EVA composite foam material and preparation method thereof

A composite foaming and blowing agent technology, applied in the field of industrial materials, can solve problems affecting human health, etc., and achieve the effects of excellent elasticity, excellent physical properties, and low compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Corresponding present invention also provides the preparation method of this EVA composite foam material, comprises the following steps:

[0049] Step 1: Weigh the following components by weight: 50-90 parts of ethylene-vinyl acetate copolymer, 0-30 parts of polyolefin thermoplastic elastomer, 0-30 parts of EPDM rubber, 0-20 parts of filler, 0.7-2.5 parts of odorless cross-linking agent, 1-8 parts of foaming agent and 5-10 parts of ammonia removal agent.

[0050] Step 2: Pour all the ingredients weighed in step 1 except the odorless cross-linking agent, ammonia removal agent, and foaming agent into the internal mixer for mixing. The mixing time can preferably be 8 minutes to 10 minutes , the temperature may preferably be 110°C to 115°C;

[0051] Step 3: Add the odorless crosslinking agent, ammonia removal agent, and foaming agent weighed in step 1 to the mixed material for mixing. The mixing time can be preferably 5 minutes to 8 minutes, and the temperature can be opti...

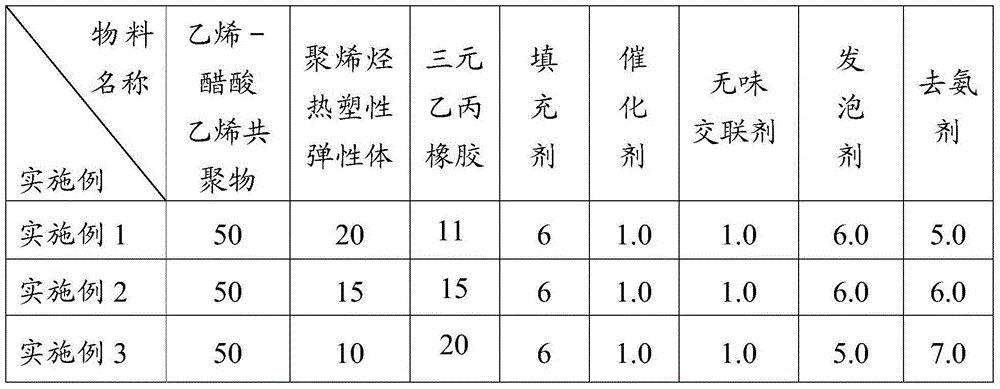

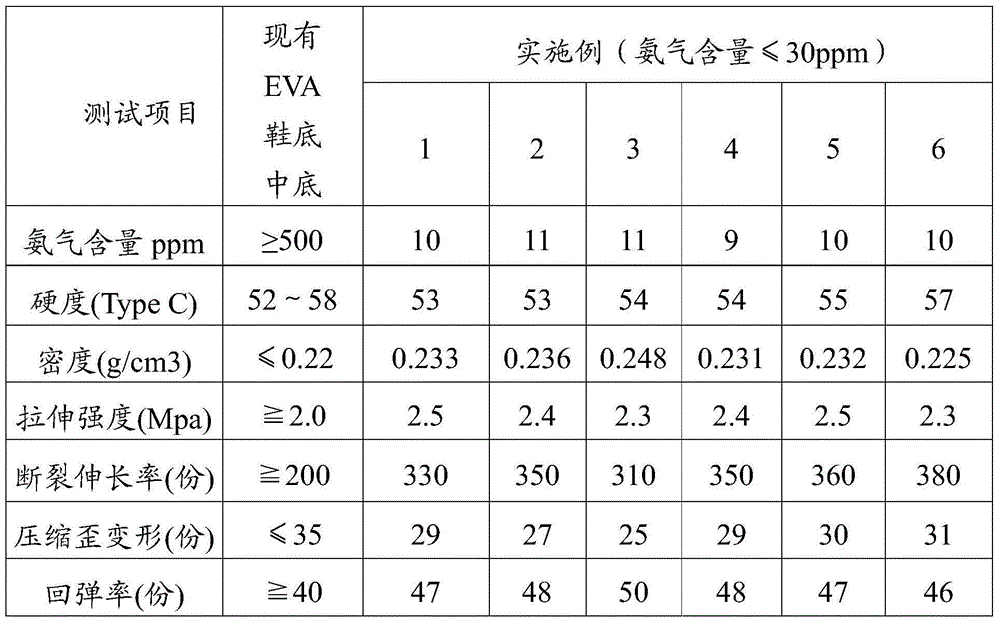

Embodiment 1~3

[0057]

[0058] Table 1: Blending formula of EVA composite foaming material (parts)

[0059] 1) each raw material is weighed by the raw material composition in Table 1 and the parts by weight of each composition;

[0060] 2) Pour all the raw materials weighed in step 1 except the cross-linking agent and foaming agent into the internal mixer for mixing. The mixing time is 8 minutes and the temperature is 110-115°C.

[0061] 3) Add an odorless cross-linking agent, an ammonia removal agent, and a foaming agent to the material kneaded in step 2, and knead for 6 minutes at a temperature of 115-120°C.

[0062] 4) Pour the obtained mixture into a granulator to granulate, and then foam by molding or one-time injection to obtain a foam material for sports shoe soles.

[0063] After the sports shoe sole obtained in step 4 is cooled with a foam material, the semi-finished product is processed and roughened, and then molded to obtain a finished shoe sole.

[0064] Among them, the sel...

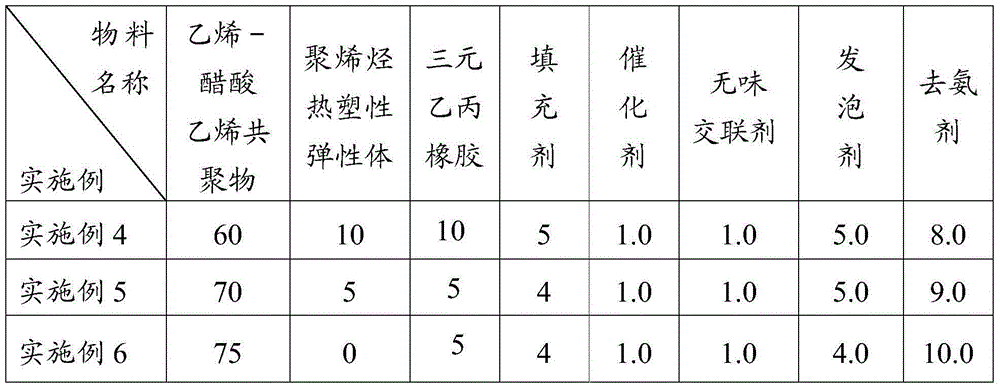

Embodiment 4~6

[0066]

[0067] Table 2: EVA composite foam material blending formula (parts)

[0068] 1) each raw material is weighed by the raw material composition in Table 1 and the parts by weight of each composition;

[0069] 2) Pour all the raw materials weighed in step 1 except the cross-linking agent and foaming agent into the internal mixer for mixing. The mixing time is 8 minutes and the temperature is 110-115°C.

[0070] 3) Add an odorless cross-linking agent, an ammonia removal agent, and a foaming agent to the material kneaded in step 2, and knead for 6 minutes at a temperature of 115-120°C.

[0071] 4) Pour the obtained mixture into a granulator to granulate, and then foam by molding or one-time injection to obtain a foam material for sports shoe soles.

[0072] After the sports shoe sole obtained in step 4 is cooled with a foam material, the semi-finished product is processed and roughened, and then molded to obtain a finished shoe sole.

[0073] Among them, the selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com