Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Reduce parking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parking-lot-vehicle cooperative intelligent parking system and method based on centralized vision

InactiveCN106846870AFully automatedRealize intelligenceImage enhancementImage analysisComputer terminalData management

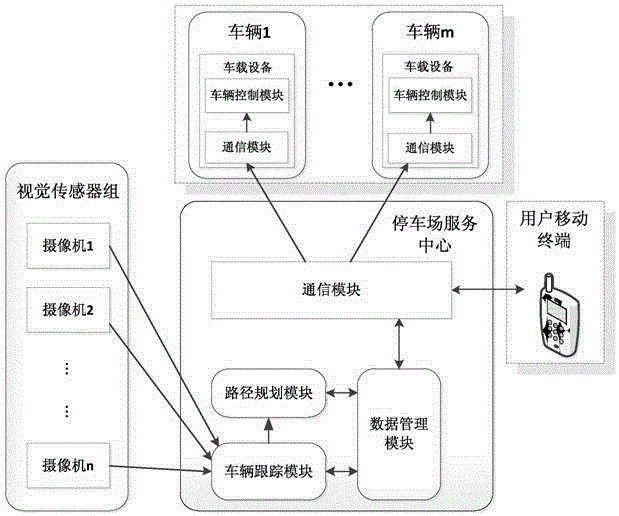

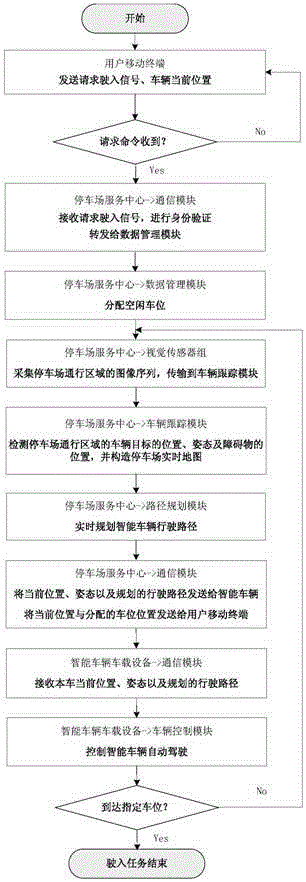

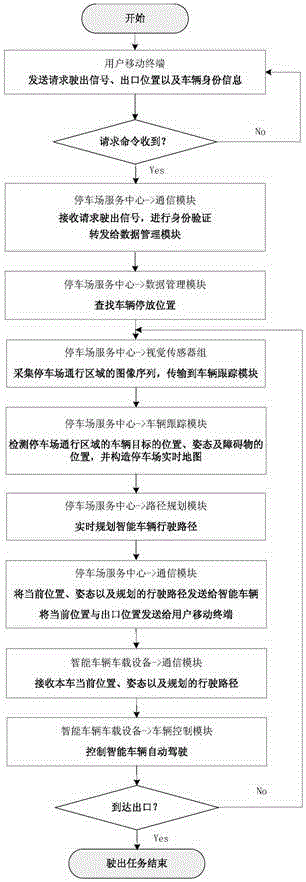

The invention relates to a parking-lot-vehicle cooperative intelligent parking system and method based on centralized vision. The system comprises a parking lot service center, an intelligent vehicle onboard device and a user mobile terminal. The parking lot service center includes a visual sensor group, a vehicle tracking module, a path planning module, a data management module and a communication module. The observation range of the visual sensor group covers all the traffic areas in a parking lot. The vehicle tracking module fuses the images collected by the visual sensor group and detects the position and the attitude of a vehicle target in the traffic area. The path planning module plans a driving route according to the current position and the attitude of the vehicle and parking stalls. The onboard device includes a communication module and a vehicle control module. The vehicle control module receives the path planned by the service center and controls the vehicle to automatically drive to the end along the path. The user mobile terminal is used to issue the request information for entering / leaving the parking lot to the parking lot service center. The parking-lot-vehicle cooperative intelligent parking system and method realize automation and intellectualization of going into or out of the parking lot.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

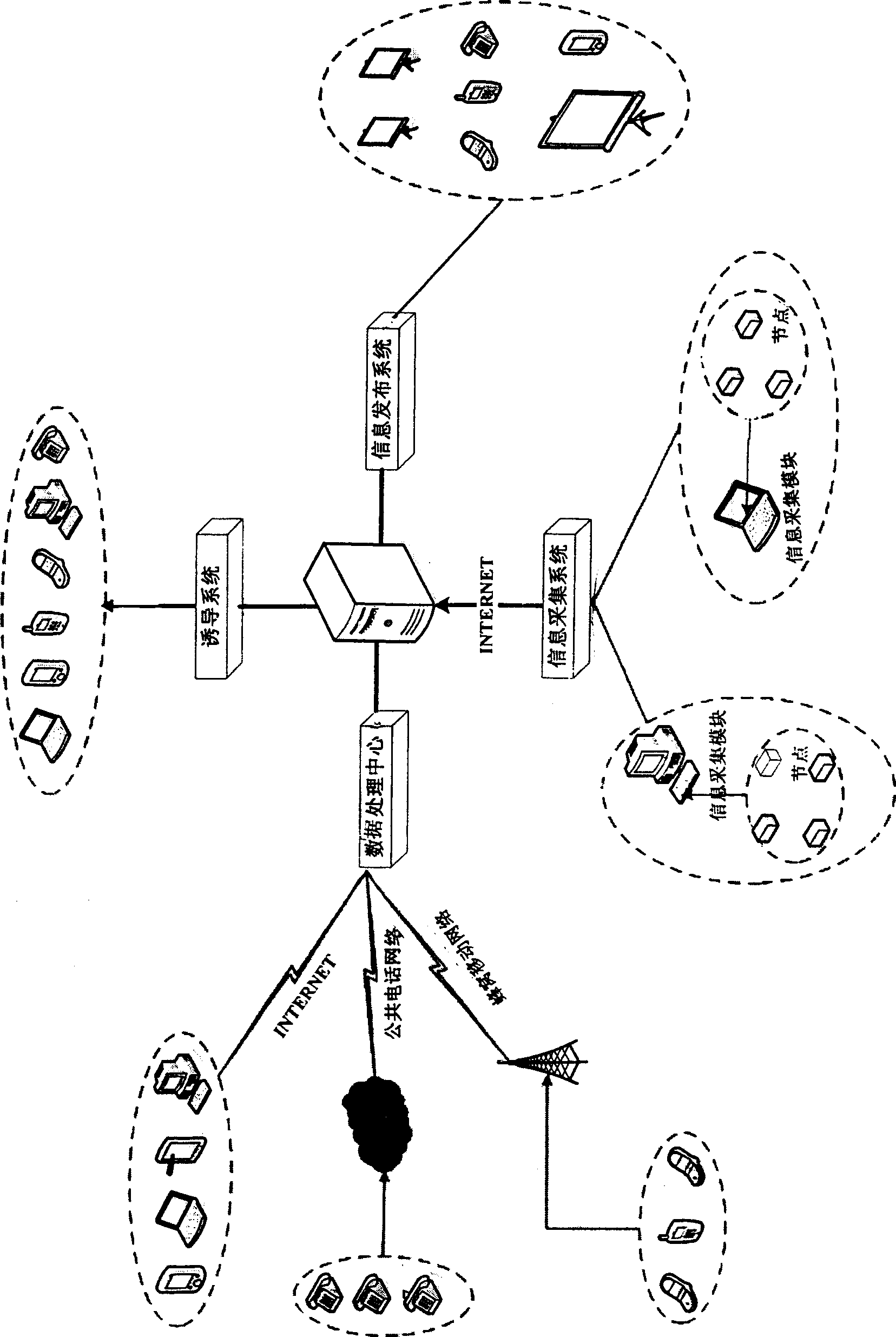

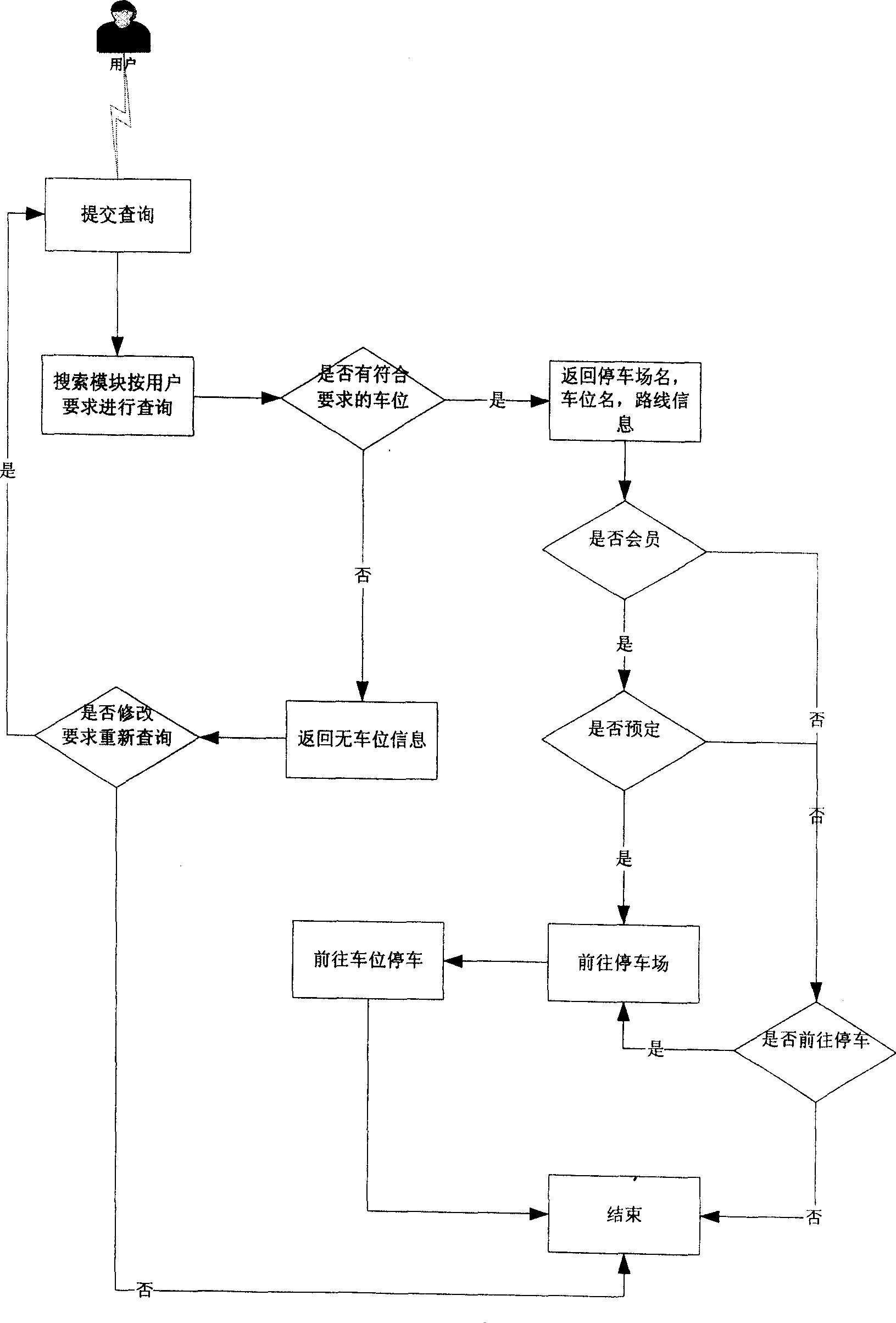

City parking position prescribing induction system based on wireless sensing network

InactiveCN101441812AReduce trafficReduce parkingTicket-issuing apparatusIndication of parksing free spacesGuidance systemInduction system

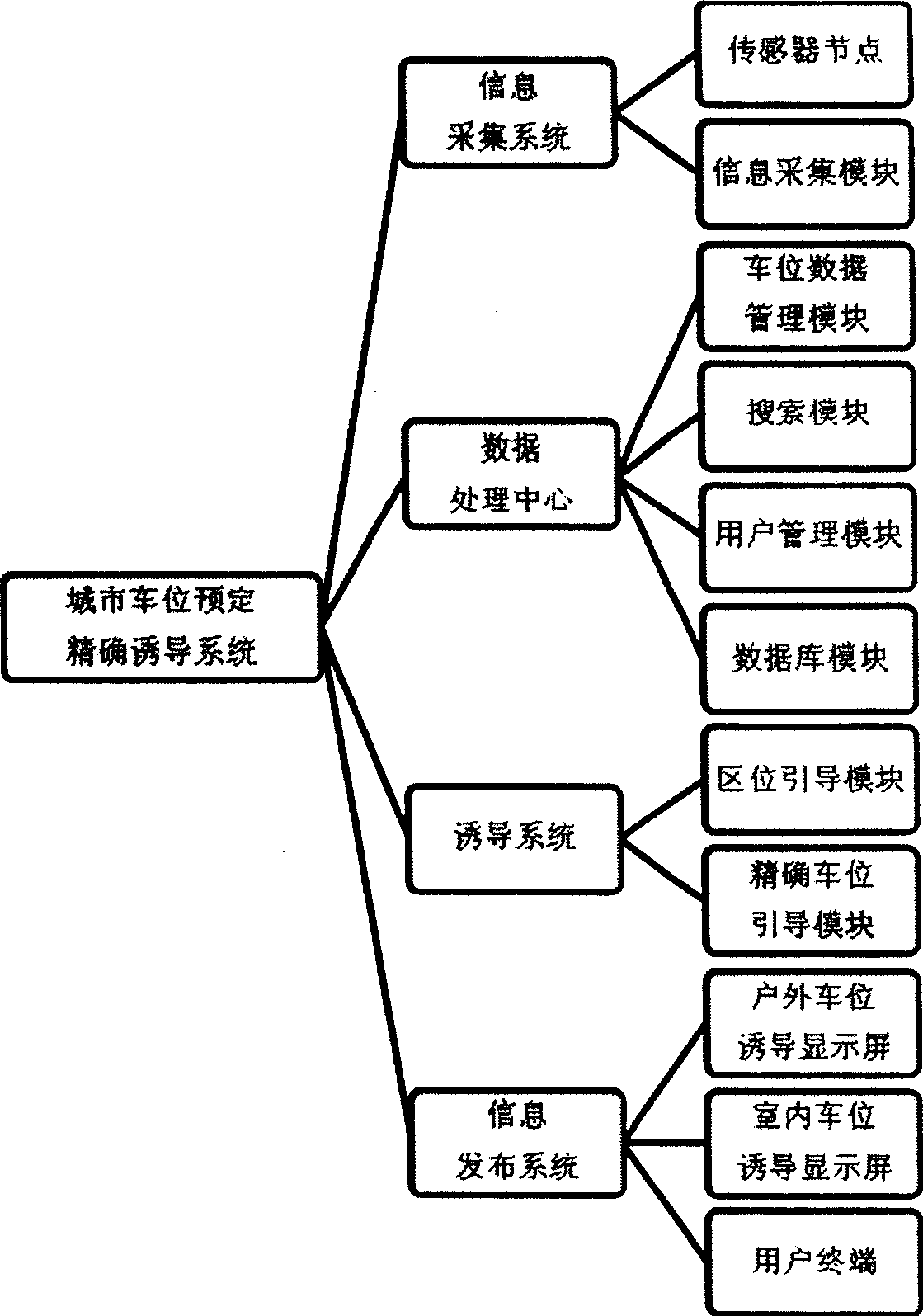

The invention relates to an urban parking space reservation and guidance system based on a wireless sensing network. An architecture used by the system comprises an information acquisition system, a data processing center, a guidance system and an information issuing system, wherein sensor nodes of the information acquisition system form the wireless sensing network to acquire parking space information and transmit parking space data to the data processing center through Internet; the data processing center receives and processes user requests and feeds back the parking space information to users through the parking space information issuing system; the guidance system provides route information and leads the users to specified parking spaces; and the information issuing system issues the urban parking space information on multiple terminals for the users to browse and select. By adoption of the architecture, any user can submit a parking space search request to the data processing center through the Internet, a public telephone network, a cellular mobile network and so on at any time and places, reserve satisfactory parking space, and quickly and conveniently obtain a garage and a parking space when led by the guidance system. The parking space reservation and precise guidance system utilizes the instantaneity and the convenience of network and science and technology to solve the problem that parking spaces are difficult to obtain.

Owner:JIAXING WIRELESS SENSOR NETWORKS CENT CAS

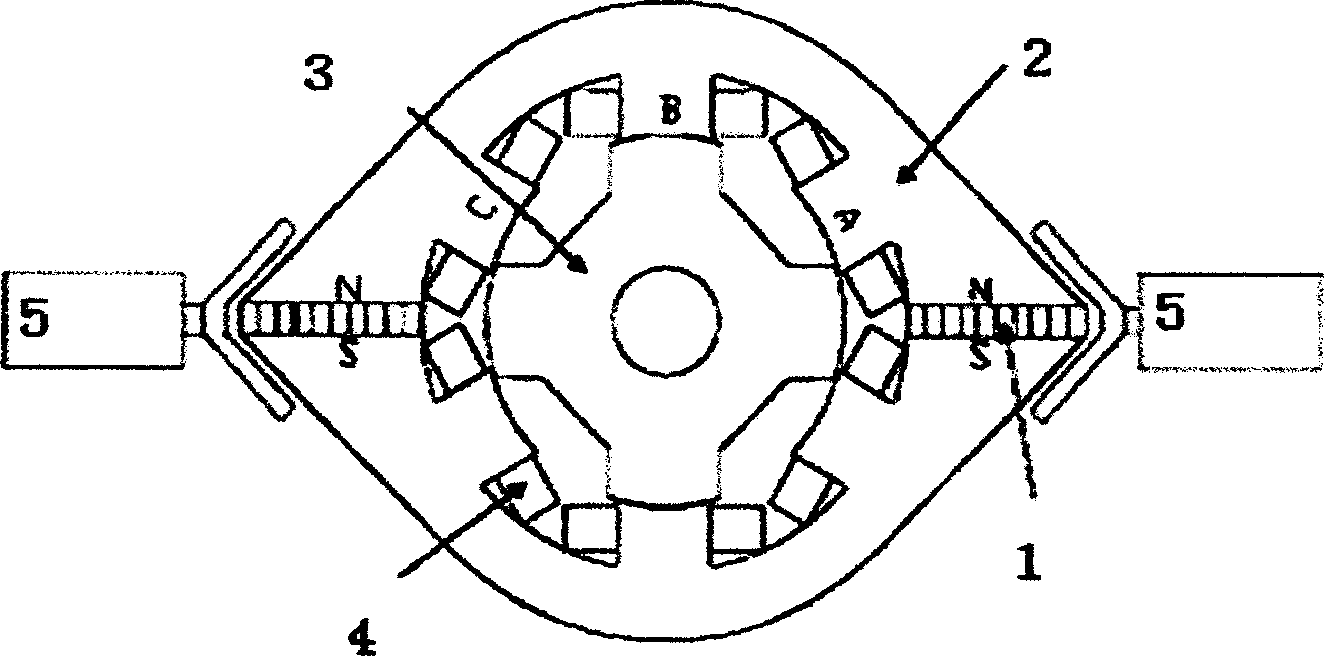

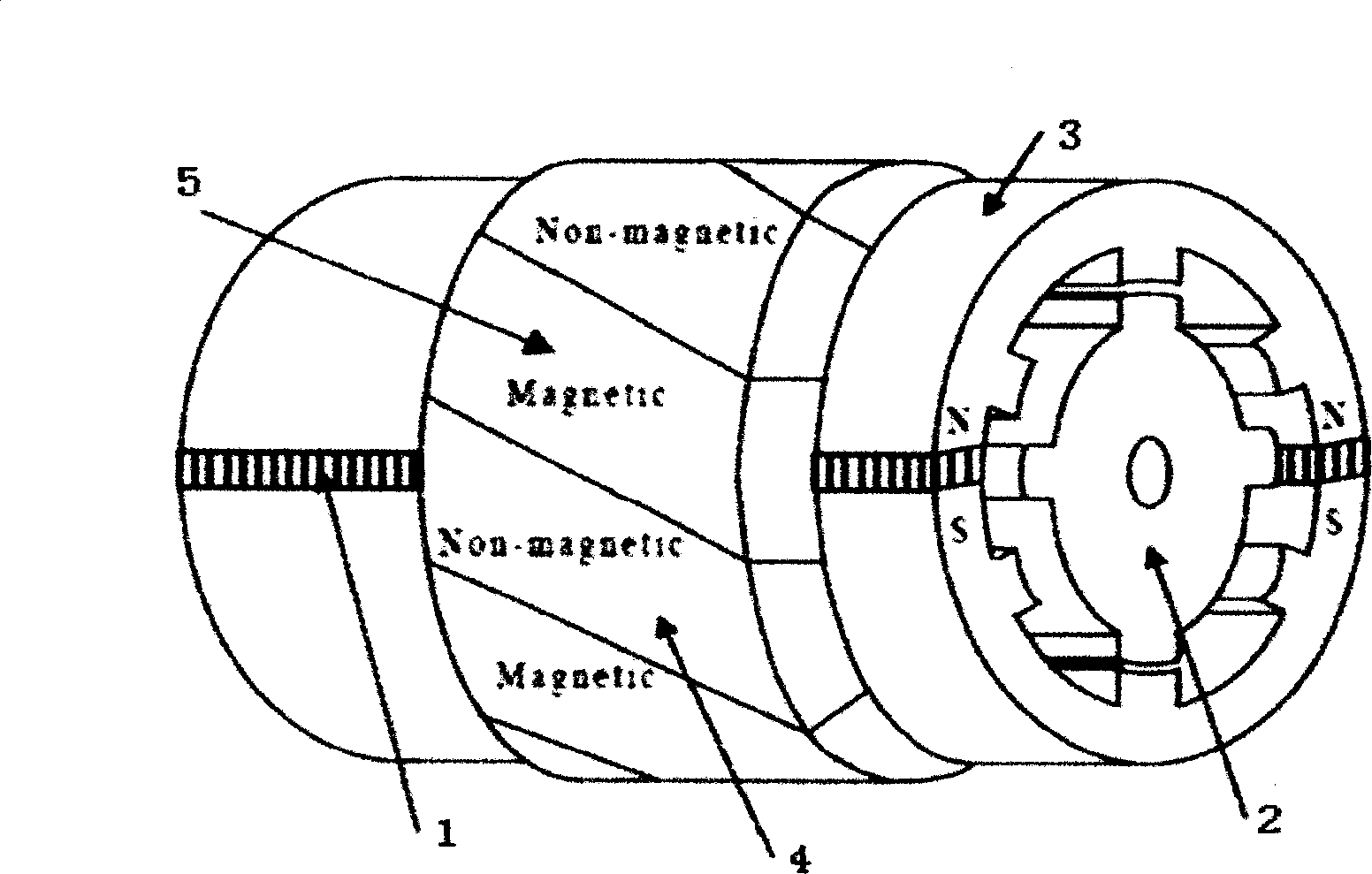

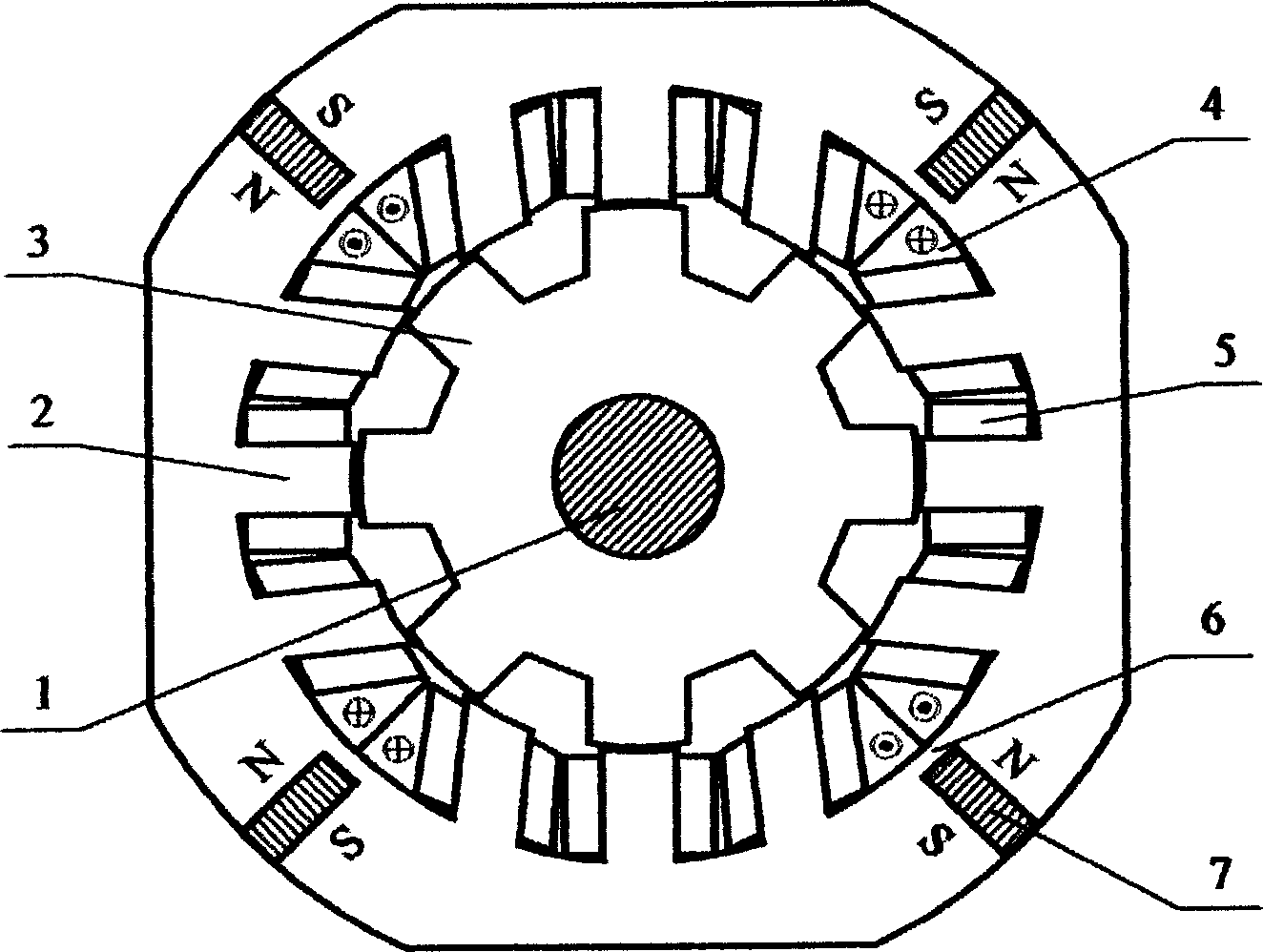

Wide governing, double salient pole, mixed excitation brushless dynamo and weak magnet control method thereof

InactiveCN1601855AWide range of constant power speed regulationSmall magnetic resistanceMagnetic circuit stationary partsDC commutatorMagnetic orientationDynamo

The motor includes following structure: DC exciting coil are setup between armature windings on stator; corresponding permanent magnet is setup at outboard of the DC exciting coil; there is bridge of guiding magnetism between DC exciting coil and the permanent magnet; direction of magnetic field is along circumferencial direction in motor. Method of mixed excitation of combining permanent magnetism excitation with electricity excitation is adopted in weak magnetism control method for controlling excitation of motor. The method increases regulating range by using smaller electricity excitation, suitable to application needed of changing speed in large range.

Owner:SOUTHEAST UNIV

Shared bicycle controlled site map and location and service big data system

ActiveCN107154006APrecise optimization serviceReduce parkingInstruments for road network navigationData processing applicationsData systemBig data management

The invention provides a shared bicycle controlled site map and location and service big data system comprising a shared bicycle cloud service platform. The shared bicycle cloud service platform comprises a preset parking site big data management module, a no-parking big data management module, a preset parking site optimization route big data management module, a cloud computing analysis module, a third-party professional organization oriented warning module, a popularity big data management module, a high-credit user management module, a credit big data management module, and a cloud service platform two-way transmission module. A user mobile terminal system comprises a user mobile terminal two-way transmission module, a surrounding check module, a start module, a navigation positioning location information acquisition module, a customer credit query module, a hotspot demand display module, and a specified location area type display module. The system can overcome the problem that precise demand popularity guidance and restriction cannot be realized due to low precision of shared bicycle parking sites and routes.

Owner:陈树铭

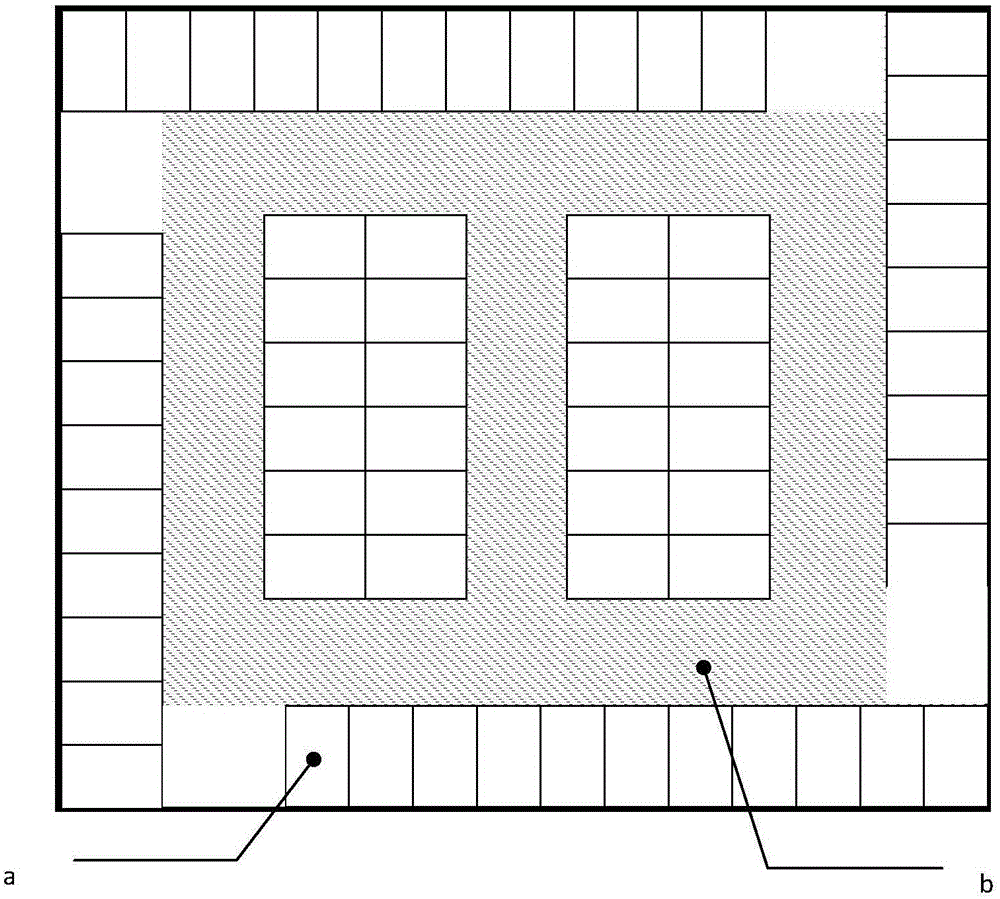

Parking lot facility capable of space saving

The invention discloses a parking lot facility capable of space saving. The facility is composed of circulated connecting tracks, multiple movable parking places combined with the circulated connecting tracks, and track opening ends, wherein each movable parking place can separately move along the circulated connecting tracks at will, at least one track opening end is connected to the circulated connecting tracks, and at least one movable parking place can be stored by the track opening end; and each circulated connecting track is a square-shaped circulated connecting track or an annular circulated connecting track, and the tracks are parallel double-track tracks or groove-shaped tracks. The facility disclosed by the invention has the advantages that the structure is simple; the facility is suitable for large or middle-sized parking lots in cities; and the problem of difficult parking in the cities can be relieved.

Owner:宁波欧冠环境科技有限责任公司

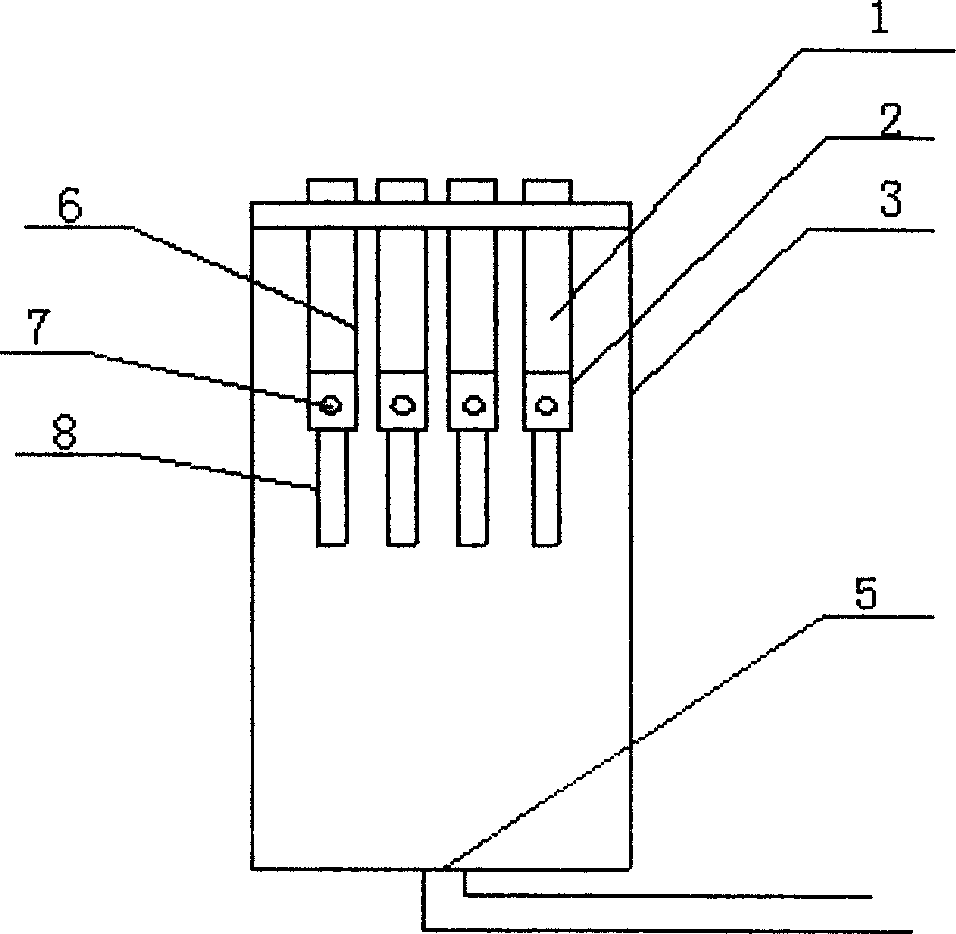

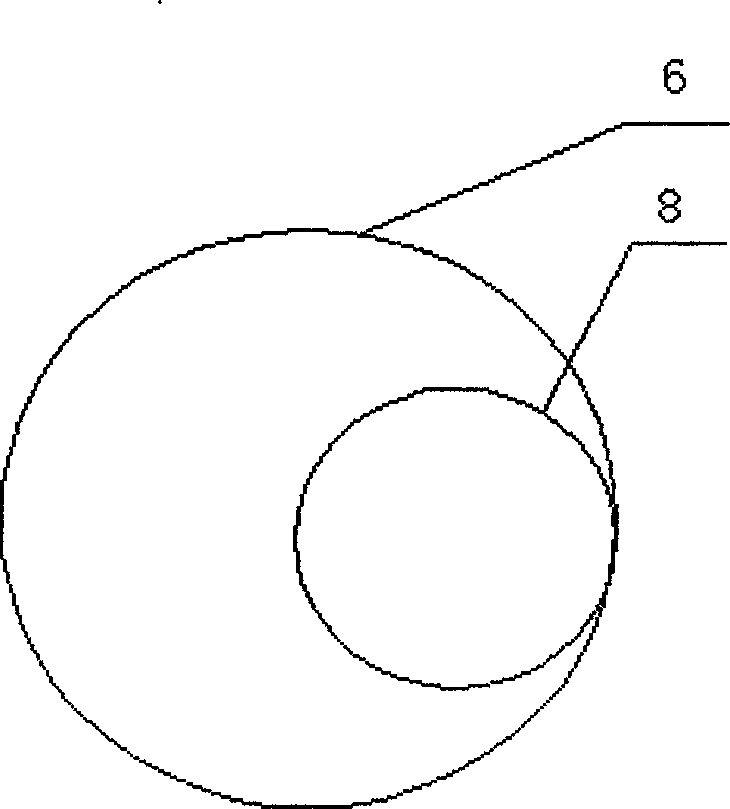

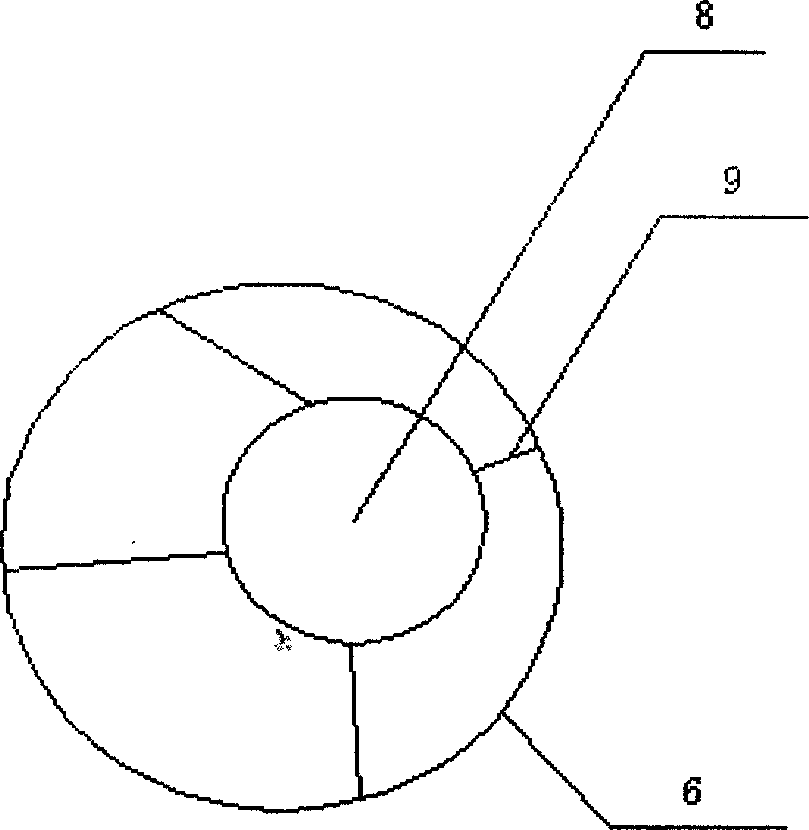

Uniform phase distribution device in liquid contained multiphase fluidized system

A uniform phase-distributing apparatus in the liquid-contained multi-phase fluidizing system where the density of solid phase is higher than that of liquid phase features that the material feeding inlet is arranged on the bottom of case, the sleeve pipe structure consisting of at least two nested pipes is arranged on the top of case, and the predistributor and master distributor are used. Its advantage is stable fluidizing state.

Owner:TIANJIN UNIV

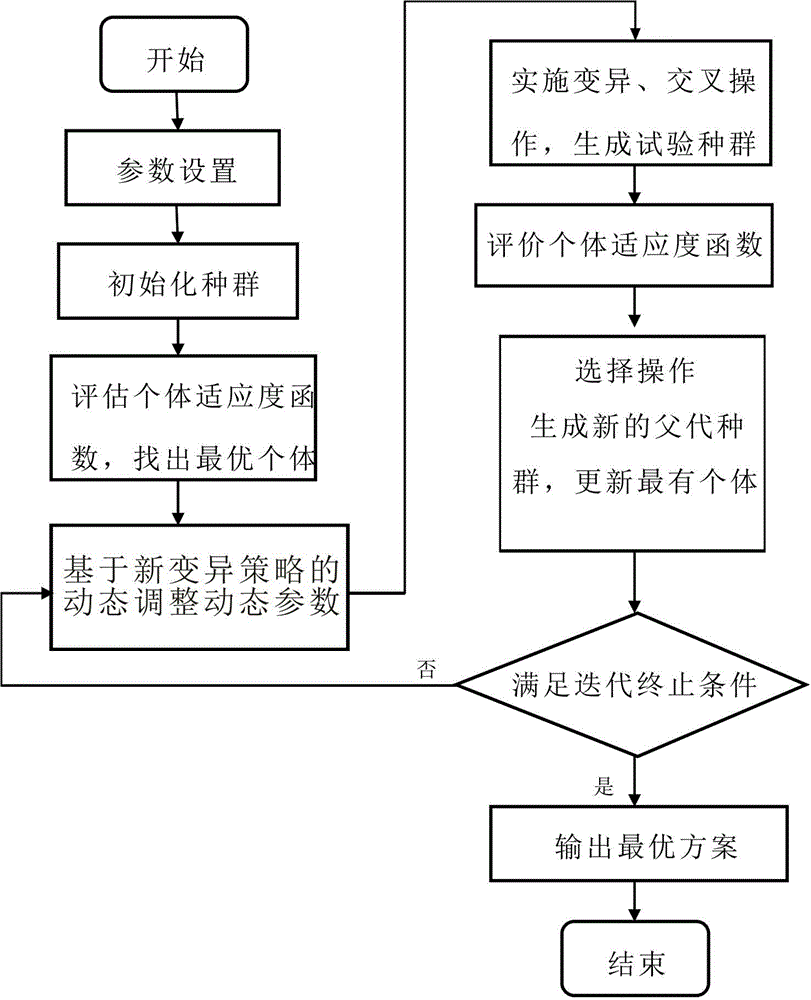

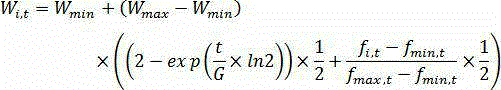

Traffic coordination control method of multiple intersections

InactiveCN104021686ASolve high-dimensionalSolve nonlinear problemsControlling traffic signalsHigh dimensionalitySimulation

The invention relates to a traffic coordination control method of multiple intersections, belonging to the technical field of intelligent transportation. The method comprises the following steps: (1) establishing an intersection transportation control model containing mixed traffic flows; (2) solving the established intersection transportation control model containing the mixed traffic flows by using a chaos differential evolution algorithm. The method has the beneficial effects that the constraints of the mixed traffic flows are taken into account, and then, the traffic conditions of the intersections are more accurately reflected, so that a signal coordination scheme developed based on the traffic conditions is more reliable; minimum vehicle delay, minimum stop number and maximum pass capacity are targeted, so that the effectiveness of traffic coordination control is improved to the maximum. The traffic control method of the intersections containing the mixed traffic flows, based on the chaos differential evolution algorithm, disclosed by the invention, has the advantage that the problems of high dimensionality, nonlinearity and multiple constraints of the intersections can be excellently solved.

Owner:GUANGDONG UNIV OF TECH

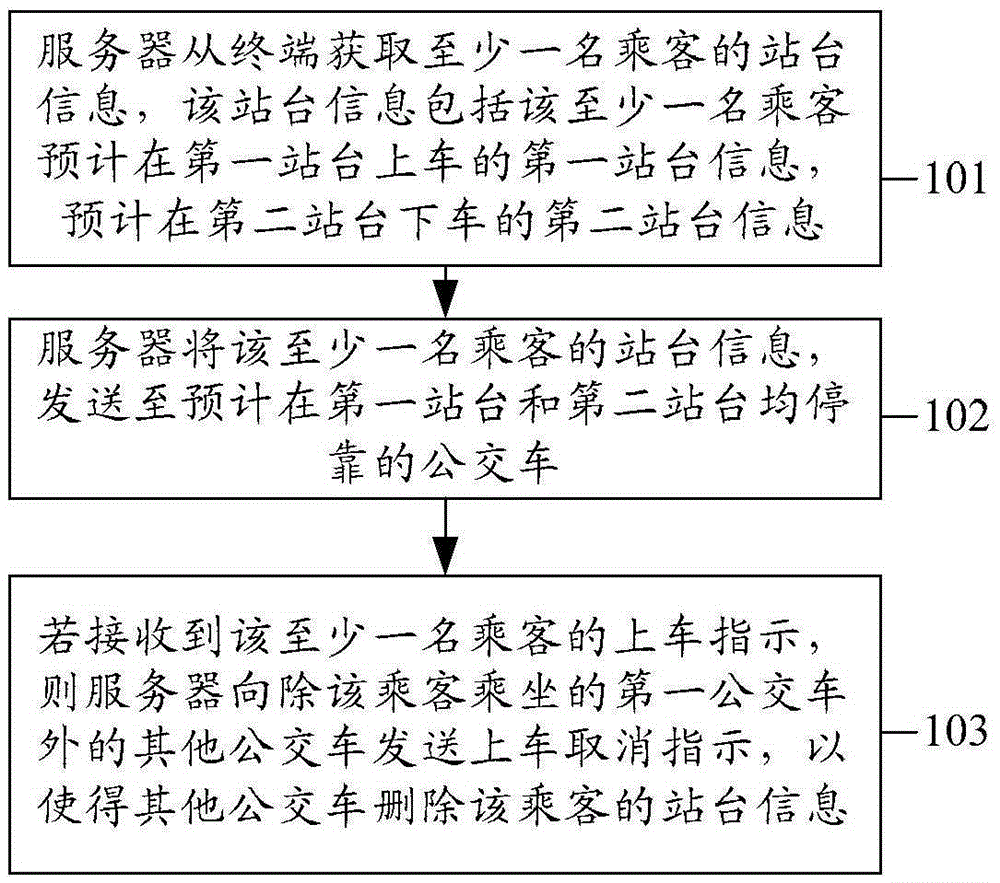

Method, device and system for bus information interaction

InactiveCN105405088AReduce parkingExtended service lifeData processing applicationsRoad vehicles traffic controlComputer terminalTransit bus

The invention provides a method, a device and a system for bus information interaction, relates to the communication technology field, can reduces unnecessary stop in a bus travelling process and alleviates traffic jam. The method comprises steps that, station information of at least one passenger is acquired by a server from a terminal, the station information comprises information of a first station from which the passenger may get on a bus and information of a second station from which the passenger may get off the bus; the station information of the at least one passenger is sent by the server to buses which stop at the first station and the second station; a get-on indication of the at least one passenger is received, a get-on cancellation indication of the at least one passenger is sent by the server to other buses except the first bus taken by the least one passenger, so the station information of the at least one passenger can be deleted from other buses. The method is applied to a station stop process of the buses.

Owner:BOE OPTICAL SCI & TECH +1

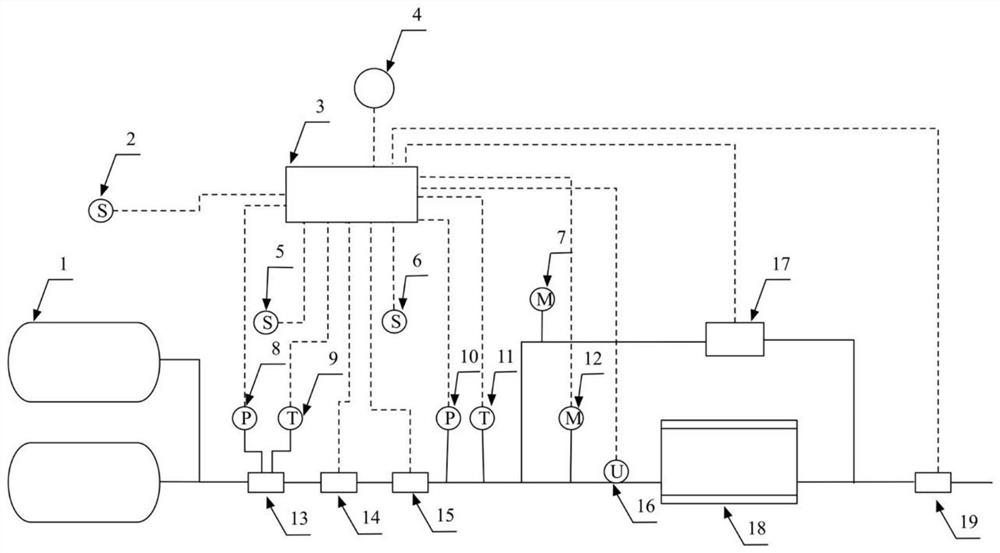

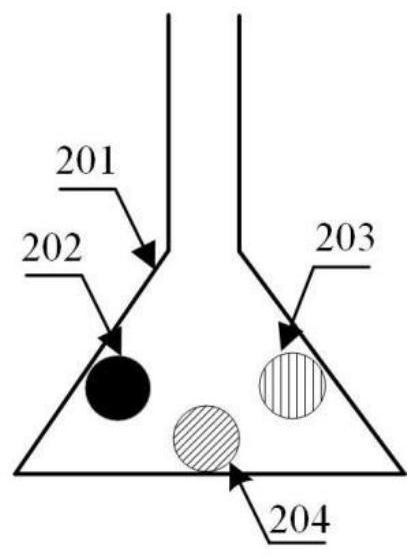

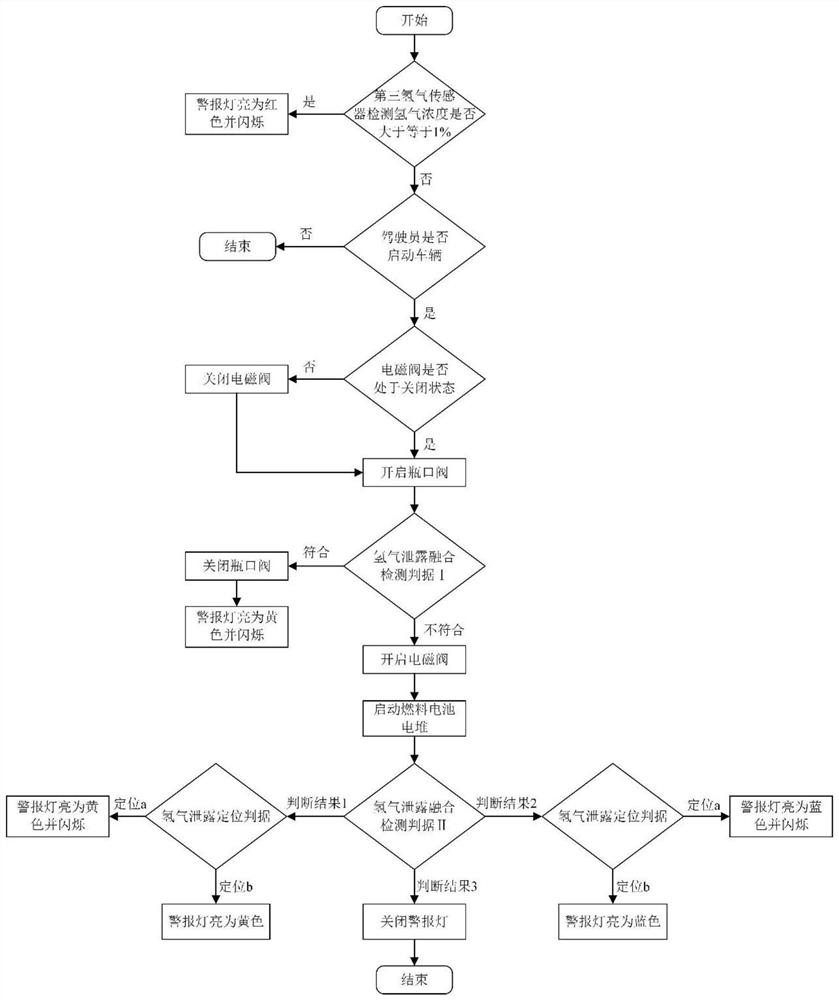

Leakage fusion detection system and method for vehicle-mounted hydrogen supply system

The invention provides a leakage fusion detection system and method for a vehicle-mounted hydrogen supply system. The system comprises a hydrogen storage bottle, a bottle opening valve, a hydrogen supply pipeline, a fuel cell stack, an exhaust recovery system, and a leakage fusion detection system. The leakage fusion detection system comprises a controller, a hydrogen sensor array, a pressure sensor, a temperature sensor, an ultrasonic sensor array, a gas mass flow sensor and an alarm lamp; and according to a grading result of a hydrogen leakage fusion detection criterion II, whether large leakage or small leakage exists in the vehicle-mounted hydrogen supply system or not is determined, then a hydrogen leakage position is judged according to a positioning result, and according to the leakage position, the alarm lamp gives an alarm in different modes. The fusion detection method adopted by the invention can enhance the accuracy of hydrogen leakage detection.

Owner:合肥龙智机电科技有限公司

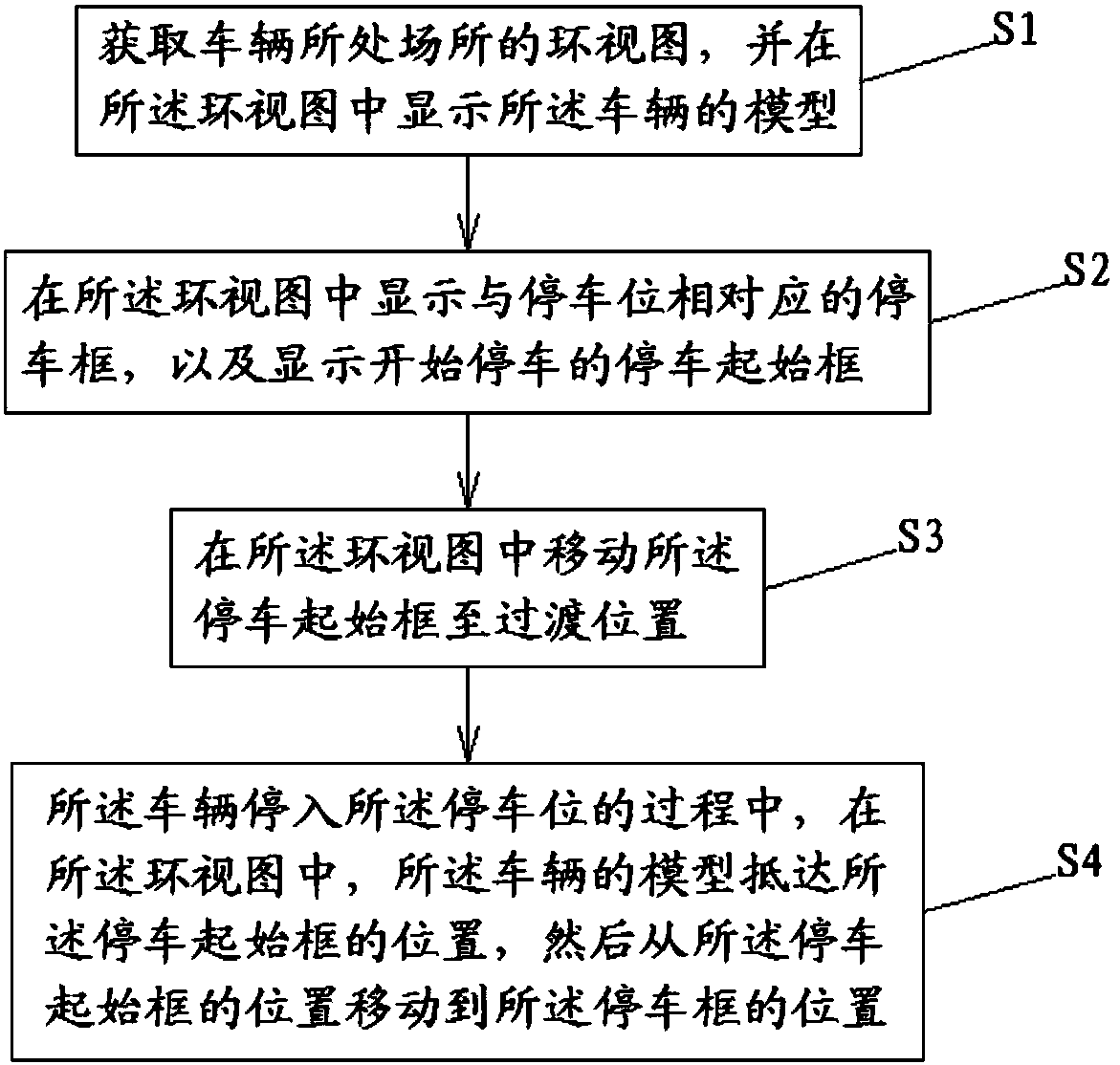

Auxiliary parking method

The invention discloses an auxiliary parking method. The method includes the steps of 1, obtaining a panorama map of a place where a car is positioned, and displaying a model of the car in the panorama map; 2, displaying a parking frame corresponding to a parking space in the panorama map, and displaying a parking starting frame for starting parking; 3, moving the parking starting frame to a transition position in the panorama map; 4, in the process that the car is parked into the parking space, in the panorama map, making the model of the car to reach the position of the parking starting frame and then move from the position of the parking starting frame to the position of the parking frame. Through the guidance function of the parking starting frame, the parking frame, a first path, a second path and a prospective proceeding path, the car can conveniently and accurately achieve parking posture adjustment at an optimum distance, therefore one-step accurate position entering of the caris achieved, repeated car position or posture adjustment caused by the situation that the car cannot enter the position accurately is further avoided, the parking difficulty is reduced, and the parking time is saved.

Owner:上海为森车载传感技术有限公司

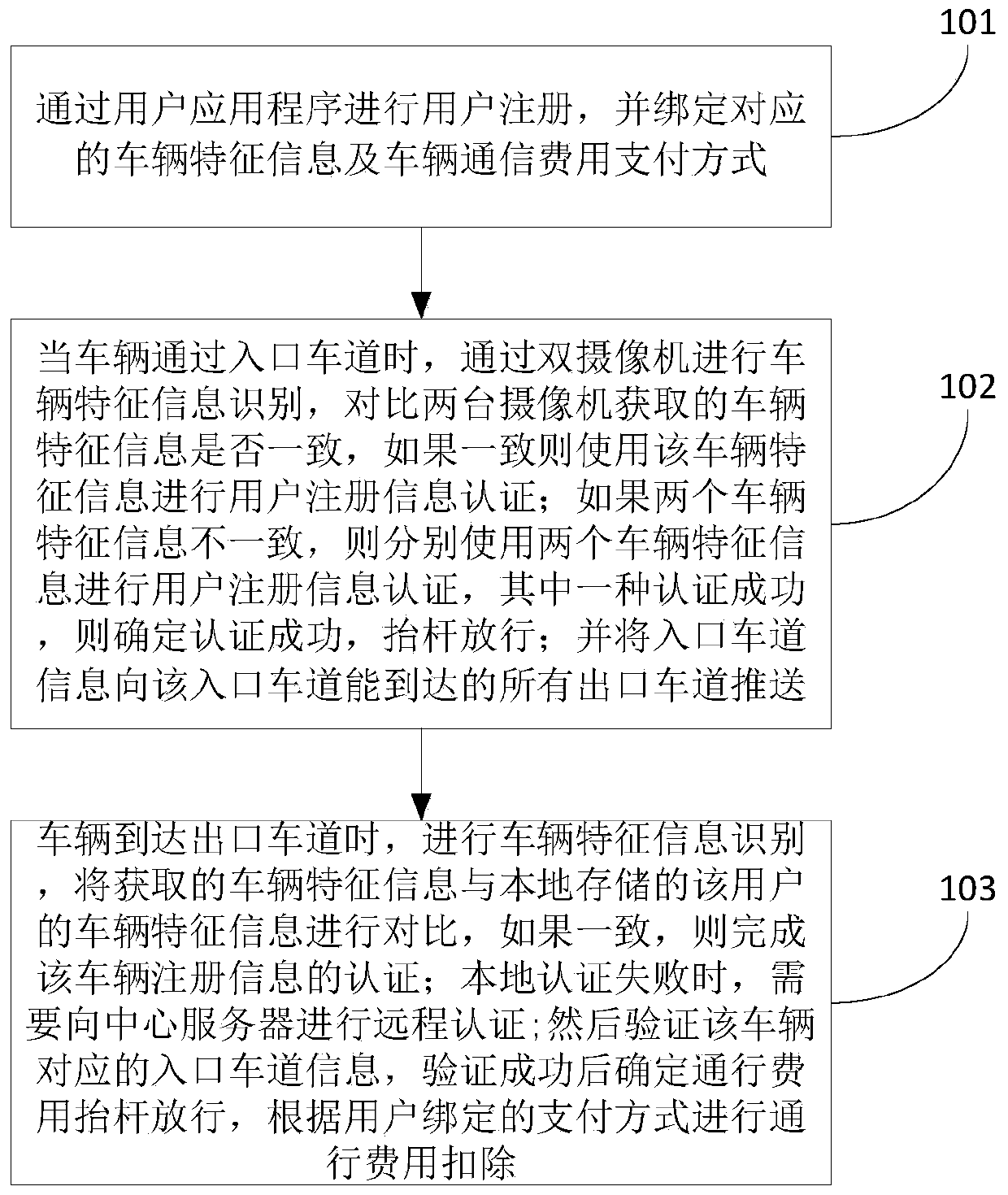

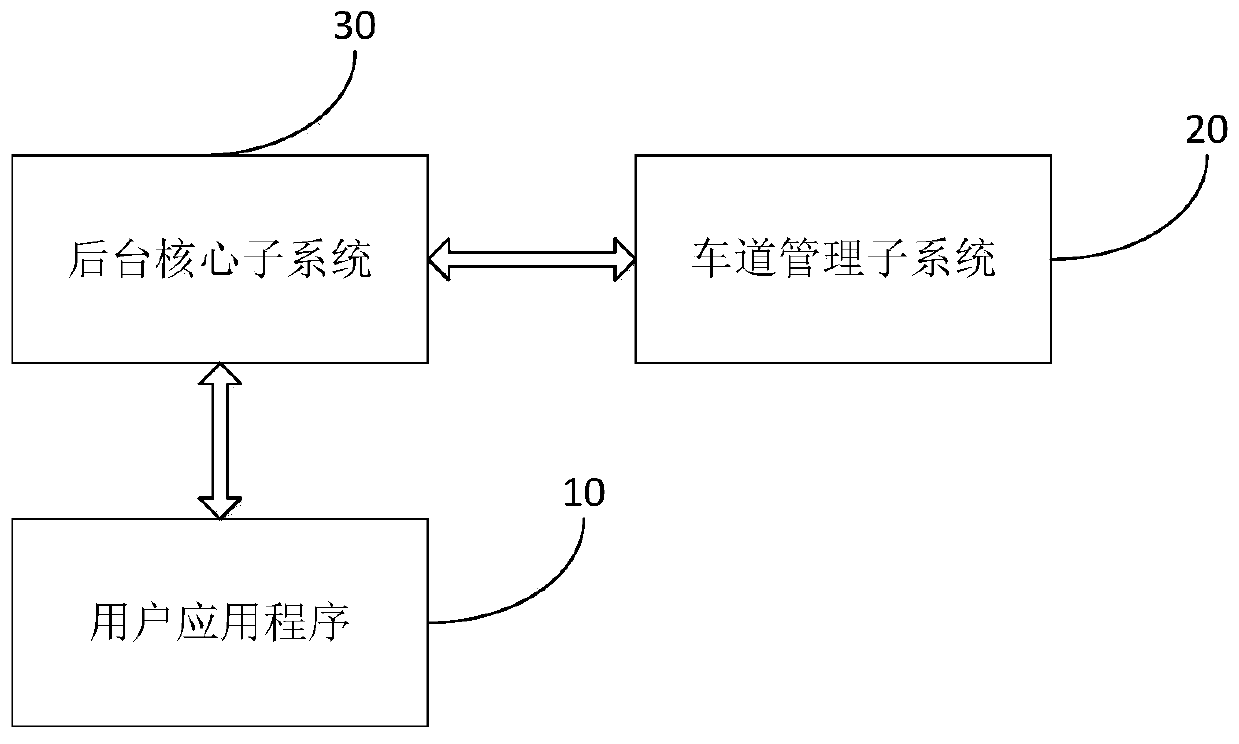

Non-stop toll collection passing method and system based on vehicle feature recognition

InactiveCN111063046AImprove recognition accuracyImprove traffic efficiencyTicket-issuing apparatusRoad vehicles traffic controlSimulationParking problem

The invention discloses a non-stop toll collection passing method based on vehicle feature recognition, and the method comprises the steps: carrying out user registration through a user application program, and binding corresponding vehicle feature information and payment mode; when a vehicle passes through an entrance lane, carrying out vehicle feature information identification and authentication through double cameras, and after authentication succeeds, lifting a lever to release the vehicle; pushing the entrance lane information to all exit lanes which can be reached by the entrance lane;and when the vehicle arrives at the exit lane, verifying the entrance lane information corresponding to the vehicle after successful identification and authentication according to the vehicle featureinformation, determining passage fee and lifting the lever to release the vehicle after successful verification, and deducting the passage fee according to the payment mode bound by the user. The invention further discloses a non-stop toll collection passing system based on vehicle feature recognition. According to the invention, vehicle feature information identification is carried out through the double cameras, so that the identification accuracy is improved, the parking problem caused by abnormal system license plate identification is reduced, and the high-speed service quality and the charging efficiency are improved.

Owner:亿雅捷交通系统(北京)有限公司 +2

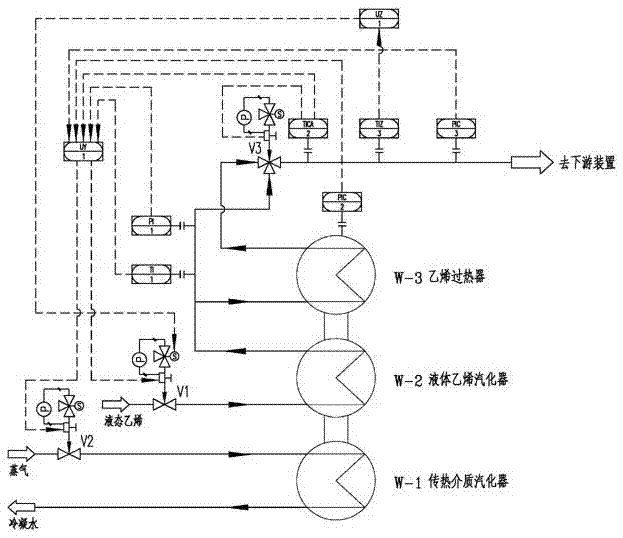

Automatic control system and control method of low-temperature ethylene vaporizer

InactiveCN107065982AImprove running stabilityReduce the difficulty of operationSimultaneous control of multiple variablesAutomatic controlEngineering

The invention relates to an automatic control system and control method of a low-temperature ethylene vaporizer. The control system comprises temperature transmitters for medium temperature measurement, pressure transmitters for medium pressure measurement, a control system for vaporizer automatic control, an emergency shutdown system for safe shutdown interlocking under emergency conditions, and regulating valves used for ethylene vaporization temperature and pressure regulation and vapor temperature and pressure regulation; the temperature transmitters are mounted on a pipeline to measure ethylene temperature and vapor temperature in the pipeline, and heat transfer medium temperature in the vaporizer; and the pressure transmitters are installed on the pipeline to measure ethylene pressure and vapor pressure in the pipeline and heat transfer medium pressure in the vaporizer. The automatic control system and control method have the advantages of reasonable composition and rapid and reliable regulation, and can reduce the work difficulty and strength of operators and improve the stability of the operation of equipment.

Owner:ZHEJIANG XIN RUI AIR SEPARATION PLANT CO LTD

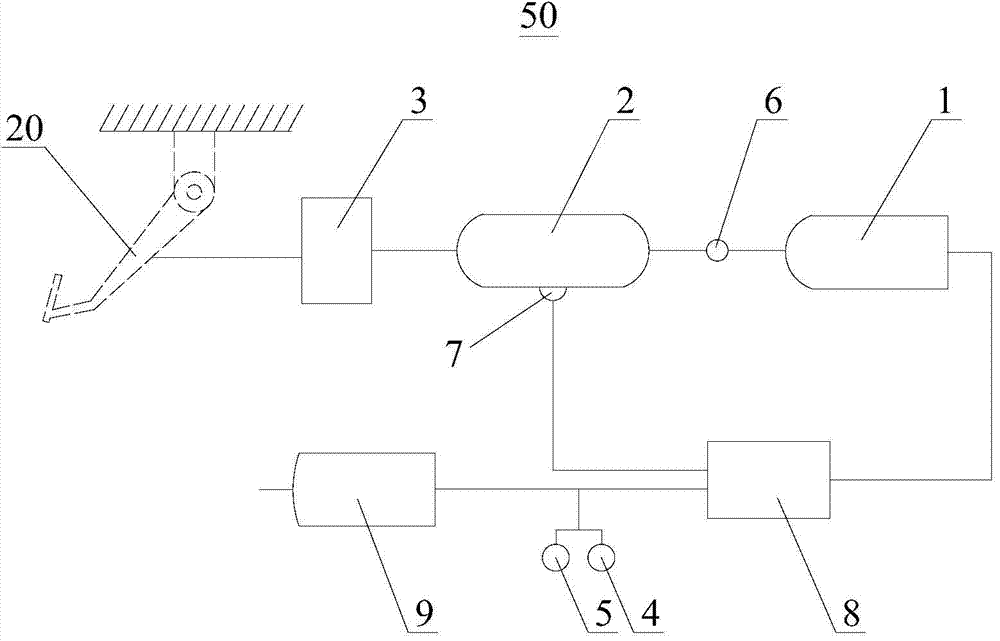

Vacuum boosting system and method of electric automobile

ActiveCN103481883AEnsure safetySecurity solutionsBraking action transmissionBrake safety systemsElectric machineDrive motor

The invention provides a vacuum boosting system and method of an electric automobile. The vacuum boosting system comprises a booster connected onto a brake device, a gas storage part connected with the booster, a sensor arranged on the gas storage part and used for detecting the vacuum degree, a vacuum pump connected to the gas storage part and used for adjusting the vacuum degree in the gas storage part and a driving motor capable of driving the electric automobile. The driving motor can enable the electric automobile to slow down or stop through setting when the vacuum degree detected by sensor is smaller than an alarm value. The vacuum boosting system of the electric automobile can assist the brake device to performing braking of the electric automobile and can effectively and actively reduce the running speed or enable the electric automobile to stop when breaking down or being in the dangerous situation, and therefore the safety of passengers is ensured.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

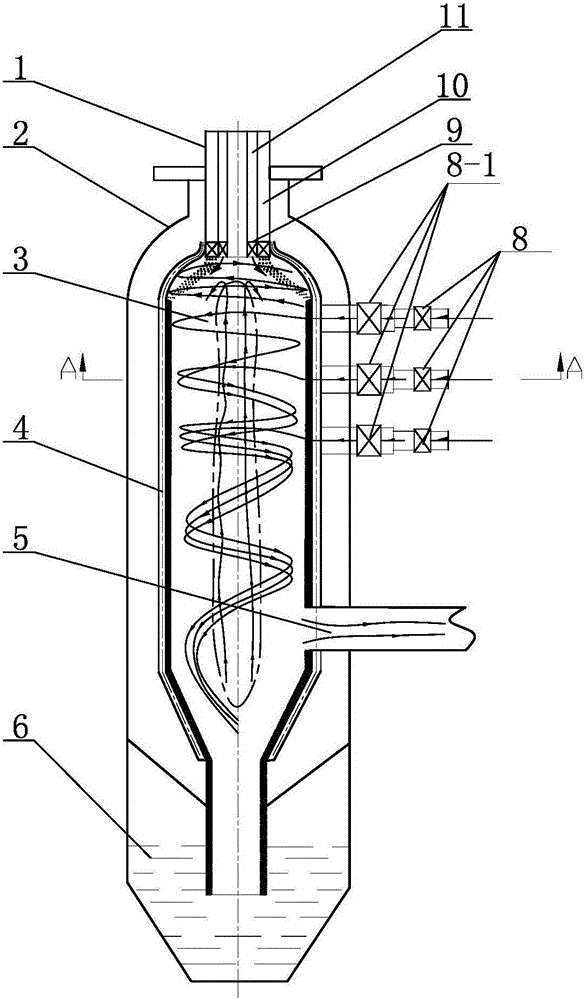

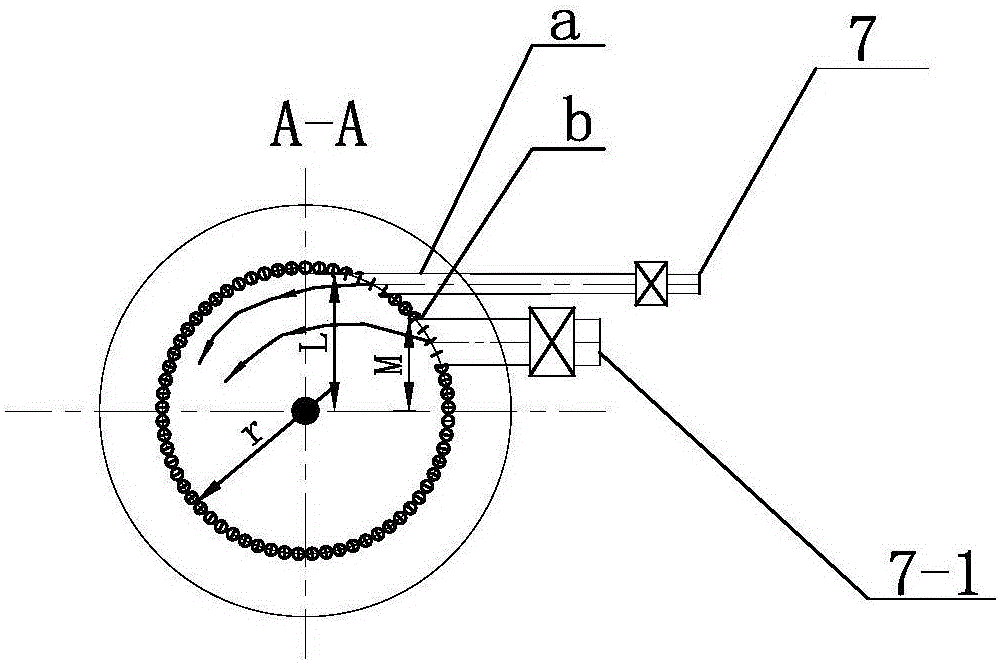

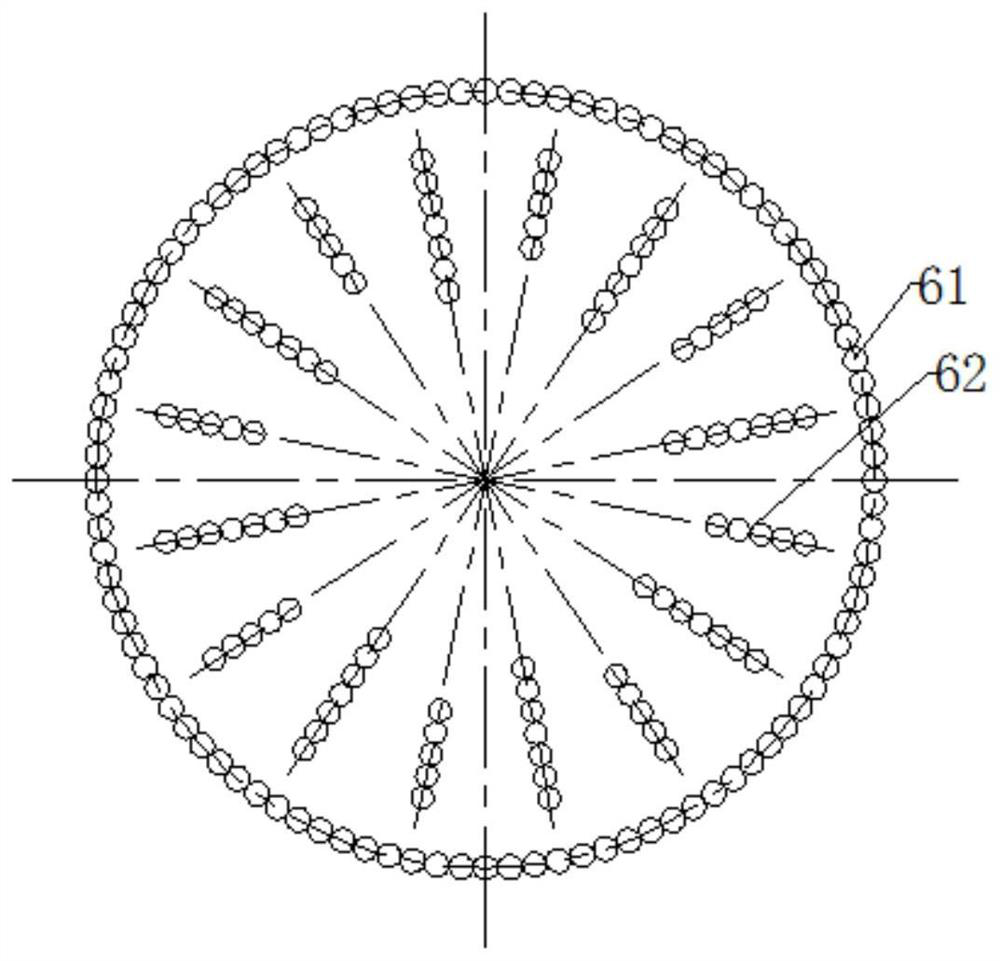

"Oxygen in water " strong swirl pulverized coal gasifier to prevent burning loss of furnace wall

InactiveCN106221813AReduce the temperatureExtended service lifeGasification processes detailsGasification apparatus detailsProduction lineWater vapor

The invention relates to a pulverized coal gasification furnace, and provides an " oxygen in water " strong swirl pulverized coal gasifier to prevent burning loss of furnace wall. The invention solves the problems that the area near the spraying spot of a furnace gasification agent of a gasification furnace wall surface is easy to be burnt in the prior art. The problem causes shut-down of the gasifier and the outage of an entire production line, resulting in huge economic losses. The gasifier includes a pulverized coal burner, a gasification furnace, a water cooling wall, a synthetic gas channel pipe, a swirl vane, a plurality of water steam nozzle tubes and a plurality of oxygen nozzle tubes. The water cooling wall comprises a plurality of vertical circular pipes side by side, and is arranged inside the gasifier; the top of the gasification furnace is provided with the pulverized coal burner; the pulverized coal burner is provided with a pulverized coal channel and a water vapor and oxygen mixed gas channel; the water vapor and oxygen mixed gas channel is in the pulverized coal channel; the swirl vane is arranged in the pulverized coal burner. The invention belongs to the field of coal gasification.

Owner:HARBIN INST OF TECH

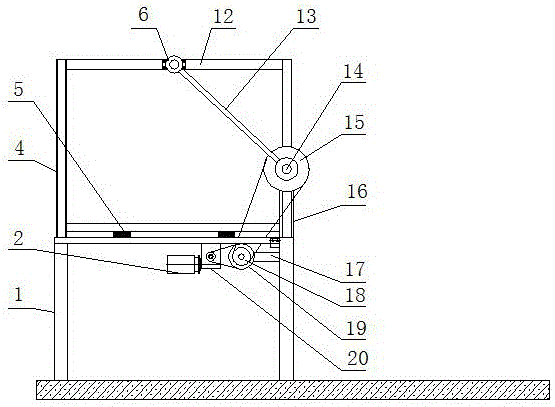

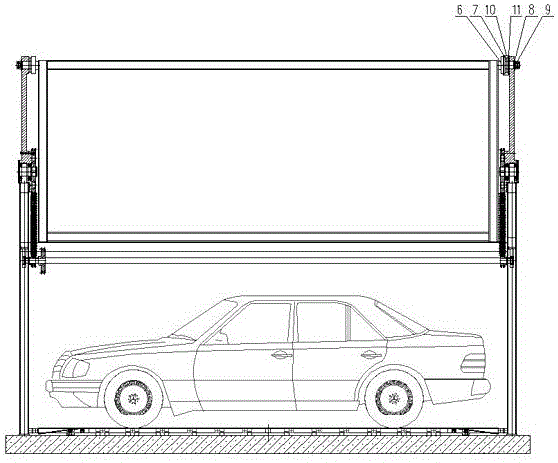

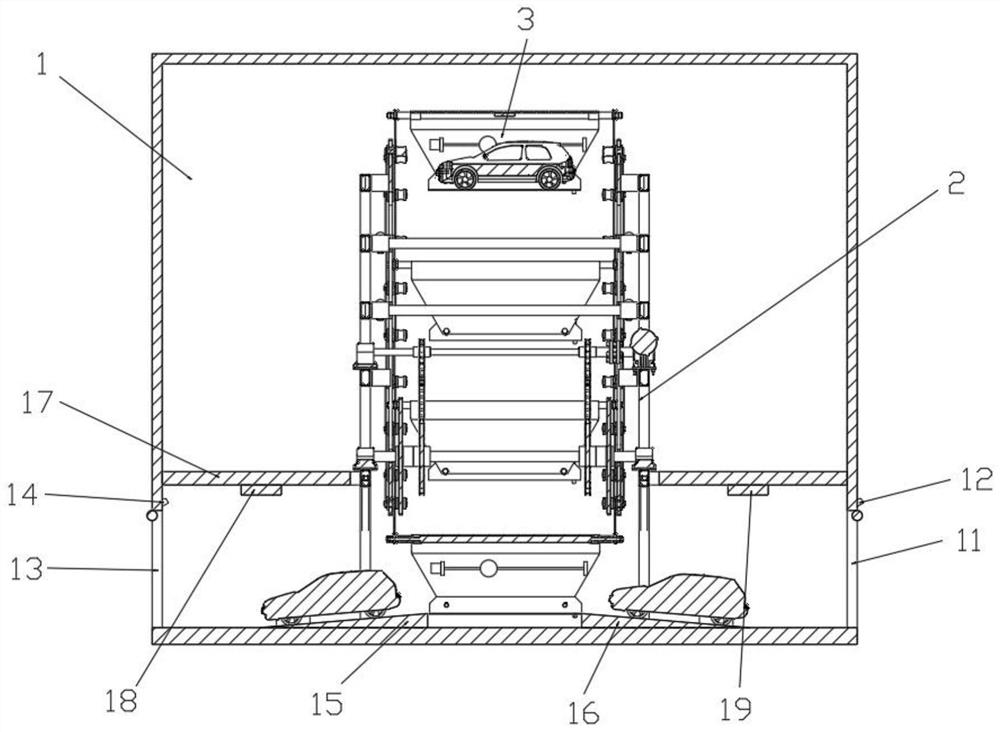

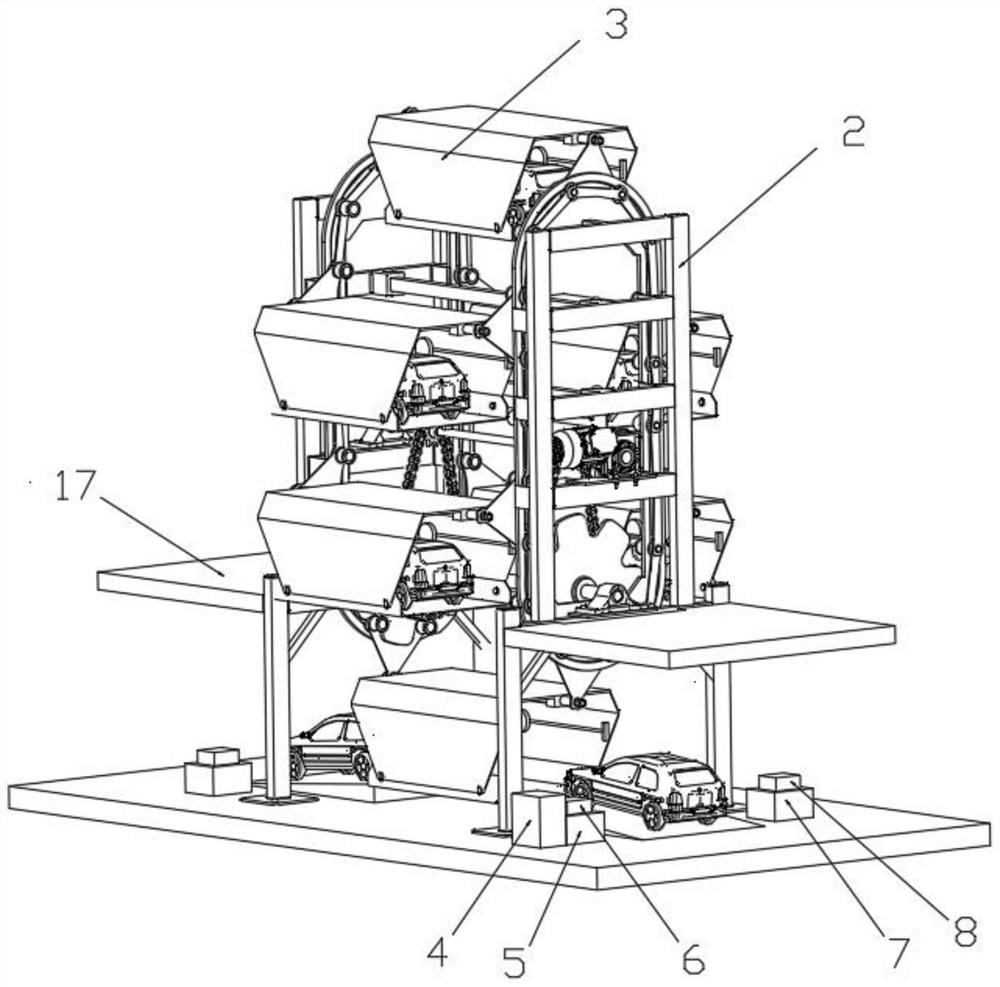

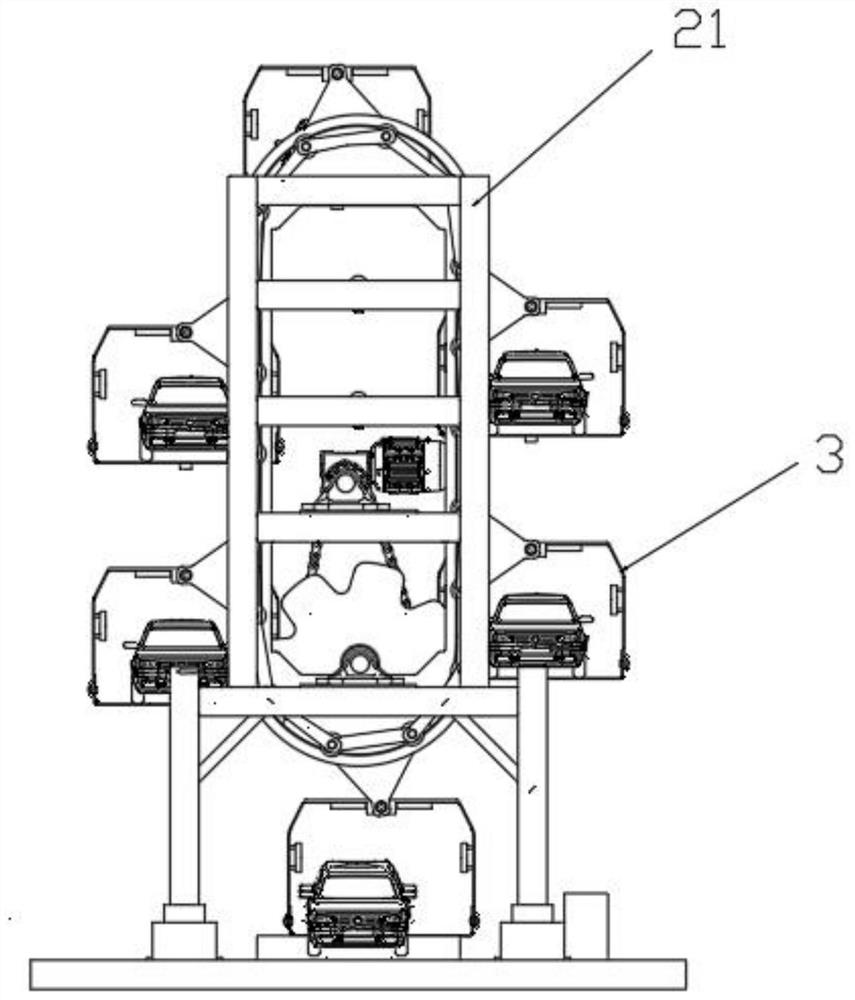

Arc hanging type vertical garage

The invention discloses an arc hanging type vertical garage. The arc hanging type vertical garage comprises a lower-layer garage body, an upper-layer garage body, an arc lifting device, a driving device, a safety protection system and a walking wheel type vehicle carrying platform. The arc lifting device is installed above the lower-layer garage body. The driving device and the safety protection system are installed at the upper end of the lower-layer garage body. The driving device and the arc lifting device are connected and drive the arc lifting device to conduct arc lifting and falling operation of the upper-layer garage body, and in addition, the swinging condition generated in the movement process of the upper-layer garage body can be controlled. The safety protection system and the driving device are connected so as to prevent out-of-control falling of the upper-layer garage body. The lower end of the lower-layer garage body is provided with the walking wheel type vehicle carrying platform which is used for accurately controlling entering and exiting of vehicles, and a plurality of damping devices are arranged at the lower end of the upper-layer garage body. The arc hanging type vertical garage is reasonable in structural design, entering and exiting of the upper-layer garage body are not affected by the lower-layer garage body, convenience and rapidness are achieved, operation is stable, the probability of rubbing of vehicles is lowered, reversing and turning are not needed, time is saved, efficiency is improved, and the service life is prolonged.

Owner:HANGZHOU XINGHE TRANSMISSION MACHINERY RES INST CO LTD

Intelligent holographic targeted public transportation system and achieving method thereof

ActiveCN103021173AAchieve efficient utilizationReduce shipping costsRoad vehicles traffic controlPunctualityOperational costs

The invention discloses an intelligent holographic targeted public transportation system and an achieving method thereof. The system and the method mainly solve the problem that the traffic burden is increased due to the low punctuality rate, the low comfort level, the low convenience and the long driving time of buses caused by the lack of a complete vehicle scheduling system in the prior art. The intelligent holographic targeted public transportation system comprises an information collection platform, a data processing center, a vehicle scheduling platform and a user terminal, wherein the information collection platform is used for collecting user riding information, vehicle driving line information is stored inside the data processing center, the data processing center is connected with information collection platform through a network and processes the collected information, the vehicle scheduling platform exchanges information with the data processing center through the network, and the user terminal exchanges information with the vehicle scheduling platform and the data processing center through communication or the network. According to the scheme, by the aid of the system and the method, the utilization ratio of public transportation vehicles is fully guaranteed, so that the traffic burden and operating costs of vehicles are effectively reduced, and the system and the method is high in practical value and popularization value.

Owner:陈旺

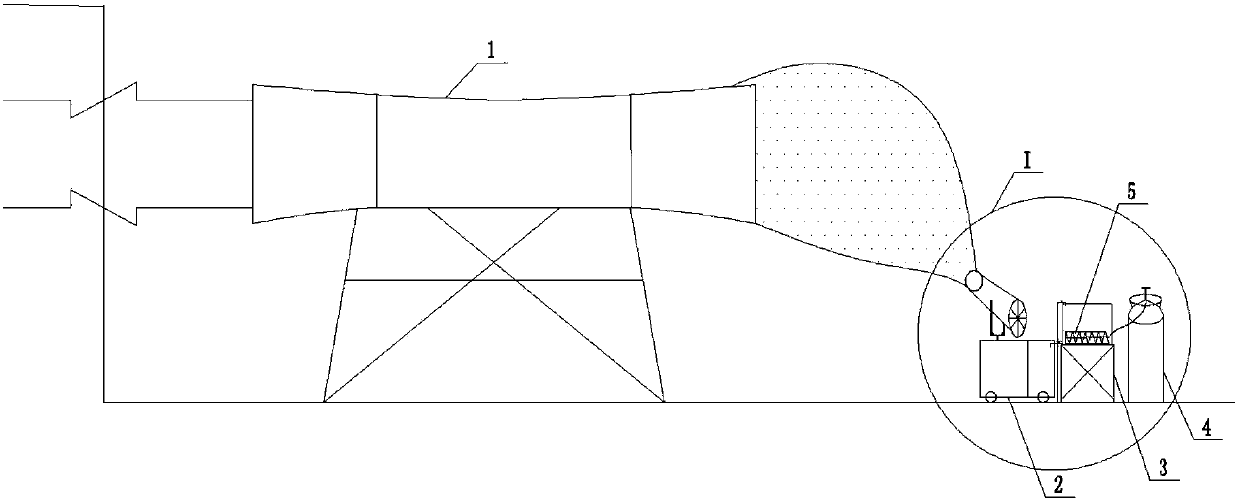

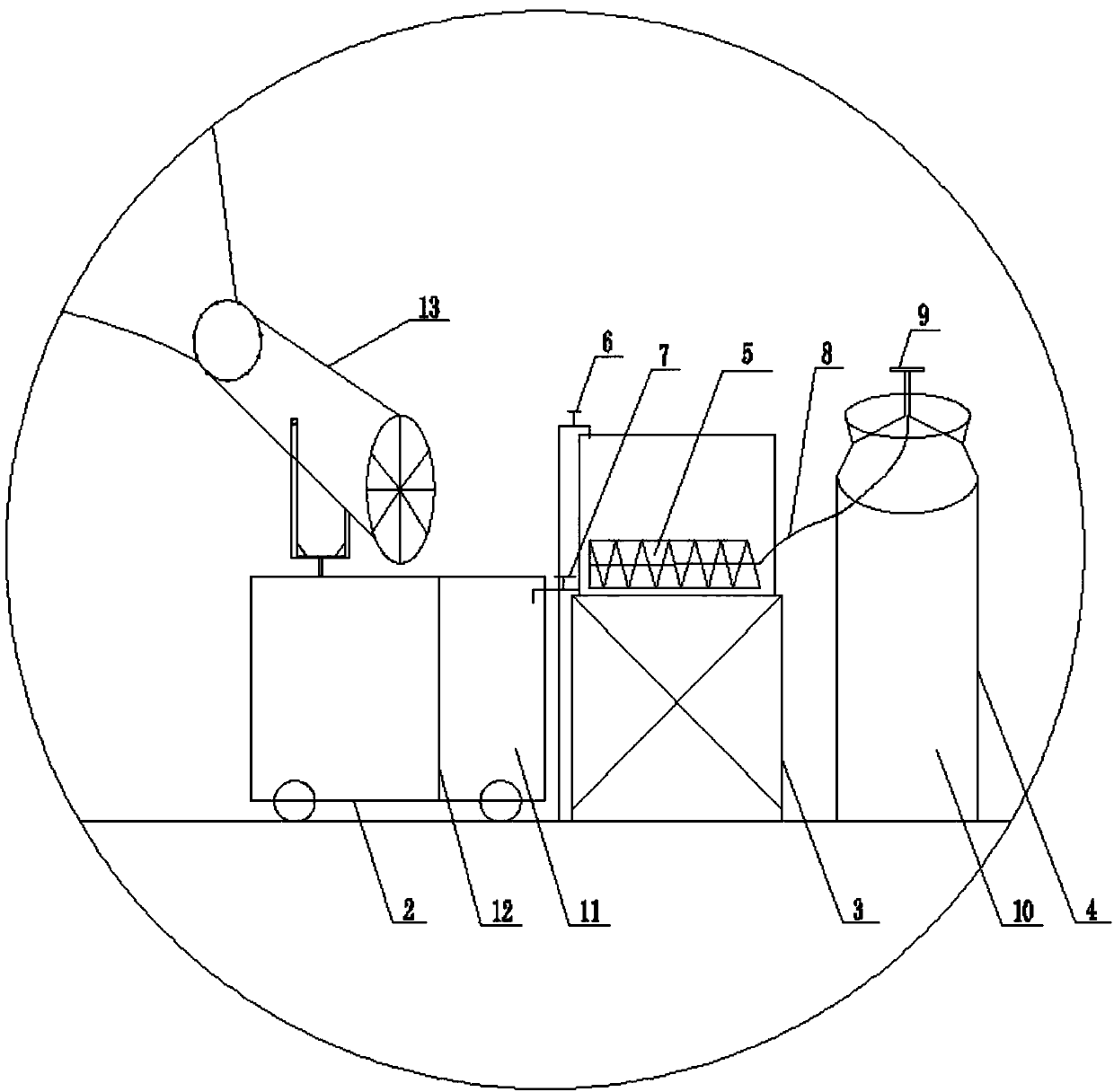

Tunnel construction cooling device and method

PendingCN107795332AReduce the temperatureImprove the construction work environmentLighting and heating apparatusTunnel/mines ventillationCold airEngineering

The invention discloses a tunnel construction cooling device and method. The tunnel construction cooling device includes a press-in type fan, a fog gun machine, a heat insulation water tank and a cooling device body. The cooling device body is installed in the heat insulation water tank. The output end of the heat insulation water tank communicates with the input end of the fog gun machine. The output end of the fog gun machine and the input end of the press-in type fan are arranged oppositely. The cooling method of the tunnel construction cooling device includes the following steps that 1, the heat insulation water tank is filled with sufficient water; 2, low-temperature liquid is led into the cooling device body; 3, the cooled water in the heat insulation water tank is led into the fog gun machine and is atomized and sprayed out by the fog gun machine; and 4, the press-in type fan sucks cold air from a spray-out area of the fog gun machine and sends wind to a construction section ina tunnel. According to the tunnel construction cooling device and method, the temperature of the construction position in the tunnel can be reduced, the life safety of workers is ensured so that the workers can be able to work normally, the cost is saved, manpower is saved, and the construction environment is kept good.

Owner:GUIZHOU BRIDGE CONSTR GROUP

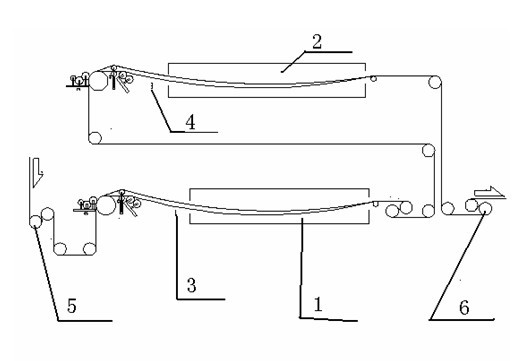

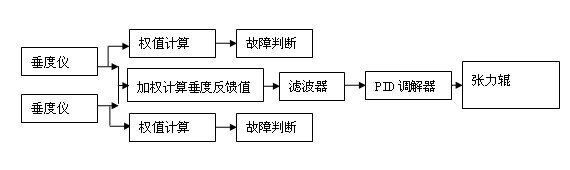

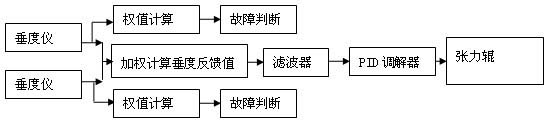

Method for realizing sag control of color-coating production line by speed regulation

InactiveCN102323749AImprove the problem of excessive sag fluctuationImprove product qualityControllers with particular characteristicsProduction lineLoop control

The invention relates to a method for realizing sag control of a color-coating production line by speed regulation, belonging to the technical field of deep processing of cold-rolled sheets in metallurgy industry. The technical scheme provided by the invention is that: the method for realizing the sag control of the color-coating production line by speed regulation comprises the following steps of: measuring data through a sag instrument in front of a curing furnace; taking weighted average as sag-feedback data; introducing sag deviation into speed closed-loop control of a tension roller outside the curing furnace; adjusting the velocity of the tension roller according to the sag-feedback data; and finally realizing the sag control of the color-coating production line. The method disclosed by the invention has the beneficial effects that: the sag deviation is introduced into the velocity closed-loop of the tension roller, therefore the problem of overlarge sag fluctuation in the curing furnace is greatly alleviated, the product quality of a cold-rolled color-coated plate can be promoted, the poweroff resulted from sag is reduced, the yield is improved, and wastes are reduced.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP

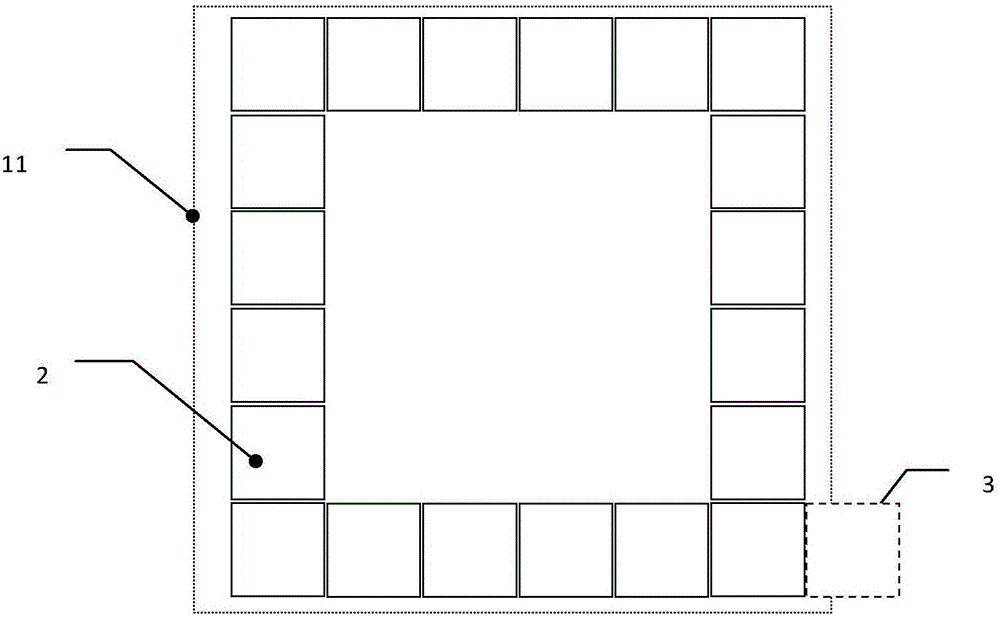

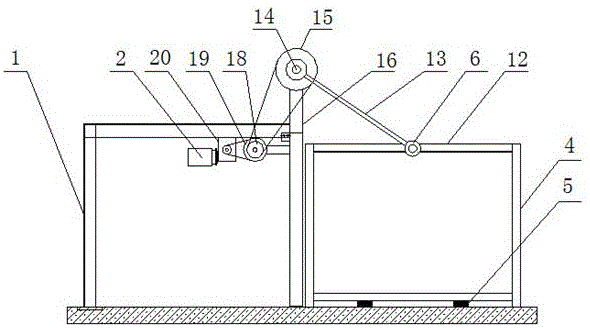

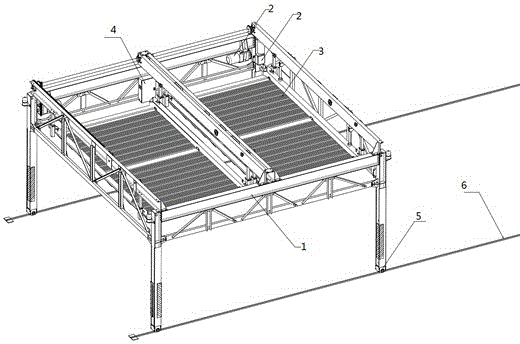

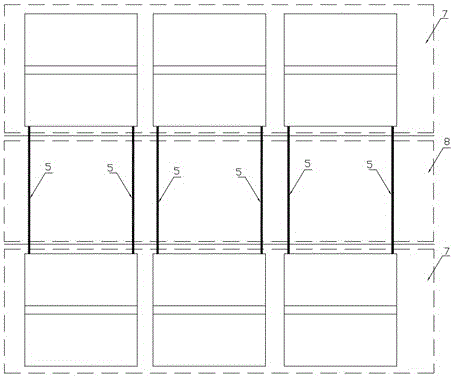

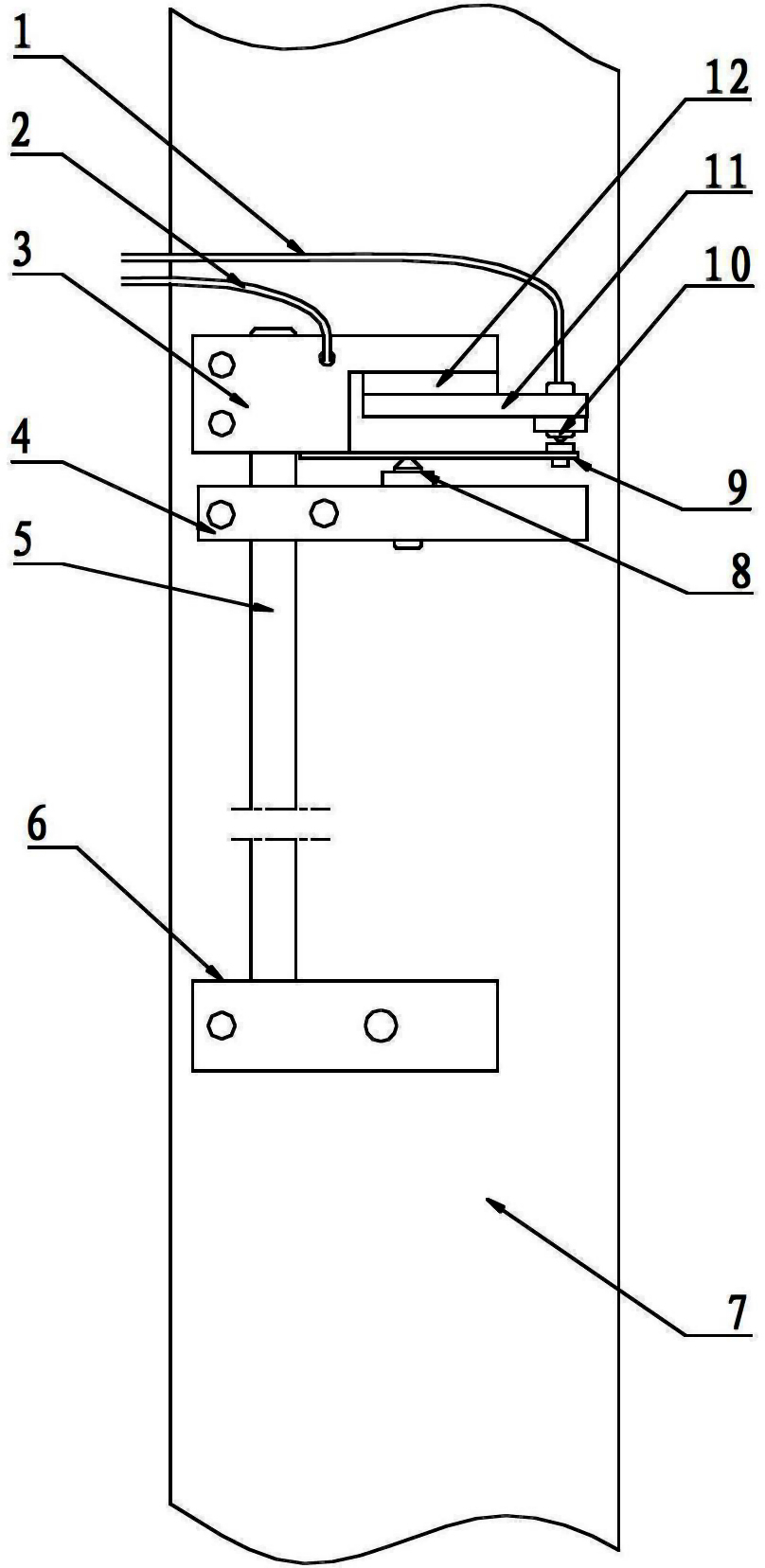

Novel two-layer three-dimensional garage

InactiveCN105735707AAchieve the goal of doublingDoes not affect layoutParkingsCar drivingParking area

Owner:CHENGDU WEST TAILI INTELLIGENT EQUIP CO LTD

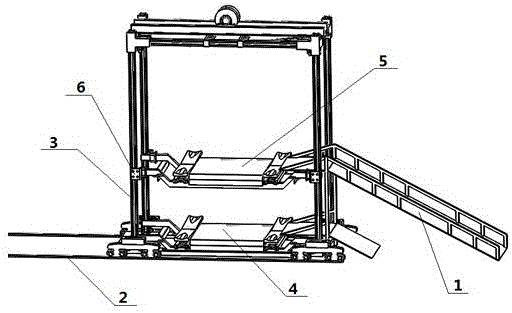

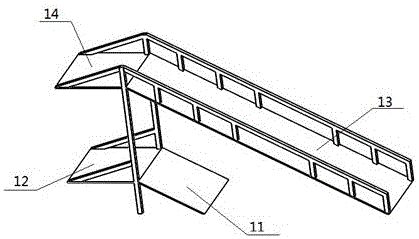

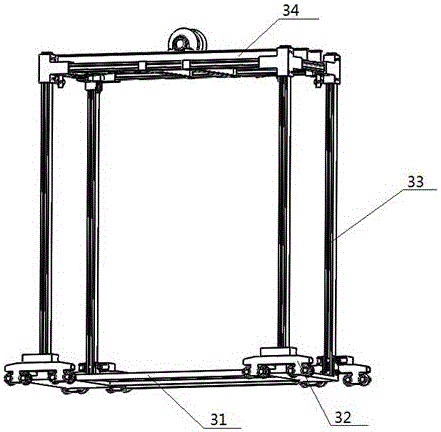

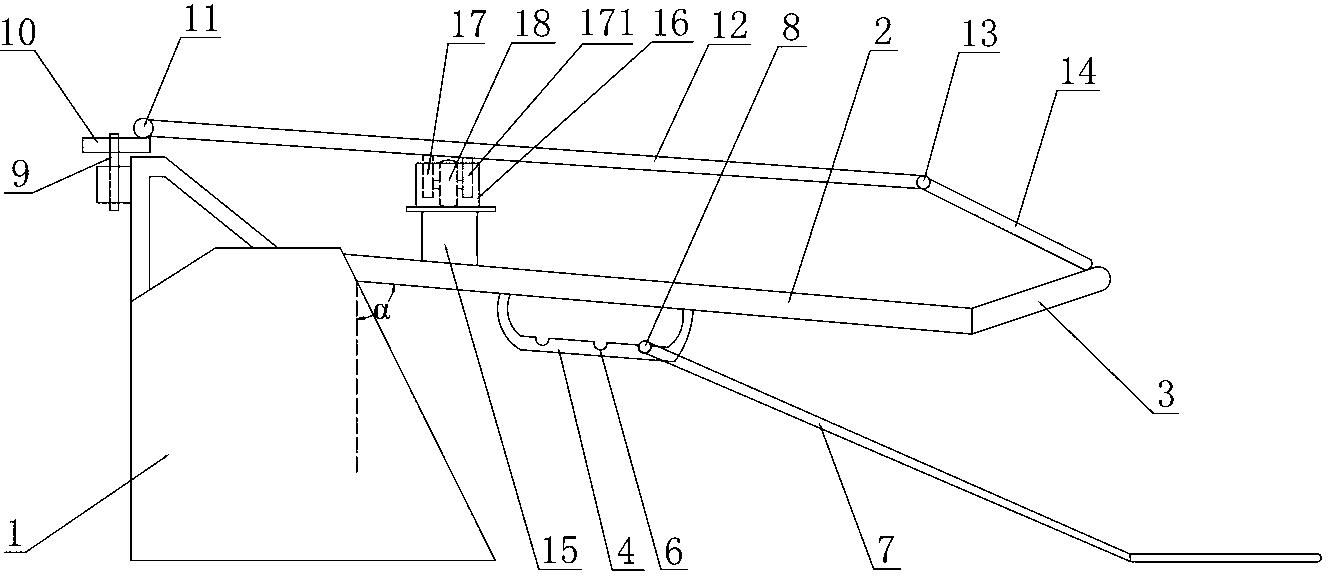

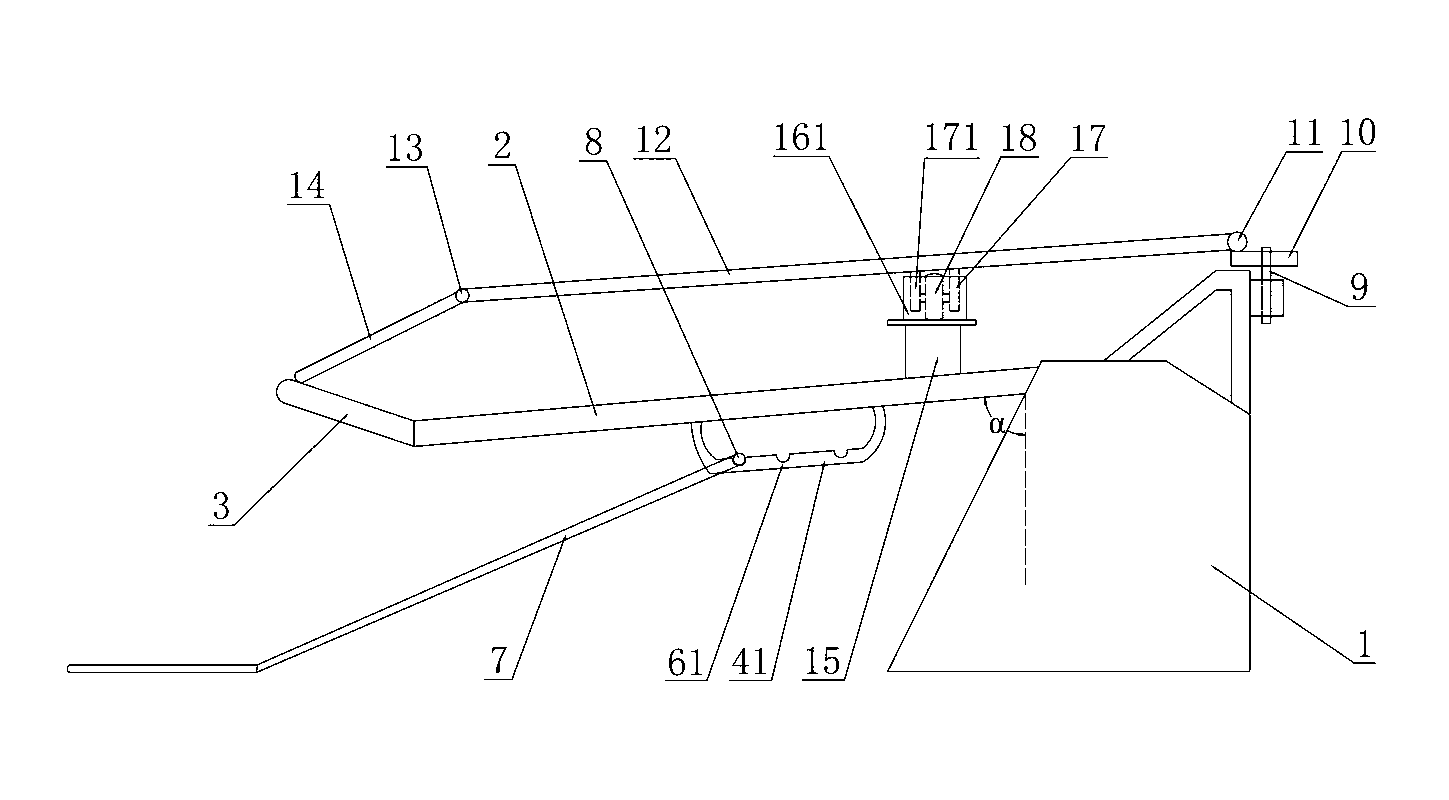

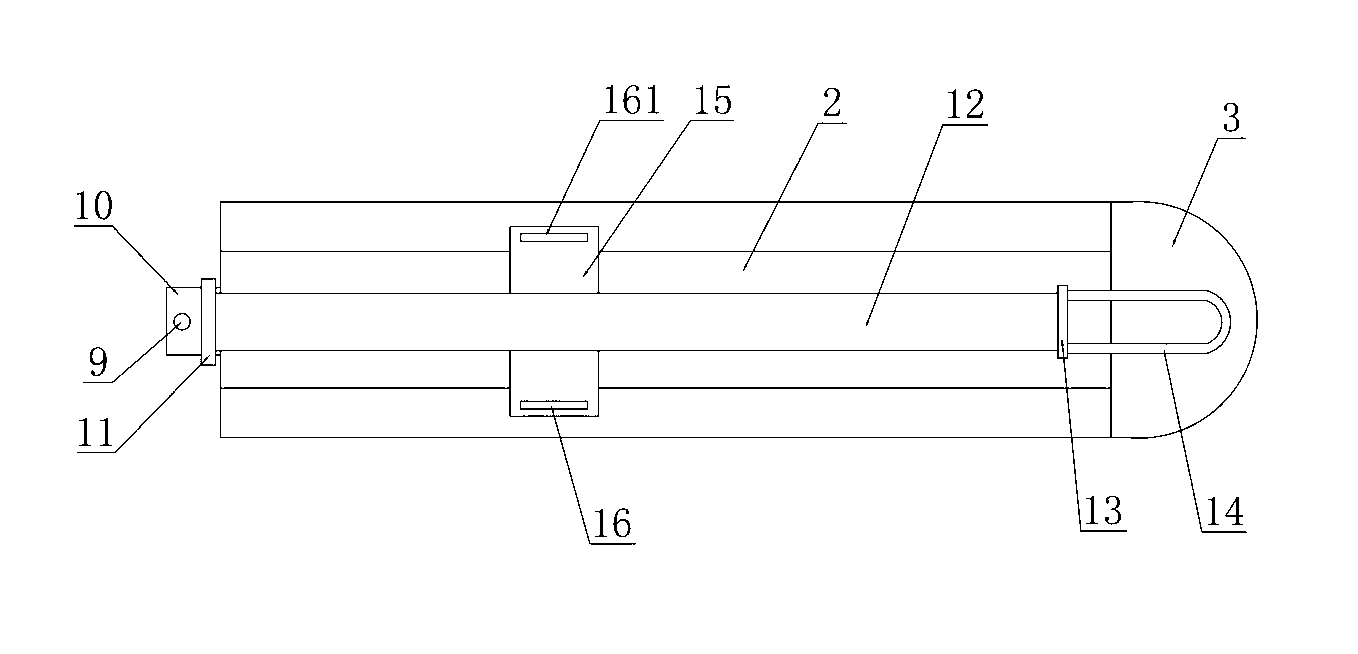

Stereo garage stacking machine and stacking method

The invention discloses a stereo garage stacking machine for conveying vehicles to empty positions of a stereo garage and taking the vehicles from the empty positions and a stacking method. A movable vertical frame is arranged on a horizontal track, the vertical frame is connected with an upper layer support mechanism and a lower layer support mechanism which are of the same structure, are fixedly connected with each other and can slide up and down along the vertical frame, the right end of each layer of support mechanism is connected with a slope group which is provided with an upper layer slope and a lower layer slope, the middle of the top of the vertical frame is provided with a roller coaxially connected with a worm mechanism, one end of each of four steel ropes are wound around the roller, the middle of each steel rope respectively bypasses a fixed pulley, the other ends of the four steel ropes are fixedly connected with four corners of the upper layer support mechanism respectively. The support mechanism comprises two identical bearing beams arranged in a front-rear mode, the upper portion of the middle of the two bearing beams is connected with a flat plate through a movement mechanism, two vehicles can be simultaneously conveyed to the stereo garage, and the two vehicles can be taken out of the stereo garage simultaneously.

Owner:JIANGSU UNIV OF SCI & TECH

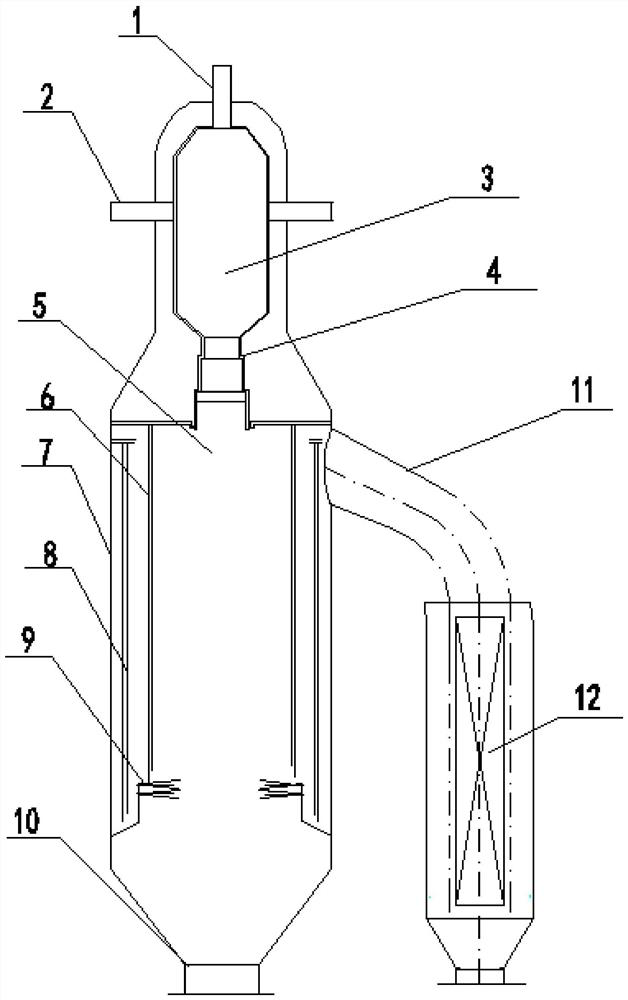

Waste boiler gasification device and method for recovering waste heat of dry pulverized coal

PendingCN111647439AReduce consumptionHigh recovery rateEnergy inputGasification processes detailsSyngasCombustion chamber

A waste boiler gasification device for recovering waste heat of dry pulverized coal comprises a shell, wherein a combustion chamber and a radiation waste boiler which are communicated with each otherare arranged in the shell from top to bottom, an overhead combustor is installed at the top end of the combustion chamber, 2N side combustors are symmetrically installed on the two sides of the combustion chamber, and a slag opening is formed in the bottom of the combustion chamber; the radiation waste boiler is communicated with the lower end of the slag hole, a first-stage water cooling wall anda second-stage water cooling wall are separately arranged in the radiation waste boiler from inside to outside in parallel at intervals, wherein a cooling spray head is mounted below the first-stagewater cooling wall, and slag discharge holes are formed in the radiation waste boiler and the bottom of the shell; a synthesis gas outlet is formed in the side face of the upper portion of the radiation waste boiler and connected with a gas conveying guide pipe, and the other end of the gas conveying guide pipe communicates with the convection waste boiler. Based on the design of the radiation waste heat boiler and the convection waste heat boiler, the radiation waste heat boiler is formed by combining the two layers of water cooling walls with the rising secondary channel and the convection waste heat boiler, sensible heat of high-temperature synthesis gas can be recycled to the maximum extent, the heat utilization rate is high, and the process is simple.

Owner:宁夏神耀科技有限责任公司

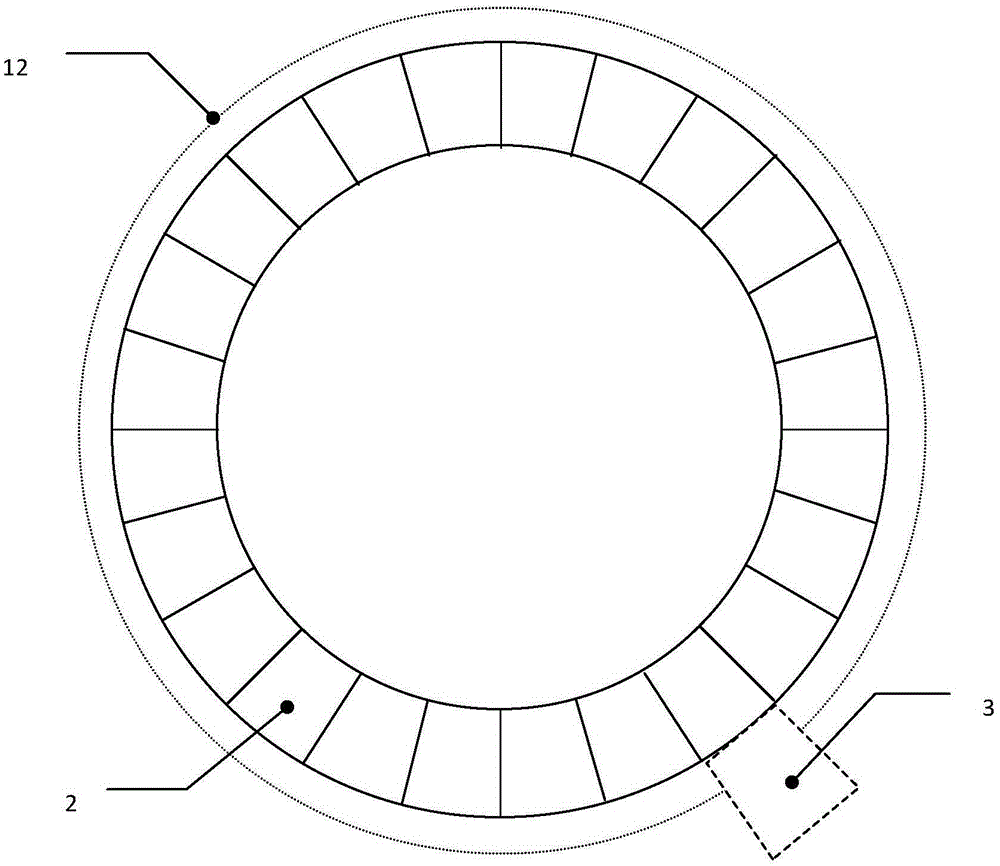

Light control system of vertical circulation intelligent garage

PendingCN113503075AFlexible controlAvoid getting off manual controlsFouling preventionElectrical apparatusStructural engineeringMechanical engineering

The invention discloses a light control system of a vertical circulation intelligent garage. The light control system comprises the garage, a rotating mechanism and a placing mechanism, wherein the rotating mechanism is arranged in the middle of the interior of the garage, the placing mechanism is mounted on the rotating mechanism, a garage entering door is formed in one side of the garage, a garage exiting door is formed in the other side of the garage, rolling gates are installed on the tops of the garage entering door and the garage exiting door, a first infrared sensor is fixedly installed on the outer side of the top of the garage entering door, a second infrared sensor is fixedly installed on the inner side of the top of the garage exiting door, two mounting top plates are fixedly mounted inside the garage, the two mounting top plates are symmetrically distributed about the rotating mechanism, and a garage entering lamp is fixedly mounted in the middle of the bottom of the mounting top plate close to one side of the garage entering door. After the structure is adopted, a vehicle can be stably parked, meanwhile, a driver can conveniently park and pick up the vehicle through light control, the parked vehicle is further cleaned through an arranged fan, and the parking satisfaction degree is improved.

Owner:合肥市春华起重机械有限公司

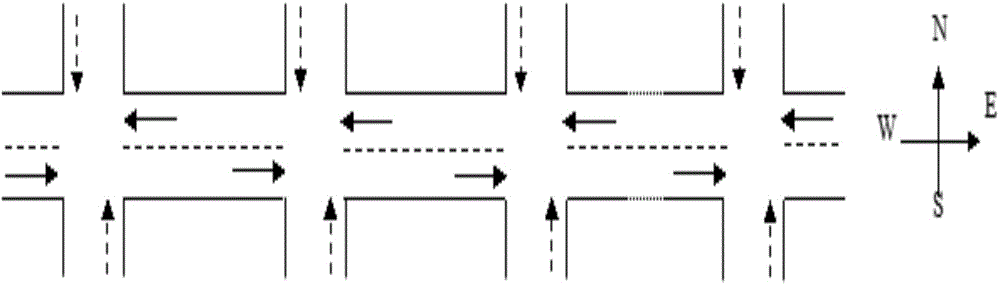

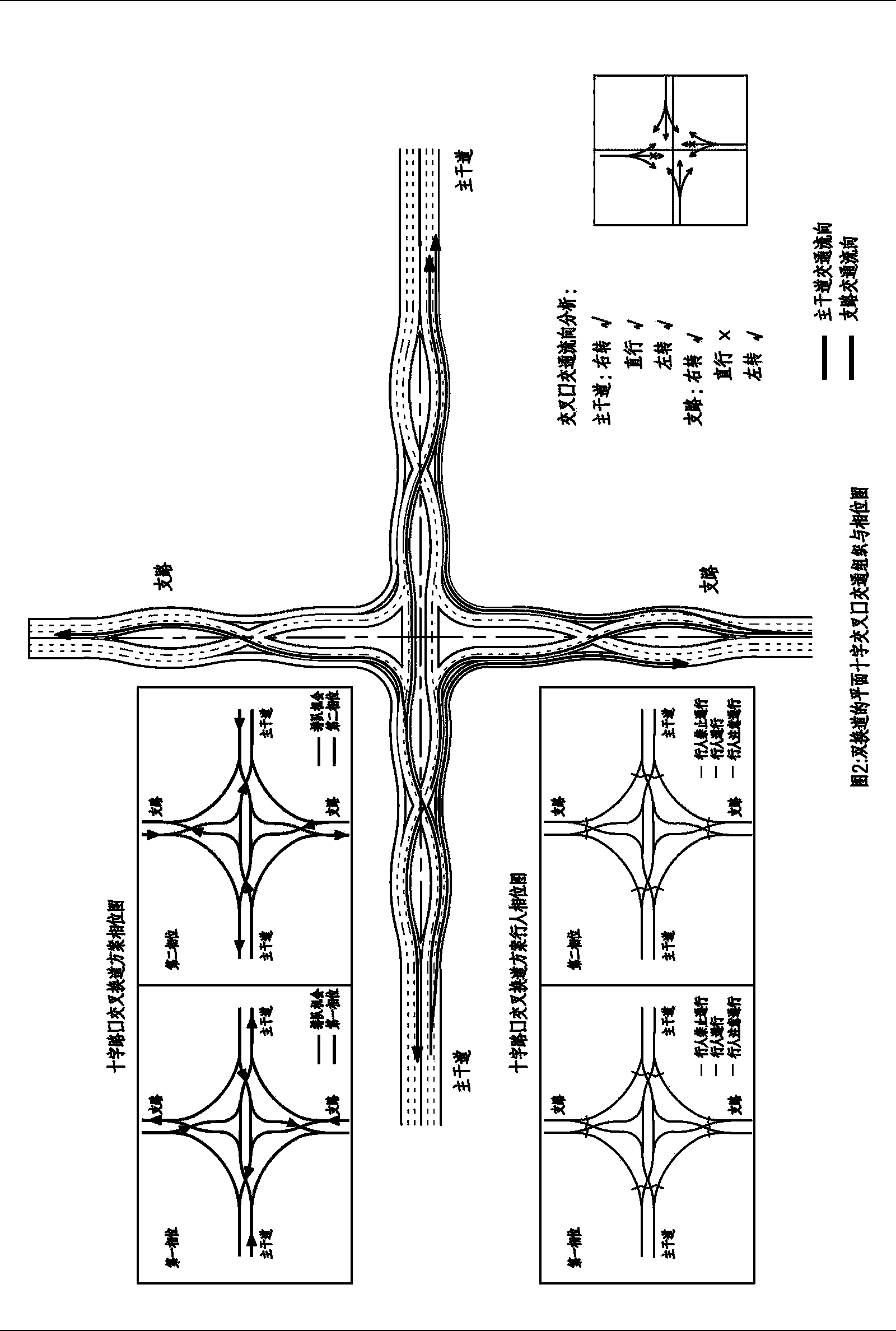

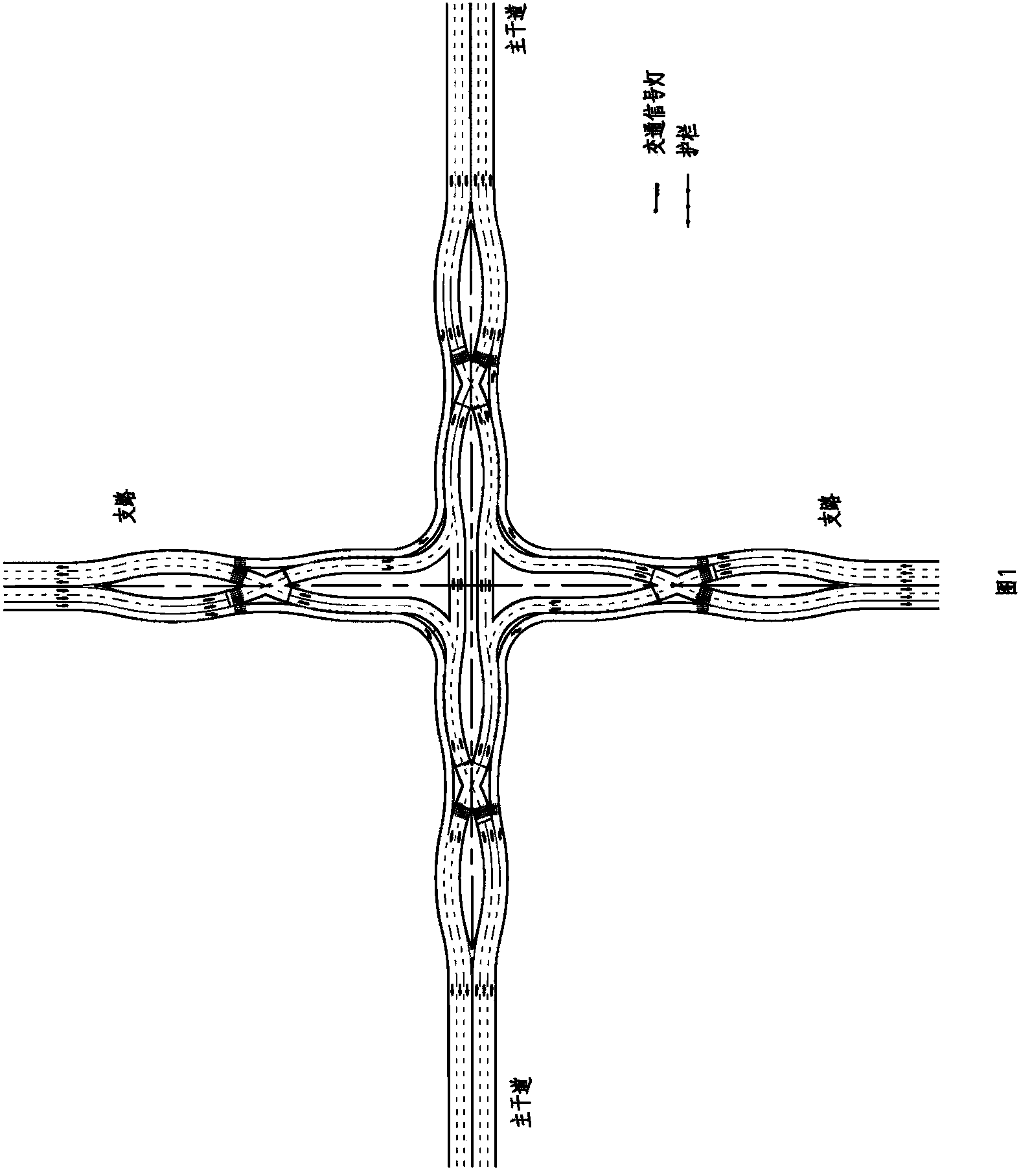

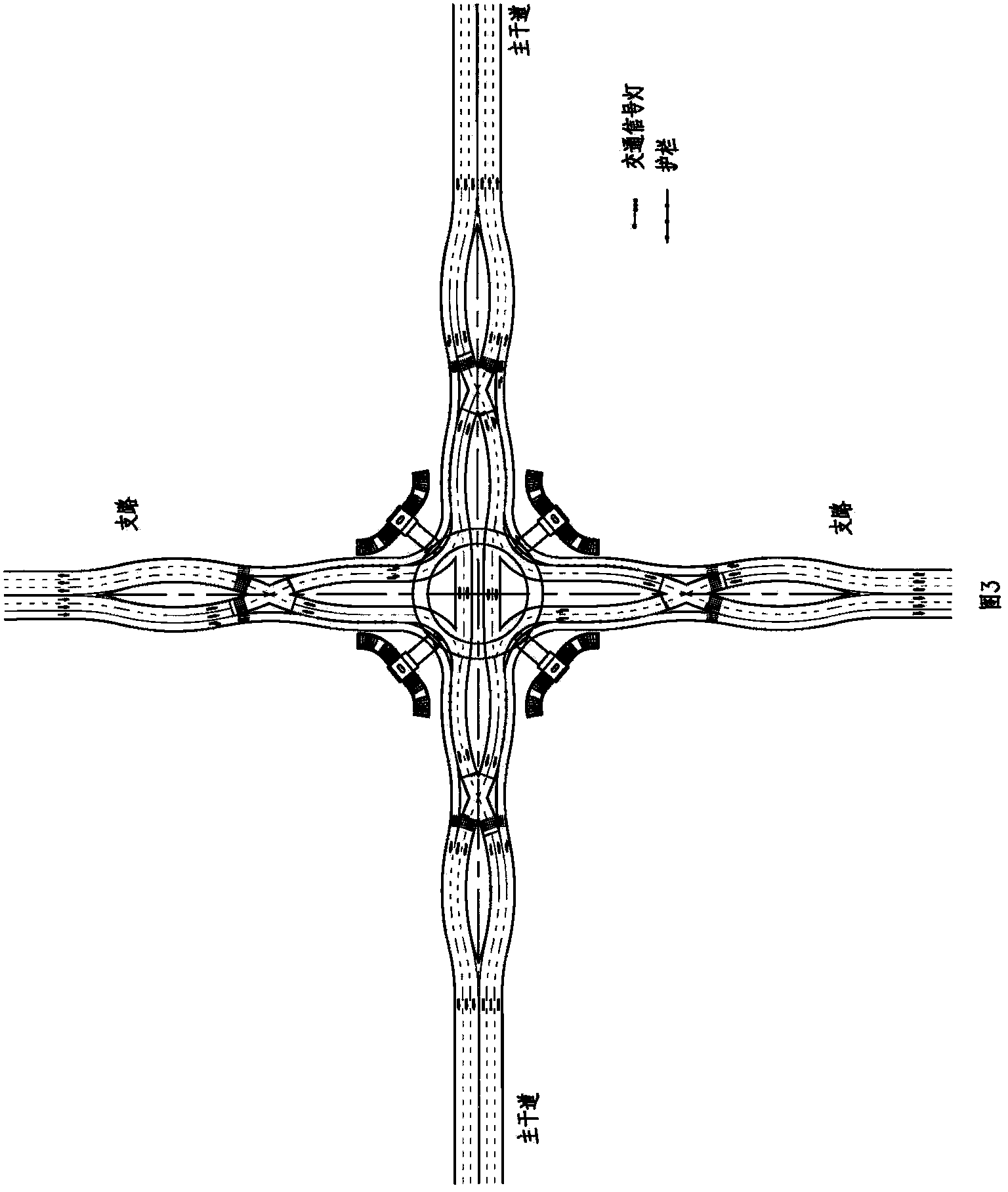

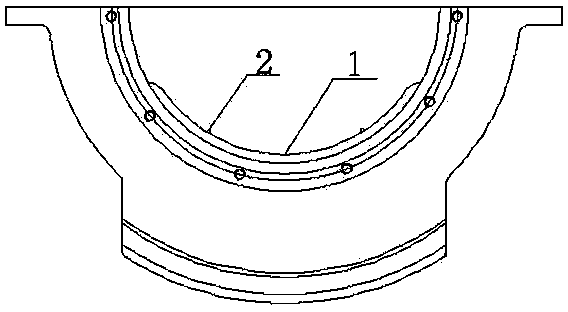

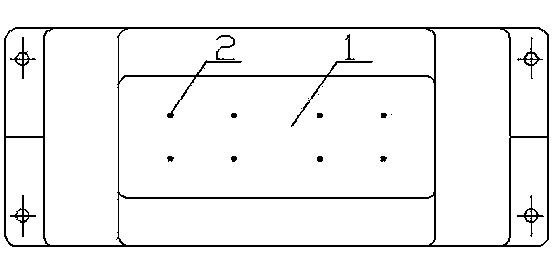

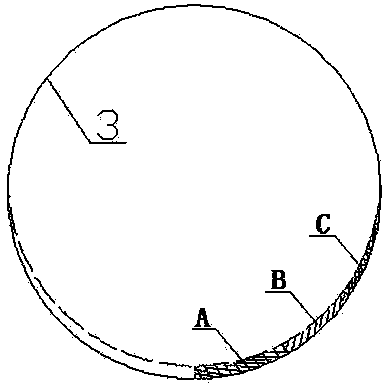

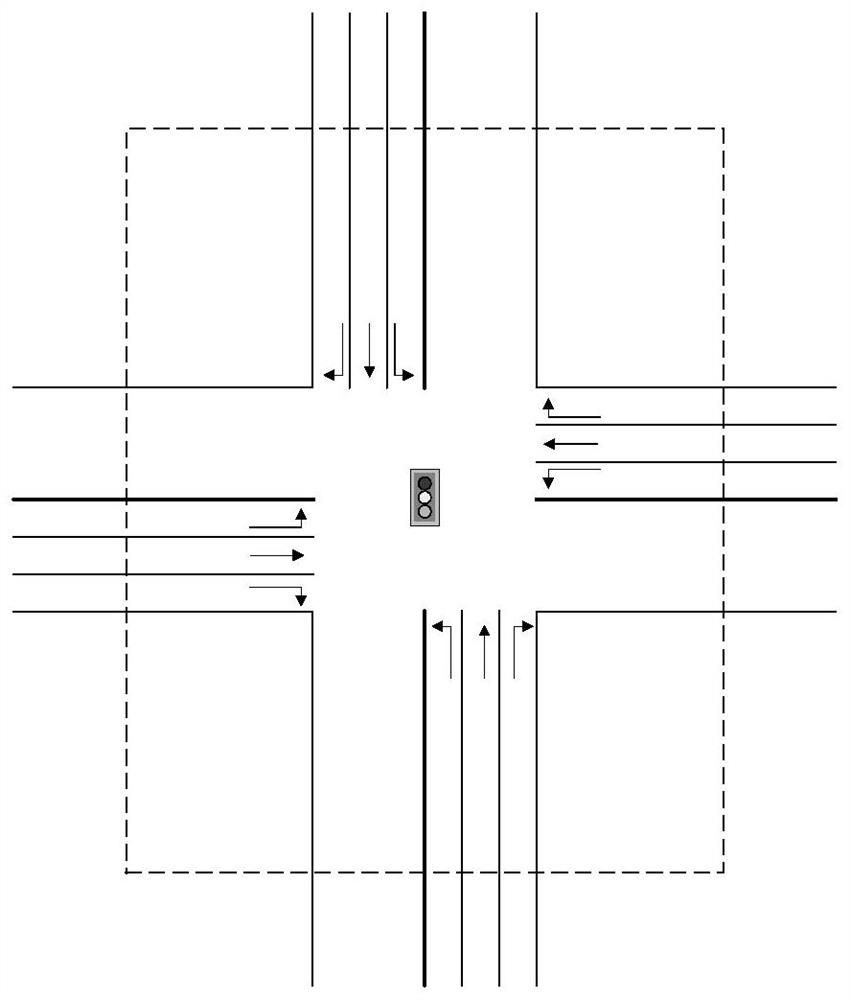

Dual-lane-changing cross road intersection design scheme

InactiveCN104318785AImprove traffic capacitySmooth traffic flowControlling traffic signalsRoadwaysTraffic capacityPhase control

The invention discloses a dual-lane-changing cross road intersection design scheme. To be specific, the invention, which belongs to the traffic design and traffic control field, provides a traffic organization design and traffic control method, thereby improving the intersection traffic capacity, reducing the intersection delay, and enhancing the pedestrian and non-motor vehicle security. According to the method, on the basis of main road intersecting changing, intersecting lane changing of a main road is realized at an intersection; a conflict point of a straight driving lane and a left turn lane is moved externally, thereby realizing a no-delay effect of the left-turn traffic volume in the intersection range. Meanwhile, the original three-phase control way is changed into a twp-phase control way, thereby substantially reducing the signal timing dial period, implementing signal and coordination control at two conflict points conveniently, realizing the green-wave traffic, and thus ensuring the left-turn demand of the primary road and the branch and smoothness of the road capacity.

Owner:吴小平

Rapid scraping repair method of babbitt metal bearing bushing surface

The invention provides a rapid scraping repair method of a babbitt metal bearing bushing surface. The rapid scraping repair method of the babbitt metal bearing bushing surface comprises the following steps of 1, slightly pricking the bearing bushing surface for 6-10 times through a point of a triangular scraper to enable corresponding tiny protrusions to appear on the bearing bushing surface; 2, mutually grinding a hollow shaft and the bearing bushing surface, and performing scraping according to changes of the tiny protrusions, wherein scraping quantity of the bushing surface with flat or low tiny protrusions is greater than that of the bushing surface with high tiny protrusions. By means of the rapid scraping repair method, grinding and scraping times are reduced, scraping repair time is greatly shortened, scraping time is shortened to one to third of the existing scraping time, workload is reduced, stopping times is reduced to the greatest extent, and production efficiency is increased.

Owner:BAIYIN NONFERROUS GROUP

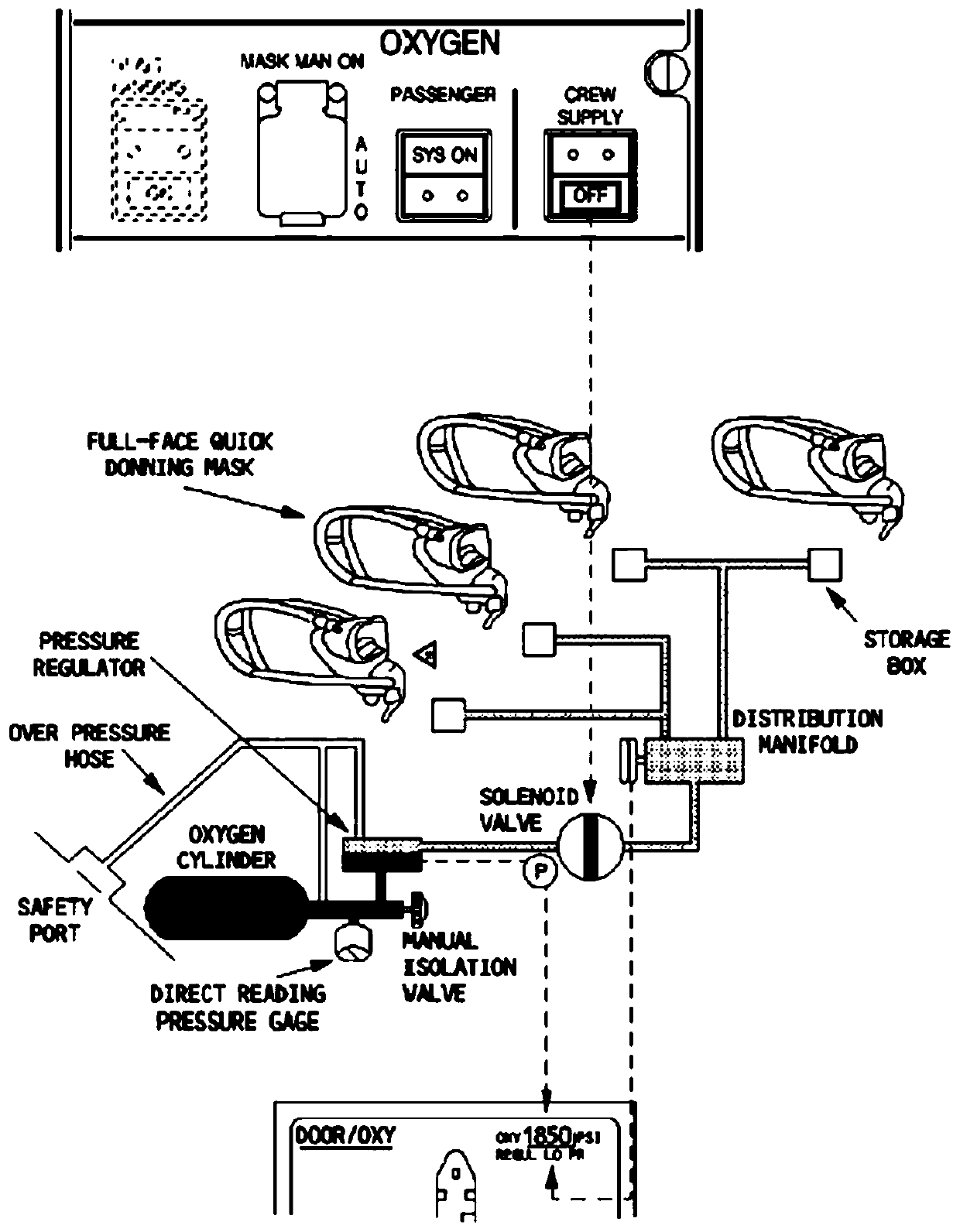

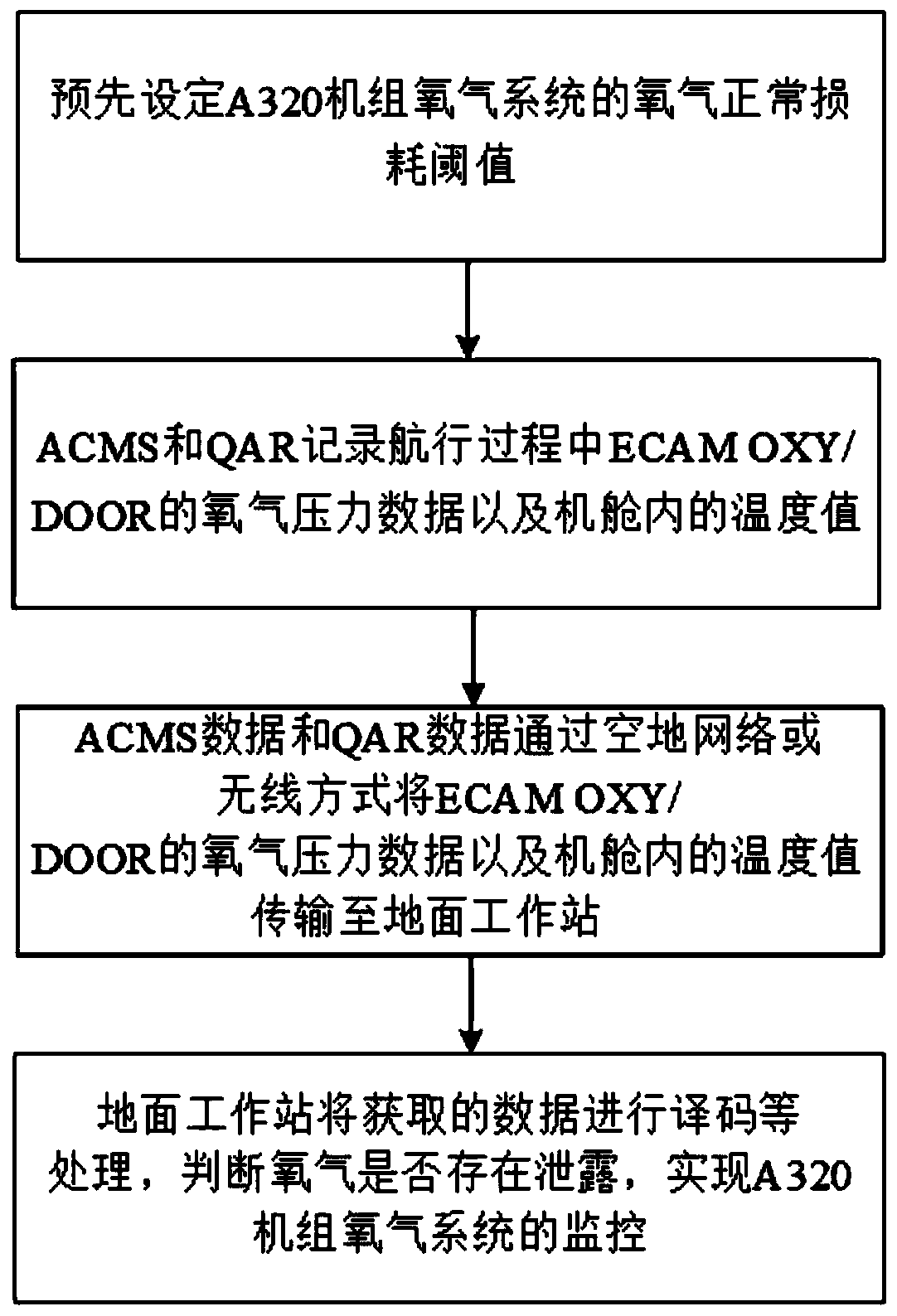

A320 unit oxygen leakage monitoring method

InactiveCN110530586AReduce parkingReduce operational riskMeasurement of fluid loss/gain rateAircraft components testingEngineeringAir ground

The invention relates to an A320 unit oxygen leakage monitoring method. The method comprises the following steps of (1) presetting an oxygen normal loss threshold of an A320 unit oxygen system, (2) allowing an ACMS and a QAR to record oxygen pressure data of ECAM OX / DOOR in a flight process, (3) allowing the ACMS data and the QAR to transmit the oxygen pressure data of ECAM OX / DOOR to a ground workstation through an air-ground network and in a wireless mode, and (4) the ground workstation carries out analysis processing such as decoding on all the obtained data and judges whether oxygen leaksor not according to the actually obtained oxygen pressure data and a set oxygen normal loss threshold value to achieve the monitoring of the A320 unit oxygen system. Compared with the prior art, the method has the advantages of reducing the operation risk and improving the working efficiency.

Owner:CHINA EASTERN AIRLINES CO LTD

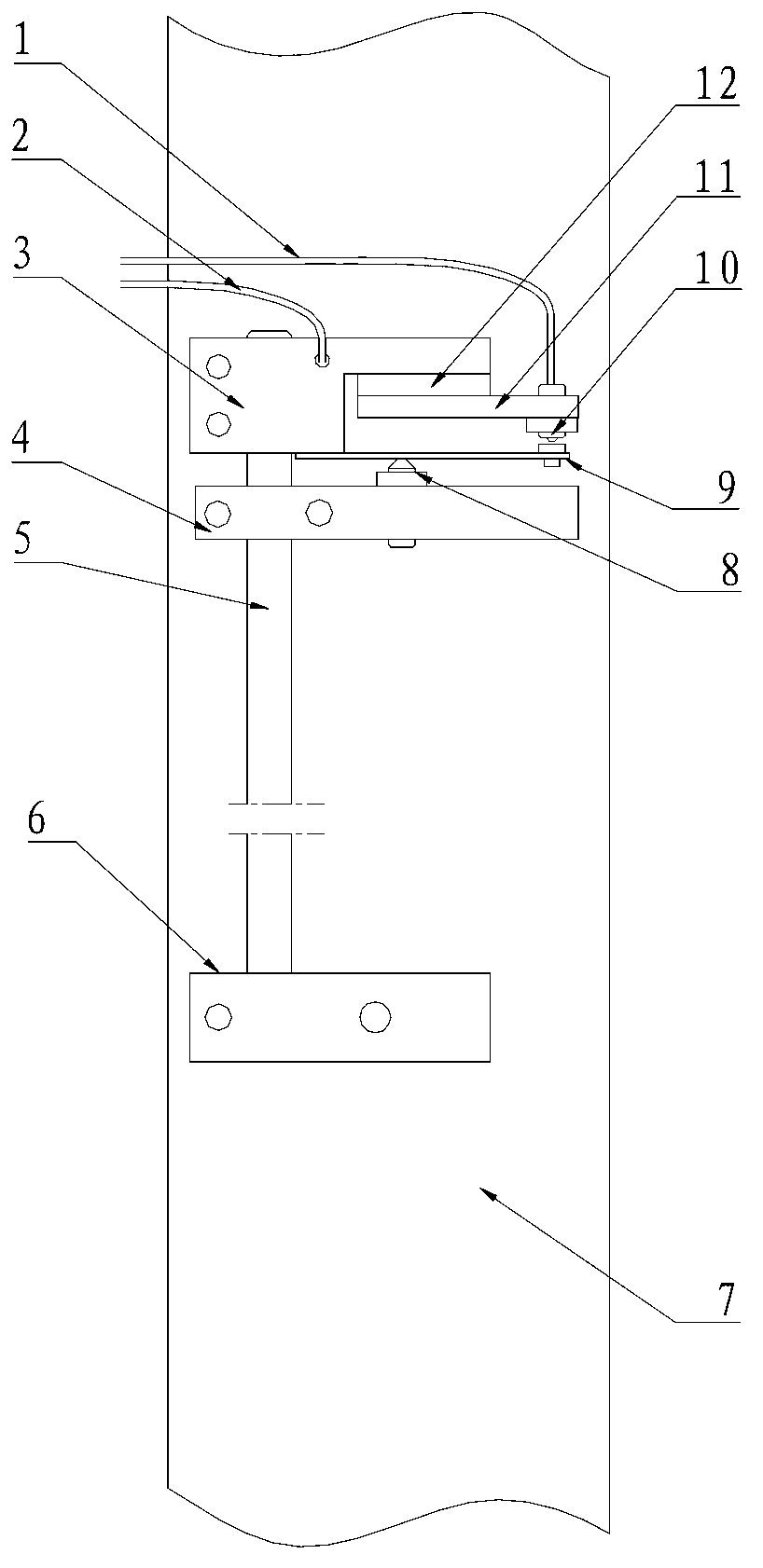

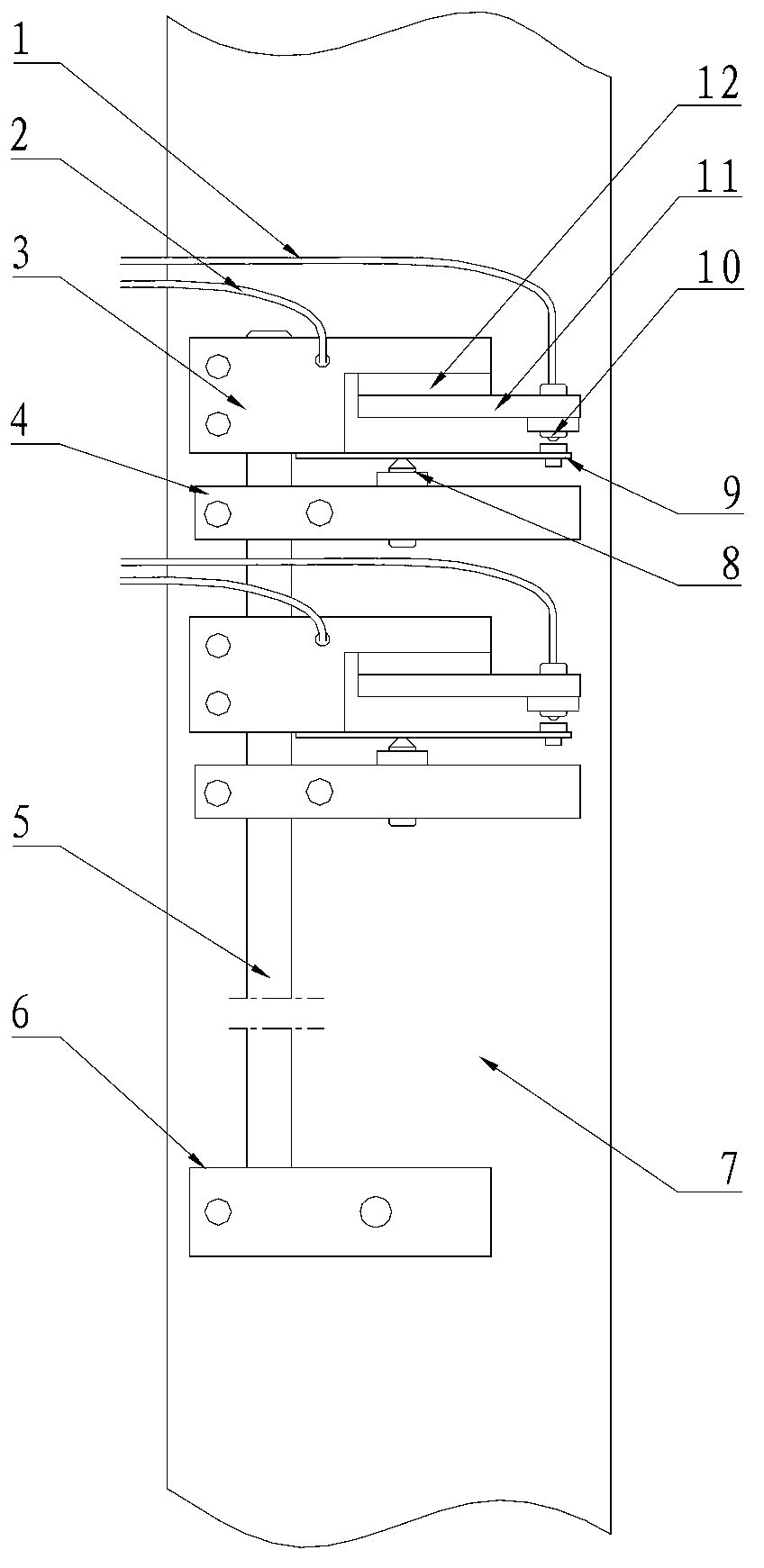

Detection device and working method thereof

ActiveCN102700248AHigh sensitivityAlarm is accurateMechanical depth measurementsPrinting press partsThermal expansionEngineering

The invention relates to a detection device and a working method thereof. The detection device comprises a slide bar, a fixed block and a detection unit and can overcome the defects of the prior art, the deformation of a wallboard due to the fact that the pressure between an upper platform and a lower platform instantaneously exceeds a set value and the deformation of the wallboard due to thermal expansion in a gold stamping process can be respectively detected, a positioning ball is touched by a leaf spring, and then a signal wire is conducted to send out an overpressure alarm. The detection device and the working method thereof disclosed by the invention have the characteristics of high reaction sensitivity, accurate alarming and easiness in realization.

Owner:天津长荣震德机械有限公司

Method for weaving cotton fiber and bamboo fiber blended home textile fabric

The invention relates to the technical field of textiles, and discloses a method for weaving a cotton fiber and bamboo fiber blended home textile fabric. Cotton fibers and bamboo fibers are used as raw materials of warp yarns and weft yarns, and the required home textile fabric is formed by layered interweaving and heald operation. The method has the advantages that by optimizing parameters in the process of weaving the fabric, the characteristics of the bamboo fibers are considered, the problems of broken end, warp shrinkage, weft stop, unclear opening and the like in the weaving process are solved, and production efficiency and product quality are improved.

Owner:SHAOXING UNIVERSITY

Wire pay-off rack

The invention discloses a wire pay-off rack. The wire pay-off rack comprises a frame. A front end of the frame is provided with a wire pay-off front support which tilts down along a wire pay-off direction. A wire pay-off shelf which tilts up along the wire pay-off direction is fixed to a front end of the wire pay-off front support. An upper end of a lower swing rod is hinged to the bottom of the wire pay-off front support and a lower end of the lower swing rod is perpendicular to the ground along the wire pay-off direction under the action of self-gravity so that a vertical straight-line distance between the lower swing rod and a joint point of the wire pay-off front support and the wire pay-off shelf is greater than the diameter of a wire. A rear end of the frame is movably provided with a vertical rotation shaft. The vertical rotation shaft is fixed to a base. The base is hinged to a rear end of a compression rear rod. A front end of the compression rear rod is hinged to a rear end of a compression front rod. A front end of the compression front rod invariably presses against an upper surface of the wire pay-off shelf under the action of self-gravity. A compression rear rod rotation support mechanism is arranged between the compression rear rod and the wire pay-off front support. The wire pay-off rack realizes ordered loop-by-loop pay-off of wires in wire drawing.

Owner:张家港市中久金属制品有限公司

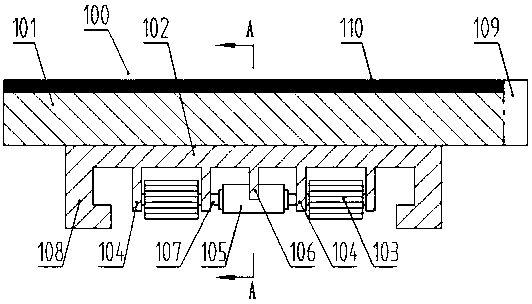

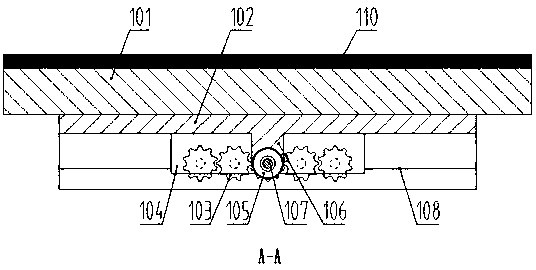

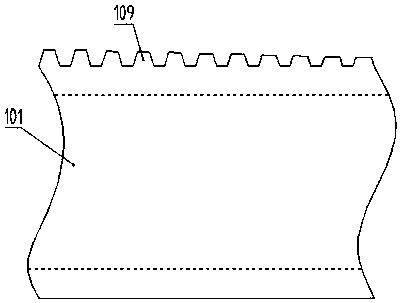

Synchronous taking track of dynamic bus station

InactiveCN107905571AReduce travel timeSimple structureSpecial buildingSmall buildingsElectric machineryDrive motor

The invention discloses a dynamic bus platform synchronous boarding track, which includes a track body slidingly connected with a fixed track fixedly installed on the bus platform; the track body includes a pedal and a mounting bracket, and the mounting bracket is fixedly connected to the lower end surface of the pedal; There are several toothed traveling wheels, and each traveling wheel is installed in mesh with each other on the same horizontal line, and is used for meshing and installing with the traveling teeth on the fixed track; at least one traveling wheel is connected with a drive motor to drive it to travel on the fixed track; There are also a number of locking teeth on the pedal, and the locking teeth are set close to the side of the vehicle track; by adopting a dynamic structural design that cooperates with the bus platform, the platform can drive passengers to run synchronously with the bus when the bus enters the station. Thereby, it is realized that the bus does not need to stop, and only needs to be dynamically connected between the established bus platform and the platform, so that the bus can be kept running, and the driving efficiency of the bus is improved.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

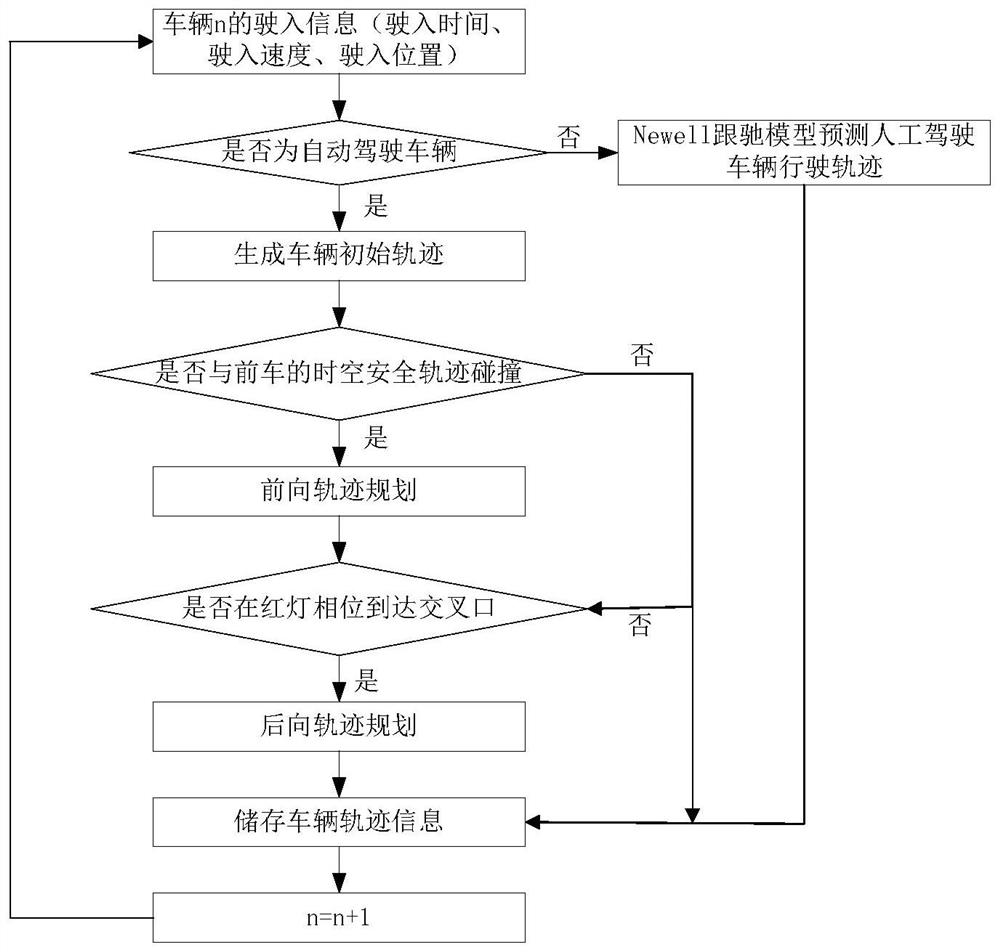

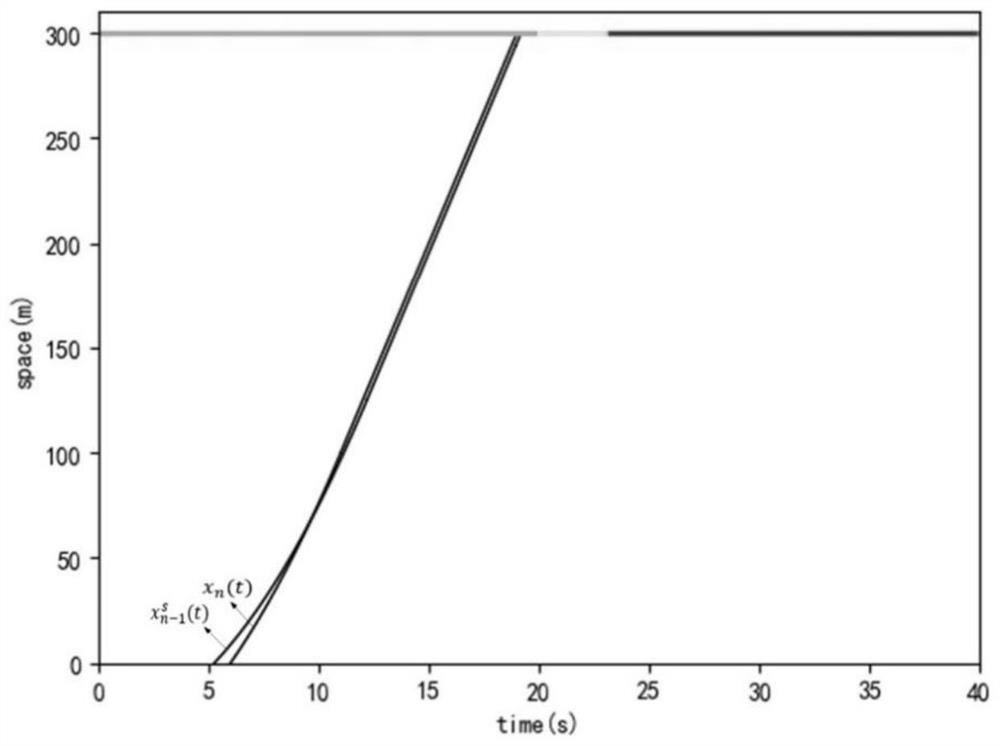

Automatic driving vehicle trajectory planning method in mixed traffic flow environment

PendingCN114852076AReduce parkingReduce delaysInternal combustion piston enginesControl devicesVehicle drivingTraffic flow

The invention provides an automatic driving vehicle trajectory planning method for fixed signal timing in a manual and automatic driving mixed driving environment. The method comprises the following steps: acquiring information of a vehicle driving into an intersection control area; judging the type of the entering vehicle, if the entering vehicle is a manual driving vehicle, predicting the trajectory of the vehicle by adopting a Newell car-following model, and if the entering vehicle is an automatic driving vehicle, planning the trajectory of the automatic driving vehicle by adopting a segmented trajectory planning method; the track information of the vehicle is stored, when it is detected that the next vehicle is driven in, the current vehicle information is updated, and vehicle track planning is started. The method belongs to a heuristic algorithm, track planning of the automatic driving vehicle in the mixed driving environment is achieved, the planning efficiency is improved on the premise that safety is guaranteed, and vehicle track planning can be achieved for signalized intersections under different traffic flows, signal phases and vehicle permeability.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com