Two phase stainless steel submerged-arc welding SAW welding procedure

A duplex stainless steel and welding process technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of limited welding use, no submerged arc welding wire and flux for duplex stainless steel welding, and high welding heat input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments accompanied with drawings are described in detail below.

[0017] This example mainly includes the following steps:

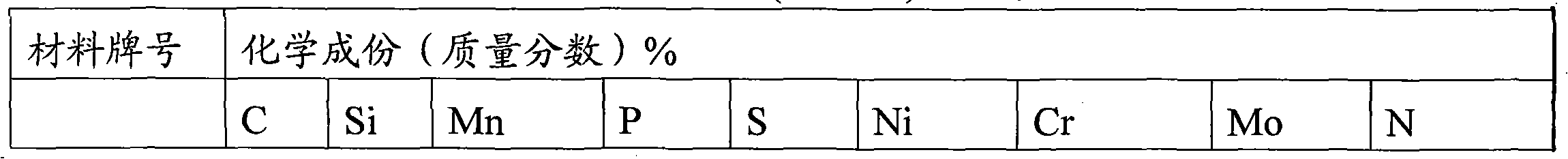

[0018] 1) Selection of welding material: on the basis of selected welding wire, look for a combination of welding wire and flux with domestic duplex stainless steel welding wire H03Cr22Ni8Mo3N (ER2209); select chemical composition WNi≥8.0%, WCr≥22.5%, WMo≥3.0%, WN ≥0.14% of the specific H03Cr22Ni8Mo3N (ER2209) welding wire with a specification of Ф4.0mm is used as the welding wire for ordinary duplex stainless steel submerged arc welding (SAW); select the appropriate flux in the flux, select the alkalinity 1.8-2.3, and the specification 8-40 Purpose SJ601 produced by Antai Technology for stainless steel welding in China is used as a duplex steel submerged arc welding (SAW) flux;

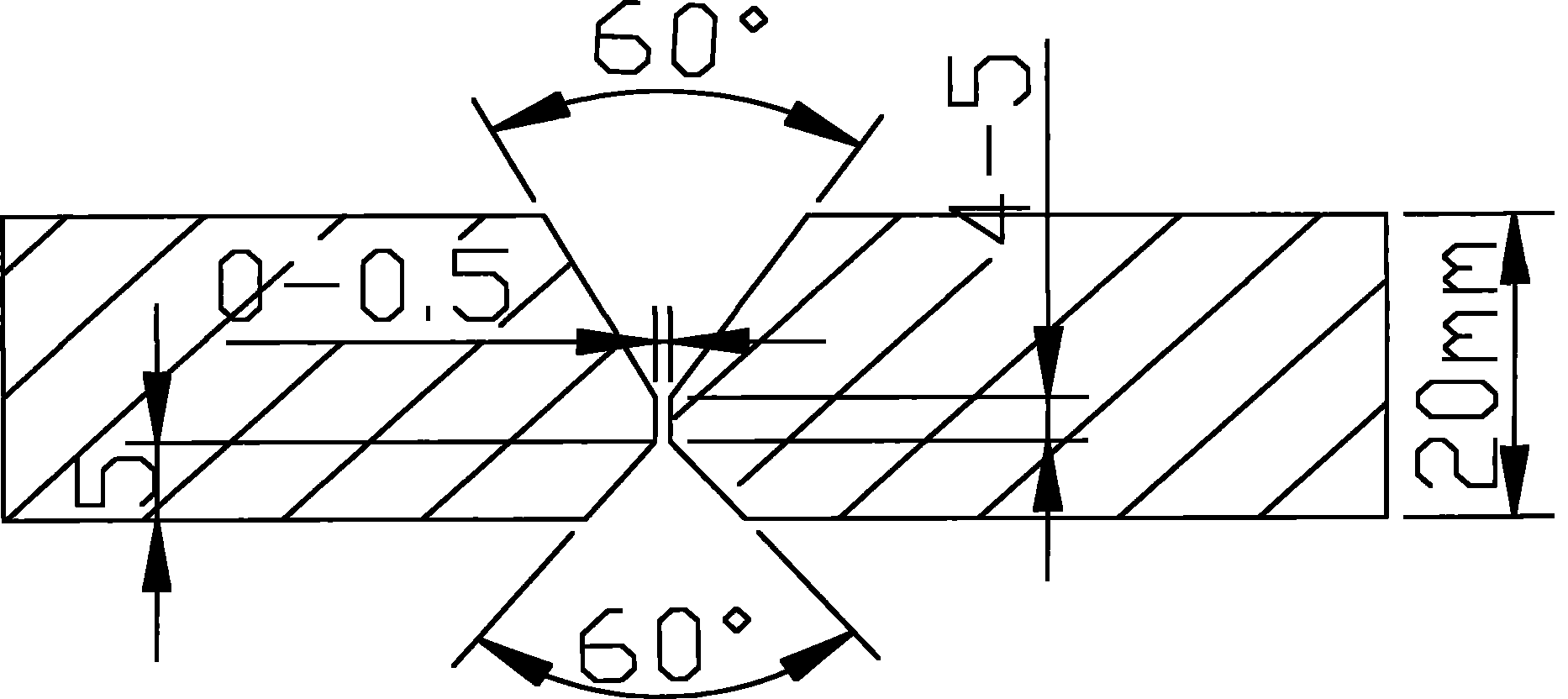

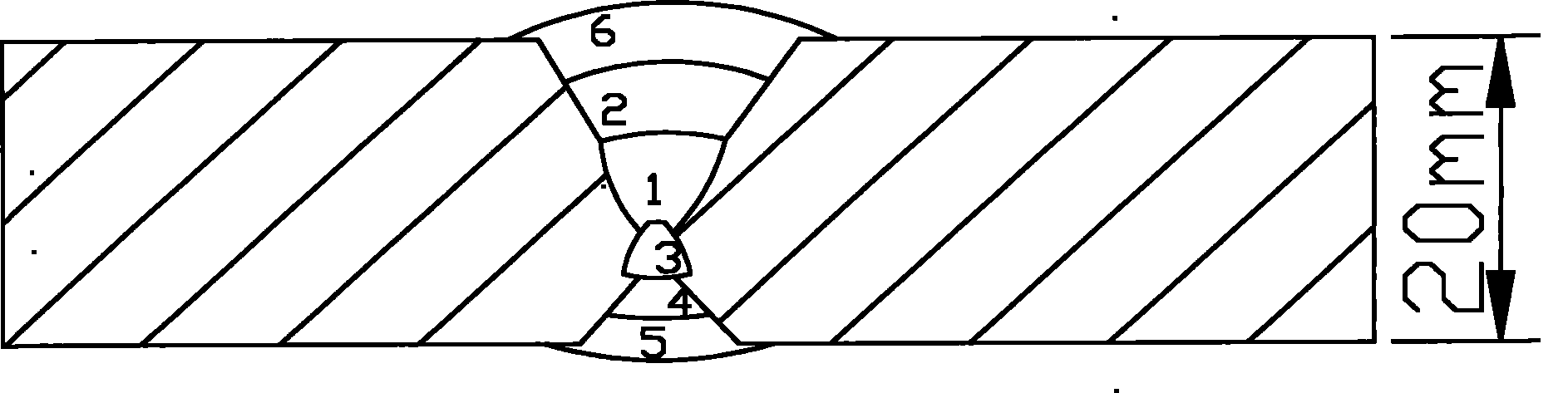

[0019] 2) Groove processing and preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com