Testing method for predicting residual service life of buried metal water supply pipeline

A technology for water supply pipelines and testing methods, applied in measurement devices, special data processing applications, instruments, etc., can solve the problems of colored water, secondary pollution, red water in the pipeline network, etc., achieve reliable technical basis, increase power costs, guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

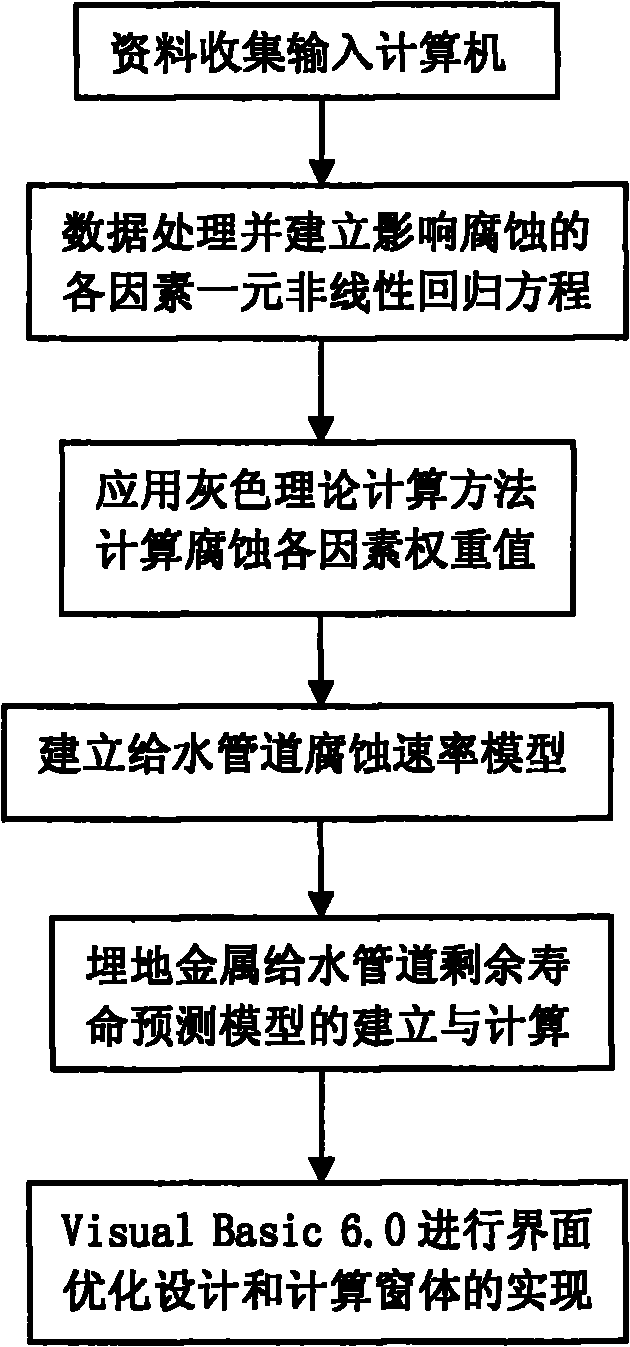

[0036] The present invention will be described in detail below with reference to the accompanying drawings.

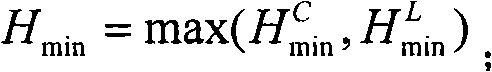

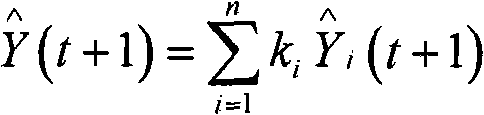

[0037] In order to solve the problem that urban water supply pipelines cannot be repaired and replaced in time due to the lack of corrosion prediction, causing pipeline leakage and water supply water quality pollution, which seriously affects the safety and quality of water supply for residents and industries, the invention for the first time removes internal corrosion of water supply pipelines Combining with the external corrosion, fully considering the internal and external corrosion forms of the water supply pipeline, a prediction model for the remaining life of the water supply pipeline is established. In the prediction of the remaining life of the water supply pipeline, the exponential fitting and polynomial fitting of the least square method are used to calculate the corrosion rate under the influence of a single factor, and the MATLAB software is used for calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com