Preparation method of porous ZnIn2S4 photo-catalyst

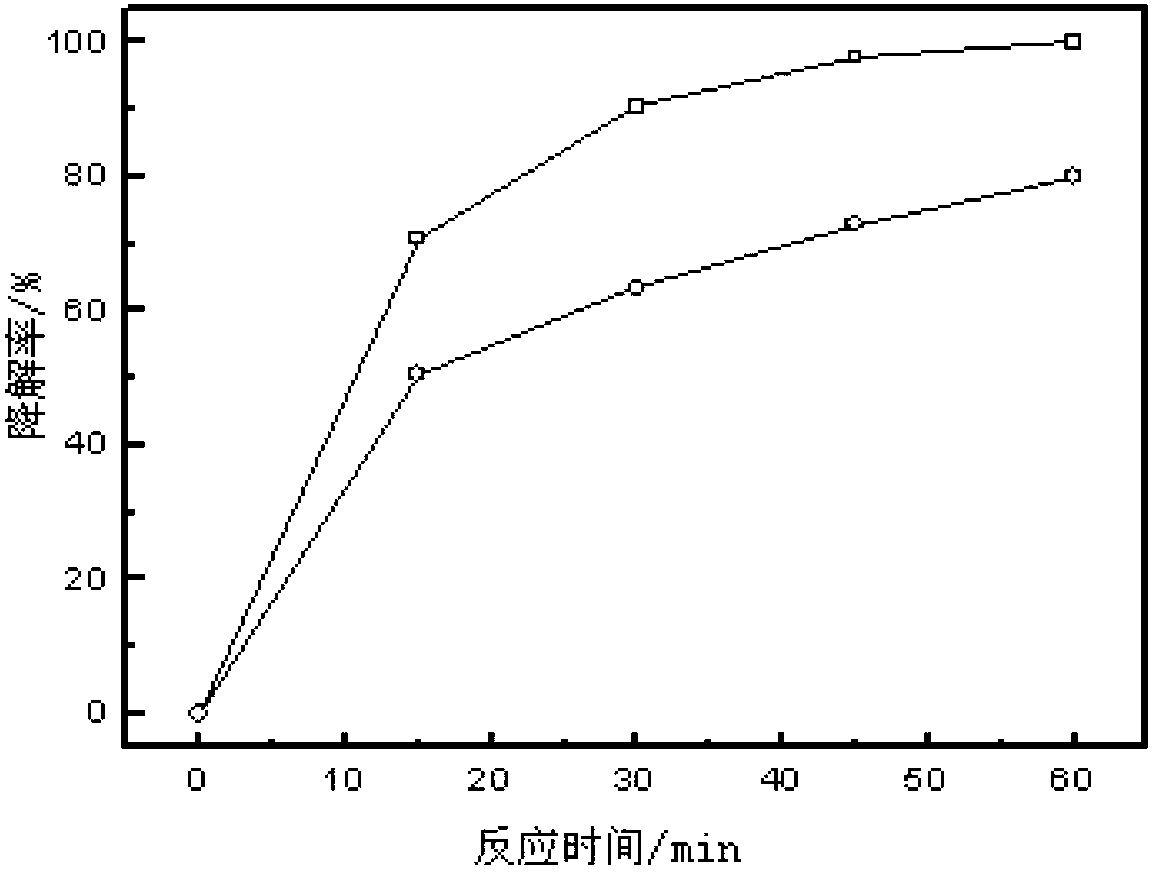

A photocatalyst, znin2s4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalytic efficiency and long time consumption, achieve high catalytic activity, reduce recombination probability, and prepare short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: a kind of porous ZnIn in this embodiment 2 S 4 The preparation method of photocatalyst is realized through the following steps:

[0019] 1. Under the condition of ultrasonic power of 100W~150W, add bromoalkylpyridine template agent into distilled water and vibrate and mix for 10min~20min to make bromoalkylpyridine with a concentration of 0.01mol / L~0.05mol / L solution; according to the ratio of 1:2:(6~8) by molar ratio, take divalent zinc salt, trivalent indium salt and thioacetamide respectively and join in the above-mentioned bromoalkylpyridine solution, wherein thioacetamide The concentration in the reaction solution is 0.1mol / L~0.5mol / L. Under the condition of ultrasonic power of 100W~150W, after the above reaction solution is vibrated and mixed for 10min~20min, the pH value of the reaction solution is adjusted to 1~7, wherein The divalent zinc salt is zinc nitrate, zinc chloride, zinc sulfate or zinc acetate, and the trivalent indium salt i...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the templating agent bromoalkylpyridine is added to distilled water and vibrated and mixed for 12min~18min to make the concentration 0.02mol / L~0.04mol / L bromoalkylpyridine solution. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, the template agent bromoalkylpyridine is added to distilled water and vibrated and mixed for 15 minutes to prepare a bromoalkylpyridine solution with a concentration of 0.03mol / L . Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com