Single-face double-point welding process for automobile

A welding process and double-spot welding technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of inability to accurately control the welding tongs, reduce the welding effect, and narrow electrode space, and achieve stability and adaptability to multiple models Improvement, welding effect is good, and the effect of reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

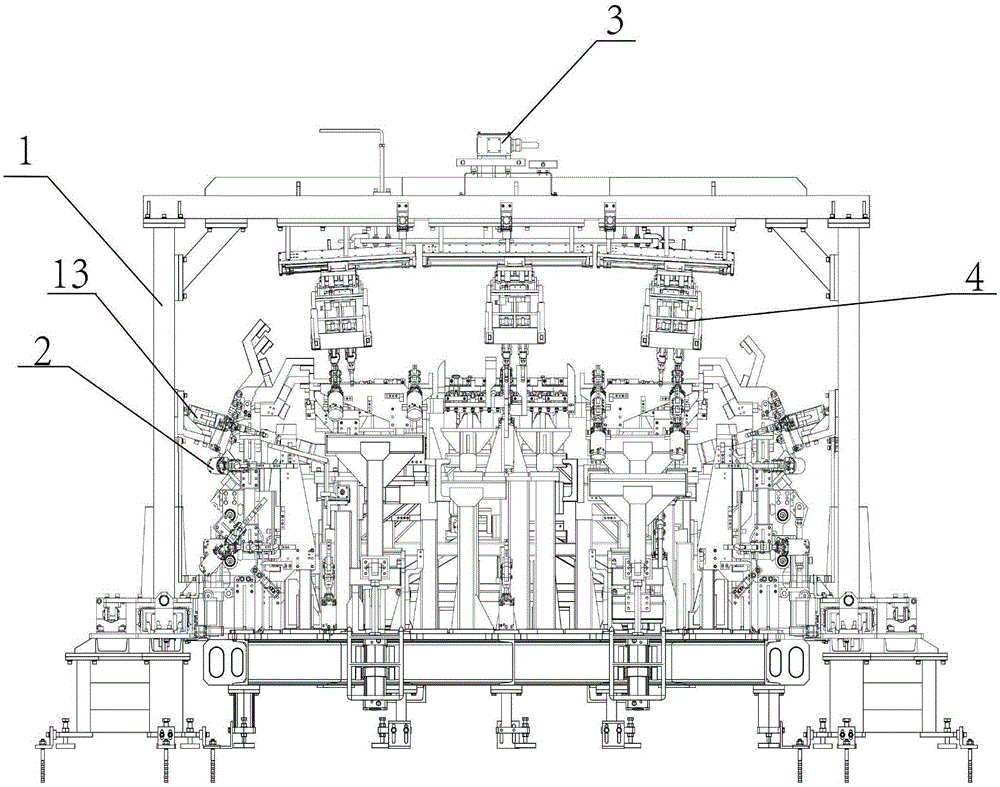

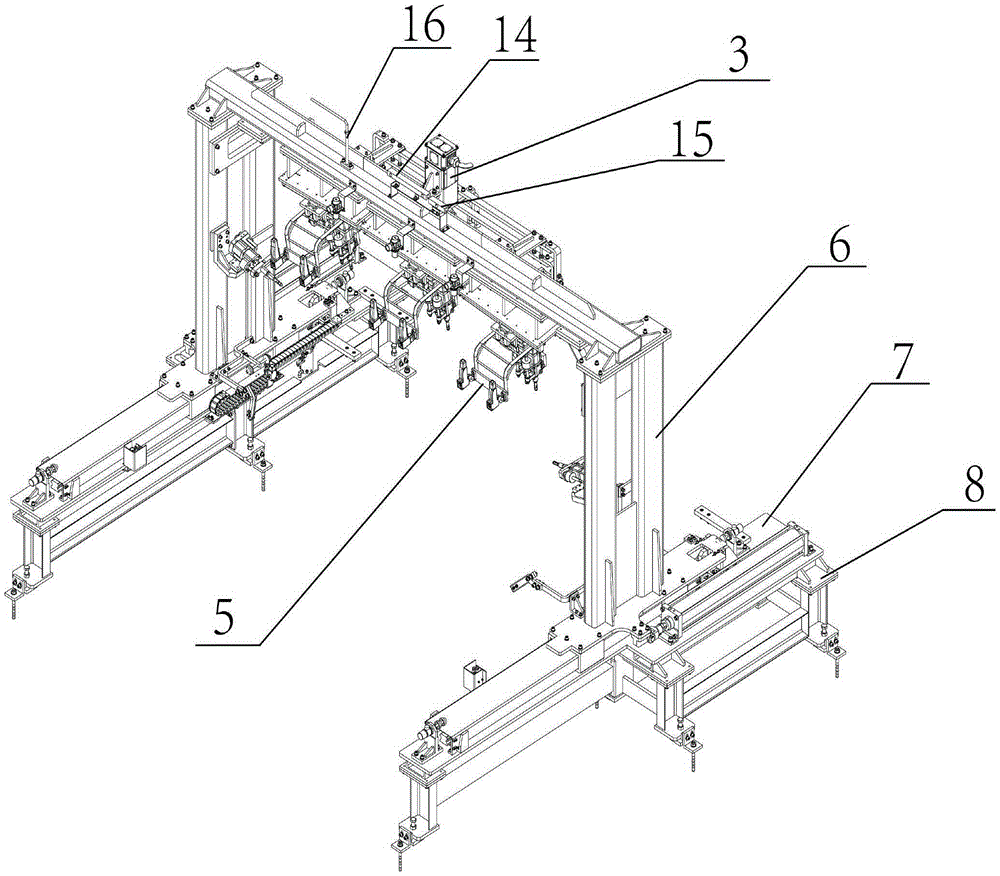

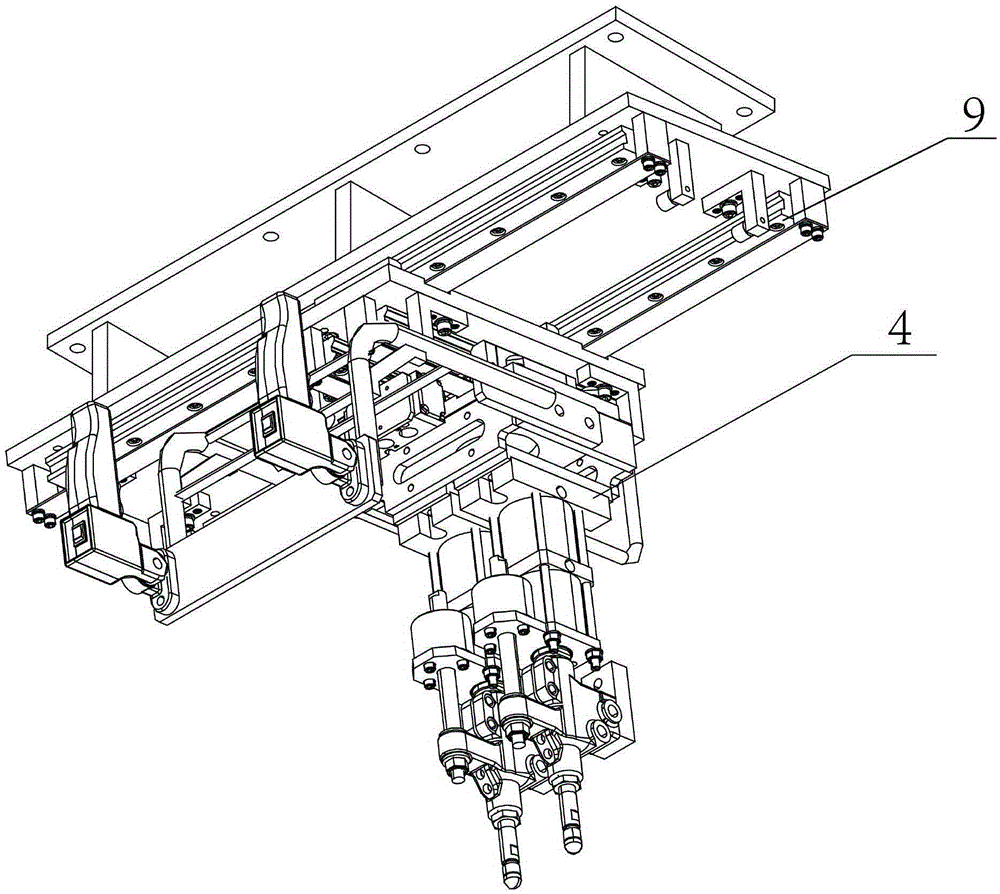

[0043] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side schematic diagram of the shaft of the gantry slide-out mechanism of the special welding machine of the present invention, image 3 It is a side schematic diagram of the single-sided double-point welding tongs and the welding plane moving structure of the welding tongs of the present invention, Figure 4 It is a side schematic diagram of the upper and lower electrode structure axes of single-sided double-point welding of the present invention; as figure 1 , image 3 The one-side double-point welding process shown in the figure includes a special welding machine 1, a special fixture for automobile welding 2, a transformer 3, a single-side double-point welding clamp 4, a single-side double-point welding mechanism 5, a gantry steel structure 6, and a gantry slide Exit mechanism 7, gantry base 8, welding tongs welding plane moving structure 9, upper electrode 10, lower electrode...

Embodiment 2

[0046] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side schematic diagram of the shaft of the gantry slide-out mechanism of the special welding machine of the present invention, image 3 It is a side schematic diagram of the single-sided double-point welding tongs and the welding plane moving structure of the welding tongs of the present invention, Figure 4 It is a side schematic diagram of the upper and lower electrode structure axes of single-sided double-point welding of the present invention; as figure 2 The one-side double-point welding process shown in the figure includes a special welding machine 1, a special fixture for automobile welding 2, a transformer 3, a single-side double-point welding clamp 4, a single-side double-point welding mechanism 5, a gantry steel structure 6, and a gantry slide Exit mechanism 7, gantry base 8, welding tongs welding plane moving structure 9, upper electrode 10, lower electrode island 11,...

Embodiment 3

[0049] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side schematic diagram of the shaft of the gantry slide-out mechanism of the special welding machine of the present invention, image 3 It is a side schematic diagram of the single-sided double-point welding tongs and the welding plane moving structure of the welding tongs of the present invention, Figure 4 It is a side schematic diagram of the upper and lower electrode structure axes of single-sided double-point welding of the present invention; as Figure 4 The one-side double-point welding process shown in the figure includes a special welding machine 1, a special fixture for automobile welding 2, a transformer 3, a single-side double-point welding clamp 4, a single-side double-point welding mechanism 5, a gantry steel structure 6, and a gantry slide Exit mechanism 7, gantry base 8, welding tongs welding plane moving structure 9, upper electrode 10, lower electrode island 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com