High-temperature compound acidizing corrosion inhibitor and preparation method thereof

A technology of acidizing corrosion inhibitor and high temperature is applied in the field of high temperature composite acidifying corrosion inhibitor and its preparation, which can solve the problems of waste of resources, endangering the health of construction workers, reducing effective components, etc., and achieves less environmental harm, good acid solubility, The effect of high corrosion inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

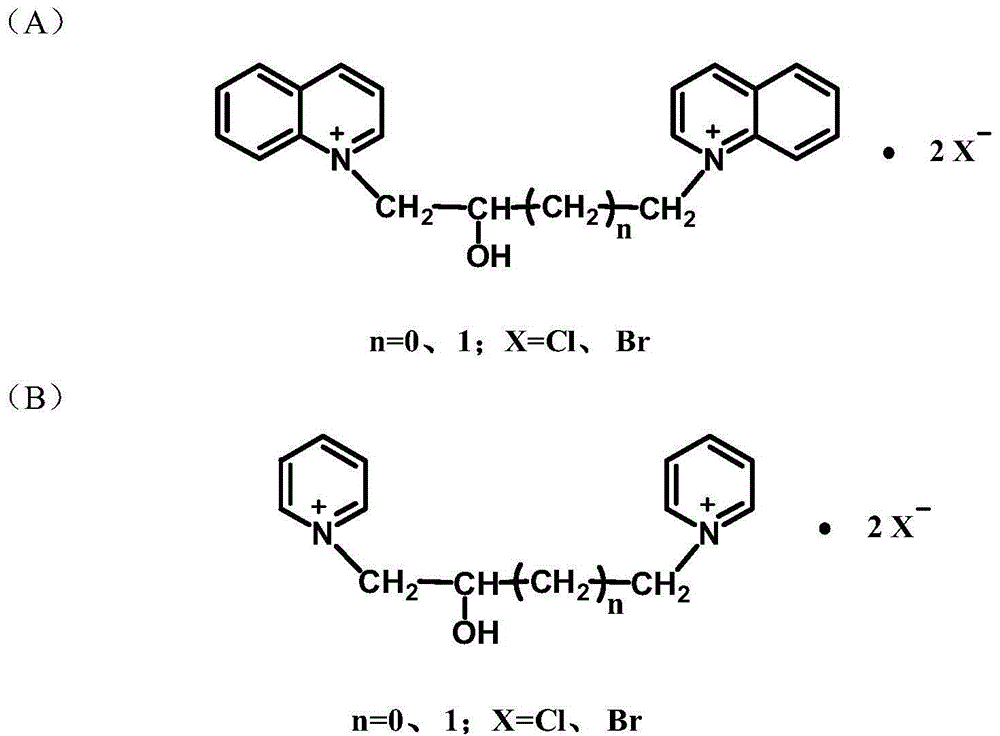

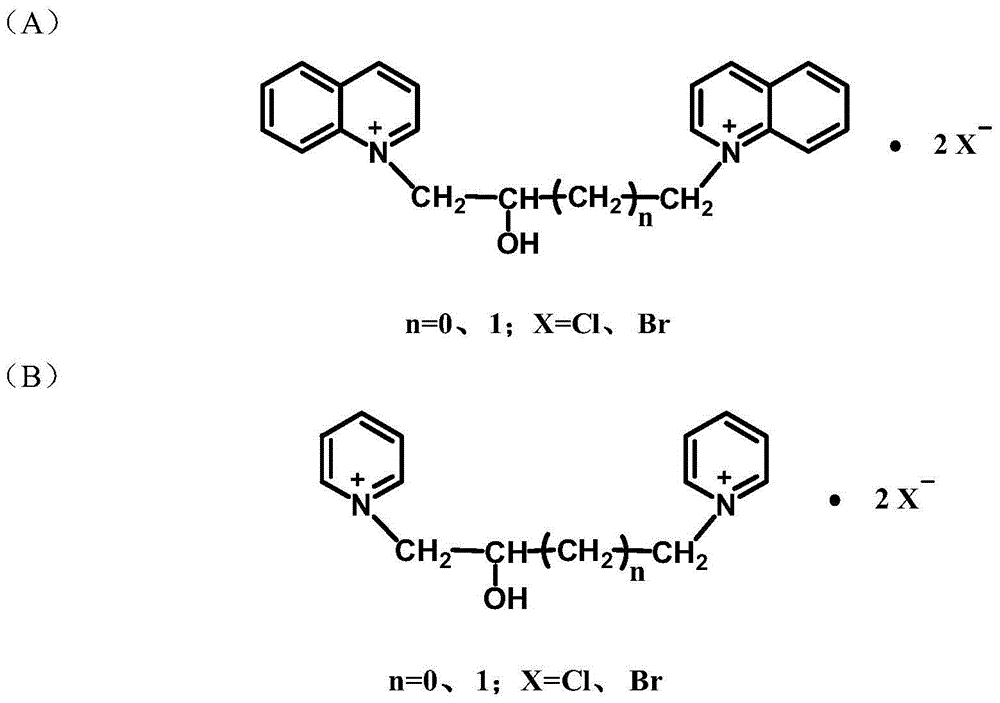

Image

Examples

Embodiment 1

[0026] Take 2 mol of quinoline in a reaction kettle, use 200 mL of absolute ethanol as a solvent, heat up to 78°C and reflux for 1 hour, then add 1 mol of 1,3-dibromo-2-propanol, continue heating and reflux for 24 hours, then cool and filter, each time with 60 mL 1,3-diquinoline propanol bromide was obtained by recrystallization three times from anhydrous ethanol-acetone mixture with a volume ratio of 1:1. Mix 1,3-diquinoline propanol bromide, rosinamine, and ethanol at a mass ratio of 60:15:25 to obtain a high-temperature composite acidification corrosion inhibitor.

[0027] In 15% HCl solution, 0.3% mass fraction of this high-temperature compound acidification corrosion inhibitor can make the corrosion inhibition rate of N80 oil pipe steel reach 99.19% at 90°C; 0.5% mass fraction of this high-temperature compound acidification corrosion inhibitor can The corrosion inhibition rate of N80 oil pipe steel at 90°C reaches 99.64%.

Embodiment 2

[0029] Take 2.4mol of quinoline in a reaction kettle, use 240mL of absolute ethanol as a solvent, heat up to 78°C and reflux for 1 hour, then add 1 mol of 1,3-dibromo-2-butanol, continue to heat and reflux for 12 hours, then cool and filter. 120 mL of anhydrous ethanol-acetone mixture with a volume ratio of 1:1 was recrystallized three times to obtain 1,4-diquinoline butanol bromide. Mix 1,4-diquinoline butanol bromide, rosinamine, and formaldehyde in a mass ratio of 70:20:10 to obtain a high-temperature composite acidification corrosion inhibitor.

[0030] In 15% HCl solution, 0.3% mass fraction of this high-temperature composite acidification corrosion inhibitor can make the corrosion inhibition rate of N80 oil pipe steel reach 99.23% at 90 °C; 0.5% mass fraction of this high-temperature composite acidification corrosion inhibitor can Make the corrosion inhibition rate of N80 oil pipe steel reach 99.67% at 90°C.

Embodiment 3

[0032] Take 2mol of pyridine in a reaction kettle, 400mL of absolute ethanol as a solvent, heat up to 78°C and reflux for 0.5h, then add 1mol of 1,3-dichloro-2-propanol, and continue heating to reflux. After reacting for 24 hours, cool and filter, and recrystallize 3 times with 100 mL of anhydrous ethanol-acetone mixture with a volume ratio of 1:1 each time to obtain 1,3-dipyridinepropanol chloride. Mix 1,3-dipyridylpropanol chloride, rosinamine, and ethanol uniformly in a mass ratio of 60:20:20 to obtain a high-temperature composite acidification corrosion inhibitor.

[0033] In 15% HCl solution, 0.4% mass fraction of this high-temperature composite acidification corrosion inhibitor can make the corrosion inhibition rate of N80 oil pipe steel reach 99.02% at 90 °C; 0.5% mass fraction of this high-temperature composite acidification corrosion inhibitor can Make the corrosion inhibition rate of N80 oil pipe steel reach 99.39% at 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com