A method for improving the decomposition yield of cumene hydroperoxide

A technology of cumene hydroperoxide and decomposer, which is applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of organic compounds, etc., can solve the problem of high acetone content, increase of decomposed liquid discharge flash system, isopropyl Solve the problems of high benzene consumption, achieve the effect of low acetone content, reduce energy consumption, and improve production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

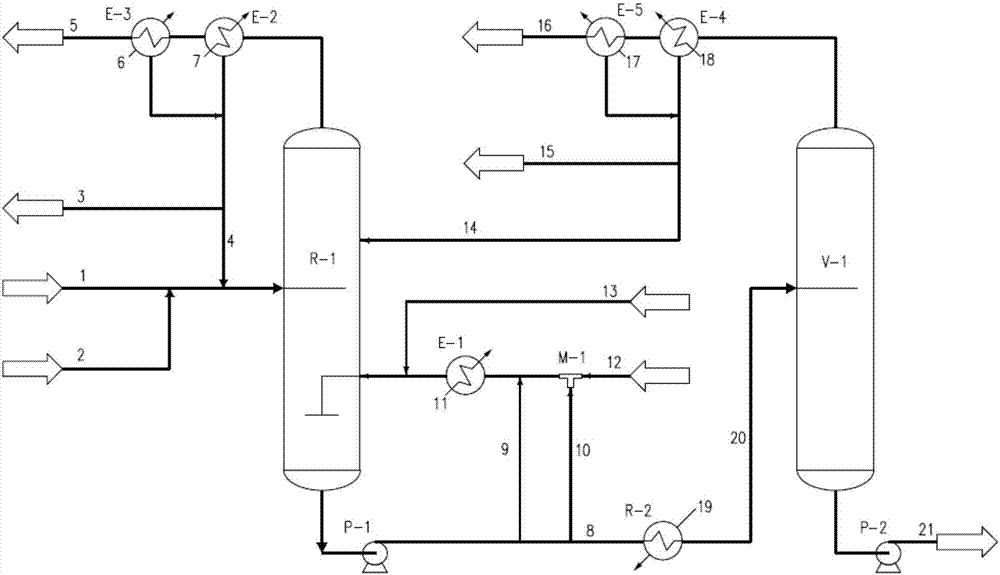

Method used

Image

Examples

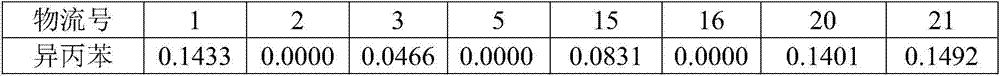

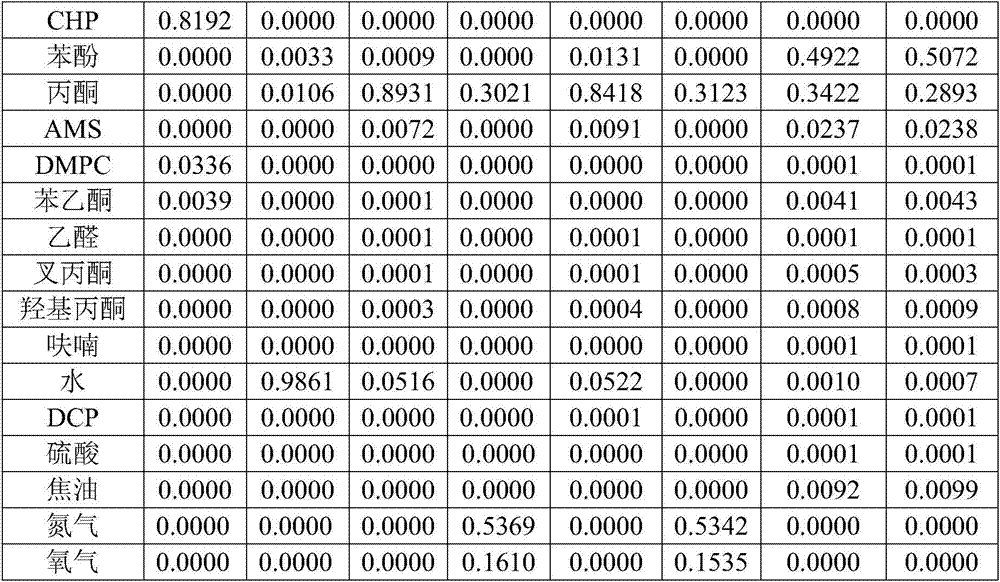

Embodiment 1

[0076] The concentrated cumene hydroperoxide solution from the oxidation unit of the phenol-acetone plant contains 81.92% cumene hydroperoxide, 14.33% cumene, 3.36% dimethyl benzyl alcohol, and 0.39% acetophenone. Send to the decomposition unit R-1 of the decomposition unit; the condensed water of the vacuum system recovered by the rectification unit is pumped into the decomposer by the rectification unit as the process adjustment water. The composition of the process adjustment water is 98.71% water content, 1.06% acetone, 0.23 %; Concentration is that the concentrated sulfuric acid of 98% divides two strands ((being specifically sulfuric acid II13 and sulfuric acid I12)) and is sent in the cracker circulation pipe by cracker discharge pump pump P-1; Cumene hydroperoxide is under the sulfuric acid catalyst Decomposition exothermic reaction occurs, the temperature of the decomposer is 62°C, the pressure is 426mmhg, the concentration of sulfuric acid is 100ppm, and the content o...

Embodiment 2

[0082] In embodiment 1, for the device of production capacity 200,000 tons of phenol acetone / year, the ratio of the sulfuric acid of two strands is 10:1 (being specifically sulfuric acid II13 and sulfuric acid I12), and recirculating cooler outlet temperature is 52 ℃, enters calorimetry The flow rate of the device) is 1.6m 3 / h, the amount of sulfuric acid added to the calorimeter is 1kg / h, the internal circulation distributor of the decomposer adopts a row-pipe type, the diameter of the injection hole is 6mm, and the number of holes is 6.

[0083] Save cumene raw material 2529 tons / year, sulfuric acid (concentration 98%) raw material 91 tons / year, caustic soda (concentration 32%) raw material 229 tons / year, circulating water 656110 tons / year, steam 3568 tons / year.

Embodiment 3

[0085] In embodiment 1, for the device of 350,000 tons of phenol acetone / year of production capacity, the ratio of the sulfuric acid of two strands is 16: 1 ((being specifically sulfuric acid II13 and sulfuric acid I12)), and circulating cooler outlet temperature is 56 ℃, amount Heater flow rate is 2.6m 3 / h, the amount of sulfuric acid added to the calorimeter is 1.7kg / h, the internal circulation distributor of the decomposer adopts the calandria type, the diameter of the injection hole is 7mm, and the number of holes is 8.

[0086] Save cumene raw material 4492 tons / year, sulfuric acid (concentration 98%) raw material 158 tons / year, caustic soda (concentration 32%) raw material 406 tons / year, circulating water 1173170 tons / year, steam 6331 tons / year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com