Nylon composition, method for preparing same and application thereof

A technology of composition and nylon, which is applied in the field of nylon composition and its preparation and application, can solve the problems of reducing warpage and preventing glass fiber, weak shock resistance, large specificity, etc., and achieves improved appearance, reduced overall density, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides the preparation method of above-mentioned nylon composition simultaneously: the step comprises

[0045] (1) Mixing of raw materials;

[0046] (2) plasticizing extrusion;

[0047] (3) Pelletizing and post-processing.

[0048] Wherein, material mixing is that the raw material of above-mentioned formula is mixed with conventional mixing method, and the present invention preferably mixes with high-speed mixer, makes mixture mix uniformly, and the mixing speed of preferred high-speed mixer of the present invention is 750 rpm, and stirring time is 3~ 5 minutes.

[0049] Among them, the plasticizing extrusion is to add the above-mentioned mixed materials into the twin-screw extruder, and introduce glass fibers from the glass fiber port during the extrusion process. The temperature of the extruder is controlled between 240°C and 260°C. The length-to-diameter ratio of the machine is selected to be greater than 36:1. The shearing in the screw co...

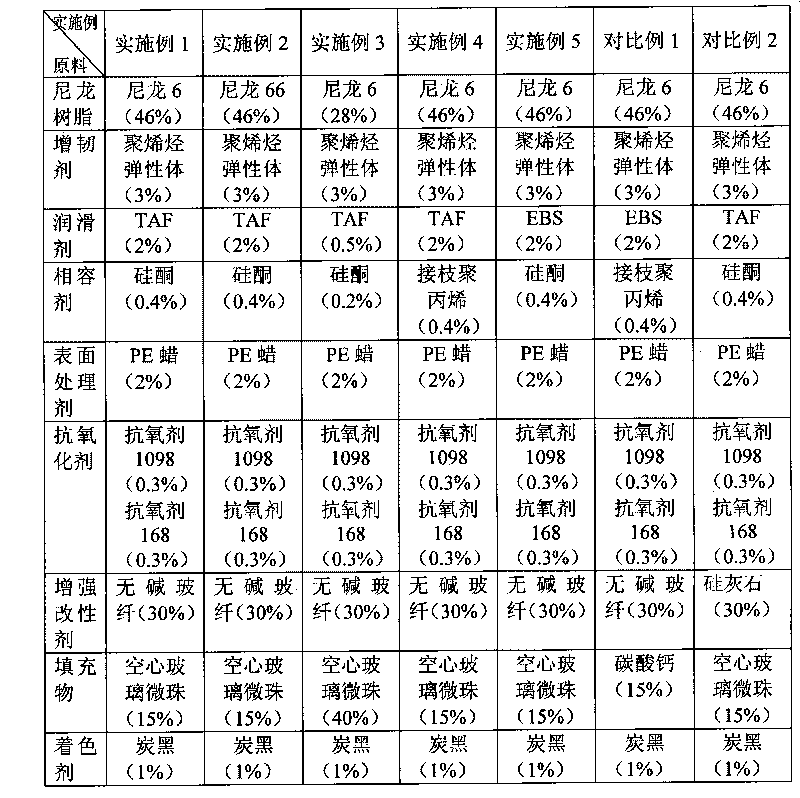

Embodiment 1

[0053] Composition Raw Materials:

[0054] E-glass fiber, 988A................................30%

[0055] Nylon 6, M2800................................46%

[0056] Hollow glass microspheres................................15%

[0057] Polyolefin Elastomer, EXACT 5061...........3%

[0058] TAF................................................2%

[0059] PE wax................................2%

[0060] Silicone................................0.4%

[0061] Antioxidant IRGANOX1098..........0.3%

[0062] Antioxidant IRGANOS168................................0.3%

[0063] Carbon Black, V9A32 Cabot................................1%

[0064] Production Process:

[0065] (1) Put the raw materials into the high mixer and stir at a speed of 750r / m for 5 minutes

[0066] (2) Put the mixed material into the extruder, and control the temperature of each section between 230°C and 255°C

[0067] (3) The extruded product is obtained after water cooling-cutting-sieving-sieving-magneti...

Embodiment 2

[0069] Prepare nylon composition according to the method for embodiment 1, difference is that composition raw material is:

[0070] E-glass fiber, 988A................................30%

[0071] Nylon 66, MPR27................................46%

[0072] Hollow glass microspheres................................15%

[0073] Polyolefin Elastomer, EXACT 5061..........3%

[0074] TAF................................................2%

[0075] PE wax...................................2%

[0076] Silicone................................0.4%

[0077] Antioxidant IRGANOX1098................................0.3%

[0078] Antioxidant IRGANOS168................................0.3%

[0079] Carbon Black, V9A32 Cabot................................1%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com