Electrochemical method for evaluating pitting resistance of stainless steel

A stainless steel, electrochemical technology, applied in the direction of material electrochemical variables, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve problems such as inability to provide accurate evaluation of pitting corrosion, limited number of pitting corrosion, and inability to provide pitting corrosion initiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

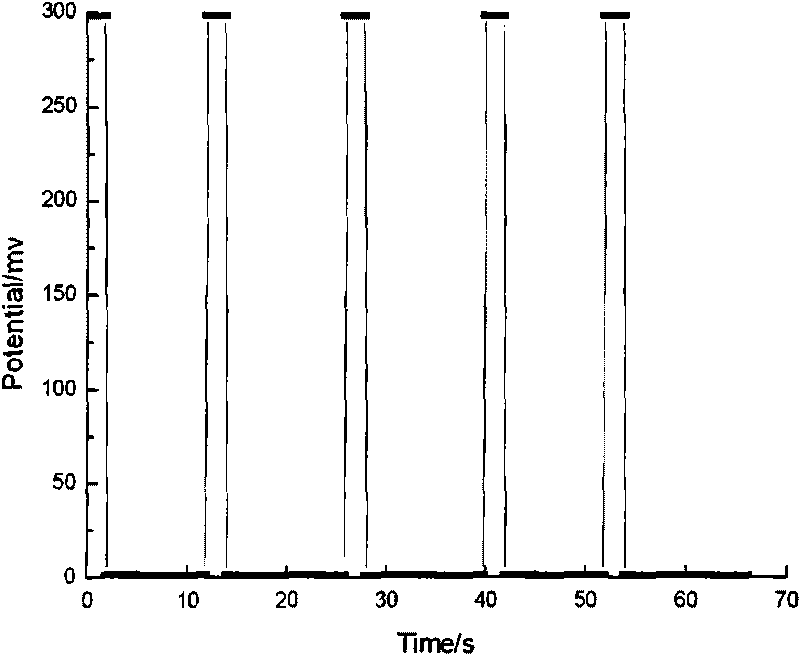

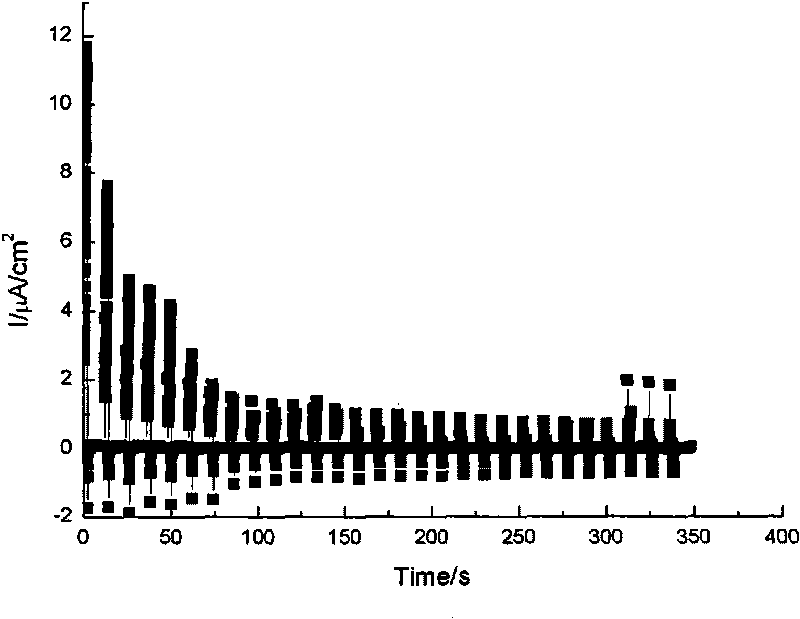

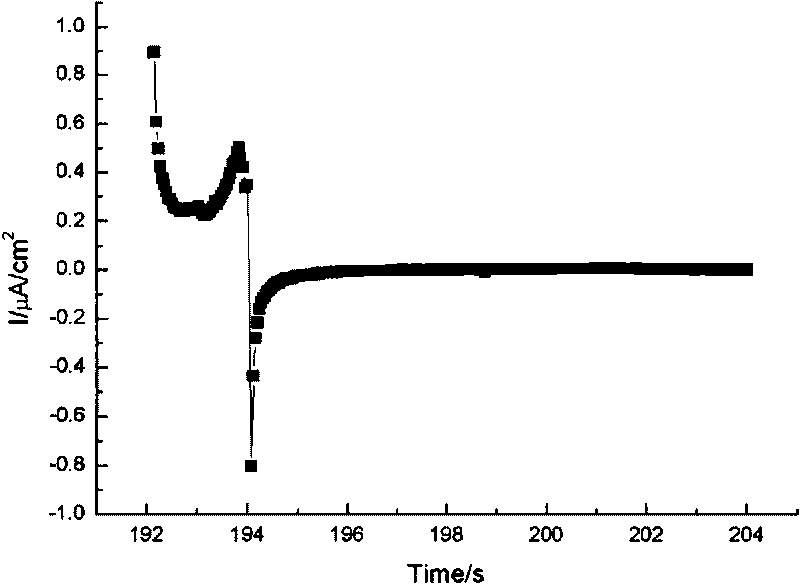

[0025] Example 1 Evaluating the Pitting Corrosion Resistance of 2205 Duplex Stainless Steel

[0026] 2205 duplex stainless steel (1100°C solution treatment for 2h) was encapsulated with epoxy resin, and a surface of 8mm×8mm was left for the experiment after polishing. The specific conditions are: the medium is 1mol / L NaCl solution, and the temperature is maintained at 80°C. The amplitude of the applied rectangular pulse is 500mV, the width is 2s, the period is 12s, and the number of pulses is 30 times (see attached Figure 1~3 ). The result shows as Figure 4~5 shown. The pitting pits generated on the surface of the sample are all distributed in the ferrite phase, with a total of 35±3 pits.

Embodiment 2

[0027] Example 2 Evaluation of Pitting Corrosion Resistance of 304 Austenitic Stainless Steel

[0028] 304 austenitic stainless steel (1100°C solution treatment for 2h) was packaged with epoxy resin and polished to leave a surface of 8mm×8mm for the experiment. The specific conditions are: the medium is 1mol / L NaCl solution, and the temperature is maintained at 60°C. The amplitude of the applied rectangular pulse is 500mV, the width is 1s, the period is 11s, and the number of pulses is 50 times. The results are shown as attached Image 6 shown. The etch pits generated on the surface of the sample are all distributed in the grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com