Membranes with fluid barrier properties and articles containing such membranes

a technology of fluid barrier and membrane, which is applied in the field of membranes, can solve the problems of many inflated articles, not attractive, and only the barrier material layer has the elasticity required for cushioning devices, etc., and achieves the effects of increasing the ability of the membrane to prevent transfer, increasing the opacity or haziness of the membrane, and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Two single-layer sheets of ethylene-vinyl alcohol copolymer [EVOH] containing 5% by weight of a laminar non-filler are prepared using ETC-133 from Kuraray / Evalca as the EVOH and Cloisite 15A (a nano-filler clay treated with dimethyl, dihydrogenated tallow, quaternary ammonium chloride) and Cloisite 30A (a nano-filler clay treated with methyl, tallow, bis-2-hydroxyethyl, quaternary ammonium chloride) as the filler. These samples were produced in a concentrate then diluted as follows: First, a high clay containing polymer sample was produced via extrusion. Then, the concentrate was re-extruded with the desired amount of polymer to achieve the 5% by weight clay content. The extrudate from this second extrusion was pelletized to produce extruded ETC-133 clay nanocomposite pellets.

The increased barrier properties of the barrier nanocomposite layer was determined as follows. The extruded ETC-133 clay nanocomposite pellets were extruded to produce 1 mil-thick cast film for gas transmiss...

example 2

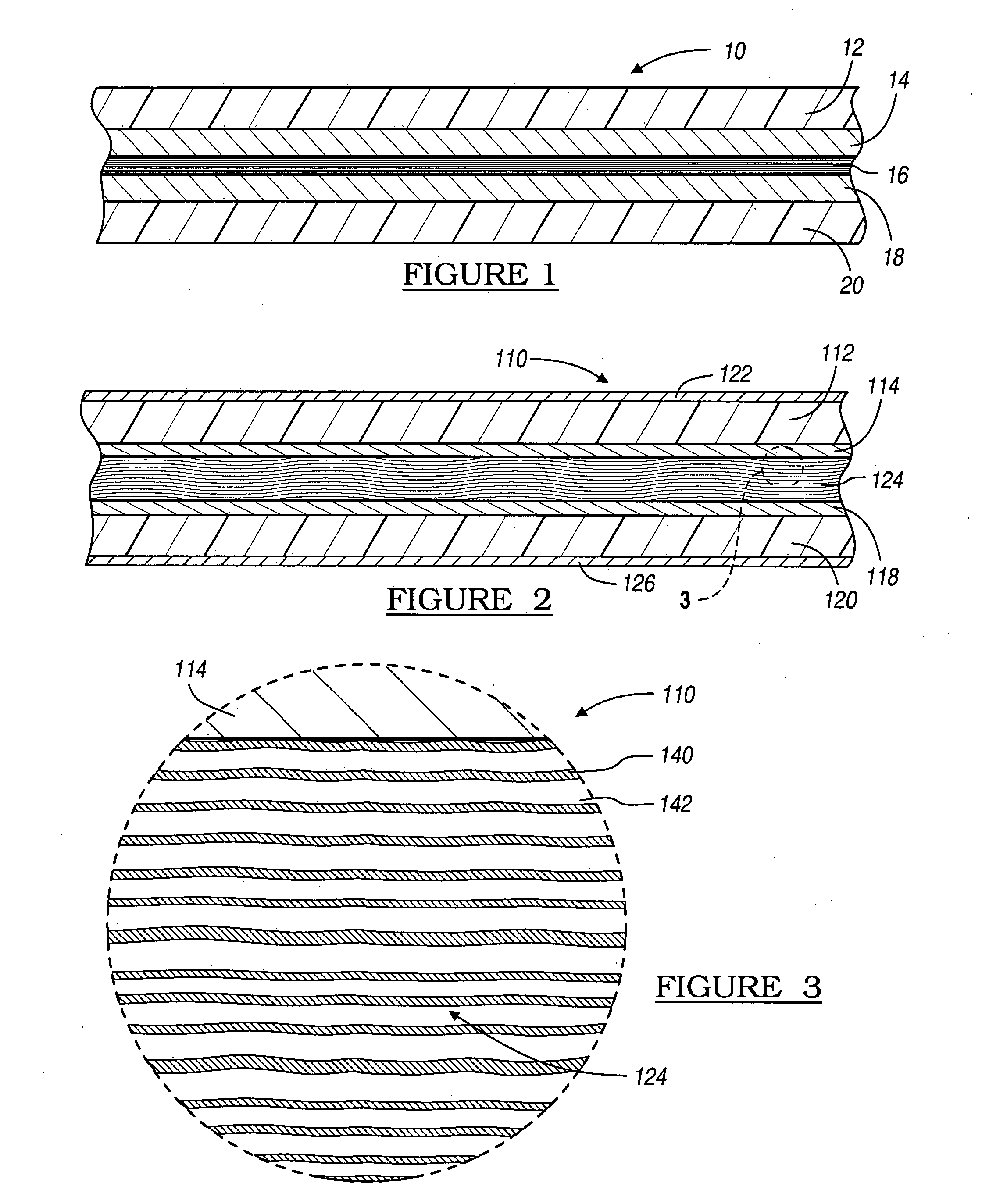

The extruded ETC-133 clay nanocomposite pellets of Example 1 are extruded to form a microlayer polymeric composite according to Example 1 of Bonk et al., U.S. Pat. No. 6,082,025, with the extruded ETC-133 clay nanocomposite pellets of Example 1 replacing the LCF 101A material of the patent example. The microlayer polymeric composite is formed into a sealed, inflated bladder, which is then incorporated into a sole of a shoe as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com