Time-varying Reliability Determination Method of Prestressed Concrete Box Girder Bridge

A technology for concrete box girders and determining methods, applied in bridges, special data processing applications, instruments, etc., can solve the problems of rare reliability evaluation, difficulty in accurately expressing the reliability of box girder bridges, and relatively difficult reliability analysis, etc., to achieve Effects of Improving Analytical Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

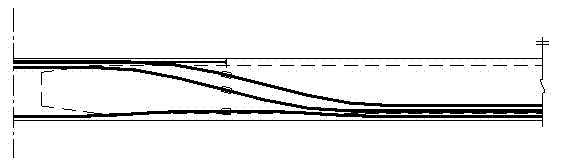

[0024] Step 1: According to the bridge structure design drawings, establish the spatial finite element calculation model of the prestressed concrete box girder bridge. The span of the bridge is 30m, the girder height is 1.75m, and the width of the half bridge deck is 12.2m. The concrete grade is C50, and the steel strand is a high-strength prestressed steel strand with a diameter of 15.24 mm, and its yield strength is 1860 MPa. Concrete box girders are simulated by combined degenerate shell elements, that is, multi-layer steel mesh simulates distributed steel bars in box girders, and steel strands are quickly generated by defining characteristic position points and shape functions; defining material constitutive relations and crack models, defining Concrete creep, shrinkage, and strand stress relaxation models, specify the time point of the analysis, and define the cross-sectional area of the steel bar or strand according to the amount of corrosion. The above models are stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com