrosion rate can be controlled at 0.076mm / a below, thereby solving the problems of small property change application range of oil well production solution media, low corrosion inhibition rate and influence of emulsification on demulsification in the corrosion inhibitor on the market.

Owner:XIAN HUANUO ENVIRONMENTAL PROTECTION CO LTD

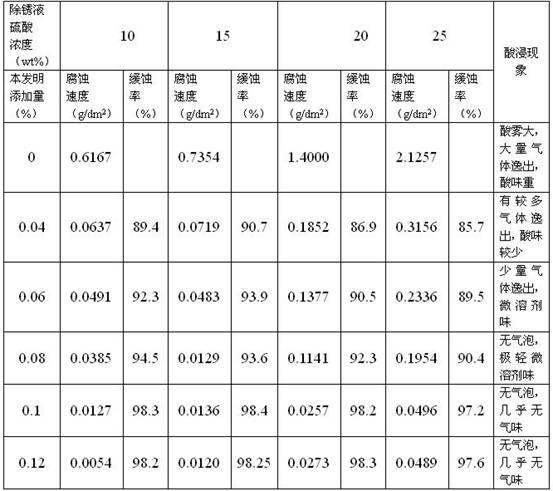

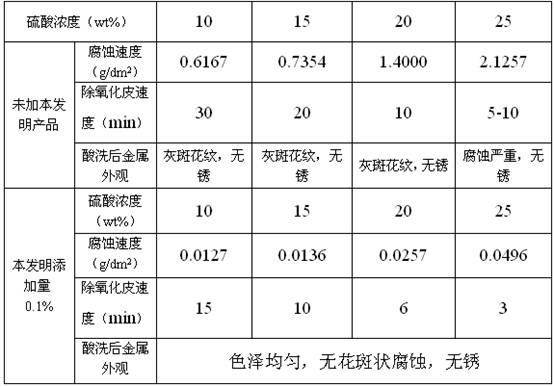

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

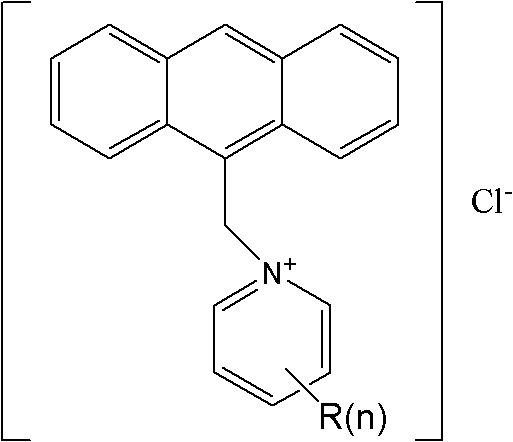

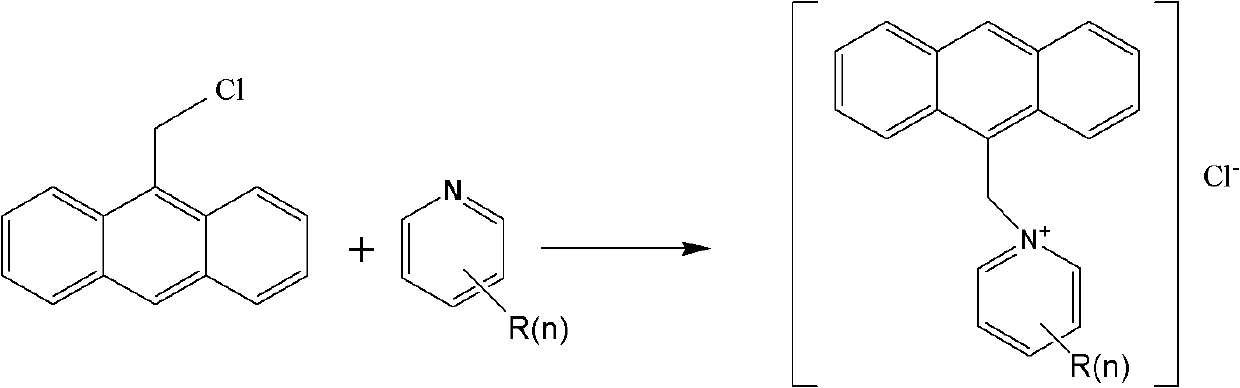

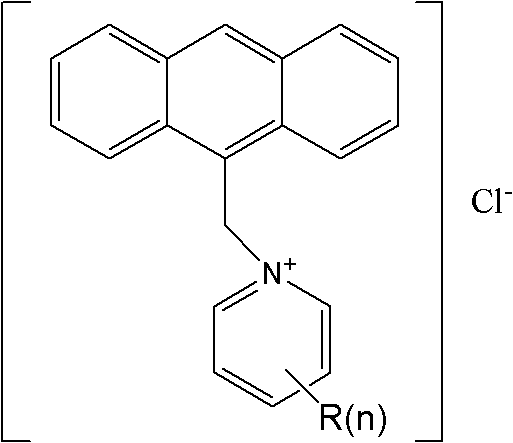

Application of pyridine compound for preparing acidization corrosion inhibitors

ActiveCN102382638AHigh corrosion inhibition rateOrganic chemistryDrilling compositionHydrogenPyridine

The invention provides application of pyridine compound represented by general formula (I) and used for preparing acidization corrosion inhibitors, wherein an R is hydrogen (H) or methyl, and an n is 1, 2 or 3. The invention further relates to application of composite for preparing the acidization corrosion inhibitors, wherein the composite adopts the pyridine compound as a main active ingredient.

Owner:南京华洲新材料有限公司

High temperature corrosion inhibitor for atmospheric vacuum distillation apparatus

The invention relates to a high-temperature corrosion inhibitor for an atmospheric vacuum distillation unit. The corrosion inhibitor consists of the following compounds: fat acid amide, organic amine, sulfonated alkylphenol, an organic parathion compound, organic phosphate and heavy aromatics, wherein the mixture ratio (weight percentage) of the compositions is: 10 to 30 percent of the fat acid amide, 5 to 15 percent of the organic amine, 0 to 10 percent of the sulfonated alkylphenol, 10 to 30 percent of the organic parathion compound, 0 to 10 percent of the organic phosphate and 35 to 65 percent of the heavy aromatics. The high-temperature corrosion inhibitor can effectively inhibit corrosion of naphthenic acid and high-temperature sulphur, has no negative influence on the normal operation of the device and achieves the aim of protecting equipment and a process pipeline in the process of processing crude oil.

Owner:金浦新材料股份有限公司

Corrosion inhibitor for treating oilfield produced water and preparation method thereof

ActiveCN102660744AShort reaction timeImprove adsorption capacityGroup 5/15 element organic compoundsPhosphorous acidPtru catalyst

The invention provides a corrosion inhibitor for treating oilfield produced water, which comprises an imidazoline group and a phosphonic acid group. 350 to 450 parts of diethylene triamine, 650 to 750 parts of oleic acid, 15 to 25 parts of heteropolyacid serving as a catalyst and 950 to 1100 parts of dimethyl benzene serving as a water-carrying agent are added to a reactor by weight, stirred and heated to a temperature of 150 DEG C, the reaction temperature is kept at 140 to 220 DEG C, and after a reaction product flows back for 5 to 8 hours, oleic acid imidazoline is obtained. Under a normaltemperature condition, 350 to 450 parts of oleic acid imidazoline, 20 to 30 parts of hydrochloric acid serving as a catalyst and 55 to 65 parts of formaldehyde are added to the reactor and stirred for 0.5 to 4 hours, 65 to 75 parts of isopropyl alcohol solutions of phosphorous acid is added to the reactor and stirred for 1 to 2 hours, then pH value of a reaction product is regulated to 6 by usinghydrochloric acid, and a finished product of the corrosion inhibitor with for treating the oilfield produced water, which has a concentration of 90 percent, is obtained. The corrosion inhibitor has ahigh corrosion inhibition rate, is easy to be dissolved in water and is modified by using cheap raw materials; and the cost for preparing the corrosion inhibitor is low.

Owner:唐山冀油瑞丰化工有限公司 +1

Corrosion inhibitor for sour oil and gas fields

The invention belongs to the field of metal corrosion prevention, and discloses a corrosion inhibitor for sour oil and gas fields, directing at the problems of poor environmental protection, stability and adaptability in traditional corrosion inhibitors. The corrosion inhibitor comprises salicylic acid cyclohexidine actidione, pyridine quaternary ammonium salt, sodium dodecyl benzene sulfonate, an antioxidant BHT, a silicon defoamer, naphthenate, a disincrustant PAC and a composite solvent. The corrosion inhibitor prepared by the invention has excellent water-soluble and oil-soluble dispersity, a simple production process, safety, environmental protection property and an excellent slow release effect, can be used for ground gathering, storage and transportation systems of sour or high sour oil and gas fields to prevent damages of corrosive gases to metal materials such as iron and steel and reduce the corrosion losses.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Disposal method of electrolysis copper powder waste liquid and application thereof

ActiveCN101570367AGood flocculation effectWill not affect the purification effectWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteIron powder

The invention provides a disposal method of electrolysis copper powder waste liquid. The disposal method is characterized in that the electrolysis copper powder waste liquid orderly undergoes the disposals of precipitation separation, roasting oxidization and twice purification crystallization; and then the disposed copper-containing waste liquid is added with reducing iron powder for chemical replacement reaction so as to obtain copper immersion plate powder formed on the surface of the reducing iron powder. The disposal method achieves the aim of fully utilizing resources, saving energy, reducing exhaustion, consumption and production cost and causing no harm to human bodies or pollution to the environment, and fully meets the requirement of taking a new road to industrialization and realizing sustainable development.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

Tungstate dirt dispersion agent

InactiveCN1837095AHigh corrosion inhibition rateNo pollution in the processTreatment using complexing/solubilising chemicalsTungstateDisperser

The invention provides a tungstate anti-scaling disperser, which comprises sodium tungstate, sodium glucoheptonate, organic phosphate, polycarboxylic acid, benzotrizaole and water, the invention also provides a method for using the tungstate anti-scaling disperser, which comprises compounding with zinc chloride to 8-12%. The invention can achieve an inhibition rate higher than 95% when applied to recirculated cooling water systems.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Metal pickling inhibitor and method for preparing the same

The preparation method for a metal pickling bio-inhibitor comprises: with hydrolysate of animal hair or sewage from cysteine preparation as material, adding proper inorganicand organic inhibitor and surfactant to obtain the target. This product has efficiency to metal more than 99%, inhibits acid mist more than 95% while just with 0.5% dosage, and has no public nuisance and little toxin. This method is simple and low cost fit to industrial production.

Owner:CHONGQING UNIV

Brass composite powder and preparation method thereof

The invention provides brass composite powder, which is characterized in that the brass composite powder is prepared from 70 to 97 percent of copper and 3 to 30 percent of zinc in percentage by weight. The invention also provides a preparation method for the brass composite powder. The invention provides a substitute raw material with low cost and good product performance and quality for manufacture, application and development of the prior brass-based powder metallurgical products and parts.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

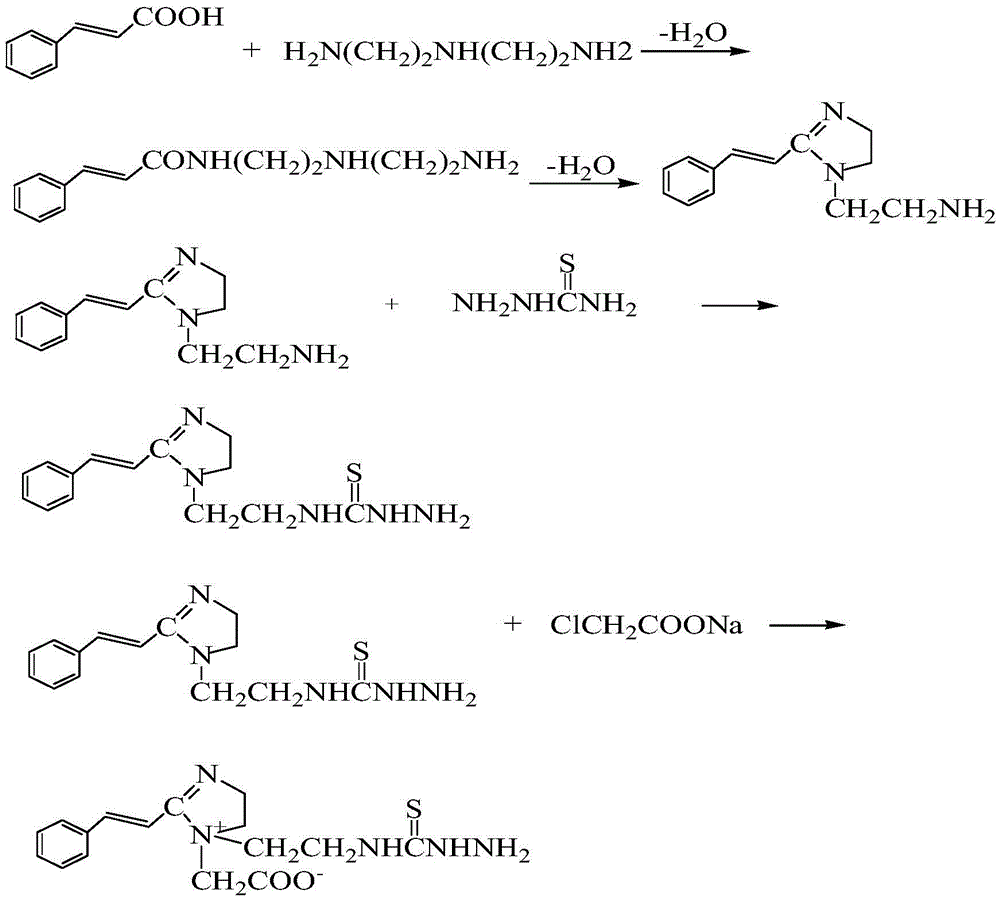

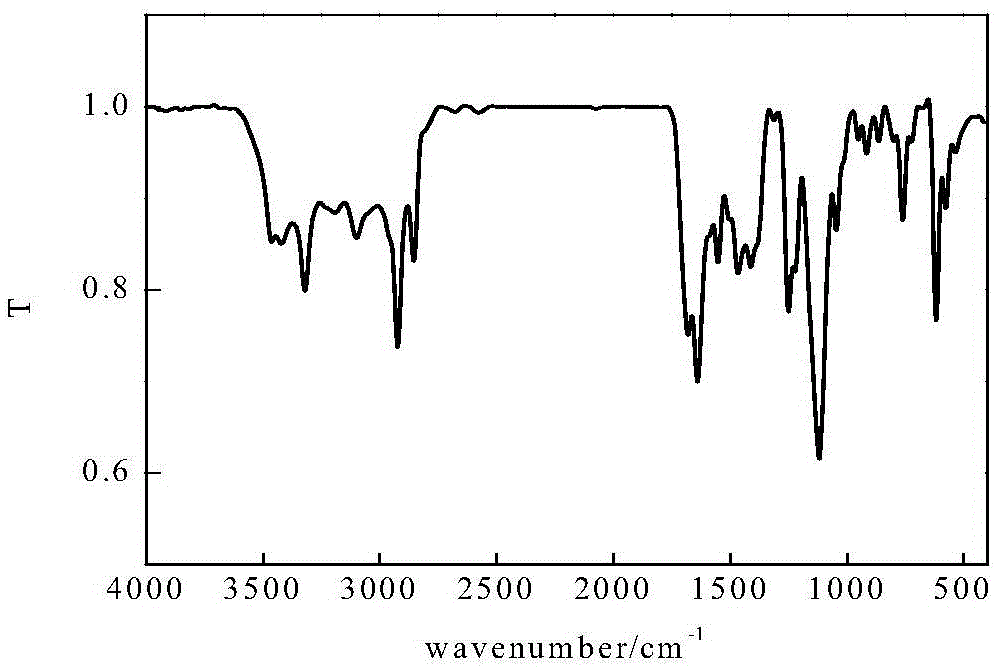

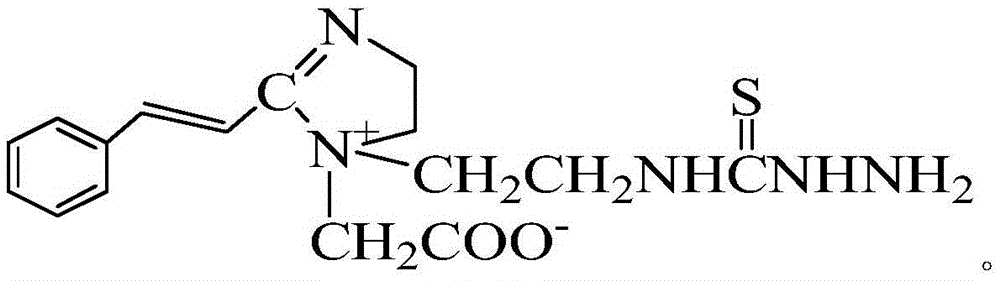

Imidazoline amphoteric surfactant and preparation method thereof

ActiveCN105561864AImprove adsorption capacityGood corrosion inhibitionOrganic chemistryTransportation and packagingSolubilitySodium chloroacetate

The invention provides an imidazoline amphoteric surfactant and a preparation method thereof. The method comprises the steps: stirring and mixing cinnamic acid and diethylenetriamine in the presence of a water carrying agent and a catalyst, and carrying out amidation reaction and cyclization reaction dehydrating, so as to obtain an imidazoline intermediate; introducing a thiourea group into the imidazoline intermediate, and carrying out quaternization by using sodium chloroacetate, thereby obtaining the imidazoline amphoteric surfactant. According to the imidazoline amphoteric surfactant and the preparation method thereof, by taking sodium chloroacetate as a quaternization reagent, the reaction is easy to carry out, the product quality is good, and the water solubility of the product is improved. The imidazoline amphoteric surfactant provided by the invention is easy to synthesize and has good stability, and the raw materials are cheap and readily available.

Owner:陕西长海油田助剂有限公司

Dirt dispersion agent

InactiveCN1837096AHigh corrosion inhibition rateGood anti-scaling and dispersing effectScale removal and water softeningWater qualityDisperser

The invention provides an anti-scaling disperser, which comprises acroleic acid-acrylate-petroleum sulfonate copolymer, acrylic acid-2-hydroxypropyl acrylate-AMPS copolymer, maleic anhydride-acrylic acid copolymer, zinc chloride and water, the invention also provides the use of the anti-scaling disperser in industrial water treatment systems. The formulation of the invention can be charged by zinc salts for the treatment of low-medium hardness water, and to increase the inhibition rate of the formulation.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

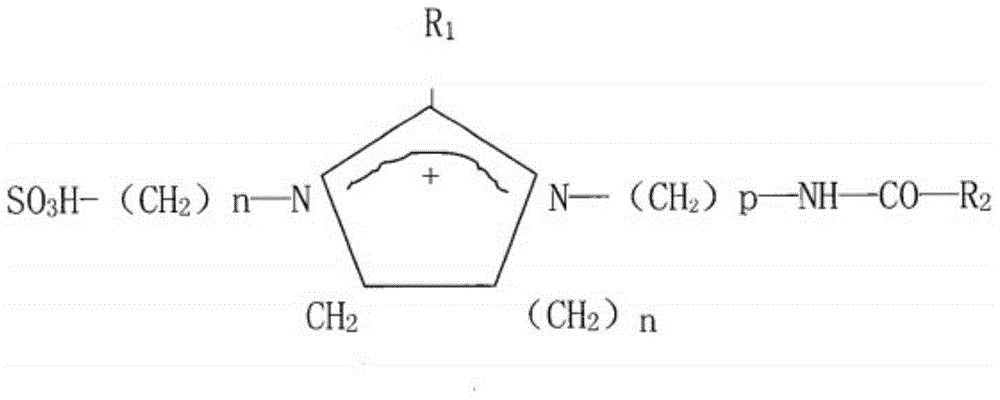

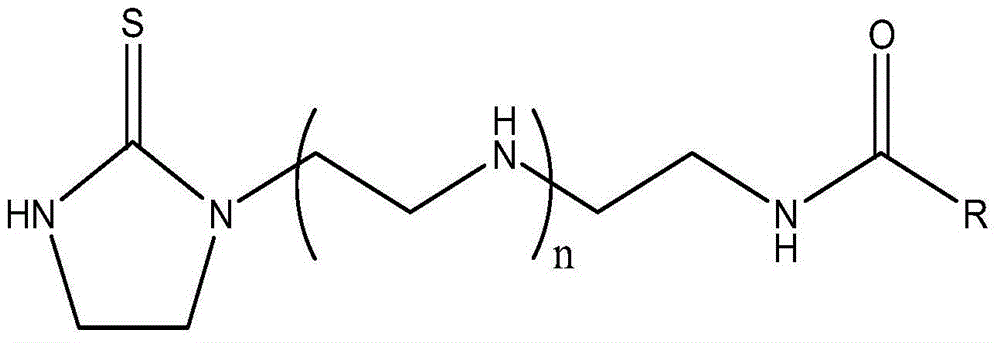

Imidazolyl thiourea derivative, corrosion inhibitor and preparation method thereof

InactiveCN105418509AImprove anti-corrosion performanceHigh corrosion inhibition rateOrganic chemistryBorehole/well accessoriesThioureaBULK ACTIVE INGREDIENT

The invention discloses an imidazolyl thiourea derivative, a corrosion inhibitor and a preparation method thereof and belongs to the field of corrosion protection of metals. The chemical structural formula of the imidazolyl thiourea derivative is represented by a formula shown in the description, wherein R is alkyl, phenyl or alkenyl containing 6-20 carbon atoms; and n is 0, 1, 2, 3, 4 or 5. The imidazolyl thiourea derivative in the structure disclosed by the invention can be used as an active ingredient for inhibiting metals, particular a L360 carbon steel material metal in a CH3COOH-H2S-Cl- corrosive environment, and has a good corrosion-resistant effect.

Owner:PETROCHINA CO LTD

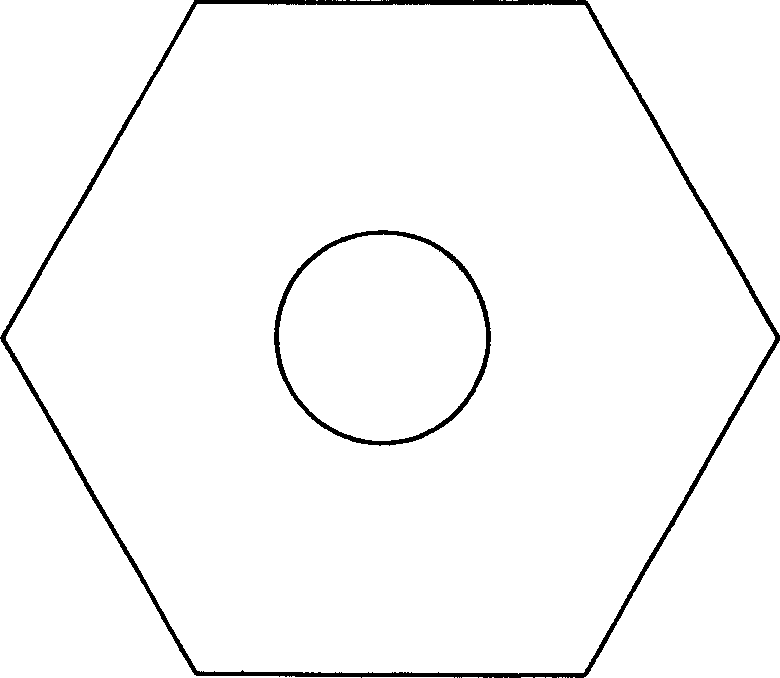

Solid inhibitor and preparation method thereof

The invention discloses a solid rust inhibitor for oil well down-hole facilities and collector pipeline, which is prepared by the following material of weight ratio: high-carbon-alkylamine surfactant 5-15%, triethylene tetraamine 2-10%, triethanolamine 2-10%, sodium hexametaphosphate 20-40%,polyethylene 20-50%. The preparation method is as follows: first synthesizing intermediate M1, placing triethylene tetraamine in agitator tank, adding triethylene tetraamine and obtaining intermediate M#-[1], intermediate M#-[2] synthesis: placing high-carbon-alkylamine surfactant in agitator tank, adding intermediate M#-[1],sodium hexametaphosphate, obtaining intermediate M#-[2], adding intermediate M#-[2] in polyethene. At last, the polygonal hollow column product is obtained by injection machine The invention operates easily, rust prevention property is consistent, and integrated rust prevention ratio is high, which prolongs the life time of apparatus.

Owner:成都孚吉科技有限责任公司

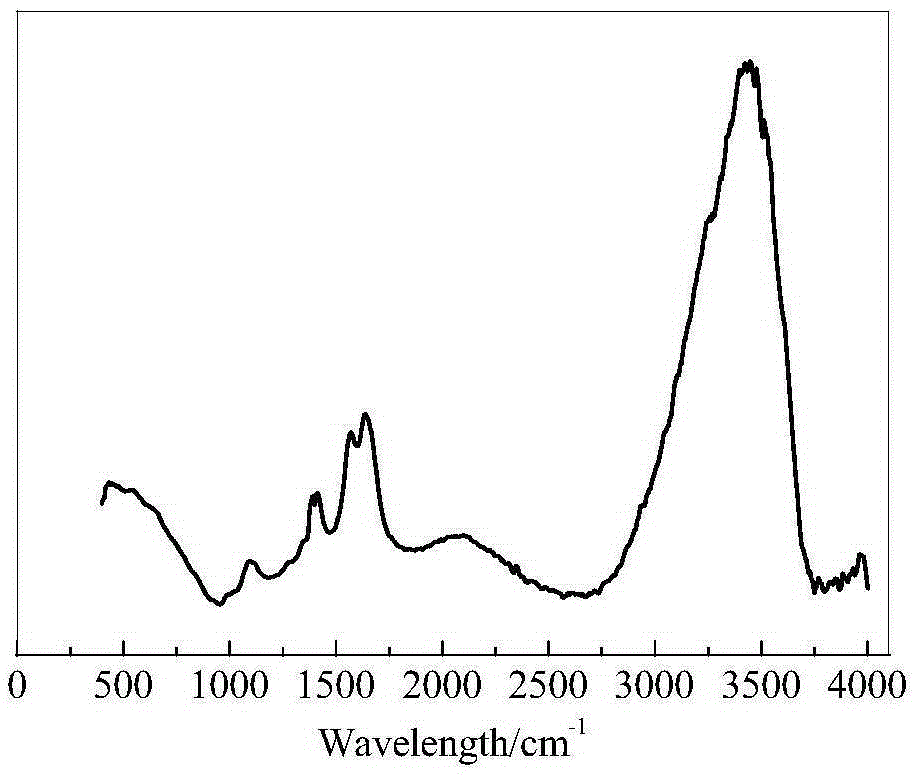

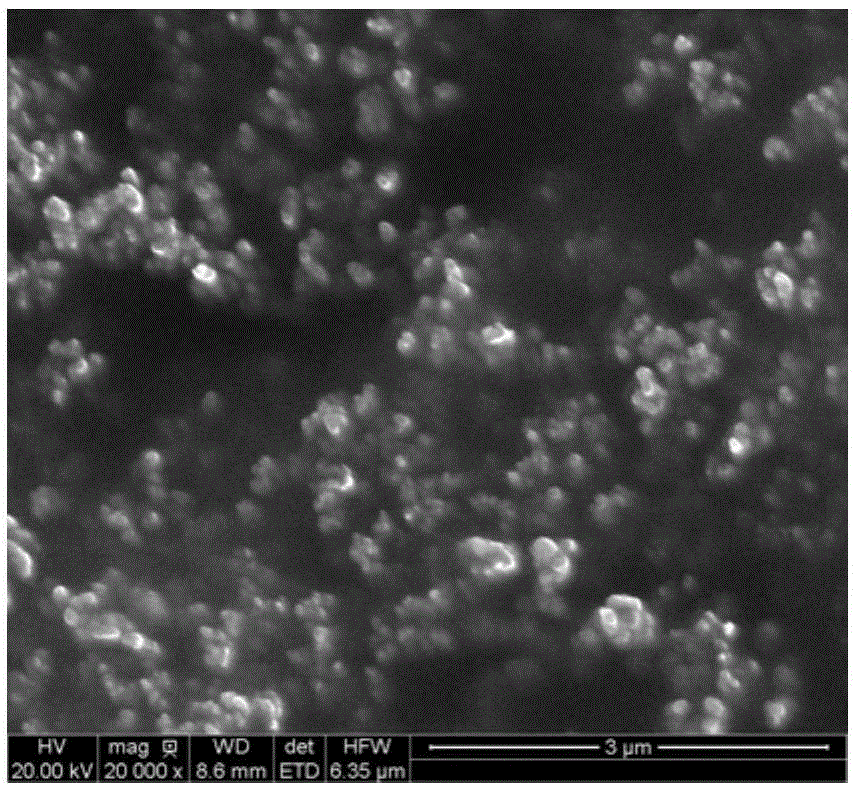

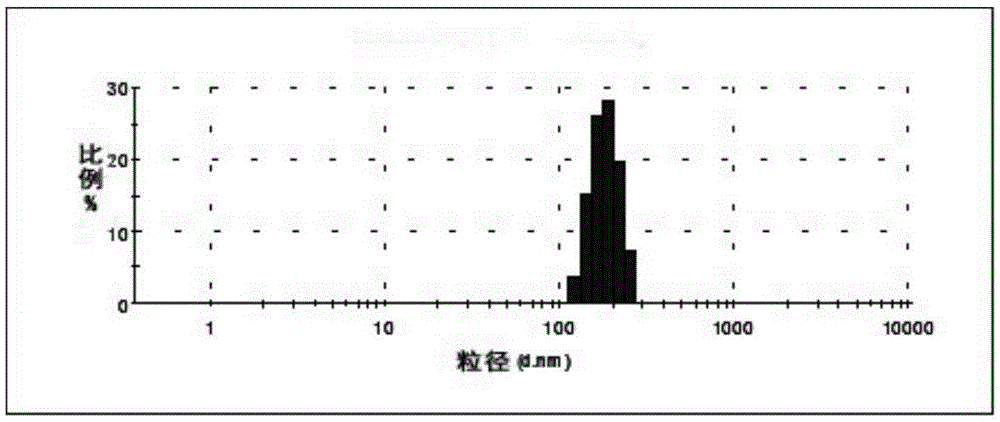

Preparation method of water-soluble polyaniline nano particles serving as corrosion inhibitor

InactiveCN105315460AEasy to useAchieve safety and environmental protection featuresNitriteReaction temperature

The invention discloses a preparation method of water-soluble polyaniline nano particles serving as a corrosion inhibitor. The preparation method comprises the following steps: adding deionized water into a template agent; completely dissolving the template agent under the action of ultrasonic; adding aniline into the completely dissolved template agent, and carrying out uniform stirring at the room temperature to obtain a solution I; adding an oxidizing agent into the solution I to ensure that aniline participates an oxypolymerization reaction under the action of the oxidizing agent, wherein the reaction temperature is 0 to 2 DEG C; after the reaction is finished, carrying out refining and drying to obtain the final product, namely the polyaniline nano particles. Compared with the prior art, the corrosion inhibitor contains no nitrite, is simple to use, and can be used as long as being diluted with water, thereby being safe and environmentally friendly. The corrosion inhibitor obtained according to the preparation method is used after being diluted by 50 to 300 times of water; when the concentration of the corrosion inhibitor is 0.5 g / L, the corrosion inhibiting effect on carbon steel reaches up to 95.6 percent.

Owner:CHINA PETROLEUM & CHEM CORP +2

Composite dirt dispersion agent

InactiveCN1837097AHigh corrosion inhibition rateGood anti-scaling and dispersing effectScale removal and water softeningWater qualityGluconic acid

The invention provides a composite anti-scaling disperser, which comprises acroleic acid-acrylate-petroleum sulfonate copolymer, silicate, 1-hydroxyethylidene-1,1-diphosphonic acid, gluconic acid, benzotrizaole and water, the invention also provides the use of the composite anti-scaling disperser in industrial water treatment systems. The disperser can be compounded with zinc chloride to 8-12%, and the formulation of the invention can be charged by zinc salts for the treatment of low-medium hardness water, and to increase the inhibition rate of the formulation.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Scale inhibitor for oilfield water injection

InactiveCN106396141AChemically stableExcellent corrosion and scale inhibitionTreatment using complexing/solubilising chemicalsEthylene diaminePolyaspartic acid

The invention belongs to the technical field of oilfield water treatment and relates to a scale inhibitor for oilfield water injection. The technical scheme includes that the scale inhibitor for oilfield water injection is characterized by being prepared from, by weight, 1-3 parts of amino trimethylene phosphonic acid, 1-2 parts of etidronic acid, 2-4 parts of ethylenediamine tetra(methylene phosphonic acid) sodium, 4-8 parts of ammonium molybdate, 6-10 parts of EDTA (ethylene diamine tetraacetic acid), 6-10 parts of polyaspartic acid, 1-3 parts of chitosan and 20-35 parts of water. The scale inhibitor for oilfield water injection is environment friendly.

Owner:WEIHAI YUNRUI INFORMATION TECH CO LTD

Modified scaling inhibitor and method for preparing same

InactiveCN106277377AReduce dosageImprove stabilitySpecific water treatment objectivesScale removal and water softeningGlycerolWater quality

The invention discloses a modified scaling inhibitor. The scaling inhibitor is prepared by usingthe following raw materials in parts by weight: 50 to 80 parts of polyaspartic acid, 30 to 50 parts of polyepoxysuccinic acid, 8 to 10 parts of sodium gluconate, 5 to 10 parts of glycerol, 20 to 30 parts of ethanol, 0 to 15 parts of acidity regulator, 0 to 15 parts of alkalinity regulator, 5 to 8 parts of benzotriazole, 5 to 10 parts of zinc sulfate, 20 to 30 parts of modifier, 10 to 20 parts of assistant and 70 to 90 parts of water. In the modified scaling inhibitor, by compounding and proportioning polyepoxysuccinic acid and polyaspartic acid, the amount of used polyepoxysuccinic acid is reduced, the production cost is decreased, the application scope is widened, the comprehensive performance is improved, the proportioning of zinc sulfate and sodium gluconate improves the stability of water quality and can maintain the high corrosion-inhibiting rate under high-temperature conditions, the steps of the method for preparing the modified scaling inhibitor are simple, the time is saved and the performance of the prepared modified scaling inhibitor is excellent.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

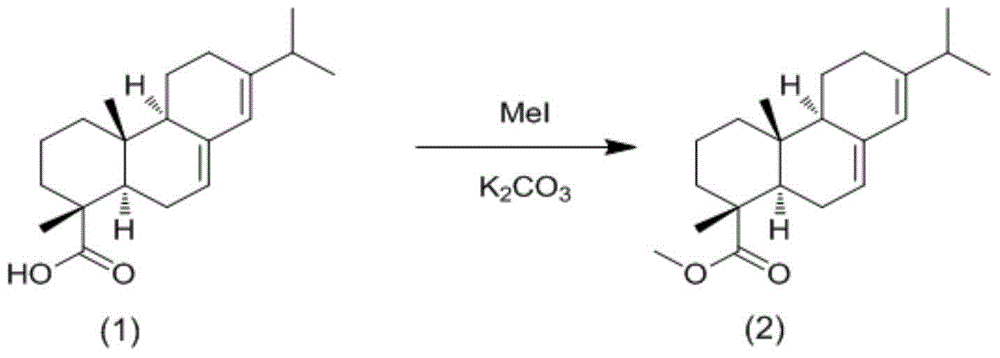

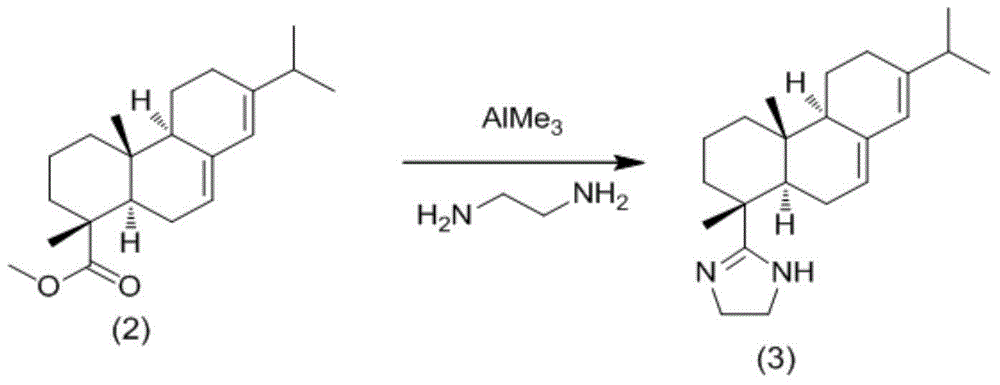

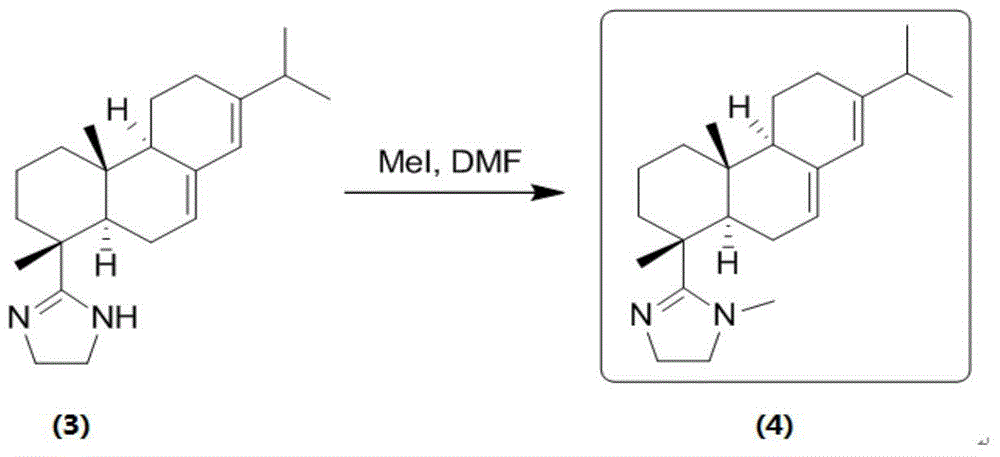

Novel rosin imidazoline corrosion inhibitor

ActiveCN105272916AImprove thermal stabilityLow toxicityOrganic chemistryBorehole/well accessoriesMetallic materialsRosin

The invention relates to the synthesis and application technology field of compounds used for metal anticorrosion, and concretely discloses a novel rosin imidazoline corrosion inhibitor, a synthetic method and applications. The initial raw material of the provided compound is rosin acid, the raw material is single and the synthetic route operation is simple. The method for preparing a corrosion inhibitor from the synthesized compound is simple, the compound is dissolved in dimethyl formamide, then the obtained solution is dissolved in water, then 1-hydroxyethylidene-1,1-diphosphonic acid is added, and uniform stirring is carried out. The corrosion inhibitor is safe and environmentally friendly, and has excellent corrosion inhibition effects. The corrosion inhibitor can be used for oil and gas field ground gathering and storage and transportation pipes, prevents damage of corrosive gases to metal materials of steel and the like and reduces corrosion loss.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

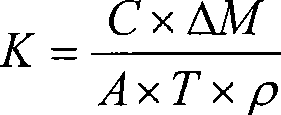

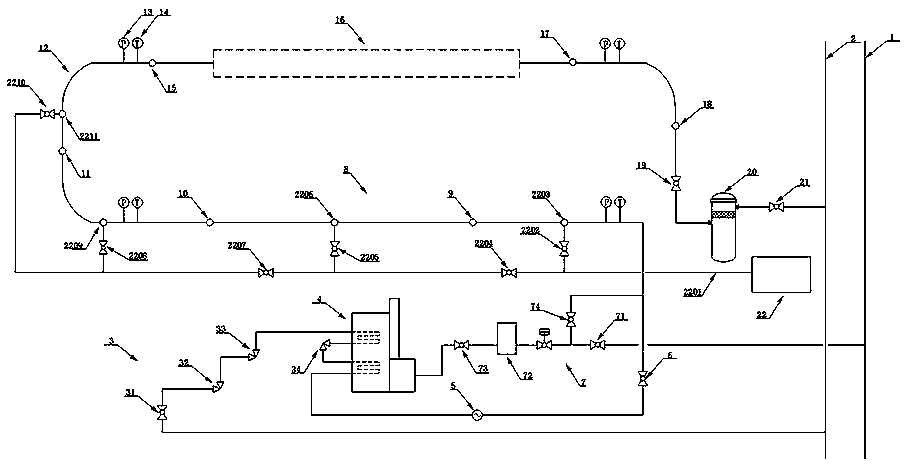

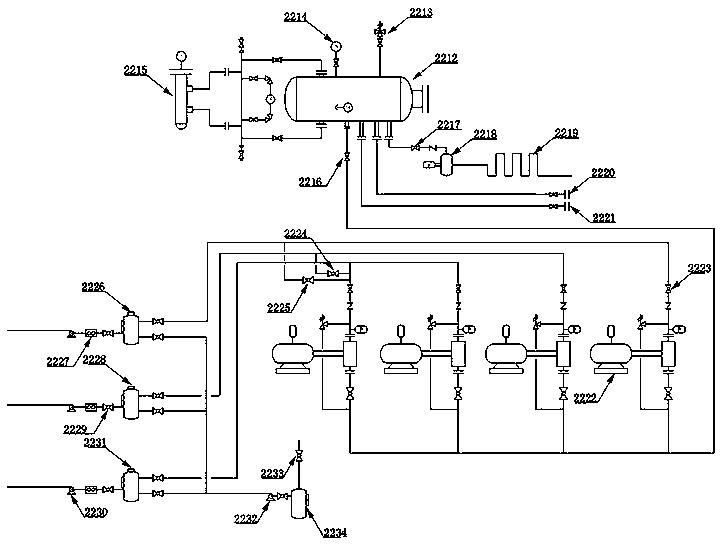

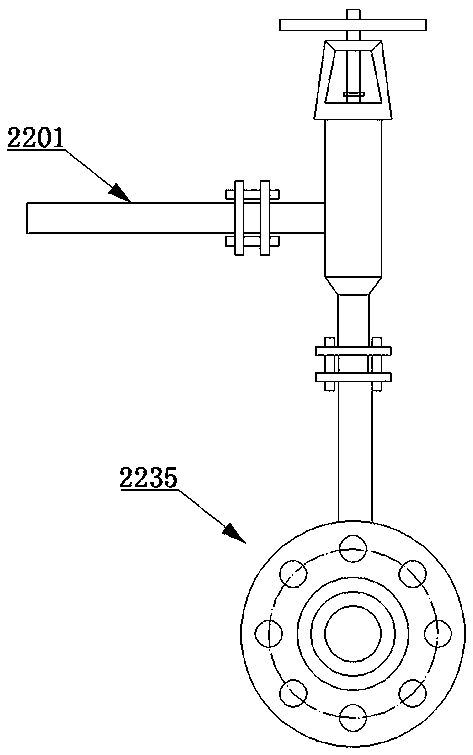

Onsite test device for testing concentration distribution of corrosion inhibitor, and method thereof

ActiveCN107907496AReduce fill volumeImprove economic efficiencyParticle size analysisColor/spectral properties measurementsProcess conditionsPetroleum

The invention relates to an onsite test device for testing the concentration distribution of a corrosion inhibitor, and a method thereof, and belongs to the technical field of petroleum and natural gas engineering. The method comprises the following steps: designing a corrosion inhibitor continuous-charging module, testing the influences of the type, the concentration, the temperature, the charging amount and the corrosion inhibitor liquid drop particle size of different corrosion inhibitors on the concentration distribution rule of a corrosion inhibitor; designing a corrosion inhibitor liquiddrop particle size test module, and testing the particle size of corrosion inhibitor liquid drops sprayed by several onsite common nozzles through experiments; and designing a corrosion inhibitor concentration analysis sampler to provide a means and way for circular test studying of the concentration distribution of the corrosion inhibitor. The onsite test device for testing the concentration distribution of the corrosion inhibitor, and the method thereof are used to test the concrete distribution of the corrosion inhibitor in a pipeline under different angle bends, different positions to a charging point, different pipeline gas pressures, different pipeline gas temperatures and different charging technology conditions and study the effective protection length of the corrosion inhibitor under different charging technologies.

Owner:SOUTHWEST PETROLEUM UNIV

Green and environment-friendly corrosion and scale inhibitor

InactiveCN112607874AGood anti-scaling effectIt has the effect of green environmental protectionScale removal and water softeningAlcoholEnvironmental engineering

The invention relates to the field of water treatment chemicals, and particularly discloses a green and environment-friendly corrosion and scale inhibitor. The environment-friendly corrosion and scale inhibitor is prepared from modified polyepoxysuccinic acid, an amino acid corrosion inhibitor, water and the like, and the preparation method of the modified polyepoxysuccinic acid comprises the following steps: adding chitosan with the deacetylation degree of 70-85% into a citric acid solution, and stirring until the chitosan is dissolved to obtain a chitosan citric acid solution; the preparation method comprises the following steps: adding absolute ethyl alcohol into a chitosan citric acid solution, uniformly stirring, heating and refluxing for 1-2h, cooling to 40-50 DEG C, adding polyepoxysuccinic acid, uniformly stirring, carrying out ultrasonic treatment for 2-4h, cooling to room temperature, and finally adjusting the pH value to 5.5-7.0, thereby obtaining the modified polyepoxysuccinic acid. The green and environment-friendly corrosion and scale inhibitor prepared by the invention still has good scale inhibition performance in a high-temperature state, does not bring in phosphorus, and has a green and environment-friendly effect.

Owner:广州市粤新工程技术有限公司

Oil-soluble hydrogen sulfide-proof corrosion inhibitor

ActiveCN103450865ADense filmImprove adsorption capacityBorehole/well accessoriesAcetic acidPhosphate

The invention discloses an oil-soluble hydrogen sulfide-proof corrosion inhibitor and relates to the technical field of chemical reagent formulas for the oil fields. The oil-soluble hydrogen sulfide-proof corrosion inhibitor comprises the following components by weight percent: 20-30% of sorbitan monooleate, 10%-20% of nonylphenoxy-acetic acid, 5%-10% of octyl phosphate and 40%-65% of solvent. The oil-soluble hydrogen sulfide-proof corrosion inhibitor is capable of effectively preventing the corrosion of a shaft and a gathering pipeline caused by H2S and sulfides, and has the characteristics of low dosage, low cost, no pollution on the environment and the like, and also has excellent protection effect in the produced liquid; simultaneously, the oil-soluble hydrogen sulfide-proof corrosion inhibitor has good capacity of inhibiting hydrogen embrittlement caused by H2S, and has good compatibility with the conventional chemical reagents used in the oil fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

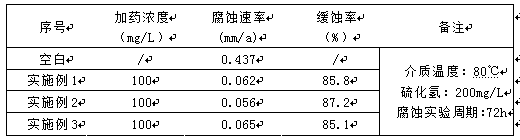

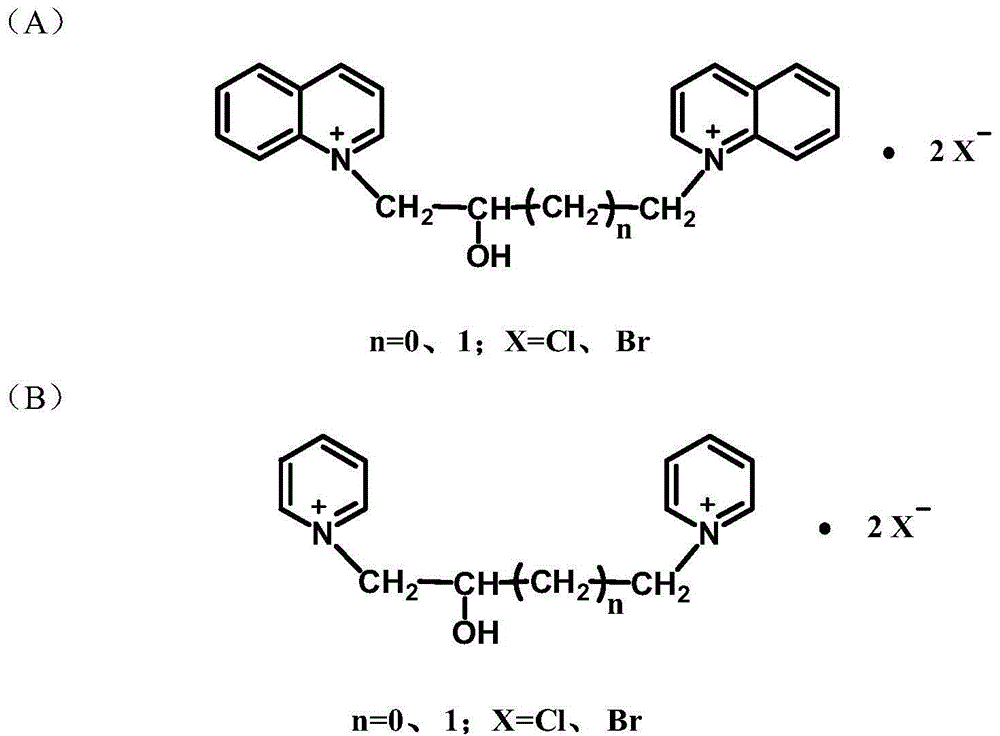

High-temperature compound acidizing corrosion inhibitor and preparation method thereof

ActiveCN105586594AHigh corrosion inhibition rateGood acid solubilityEnvironmental resistanceNitrogenous heterocyclic compound

The invention provides a high-temperature compound acidizing corrosion inhibitor and a preparation method thereof. The high-temperature compound acidizing corrosion inhibitor is prepared from, by mass, 60-80 parts of hydroxyl bis-quaternary ammonium salt, 10-20 parts of synergist and 10-25 parts of solvent. The preparation method includes the preparation steps that (1) the hydroxyl bis-quaternary ammonium salt is synthesized, a nitrogen heterocyclic compound is selected to be placed in a reaction kettle, absolute ethyl alcohol is used as the solvent, reflux is conducted when the temperature is raised to 78 DEG C through heating, then bis-halohydrin is added, cooling and filtering are conducted after reflux is conducted for 12-24 hours through continuous heating, absolute ethyl alcohol-acetone mixed liquor is used for recrystallization three times, and accordingly the hydroxyl bis-quaternary ammonium salt is obtained; and (2) the synthesized hydroxyl bis-quaternary ammonium salt is evenly mixed with the synergist and the solvent so that the high-temperature compound acidizing corrosion inhibitor can be obtained. The high-temperature compound acidizing corrosion inhibitor prepared through the method has the advantages of being good in acid-soluble property, small in dosage, high in inhibition rate, low in toxicity, environmentally friendly and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion inhibitor for inhibiting copper corrosion in saline water (seawater) and preparation method of corrosion inhibitor

The invention discloses a corrosion inhibitor for inhibiting copper corrosion in saline water (seawater) and a preparation method of the corrosion inhibitor, belonging to the field of corrosion prevention. The corrosion inhibitor is composed of 3-9 parts of calcium gluconate, 5-15 parts of sodium tungstate, 2-8 parts of sodium gluconate, 1-3 parts of tolytriazole, 0.6-2 parts of polyaspartic acid, 0.3-0.8 part of dodecyl glucoside, 0.2-0.5 part of methylchloroisothiazolinone and 10-15 parts of water. The preparation method comprises the following steps: (a) dissolving calcium gluconate into water according to a certain ratio, and dissolving by stirring; (b) adding tolytriazole into the solution according to a certain ratio, and dissolving by stirring; (c) sequentially adding sodium tungstate, sodium gluconate, polyaspartic acid and dodecyl glucoside according to a certain ratio, and dissolving by stirring; and (d) finally, adding methylchloroisothiazolinone according to a certain ratio, and stirring for 10-15 minutes. The corrosion inhibitor disclosed by the invention is simple in preparation process, mild in condition, convenient to use and environmentally friendly.

Owner:马鞍山市鸿伟环化有限公司

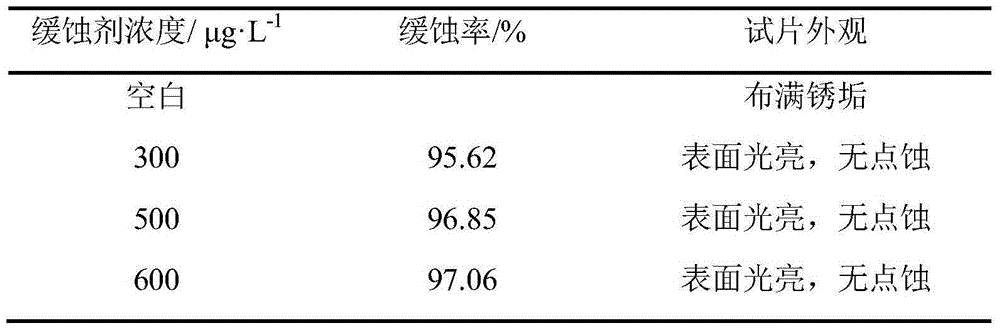

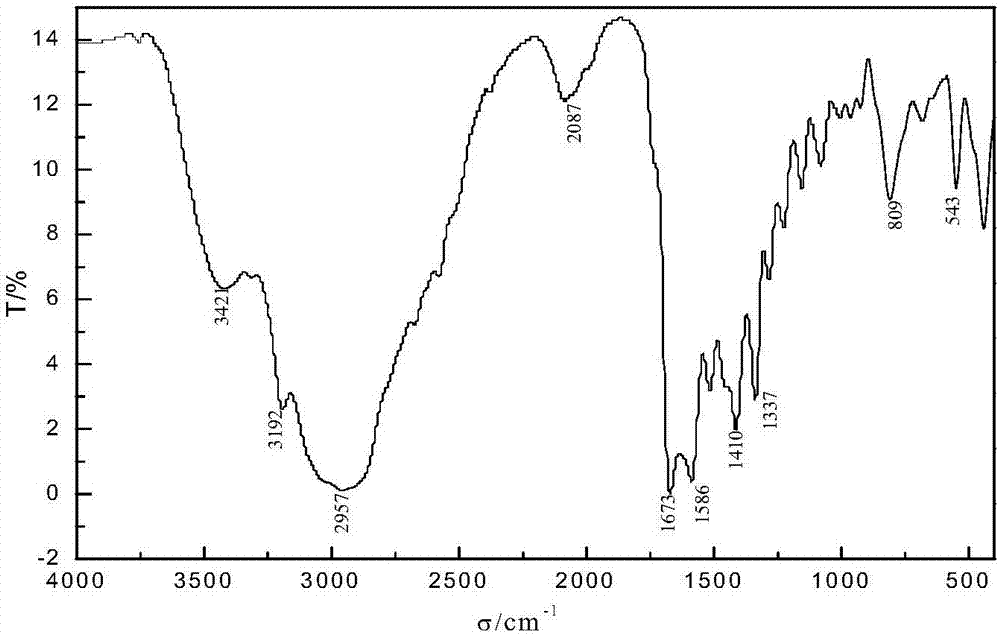

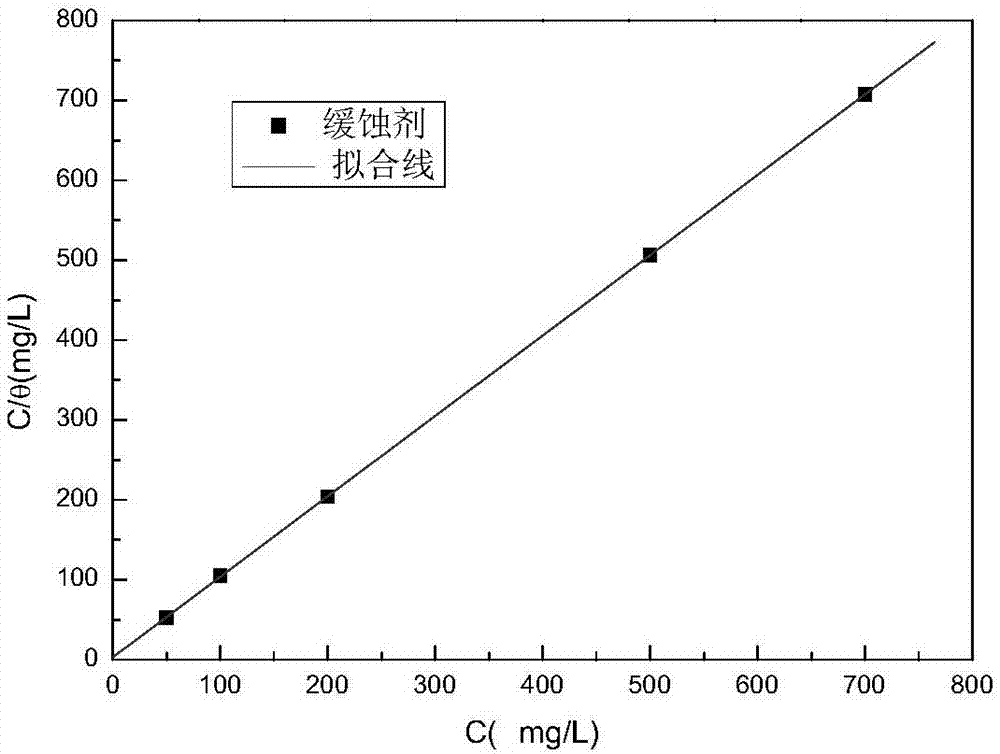

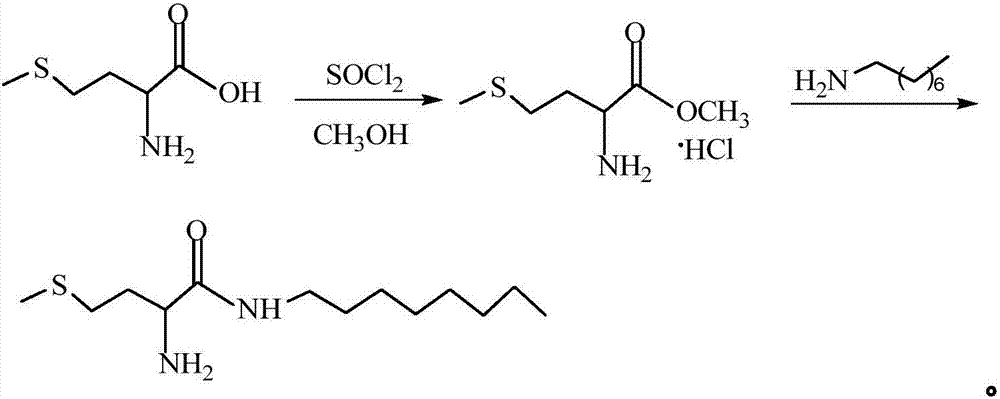

Methionine derivate corrosion inhibitor for steel pickling and compounding method thereof

ActiveCN107459473AGood corrosion inhibition rateHigh corrosion inhibition rateSulfide preparationSolubilityCarbon chain

The invention relates to a methionine derivate corrosion inhibitor for steel pickling and a compounding method thereof. The name of the methionine derivate corrosion inhibitor is 2-amino-3-methylmercapto-N-octyl-butyrylamide. The derivate is capable of spontaneously and effectively absorbing the steel surface, is principal in chemical absorption and is higher in adsorption capacity. The introduced carbon chain contains 8 carbon atoms, so that the derivate is higher in water solubility in the use concentration scope and the inhibition efficiency is above 98%.

Owner:宁波德诚工具有限公司

Acid pickling inhibitor and preparation method thereof

This invention relates to pickling inhibitor and its preparation method, in which, this invented product is composed of concentrated liquid of hexanitro-production waste water, organic inhibitor and a surface active agent. The preparation mehod includes: utilizing waste water in the production as the main material to evaporate, concentrate and filter it to remove impurities then adding small amount of organic inhibitor, inorganic inhibitor and surface active agent and mixing them to get the product.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com