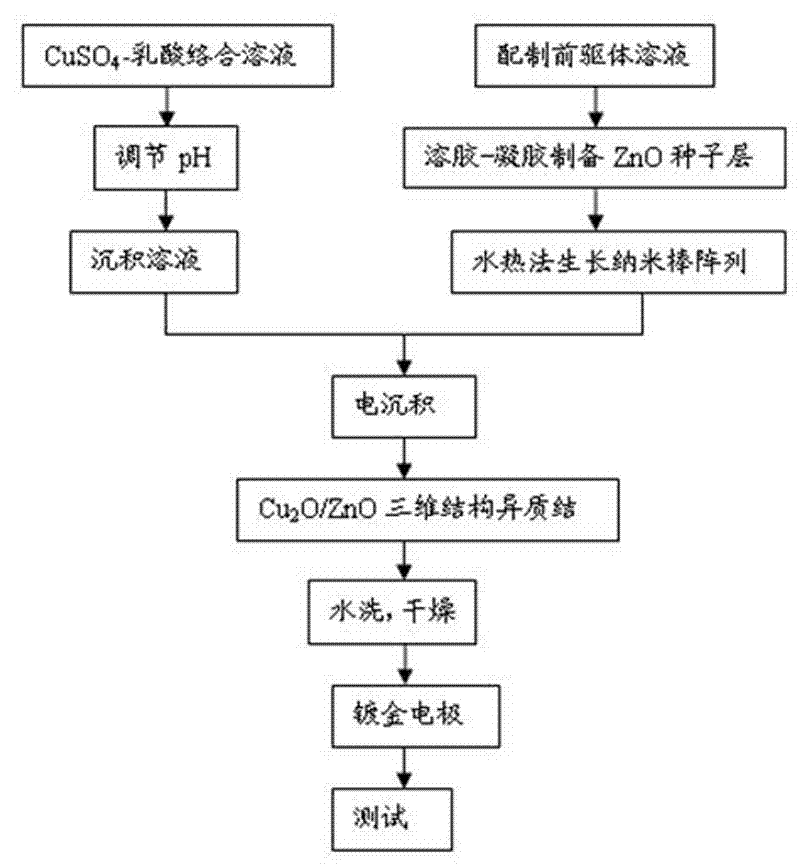

Method for preparing zno/cu2o heterojunction material and zno/cu2o three-dimensional structure heterojunction solar cell

A three-dimensional structure, heterojunction technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as insufficient carrier transport and separation, short collection length of photogenerated carriers, limiting cell efficiency, etc. , to achieve the effect of excellent overall performance, high photoelectric conversion efficiency and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

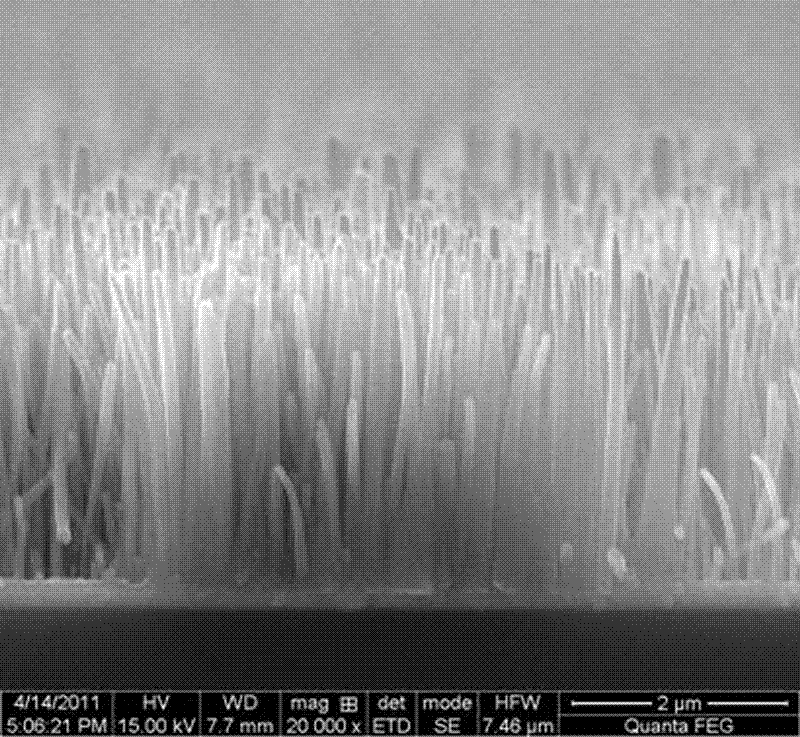

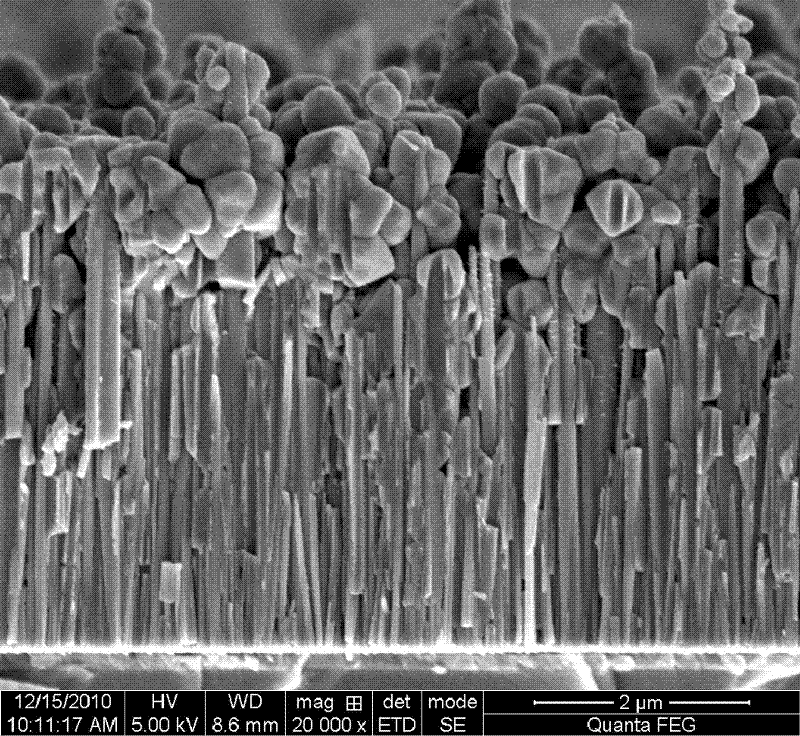

[0055] (1) The ZnO nanorod array was grown by hydrothermal method on the ITO conductive substrate, the seed layer thickness was 150nm, the rod length was 4μm, the rod spacing was 150nm, and the rod diameter was 150.

[0056] (2) Preparation of p-type Cu 2 O semiconductor precursor solution to CuSO 4 solution as a precursor solution, adding lactic acid as a stabilizer, where CuSO 4 The concentration of lactic acid is 0.2mol / L, the concentration of lactic acid is 3mol / L, and the pH of the solution is adjusted to 10.5 with NaOH;

[0057] (3) Electrochemical conformal deposition of Cu on the surface of ZnO nanorods using the above precursor solution as the electrolyte 2 O seed layer, the conditions of the deposition process are: temperature 25°C, deposition potential -0.4V, deposition time 100s.

[0058] (4) Preparation of p-type Cu 2 O semiconductor deposition solution to CuSO 4 solution as a deposition solution, adding lactic acid as a stabilizer, where CuSO 4 The concentr...

Embodiment 2

[0062] (1) ZnO nanorod arrays were grown hydrothermally on the ITO conductive substrate, the seed layer thickness was 100nm, the rod length was 4μm, the rod spacing was 100nm, and the rod diameter was 50nm.

[0063] (2) Preparation of p-type Cu 2 O semiconductor precursor solution to CuSO 4 solution as a precursor solution, adding lactic acid as a stabilizer, where CuSO 4 The concentration of lactic acid is 0.2mol / L, the concentration of lactic acid is 3mol / L, and the pH of the solution is adjusted to 9.0 with NaOH;

[0064] (3) Electrochemical conformal deposition of Cu on the surface of ZnO nanorods using the above precursor solution as the electrolyte 2 O seed layer, the conditions of the deposition process are: temperature 15°C, deposition potential -0.5V, deposition time 100s.

[0065] (4) Preparation of p-type Cu 2 O semiconductor deposition solution to CuSO 4 solution as a deposition solution, adding lactic acid as a stabilizer, where CuSO 4 The concentration of l...

Embodiment 3

[0068] (1) The ZnO nanorod array was grown by hydrothermal method on the ITO conductive substrate, the seed layer thickness was 150nm, the rod length was 4μm, the rod spacing was 150nm, and the rod diameter was 150.

[0069] (2) Preparation of p-type Cu 2 O semiconductor precursor solution to CuSO 4 solution as a precursor solution, adding lactic acid as a stabilizer, where CuSO 4The concentration of lactic acid is 0.2mol / L, the concentration of lactic acid is 3mol / L, and the pH of the solution is adjusted to 9.0 with NaOH;

[0070] (3) Electrochemical conformal deposition of Cu on the surface of ZnO nanorods using the above precursor solution as the electrolyte 2 O seed layer, the conditions of the deposition process are: temperature 25°C, deposition potential -0.4V, deposition time 100s.

[0071] (4) Preparation of p-type Cu 2 O semiconductor deposition solution to CuSO 4 solution as a deposition solution, adding lactic acid as a stabilizer, where CuSO 4 The concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com