Heat shrinkable film applicable to automatic quick packaging on production line

A heat shrinkable film, production line technology, applied in the direction of layered products, synthetic resin layered products, containers, etc., to achieve the effect of reducing operating procedures and steps, good heat sealing performance, and high barrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

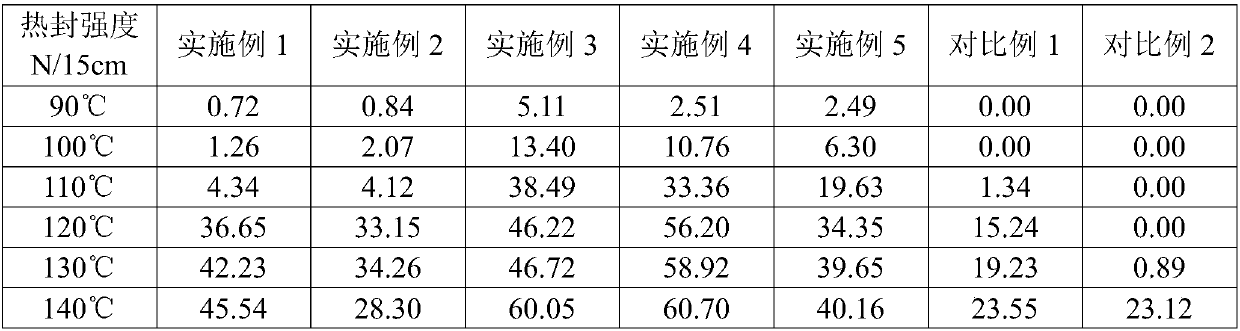

Examples

Embodiment 1

[0076] The heat-shrinkable film includes a surface layer 1 (PA), a structural layer 2 (PE), a barrier layer 3 (PA / EVOH / PA) from outside to inside, including an EVOH barrier middle layer 31 and barrier layer protection layers 32 on both sides. PA layer), heat seal layer 4 (POP+mLLDPE). The surface layer 1, the structural layer 2, the barrier layer 3 and the heat-sealing layer 4 are respectively connected by an adhesive resin 5 (Tie).

[0077] The specific membrane structure is: PA / Tie / PE / Tie / PA / EVOH / PA / Tie / POP+mLLDPE;

[0078] The PA of the surface layer 1 and the middle two layers are all blended by PA6, copolymerized PA and amorphous PA. The mass percentage of copolymerized PA in the resin of the PA layer is 10%, the content of 4POP in the heat-sealing layer is 90%, and the total thickness of the film is It is 75um. PE is a lower density (≤0.91g / cm 3 ) PE.

[0079] The production process includes the following steps:

[0080] S1: Place the raw materials in an extruder to...

Embodiment 2-4

[0084] The metallocene material mLLDPE is added to the heat-sealing layer, and the difference from Example 1 is that the contents of POP in the heat-sealing layer are 85%, 70%, and 50%, respectively.

Embodiment 5-8

[0086] There are two layers of PA in the surface layer and the middle layer, and the mass percentages of the resin copolymerized PA in the PA layer are 20%, 30%, 40%, and 50% respectively. The inflation ratio of the secondary inflation in S2 is 2.0-4.5, and the traction ratio is 3.0-3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com