Automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision

A technology of automatic cutting and file analysis, which is applied to the mechanism of embroidery machines, automatically controlled embroidery machines, instruments, etc., can solve the problems of low technological content and work efficiency of cutting systems, low material utilization rate, and high proportion of defective products. Achieve the effect of improving labor productivity, high work efficiency and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Theoretical Basis: Image Recognition. The first step in image recognition is to extract effective image features. Here, we mainly introduce moment features and contour features. The moment features include Hu moment, normalized moment of inertia (NMI) and affine invariant moment. The contour feature quantity includes contour discretization parameters and singular value decomposition. These five feature quantities all have good translation, rotation and scale invariance, and have been widely used in image target recognition.

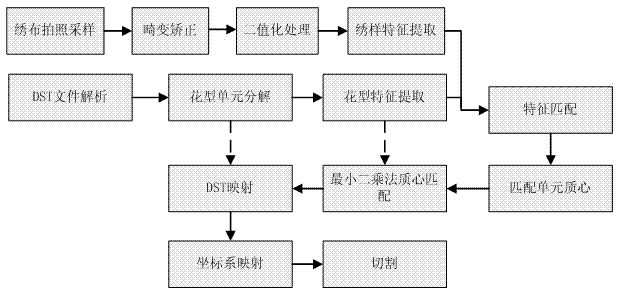

[0033] Attached below figure 1 The present invention is described further.

[0034] 1DST file analysis

[0035] Because the computer-designed embroidery file is in DST format, its internal features and image information cannot be directly obtained. Therefore, the first step of the present invention is to analyze the DST file to obtain its image information and internal features. The DST file is composed of a header file and a pattern file body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com