Stone paper and manufacturing method thereof

A stone paper, linear low-density technology, applied in the field of non-wood pulp paper, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

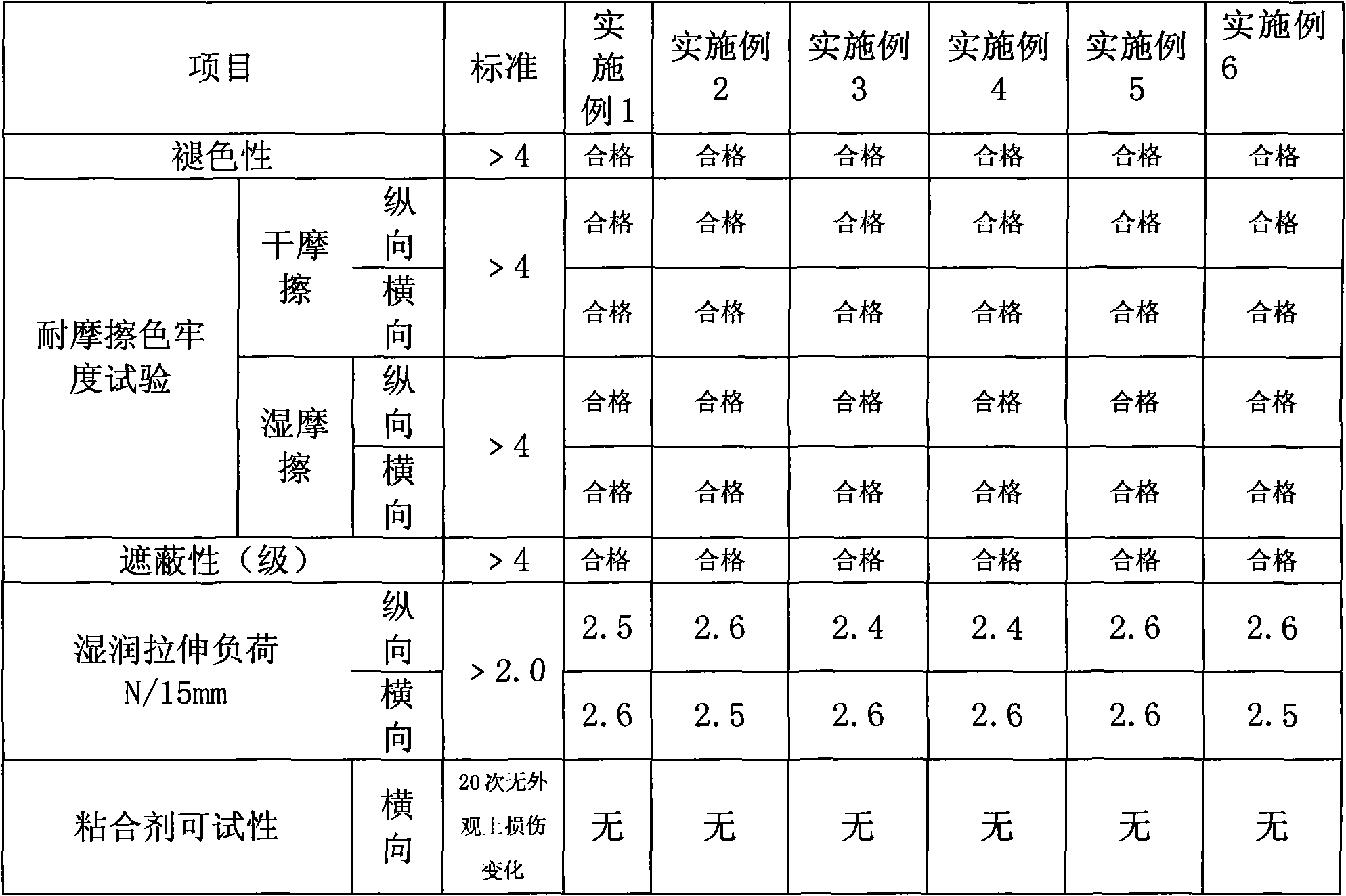

Examples

Embodiment 1

[0031] formula:

[0032] 6 parts of low density polyethylene (MI 0.2), 12 parts of linear low density polyethylene (MI 0.6), 3 parts of hot melt adhesive (melting point 80°C), 65 parts of 1500 mesh heavy calcium carbonate, r-methacryloyloxy 3 parts of propyl propyl trimethoxysilane, 10 parts of 1500 mesh titanium dioxide, 0.5 parts of stearic acid, 0.5 parts of dioctyl epoxy tetrahydrophthalate, 0.2 parts of polyethylene wax, sorbitan stearic acid 0.5 part of ester, 0.2~0.6 part of antioxidant, 0.1~0.3 part of anti-ultraviolet agent;

[0033] Among them, the antioxidant is dilauryl thiodipropionate; the anti-ultraviolet agent is a benzotriazole anti-ultraviolet agent.

[0034] The density of low density polyethylene is 0.925, and the density of linear low density polyethylene is 0.92~0.93;

[0035] The hot melt adhesive is ethylene-vinyl acetate copolymer (EVA) with a melting point of 100°C;

[0036] The fineness of heavy calcium carbonate is 2000 mesh;

Embodiment 2

[0041] 8 parts of low density polyethylene (MI 0.3), 10 parts of linear low density polyethylene (MI 0.7), 4 parts of hot melt adhesive (melting point 85℃), 70 parts of heavy calcium carbonate of 1600 mesh, r-methacryloyloxy 4 parts of propyl propyl trimethoxysilane, 10 parts of titanium dioxide, 1 part of stearic acid, 1 part of dioctyl epoxy tetrahydrophthalate, 0.3 part of polyethylene wax, 0.3 part of antioxidant, 0.15 part of anti-ultraviolet agent Copies. 0.6 parts of sorbitan stearate.

[0042] The density of low density polyethylene is 0.92, and the density of linear low density polyethylene is 0.92;

[0043] The hot melt adhesive is ethylene-vinyl acetate copolymer (EVA) with a melting point of 80°C;

[0044] The fineness of heavy calcium carbonate is 1500 mesh;

[0045] Titanium dioxide is rutile, with a fineness of 1500 mesh.

[0046] The antioxidant is dilauryl thiodipropionate; the anti-ultraviolet agent is salicylate.

[0047] Preparation method: mix heavy calcium carbon...

Embodiment 3

[0049] 10 parts of low density polyethylene (MI 0.4), 8 parts of linear low density polyethylene (MI 0.8), 5 parts of hot melt adhesive (melting point 90℃), 75 parts of heavy calcium carbonate of 1700 mesh, r-methacryloyloxy 4 parts of propyl propyl trimethoxysilane, 7 parts of 1800 mesh titanium dioxide, 1.5 parts of stearic acid, 1.5 parts of dioctyl epoxy tetrahydrophthalate, 0.4 parts of polyethylene wax, 0.4 parts of antioxidants, anti-ultraviolet rays Agent 0.2 parts. 0.7 parts of sorbitan stearate.

[0050] Among them, the antioxidant is dilauryl thiodipropionate; the anti-ultraviolet agent is benzotriazole.

[0051] The density of low density polyethylene is 0.92, and the density of linear low density polyethylene is 0.92;

[0052] The hot melt adhesive is ethylene-vinyl acetate copolymer (EVA) with a melting point of 80°C;

[0053] The fineness of heavy calcium carbonate is 1500 mesh;

[0054] The titanium dioxide is rutile, with a fineness of 1500 mesh;

[0055] Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com