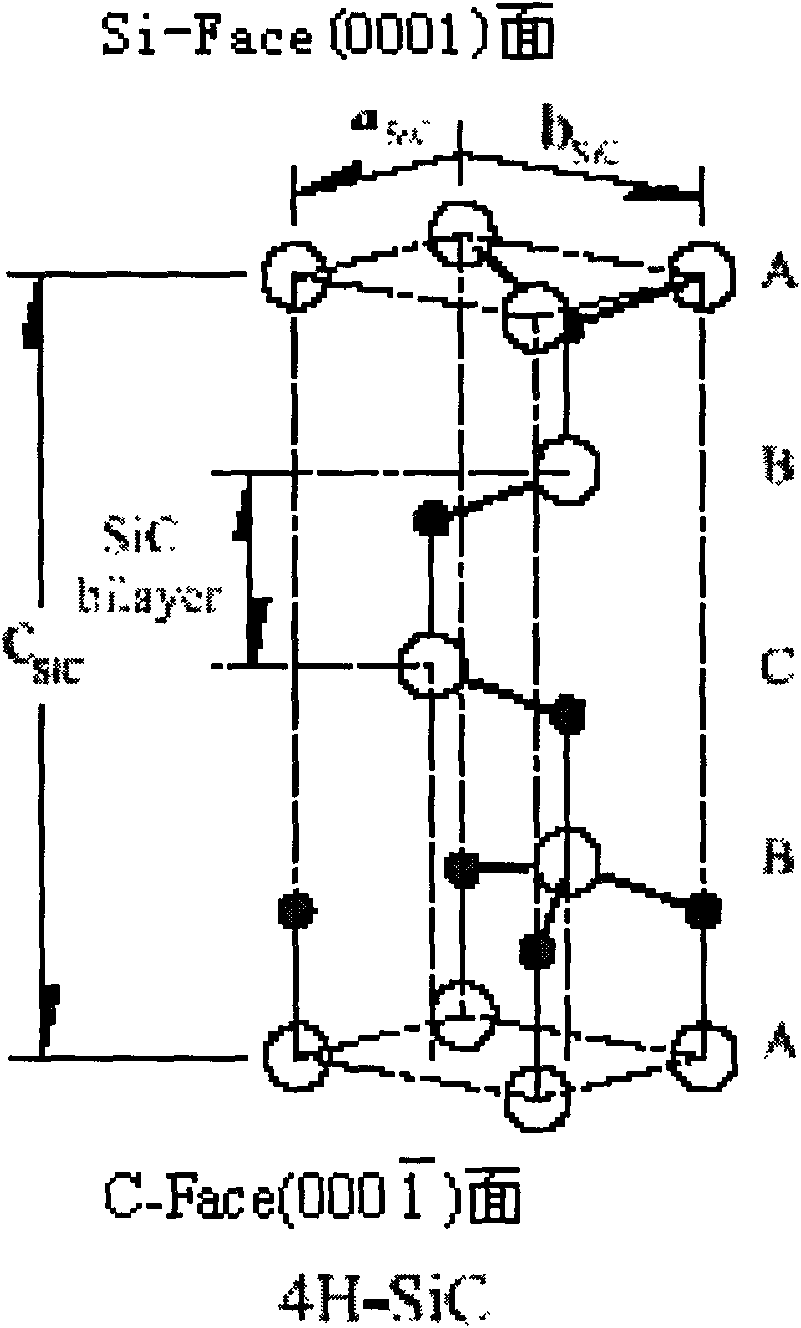

Method for graphene epitaxial growth on 4H-SiC silicon surface

An epitaxial growth and graphene technology, applied in the field of microelectronics, can solve the problems of difficult to control the growth process, difficult to obtain large-scale uniform samples, and low uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

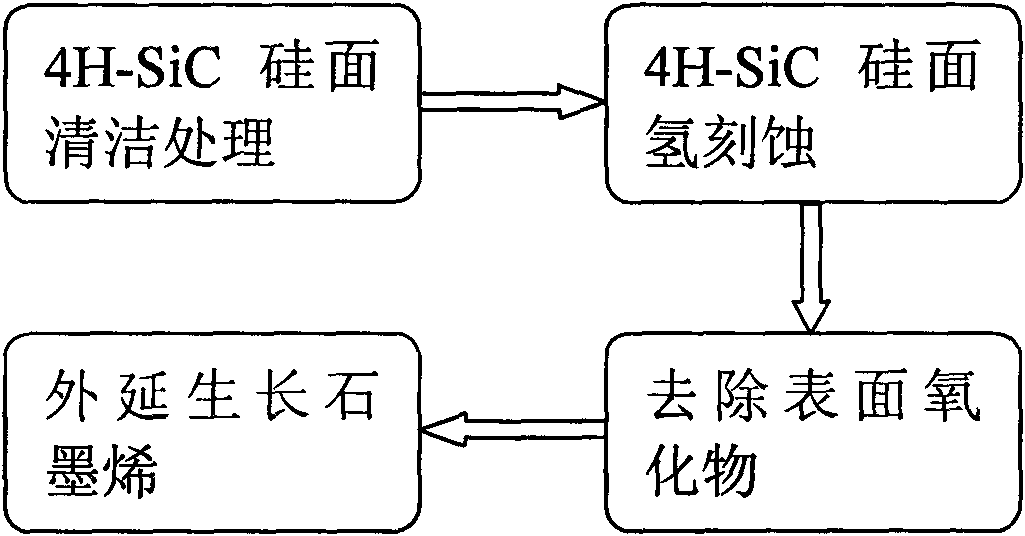

[0016] Embodiment 1, the steps of the present invention to epitaxially grow Graphene on the 4H-SiC silicon surface are as follows:

[0017] Step 1, remove sample surface pollutants.

[0018] For surface cleaning of 4H-SiC silicon surface, first use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0019] Step 2, performing hydrogen etching on the 4H-SiC silicon surface.

[0020] Place the 4H-SiC silicon surface in a vacuum of 2.4×10 -6 mbar CVD furnace chamber, and feed hydrogen gas with a flow rate of 60l / min, when the temperature rises to 1400°C, then feed propane with a flow rate of 8ml / min, heat up to 1500°C, pressure 90mbar, keep for 10 minutes, and then cool down to room temperature Finally, take it out to remove surface scratches and form regular...

Embodiment 2

[0025] Embodiment 2, the steps of the present invention to epitaxially grow Graphene on the 4H-SiC silicon surface are as follows:

[0026] Step 1, remove sample surface contaminants.

[0027] For surface cleaning of 4H-SiC silicon surface, first use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0028] Step 2, performing hydrogen etching on the 4H-SiC silicon surface.

[0029] Place the 4H-SiC silicon surface in a vacuum of 2.4×10 -6 mbar CVD furnace chamber, and feed hydrogen with a flow rate of 100l / min, when the temperature rises to 1500°C, then feed propane with a flow rate of 12ml / min, raise the temperature to 1650°C, press 100mbar, keep for 20 minutes, and then cool down to room temperature Finally, take it out to remove surface scratches and ...

Embodiment 3

[0034] Embodiment 3, the steps of the present invention to epitaxially grow Graphene on the 4H-SiC silicon surface are as follows:

[0035] Step A, remove sample surface contaminants.

[0036] For surface cleaning of 4H-SiC silicon surface, first use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0037] Step B, performing hydrogen etching on the 4H-SiC silicon surface.

[0038] Place the 4H-SiC silicon surface in a vacuum of 2.4×10 -6 mbar CVD furnace cavity, and feed hydrogen with a flow rate of 90l / min, when the temperature rises to 1450°C, then feed propane with a flow rate of 10ml / min, heat up to 1600°C, pressure 96mbar, keep for 15 minutes, and then cool down to room temperature Finally, take it out to remove surface scratches and form regular ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com