Polyethylene composite film capable of 100% recovery as well as preparation method and application thereof

A polyethylene and composite film technology, applied in the field of polyethylene materials, can solve problems such as difficulty in meeting process requirements, poor temperature resistance, failure to meet the temperature resistance requirements of zipper bags and nozzle bags, etc., and achieve excellent composite fastness, Difficult to delaminate, excellent hot-tack and heat-sealing strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of the 100% recyclable polyethylene composite film described in the above technical solution, when the adhesive layer is a low-density polyethylene film, the method comprises the following steps:

[0056] After melting and plasticizing the raw materials of the outer layer of the printing layer, the middle layer of the printing layer and the inner layer of the printing layer, the three-layer blown film co-extrusion process is used to co-extrude the blown film to obtain the primary printing layer;

[0057] The primary printing layer is sequentially subjected to longitudinal uniaxial stretching, annealing and corona treatment to obtain a composite printing layer;

[0058] Melting and plasticizing the raw materials of the outer layer of the heat-sealing layer, the middle layer of the heat-sealing layer and the inner layer of the heat-sealing layer, and then co-extruding the blown film using a three-layer blown film co-...

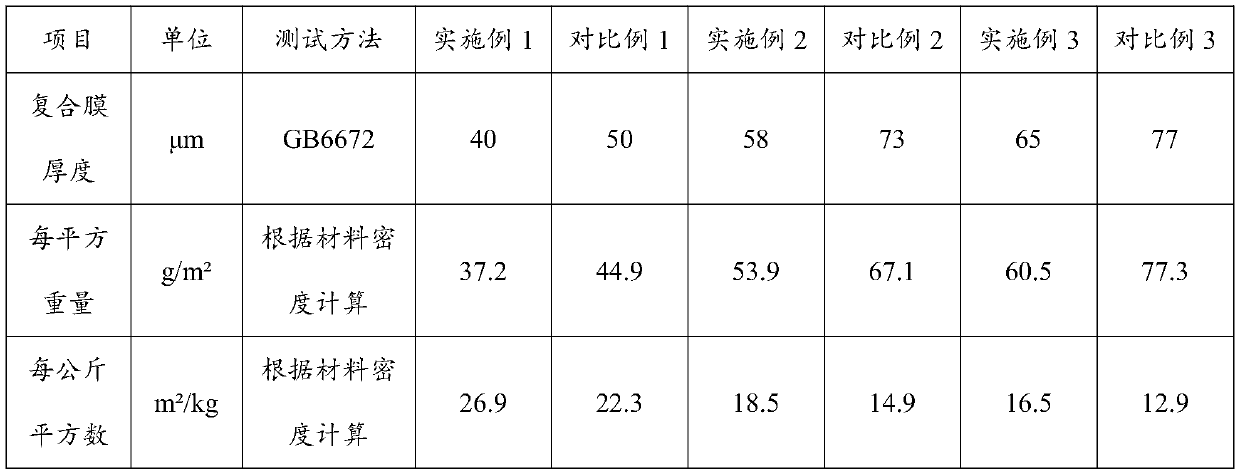

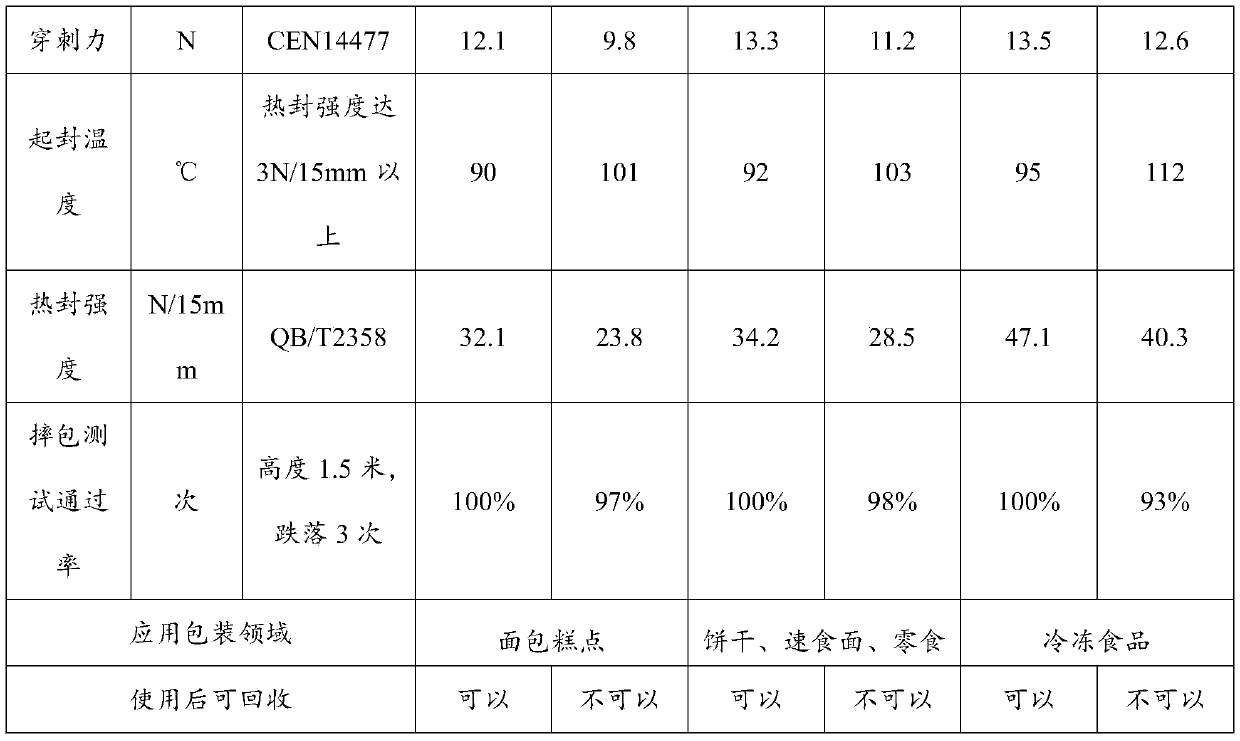

Embodiment 1

[0088] In the 100% recyclable polyethylene composite film prepared in this example, the adhesive layer is a solvent-free glue layer, the thickness is negligible, the thickness of the printing layer is 20 μm, and the heat-sealing layer is 20 μm;

[0089] In the printing layer, the mass ratio of the outer layer of the printing layer, the middle layer of the printing layer and the inner layer of the printing layer is 3:4:3; in terms of mass percentage, the outer layer of the printing layer includes 45% of metallocene medium density polyethylene 3505MC and 55% of High-density polyethylene HTA108; in terms of mass percentage, the middle layer of the printing layer includes 25% of bimodal medium-density polyethylene FB1350 and 75% of metallocene low-density polyethylene 6056ML; in terms of mass percentage, the inner layer of the printing layer includes 35% of Metallocene medium density polyethylene 4002ML and 65% high density polyethylene 5960G;

[0090] In the heat-sealing layer, t...

Embodiment 2

[0102] In the 100% recyclable polyethylene composite film prepared in this example, the adhesive layer is a solvent-free glue layer, the thickness is negligible, the thickness of the printing layer is 30 μm, and the heat-sealing layer is 20 μm;

[0103] In the printing layer, the mass ratio of the outer layer of the printing layer, the middle layer of the printing layer and the inner layer of the printing layer is 1:2:1; in terms of mass percentage, the outer layer of the printing layer includes 45% of metallocene medium density polyethylene 3505MC and 55% of High-density polyethylene HTA108; in terms of mass percentage, the middle layer of the printing layer includes 25% of bimodal medium-density polyethylene FB1350 and 75% of metallocene low-density polyethylene 6056ML; in terms of mass percentage, the inner layer of the printing layer includes 35% of Metallocene medium density polyethylene 4002ML and 65% high density polyethylene 5960G;

[0104] In the heat-sealing layer, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com