Imidazoline amphoteric surfactant and preparation method thereof

A technology of surfactant and imidazoline, which is applied in the field of imidazoline amphoteric surfactant and preparation, can solve the problems of environmental friendliness and low toxicity, great harm to production personnel, unfriendly environment, etc., and achieve superior corrosion inhibition performance, Strong adsorption and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

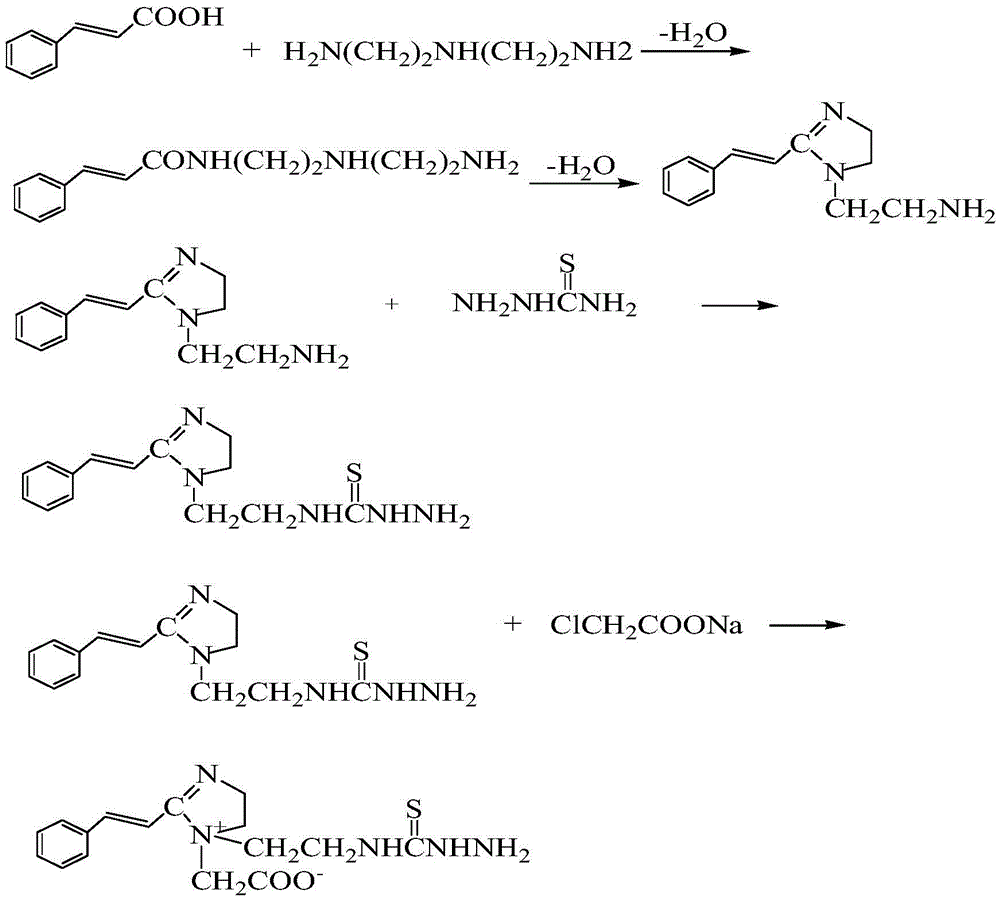

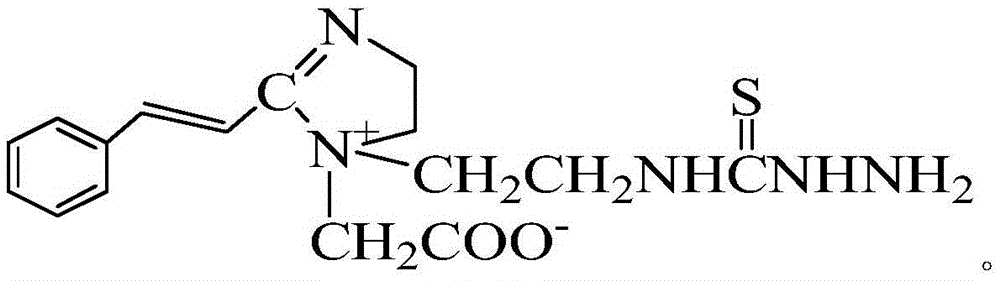

[0038] The preparation method of imidazoline amphoteric surfactant comprises the following steps:

[0039] 1) Cinnamic acid, diethylenetriamine, xylene, Al 2 o 3 Add a reflux condenser, stirrer, thermometer, water separator and N 2 In the four-necked flask of the protection device, dehydration reaction was carried out at 150°C for 4 hours. During the reaction process, water was gradually taken out by the solvent, and the water output was basically stable after 4 hours of reaction. Then the temperature was raised to 210°C, and the dehydration reaction was carried out for 4 hours. An imidazoline intermediate is obtained.

[0040] Wherein, the molar ratio of cinnamic acid and diethylenetriamine is 1:1.1, and the amount of xylene added is 20% of the total mass of cinnamic acid and diethylenetriamine; Al 2 o 3 The addition amount is 0.1% of the cinnamic acid quality.

[0041] 2) Add thiosemicarbazide and n-octanol to the imidazoline intermediate, react at 140°C for 2 hours, di...

Embodiment 2

[0046] The preparation method of imidazoline amphoteric surfactant comprises the following steps:

[0047] 1) Add cinnamic acid, diethylenetriamine, xylene, and magnesium chips to the equipment equipped with a reflux condenser, agitator, thermometer, water separator, and N 2 In the four-necked flask of the protection device, dehydration reaction was carried out at 150°C for 4 hours. During the reaction process, water was gradually taken out by the solvent, and the water output was basically stable after 4 hours of reaction. Then the temperature was raised to 220°C, and the dehydration reaction was carried out for 5 hours. Imidazoline intermediate.

[0048] Among them, the molar ratio of cinnamic acid to diethylenetriamine is 1:1.2, the amount of xylene added is 25% of the total mass of cinnamic acid and diethylenetriamine; the amount of added magnesium chips is 0.2% of the mass of cinnamic acid.

[0049] 2) Add thiosemicarbazide and n-octanol to the imidazoline intermediate, ...

Embodiment 3

[0054] The preparation method of imidazoline amphoteric surfactant comprises the following steps:

[0055] 1) Cinnamic acid, diethylenetriamine, xylene, Al 2 o 3 Add a reflux condenser, stirrer, thermometer, water separator and N 2 In the four-necked flask of the protective device, dehydration reaction was carried out at 160°C for 4 hours. During the reaction process, water was gradually taken out by the solvent, and the water output was basically stable after 4 hours of reaction. Then the temperature was raised to 230°C, and the dehydration reaction was carried out for 6 hours. Imidazoline intermediate.

[0056] Wherein, the molar ratio of cinnamic acid and diethylenetriamine is 1:1.3, and the amount of xylene added is 30% of the total mass of cinnamic acid and diethylenetriamine; Al 2 o 3 The addition amount is 0.3% of cinnamic acid quality.

[0057] 2) Add thiosemicarbazide and n-octanol to the imidazoline intermediate, react at 160°C for 4 hours, distill under reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com